Explosion-proof gas-hydraulic coupling device for projectile and cartridge

A gas-hydraulic, cartridge technology, applied in the field of small-caliber ammunition assembly, achieves the effects of good safety performance, good dynamic performance and reduced labor intensity

Inactive Publication Date: 2008-04-30

SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the safety and quality problems existing in the assembly of small-caliber bullets, manual loading and unloading, and press pressing of projectiles and cartridges with a punch, the invention provides an explosion-proof gas-hydraulic bonding device for projectiles and cartridges

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

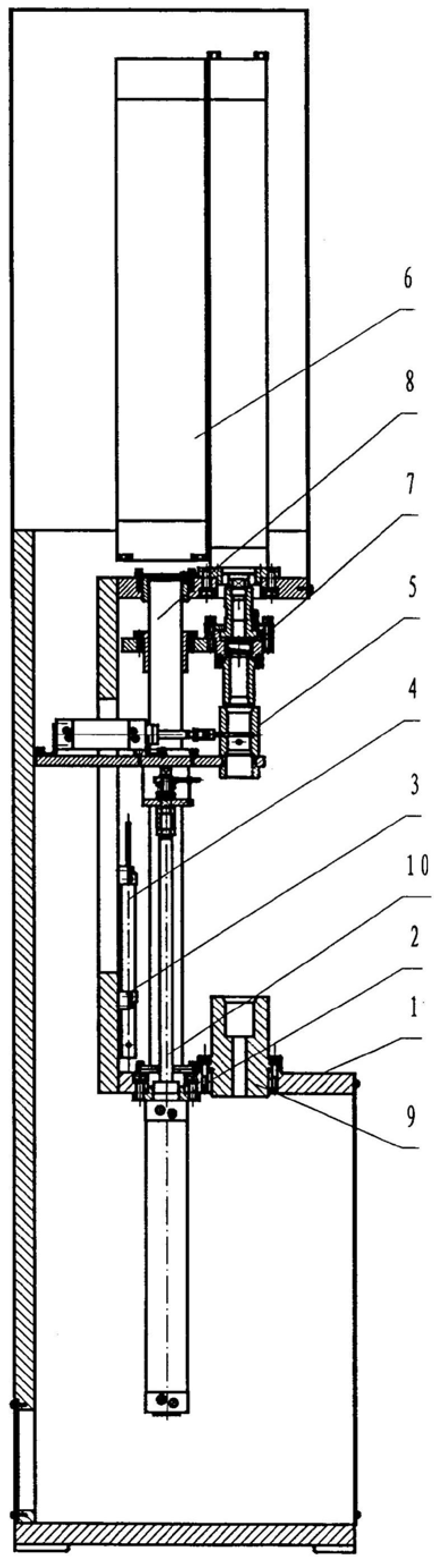

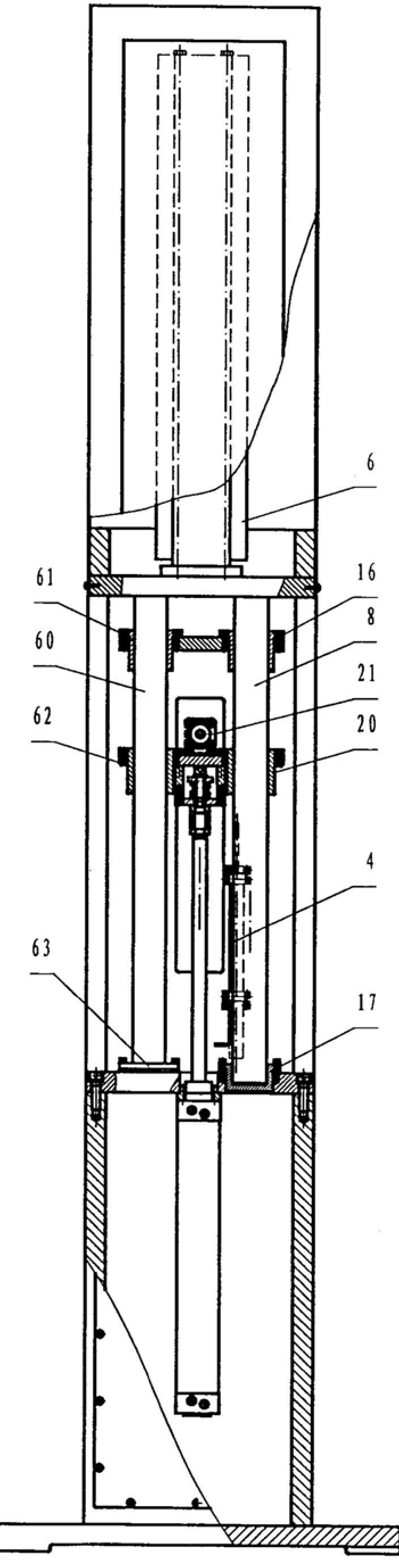

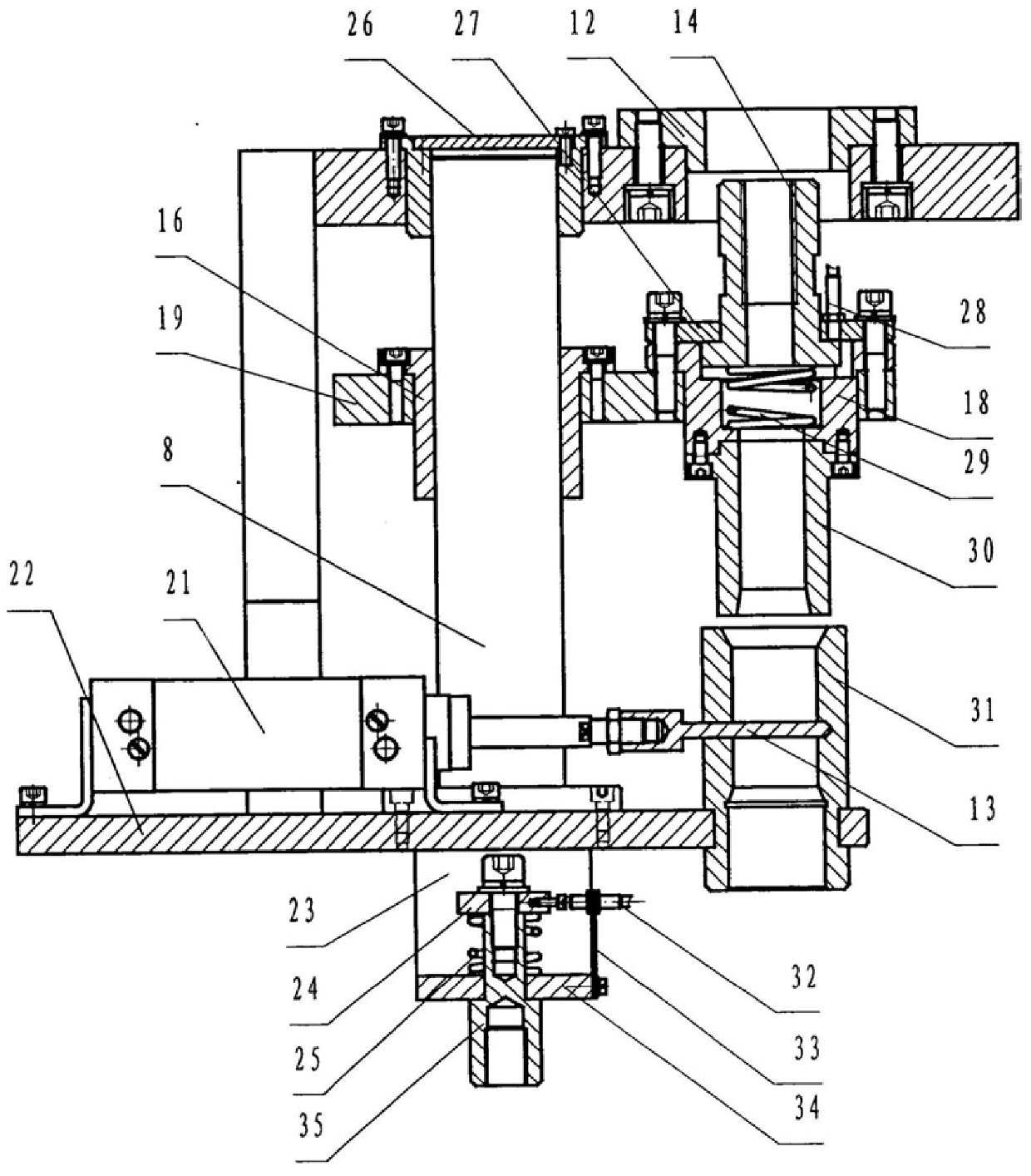

The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to an explosion-proof gas-hydraulic combination device for projectiles and cartridges used in the assembly of small-caliber bullets. An explosion-proof gas-hydraulic combination device for projectiles and cartridges of the present invention includes a machine base, a lifting mechanism, a cartridge positioning cup, a pressing mechanism, an air circuit system, a control part and control software. The lifting mechanism of the explosion-proof gas-hydraulic combination device for projectiles and cartridges is located behind the cartridge positioning cup and is fixed on the lower part of the machine base; the pressing mechanism is located above the cartridge positioning cup and is fixed on the upper part of the machine base; the air source, valve 1. The air pipe and the pneumatic components of the above-mentioned mechanical part form an air circuit system; the control software is set in the controller of