Vibration distribution and guide type gunpowder mixer

A medicine mixer and vibrator technology, which is applied to weapon types, pyrotechnics, offensive equipment, etc., can solve the problems of easy discharge, personal casualties, and high degree of danger, achieve uniform mixing, safety and reliability, and eliminate potential safety hazards. Mixtures with good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

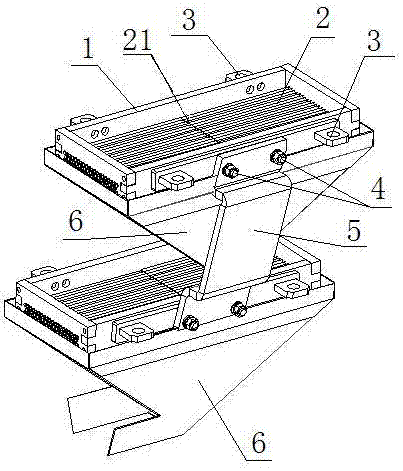

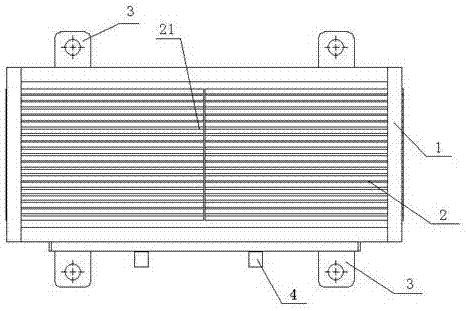

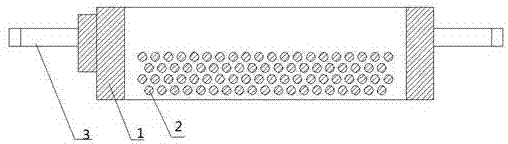

[0020] Referring to the above-mentioned drawings, a vibration sub-guided drug mixer, the vibration sub-guided drug mixer includes a frame 1, a mixing rod 2 and a vibrator;

[0021] The frame 1 is provided with 5 layers of drug mixing rods 2 uniformly distributed in the transverse direction. The mixing rod on the corresponding upper layer is set for dislocation distribution;

[0022] The drug mixing rods 2 in the frame 1 are arranged as a distribution of the whole rod, or the whole rod is cut into two halves and arranged correspondingly, so that the drug mixing rods 2 on the same layer form a middle longitudinal distance 21 of 1 mm;

[0023] A vibrator interface 4 is provided in the middle of the front outer side of the frame 1 , that is, the vibrator is connected to the vibrator interface 4 .

[0024] The medicine mixing rod 2 is a cylindrical rod made of carbon fiber material, and the diameter of the medicine mixing rod 2 is 4mm.

[0025] The distance between the mixing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com