Wet mixing machine capable of facilitating material clearing for chemicals

A technology for cleaning materials and pharmaceuticals, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problems that the structure of the stirring paddle cannot be stirred evenly, the stirring effect is not good, and the material cleaning is not designed, and the realization of The effect of man-machine separation, convenient cleaning work, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

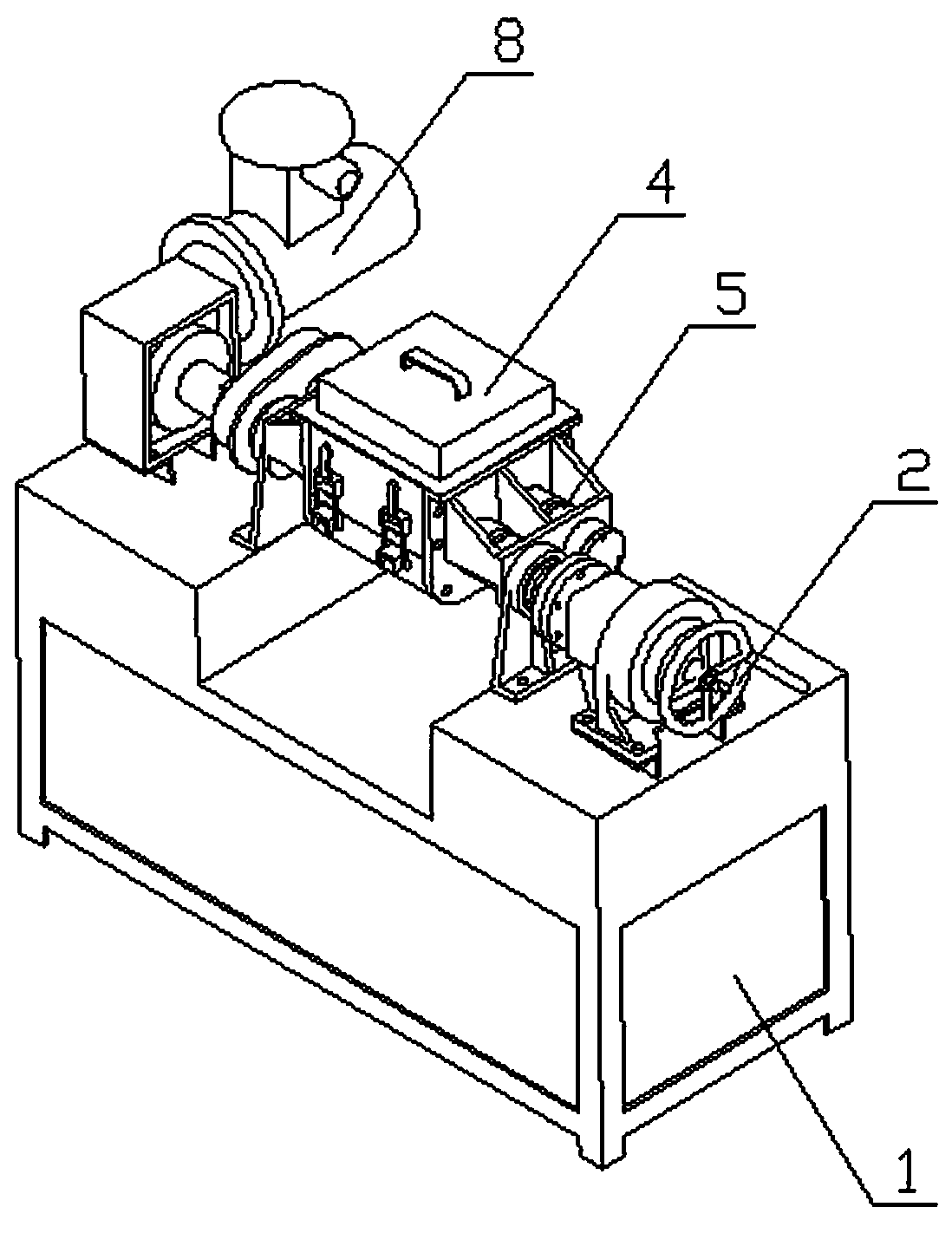

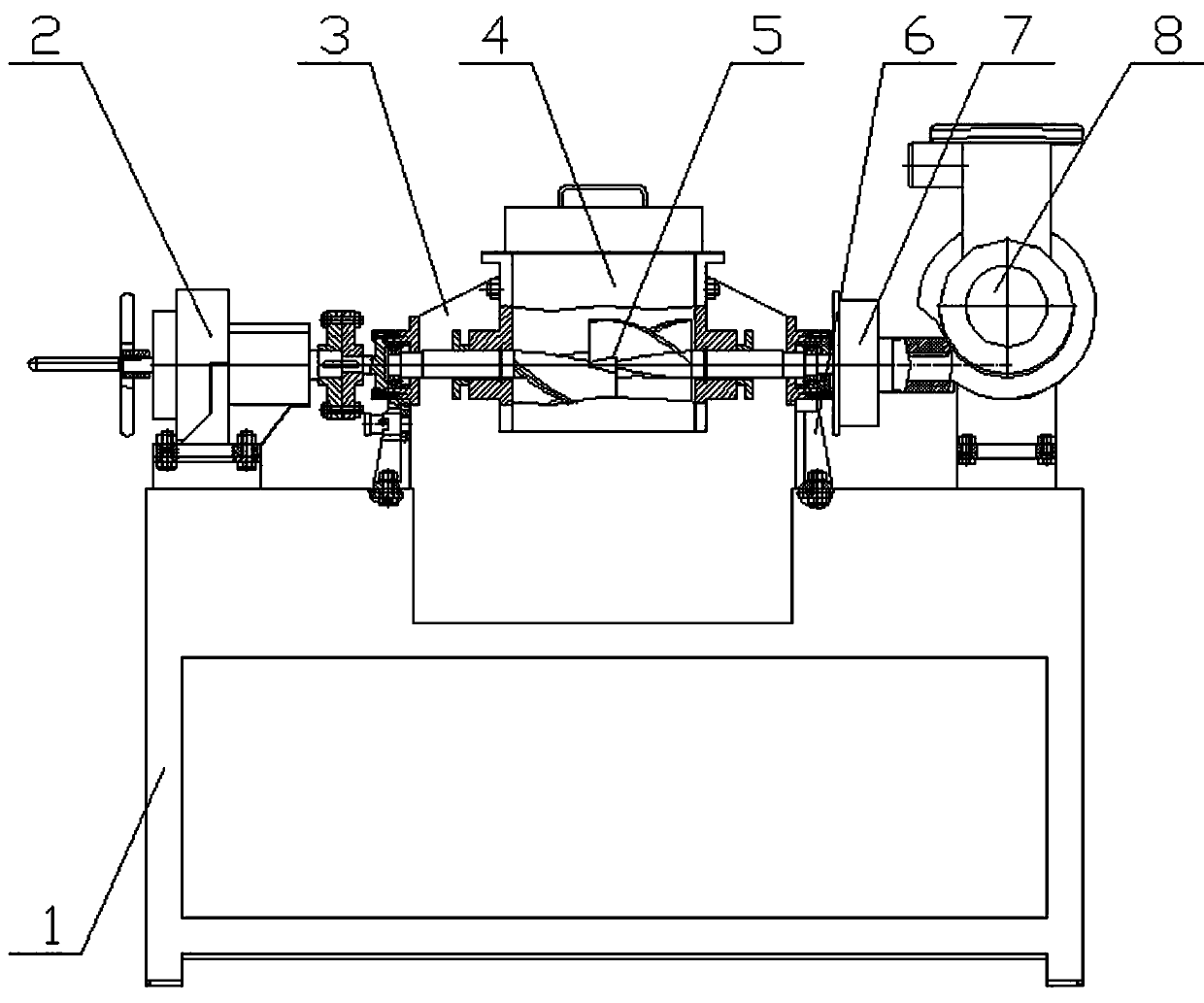

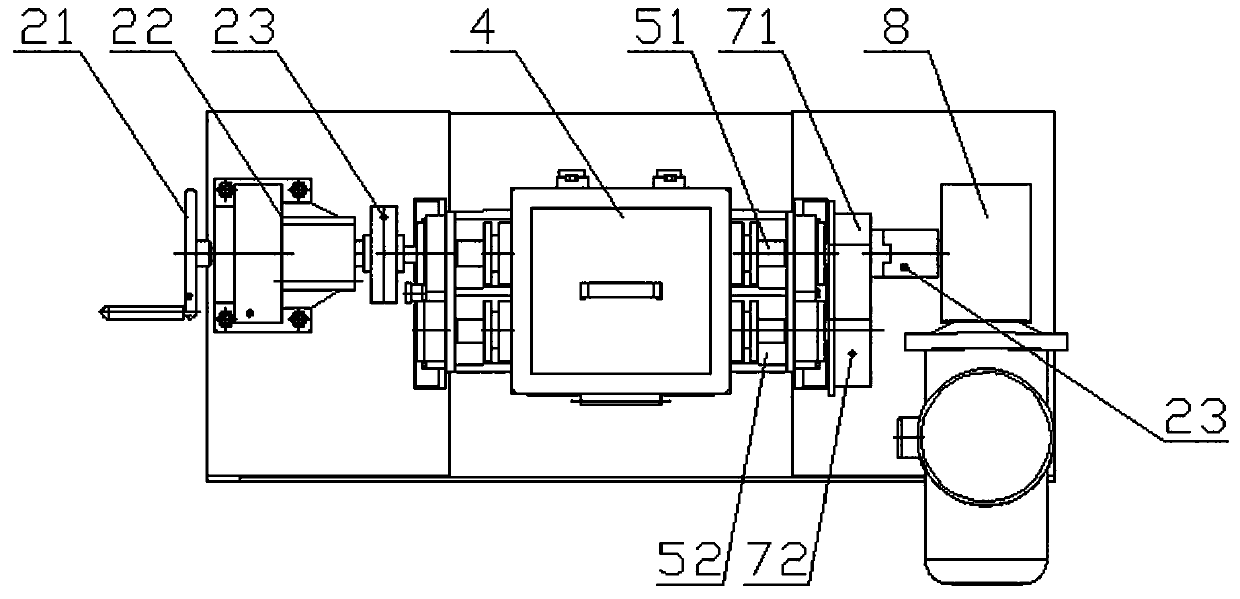

[0042] Such as figure 1 As shown, in order to realize the human-machine isolation operation and improve the safety of production when the bottom row of medicaments is wet-mixed, a medicament wet mixer that is convenient for cleaning materials is designed. The medicament mixed in this example is military B medicine, including Platform 1, the upper side of the working platform 1 is provided with a mixing pot 4, the mixing pot 4 is connected with the working platform 1 through a rotary support mechanism, the mixing pot 4 is connected with a rotary device 2 for controlling the rotation of the mixing pot 4, and the mixing pot Stirring device 5 is arranged horizontally inside material pot 4, and power device 8 is connected on the described stirring device 5, and power device 8 is positioned at the outside of mixing pot 4, and the joint of stirring device 5 and power device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com