the controller part, and the controller and control software control the work of the above-mentioned mechanical part. The explosion-proof air-hydraulic combination device for projectile and cartridge can not only automatically complete the loading and unloading, press the projectile and cartridge according to the set pressing depth and pressure, but also realize the separation of man and machine, and reduce the labor of workers Strength, good dynamic performance during the pressing process, after pressing, it can ensure the requirements of the pressing gap and the coaxiality of the whole elastic, and can meet the CIIT4 explosion-proof standard, with good safety performance.

Description

Explosion-proof gas-hydraulic coupling device for projectile and cartridge technical field The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to an explosion-proof gas-hydraulic combination device for projectiles and cartridges used in the assembly of small-caliber bullets. Background technique In the assembly of small-caliber bullets, the explosion-proof gas-hydraulic combination device of projectiles and cartridges is a key equipment. It determines the coaxiality of the whole bomb, which in turn affects its ballistic performance. At present, the production of small-caliber bullets in China mostly adopts manual loading and unloading, and a punching machine is used to press the projectile and the cartridge, which cannot guarantee the technical indicators of the pressing gap and the coaxiality of the whole bullet, and easily leads to waste products. Again, it is difficult to guarantee the safety of the operator because it is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F42B39/14F15B15/00

Inventor 彭旭黄权肖静李作武刘臣胡翔

Owner SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com