A flow mixing device arranged in the descending section of the integrated reactor pressure vessel

A technology for pressure vessels and reactors, which is used in reactors, cooling devices, and greenhouse gas reduction to achieve uniform temperature and pressure and ensure safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

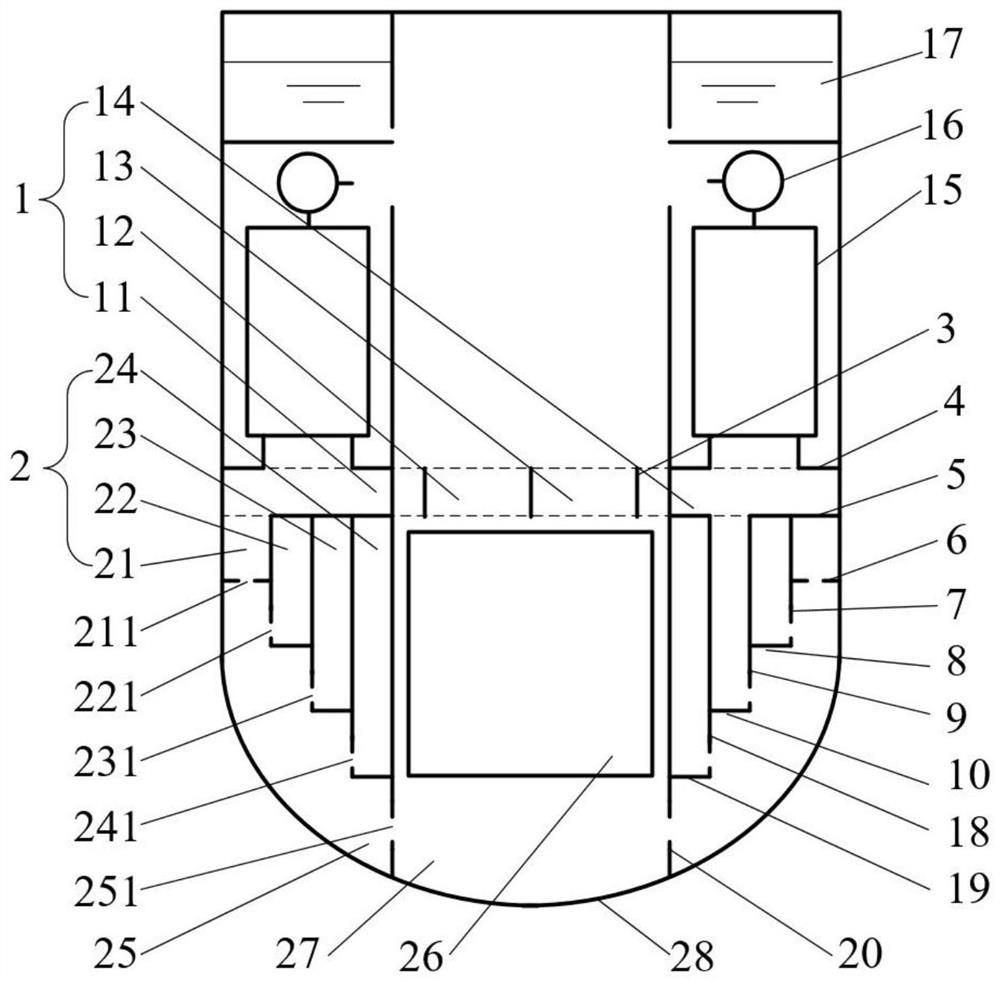

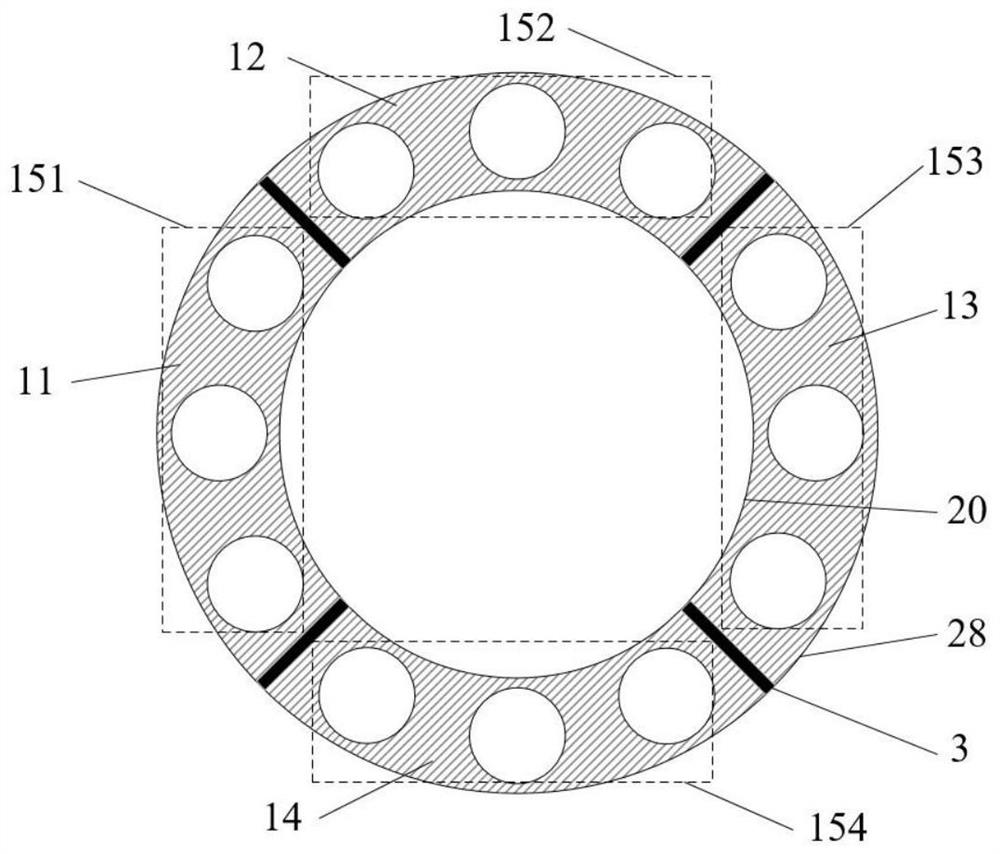

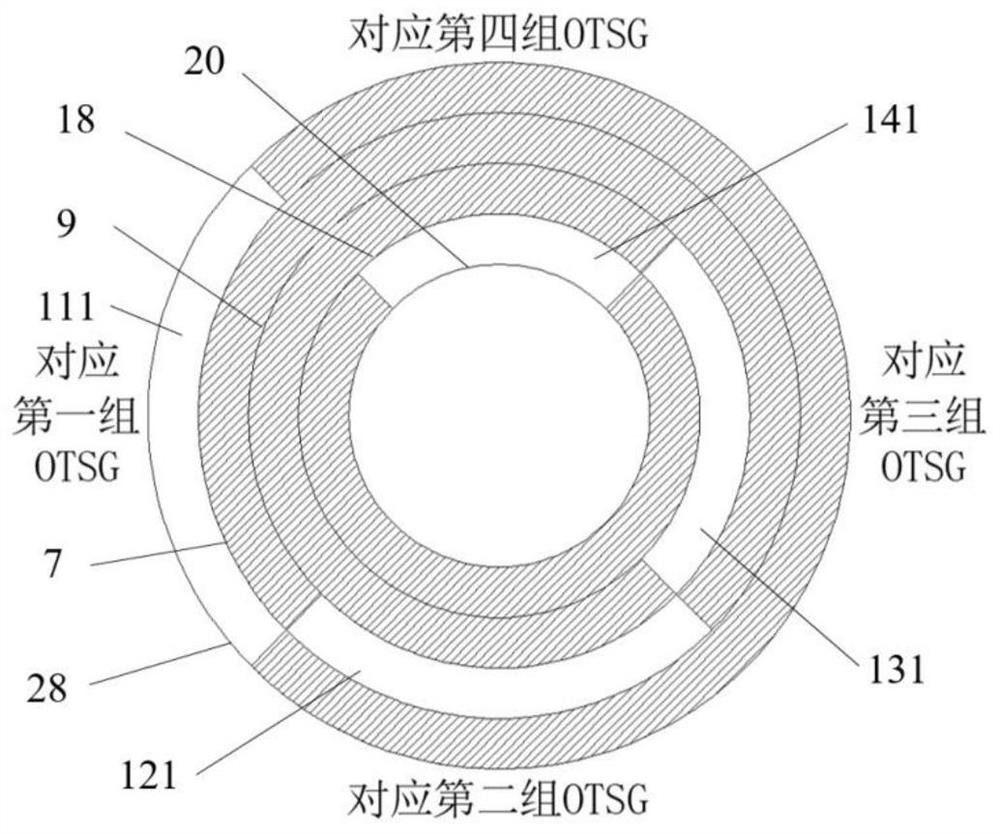

[0030]A flow mixing device arranged in the descending section of the integrated reactor pressure vessel, including a flow distribution part 1 and a flow mixing part 2; the flow distribution part 1 is arranged on the inner wall of the integrated reactor pressure vessel, including: an annular shape with upper and lower gaps The inlet annular dividing plate 4 and the outlet annular dividing plate 5, the annular vertical baffle plate 20 arranged on the inner ring of the inlet annular dividing plate 4 and the outlet annular dividing plate 5, and form an annular airtight cavity; the annular airtight cavity is provided with N Evenly arranged vertical partitions 3, N≥2, form N fan-shaped spaces; the upper end of each fan-shaped space is correspondingly provided with a DC steam generator connected thereto; in this embodiment, N is preferably 4.

[0031] Such as figure 1 As shown, this embodiment is an embodiment of a flow mixing device arranged in the descending section of the integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com