Automatic thermal protruding device for printed circuit board

A technology for printed circuit boards and equipment, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as affecting product performance, high scrap rate, low degree of automation, etc., to reduce the frequency of product testing, reduce product testing cost, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

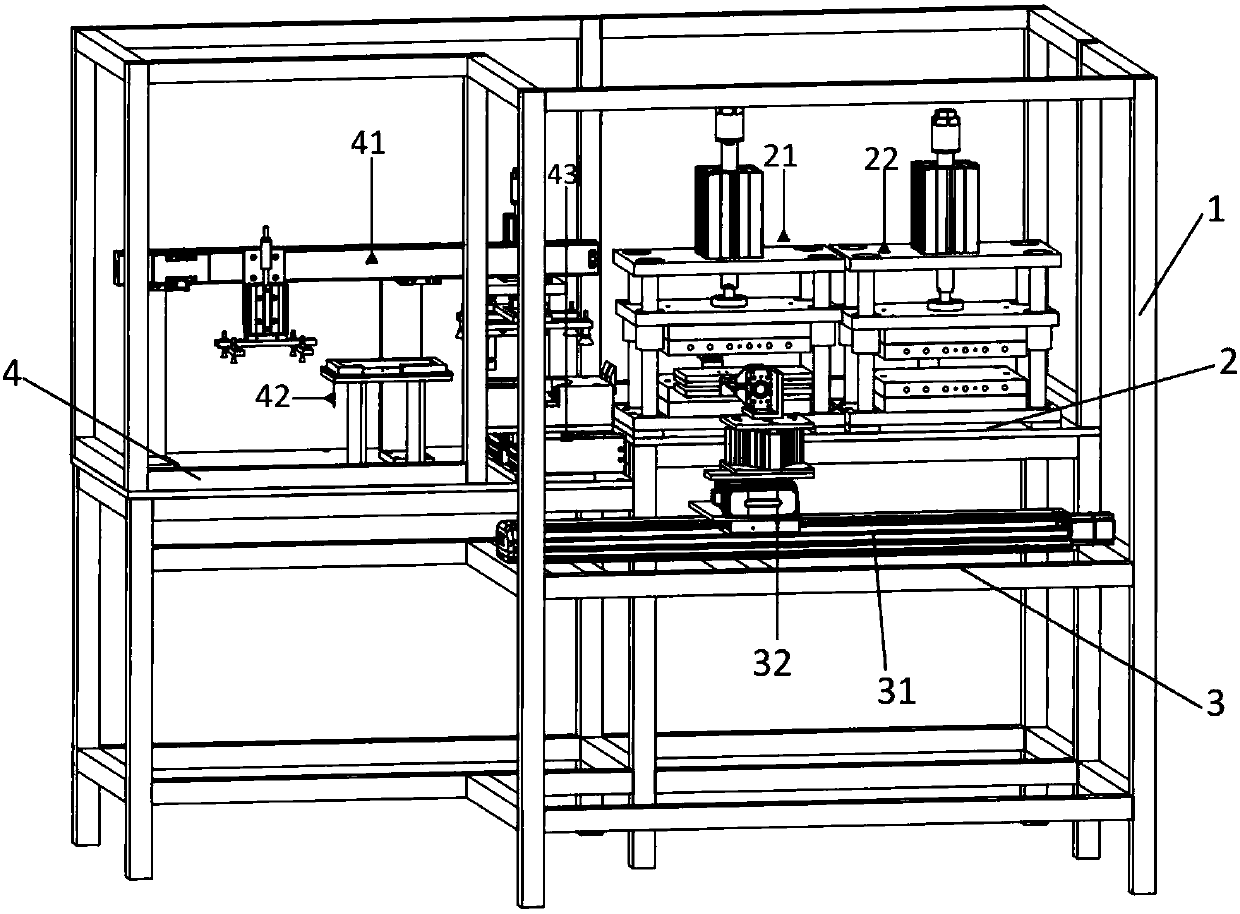

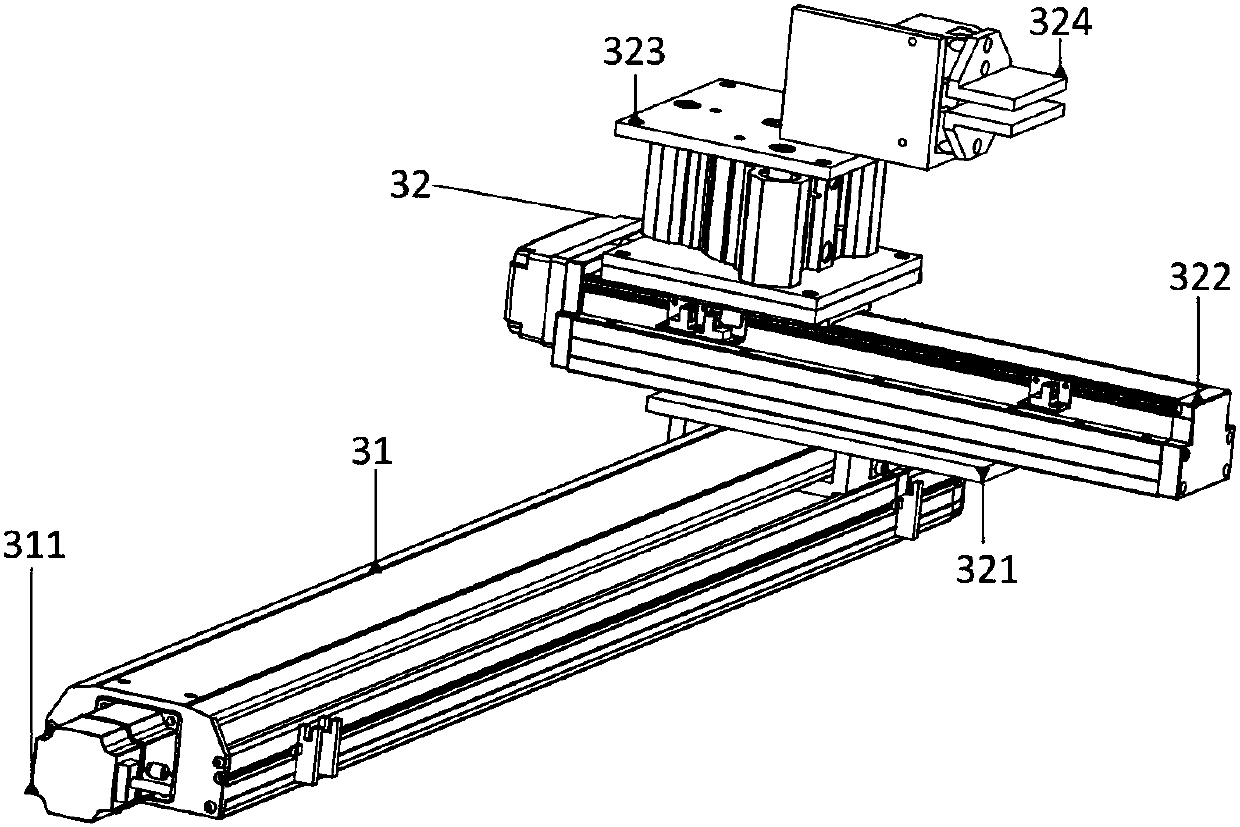

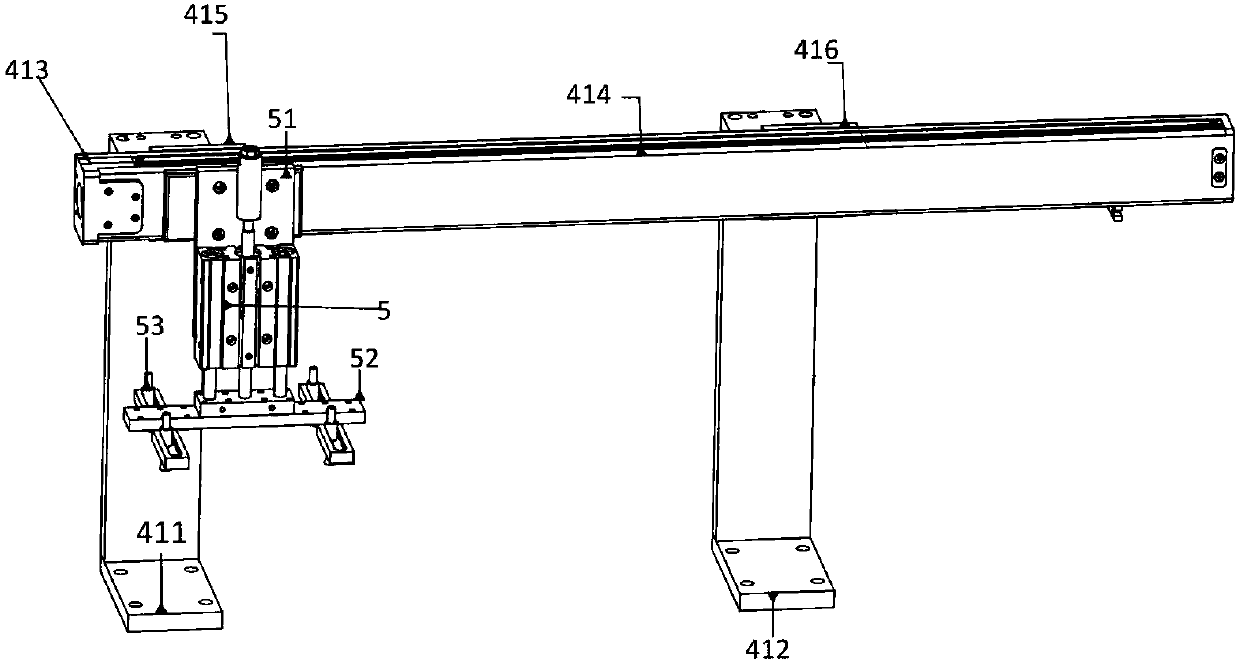

[0027] Such as figure 1 As shown, an automatic heat embossing equipment for printed circuit boards includes an equipment frame 1 and a punching platform 2, a handling system platform 3 and a loading and unloading platform 4 arranged on the equipment frame 1. The punching platform 2 is respectively provided with adjacent The heating punch mechanism 21 and the cooling punch mechanism 22, the upper die loading plate is provided on the equal horizontal positions of the heating punch mechanism 21 and the cooling punch mechanism 22, and the heating punch mechanism 21 includes a mold frame and a heating punch arranged on the punch platform 2, The heating punch and the loading plate of the upper die are arranged on the mold base, and a heating plate is arranged on the heating punch, and the heating plate corresponds to the loading plate of the upper die. The cooling punch mechanism 22 includes a die frame and a cooling punch disposed on the punch platform 2, the cooling punch and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com