Solvent mixing device for petroleum asphalt production

A petroleum asphalt and mixing device technology, which is applied in the field of petroleum asphalt production, can solve the problems of easy adhesion, uneven solvent mixing, inability to mix and stir in multiple directions, and achieve the effect of ensuring good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

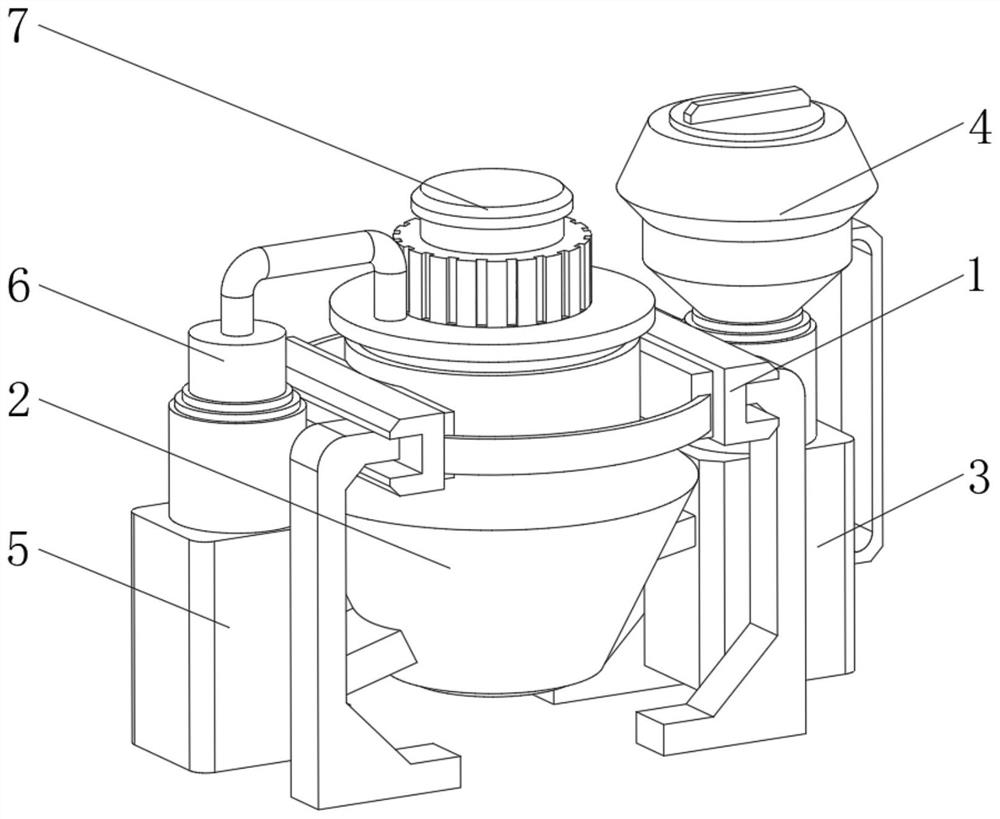

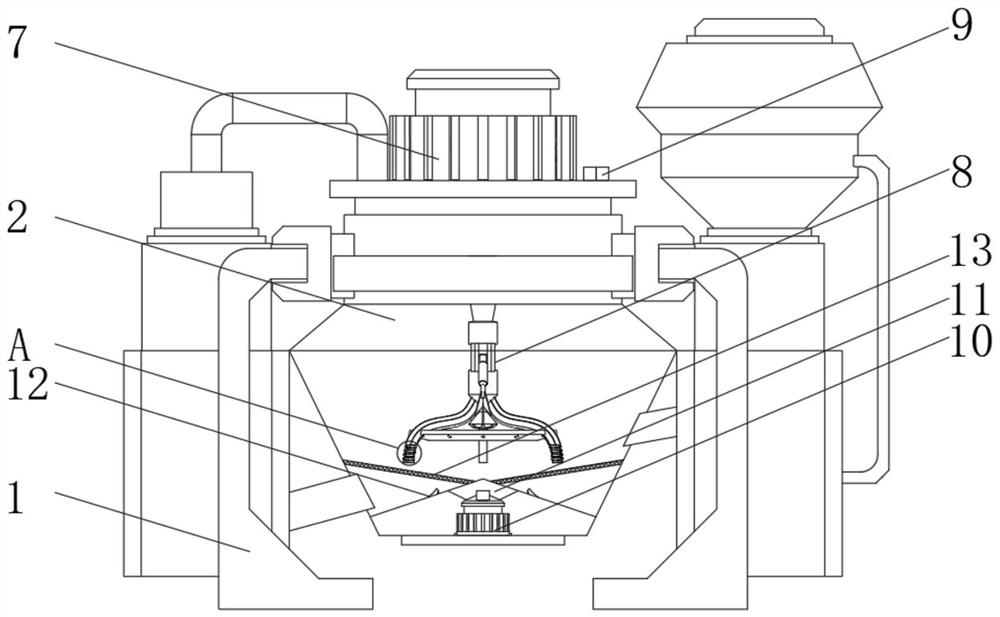

[0032] see Figure 1-2 , the present invention provides a technical solution: a solvent mixing device for petroleum asphalt production, specifically comprising:

[0033] A work frame 1, the work frame 1 has a supporting frame body, a docking installation frame arranged above the work frame 1 and a supporting foot frame at the bottom;

[0034] A mixing box 2, the mixing box 2 has a mixing box body, and a docking sleeve arranged on the upper side of the mixing box 2;

[0035] Pretreatment box 3, the pretreatment box 3 has a side treatment box body, and a drain pipe arranged inside the pretreatment box 3, and the pretreatment box 3 communicates with the mixing box 2 through the drain pipe;

[0036] Return box body 5, this backflow box body 5 has storage tank body 5, and the inclined feed pipe that is arranged on the inside of return flow box body 5, backflow box body 5 communicates with mixing box 2 through inclined feeding pipe, and mixing box 2 is installed on Inside the work...

