Explosion-proof fuze tightening machine

A technology of fuze and special machine, which is applied to the tightening of explosion-proof fuze

In the field of special planes, it can solve problems such as safety and artificial quality problems, and achieve the effect of ensuring safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

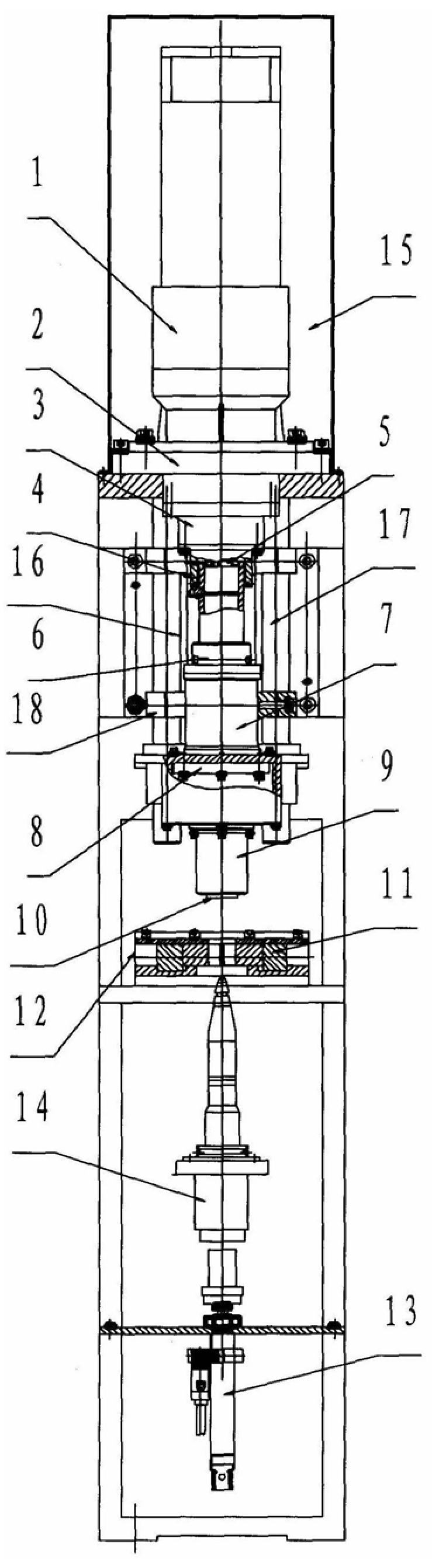

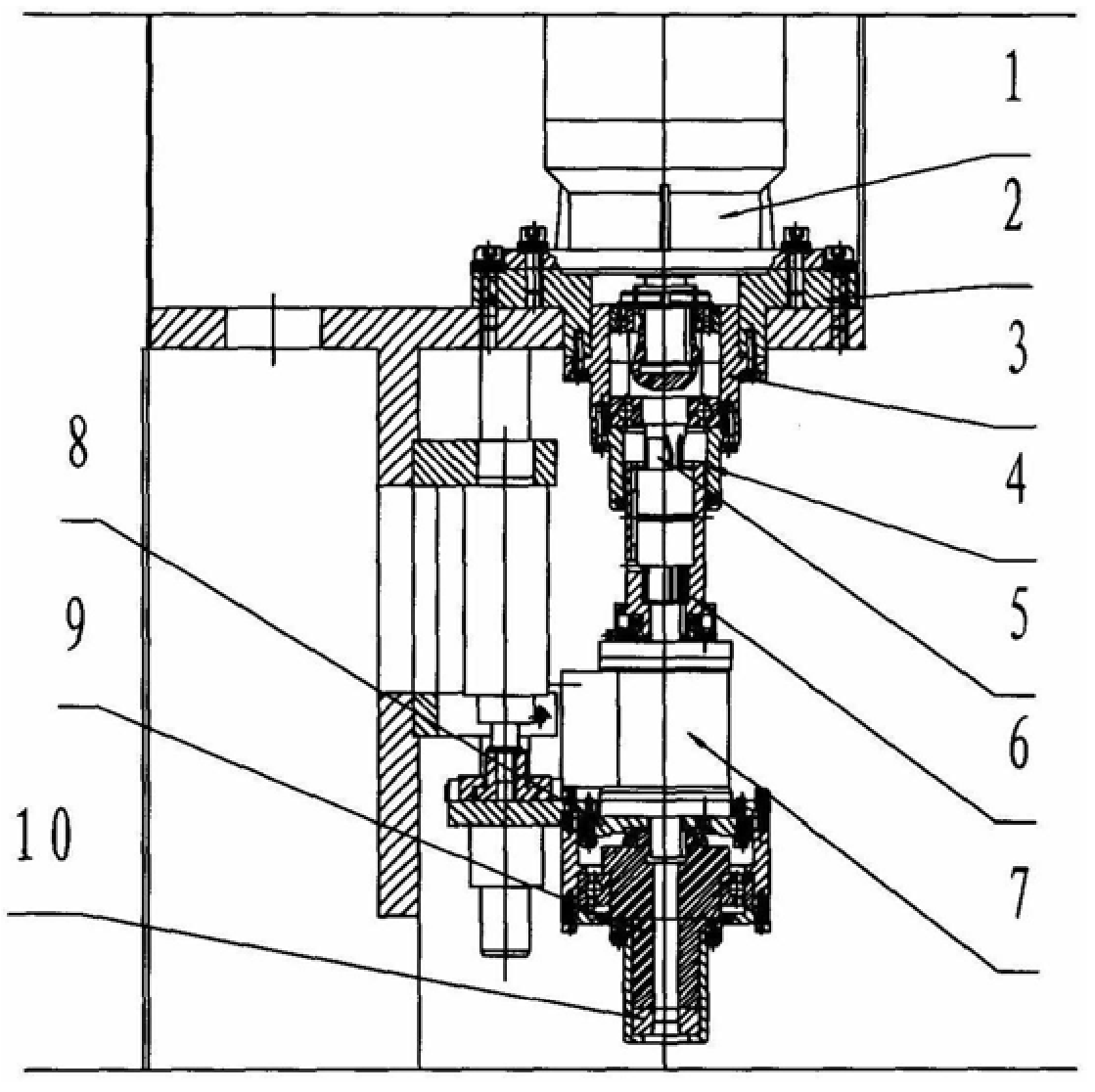

[0040] Below in conjunction with the accompanying drawings and embodiments the present invention will be further described in detail.

[0043] The automatic pressurizing device is used to apply pressure on the fuze tightening head to facilitate the tightening of the fuze.

