Railway yard container intelligent loading and unloading control system

A control system, railway station technology, applied in transportation and packaging, load hoisting components, etc., can solve the problems of low loading and unloading efficiency, affecting loading and unloading efficiency, difficult to achieve smooth information, timely management and control, etc., to solve the problem of high noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

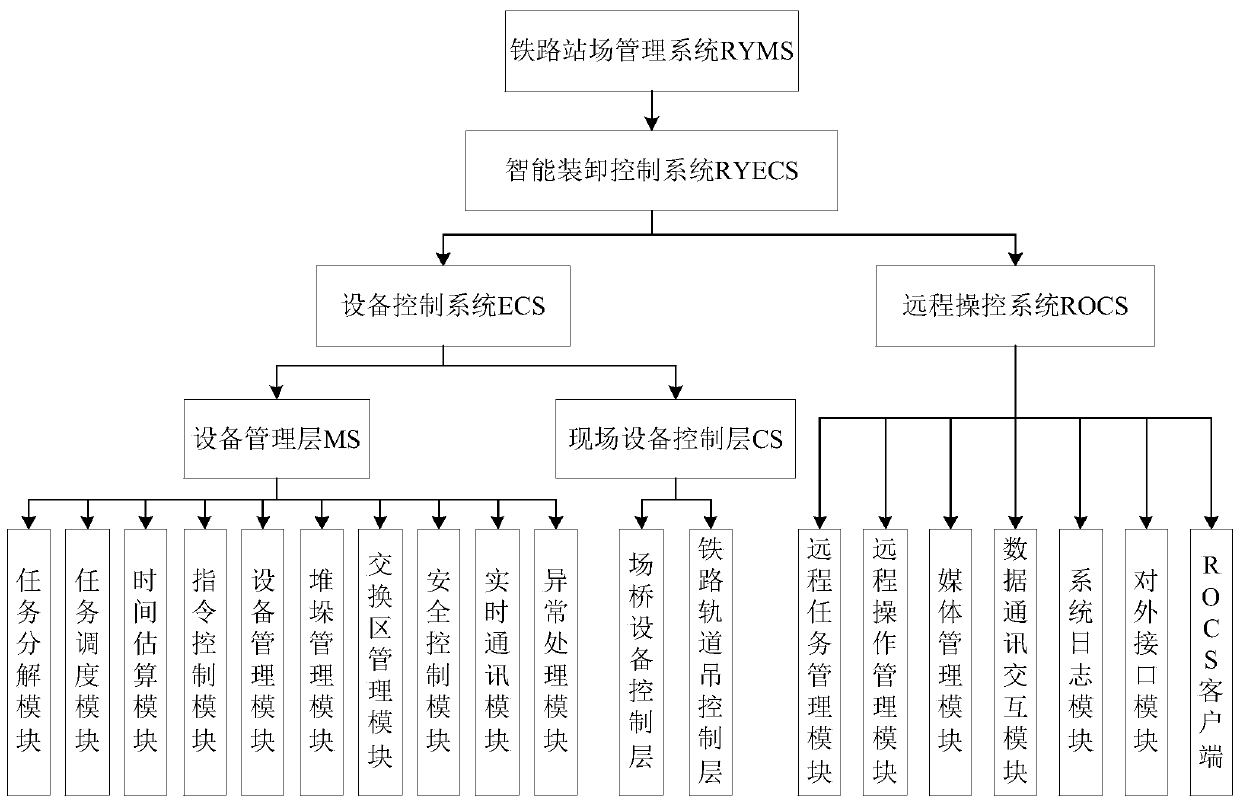

[0021] The invention provides an intelligent loading and unloading control system for railway yard containers, such as figure 1 With the structure shown, the intelligent loading and unloading control system can improve the intelligent system technology and industrial system of container intelligent loading and unloading in railway yards, and provide technical support and theoretical verification for the subsequent application of intelligent railway yard system engineering.

[0022] like figure 1 Shown is an intelligent loading and unloading control system for railway yard containers. The intelligent loading and unloading control system RYECS is responsible for receiving instructions from the railway yard management system RYMS, automatically planning the operation route of mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com