Embodiment example 2

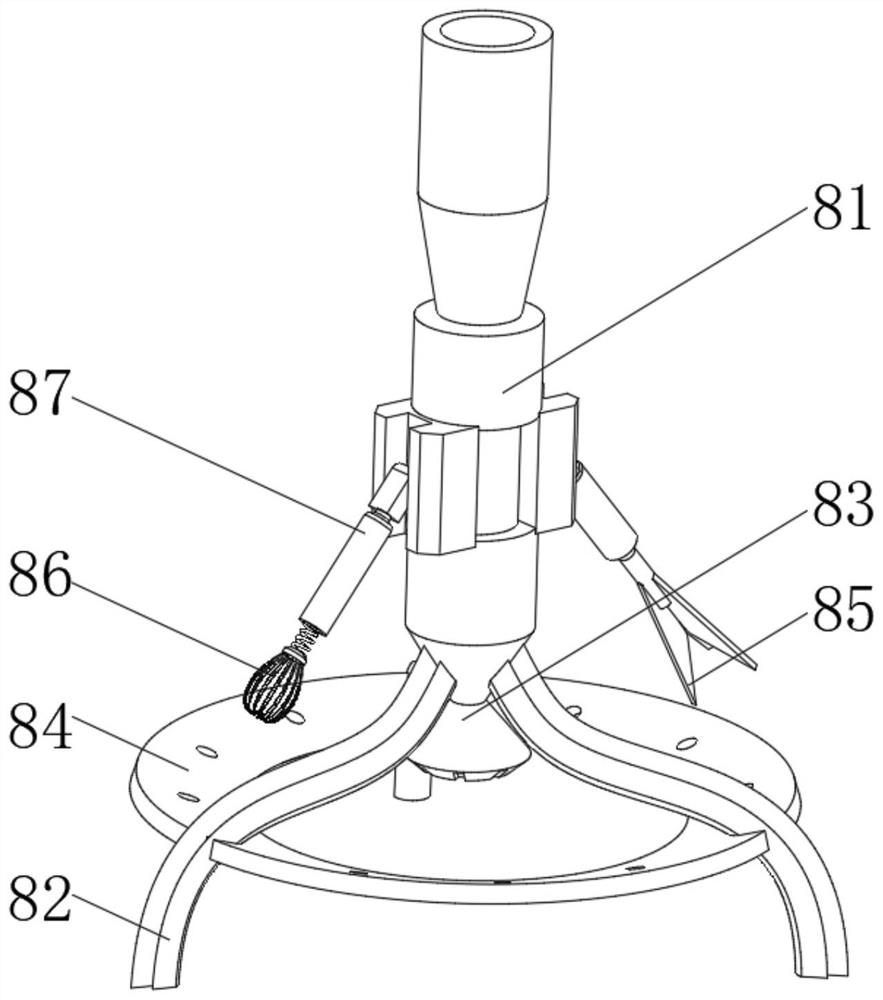

[0040] On the basis of implementing Case 1, please refer to Figure 1-3 , the present invention provides a technical solution: the mixer 8 includes a central column 81, the bottom of the central column 81 is provided with a separation and mixing arc frame 82, the bottom of the central column 81 is provided with an injection and split flow processing device 83, and the mixing arc frame 82 The middle position of the inner concave storage tray 84 is provided with a separation hole on the outer ring of the inner concave storage tray 84, and the side of the central column 81 is provided with an extended trident mixing knife 85, and the central column 81 is far away from the side extending the trident mixing knife 85 A solvent bubbler 86 is installed through an external connection pipe 87 .

[0041] The center tube column 81 is provided with a center lumen inside, and the center lumen communicates with the injection nozzle 9 through a catheter, and the bottom end of the outer connecti...

Embodiment example 3

[0043] On the basis of implementation case 1 and implementation case 2, please refer to Figure 1-4 , the present invention provides a technical solution: the injection and diversion processing device 83 includes a conical disc body 831, a butt joint lumen 832 is provided at the middle position inside the conical disc body 831, and an outer drainage groove 833 is provided at the outer bottom of the conical disc body 831 , the inner side of the conical disc body 831 is located above the outer row groove 833, and a connecting pipe 834 is provided. The inner connecting pipe 834 is equipped with a honeycomb centrifugal terminal 835 through an inner connecting spring, and the outer side of the honeycomb centrifugal terminal 835 is provided with a perforated sealing rubber ring. When the injected solution additives are mixed internally, when the centrifugal force generated by the rotation of the injection and diversion processing device 83 is large, the honeycomb centrifugal terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com