[0044] The fuze tightening device is used to tighten the fuze under the pressure of the automatic pressurizing device.

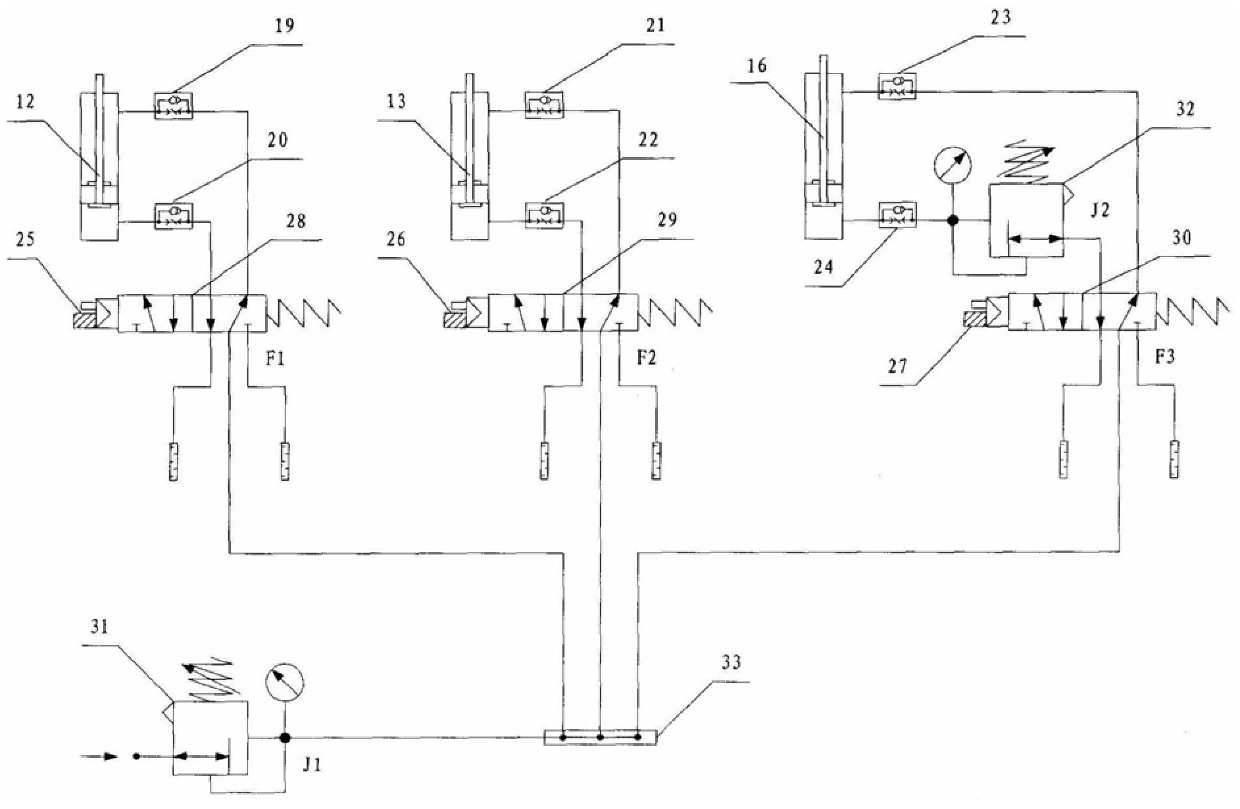

[0045] The gas circuit system is used to convert the gas source into the motion of the above-mentioned mechanical parts.

[0072] The jacking cylinder action will bounce to the working position.

[0073] The action of the clamping cylinder fixes the elastic body.

[0074] The tightening head starts to rotate rapidly, and the pressing cylinder acts to press down the tightening head.

[0075] Moment sensor real-time monitoring. In the process of fast screwing, if the preset torque value M is not exceeded, go to step 6, if it exceeds

[0077] Tighten the motor to stop, and press down the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com