Combined fireworks explosive automatic filling equipment

A technology for automatic filling and combination of fireworks, which is applied in pyrotechnics, offensive equipment, weapon types, etc. It can solve the problems of overall structural collapse of fireworks, injury to people, and inability to match other processes, so as to prevent personal safety accidents and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

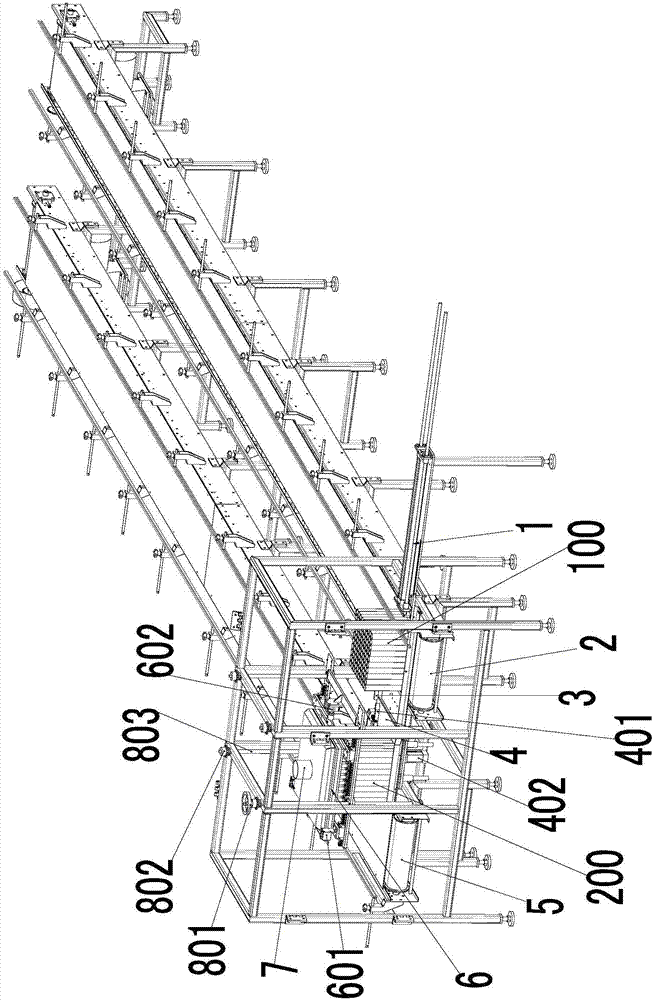

[0024] Embodiment 1: see attached Figure 1-5 , reflecting a specific structure of the present invention, the automatic filling equipment for combined fireworks and pyrotechnics is installed in an explosion-proof workshop (not shown in the figure), and the first conveyor belt 2 passes through the explosion-proof wall and is sent into the cartridge cake 100 to be loaded, The second conveyor belt 5 passes through the explosion-proof wall and takes away the loaded cartridge cake 200.

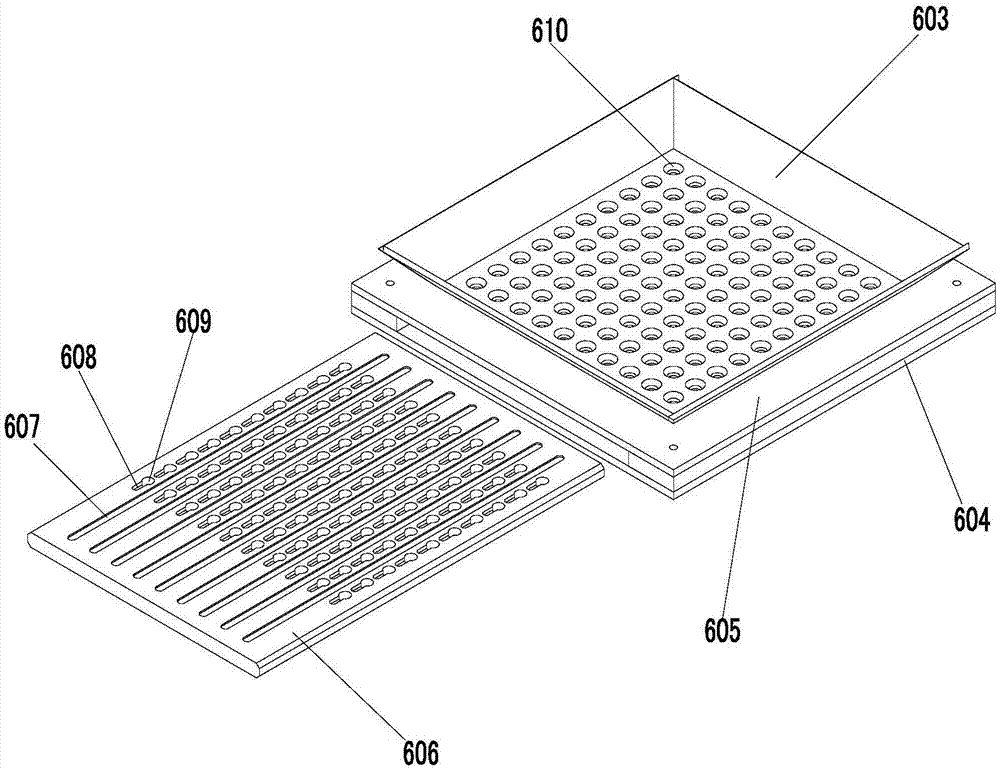

[0025] This equipment comprises the tube cake carrying plate 4 that is installed on the frame, and the two sides of the tube cake carrying plate 4 respectively connect the discharge end of the first conveyor belt 2 and the feeding end of the second conveyor belt 5; The connecting part of the discharge end of the conveyor belt 2 is provided with a tube cake guide frame 3; one side of the discharge end of the first conveyor belt 2 is provided with a pushing cylinder 1; the tube cake bearing plate 4 i...

Embodiment 2

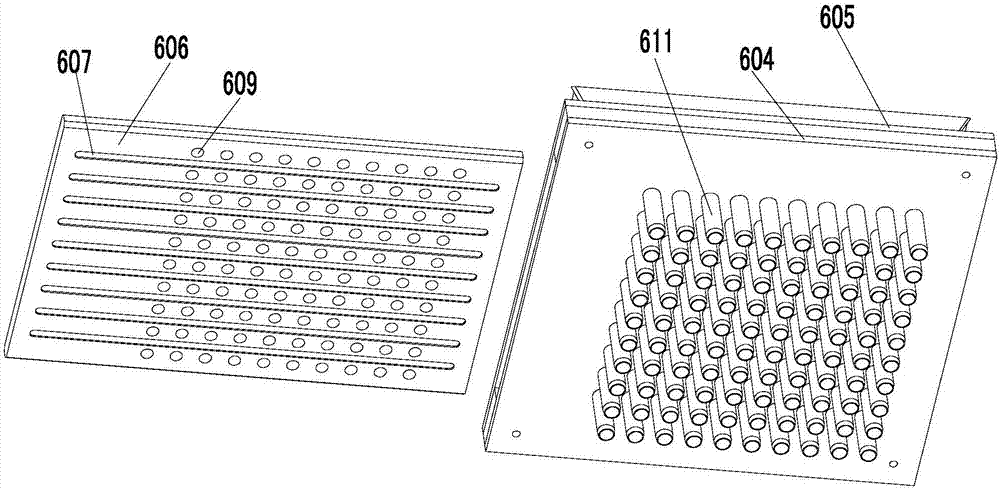

[0032] Embodiment 2: see attached Image 6, the difference from Embodiment 1 is that several groups of convex strips 902 are arranged on the middle sliding plate 901, the middle through hole 903 and the remaining drug temporary storage cavity 904 are arranged on the convex strips 902, and the middle through hole 903 is arranged on the convex strip 902. The upper end of the hole 903 is provided with an outer ring concave cavity 905, which communicates with the residual medicine temporary storage cavity 904. This embodiment solves the problem that it is difficult to adjust the matching gap between the upper plate, the middle plate and the lower plate, even if it is worn due to long-term work. It can also work normally, and the safety performance has been effectively guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com