Full-automatic welding device of magnetic inductor

A fully automatic welding and magnetic sensor technology, which is applied in the field of automatic welding devices and magnetic sensor automatic welding devices, can solve the problems affecting the production quality and production efficiency of magnetic sensors, uncontrollable weld quality, and low manual welding efficiency. Achieve the effect of eliminating the influence of smoke and dust on the human body, solving the problem of welding uniformity, and humanizing industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

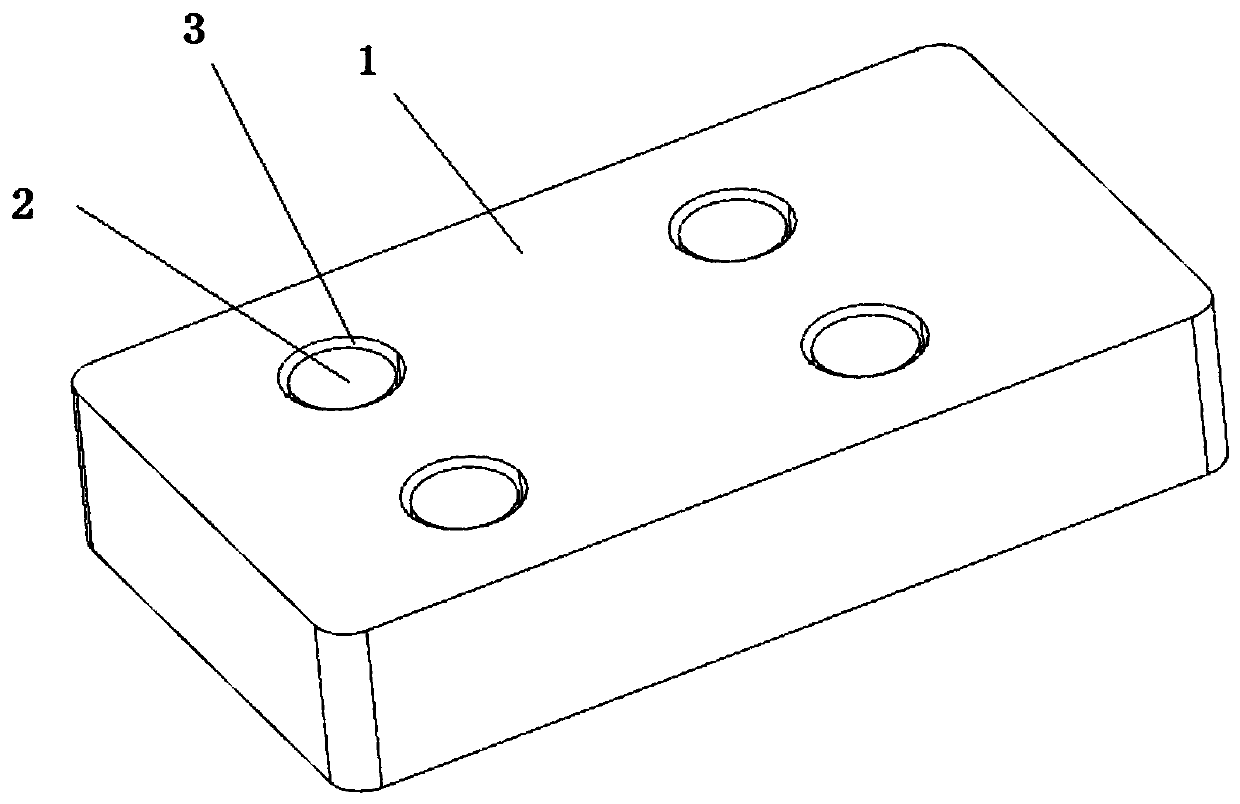

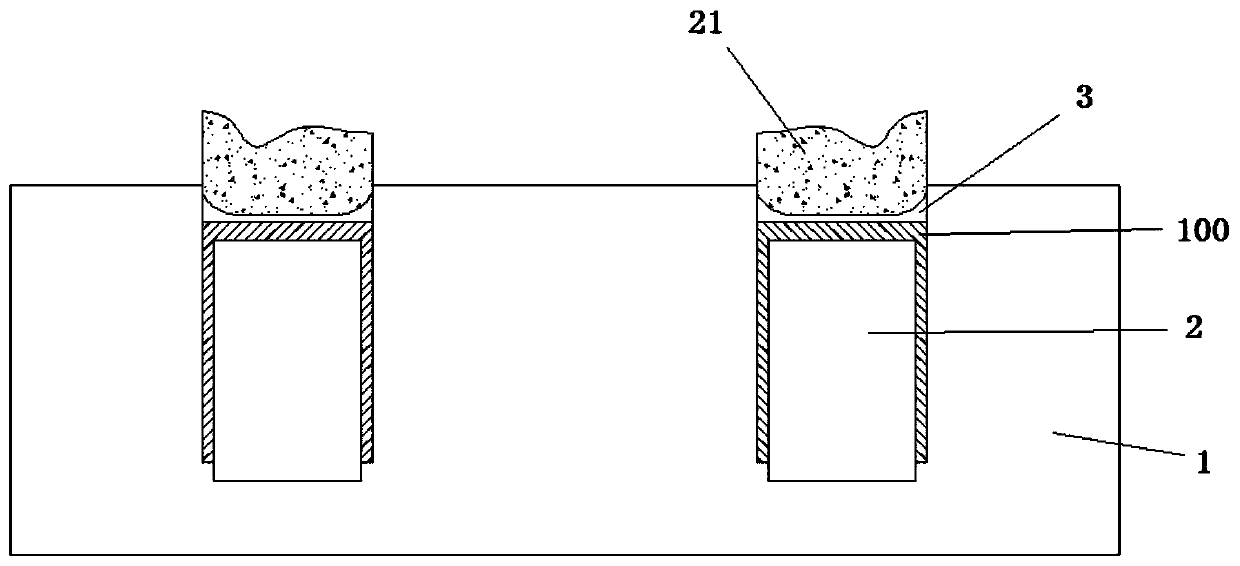

[0041] The magnetic inductor to be welded in the present invention is as Figure 1-2 As shown, the magnetic inductor 1 is provided with a plurality of welding holes 3, the permanent magnet 2 is installed in the welding hole 3, the height of the permanent magnet 2 is lower than the opening position of the welding hole 3, and the gap between the welding hole 3 forms a weld seam . Welding is to inject the insulating material 100 in the molten state into the weld and cover the upper surface of the permanent magnet 2. The insulating material 100 is solidified by self-cooling, so that the gap between the permanent magnet 2 and the welding hole 3 is formed after the insulating material 100 condenses and solidifies. Insulating isolation.

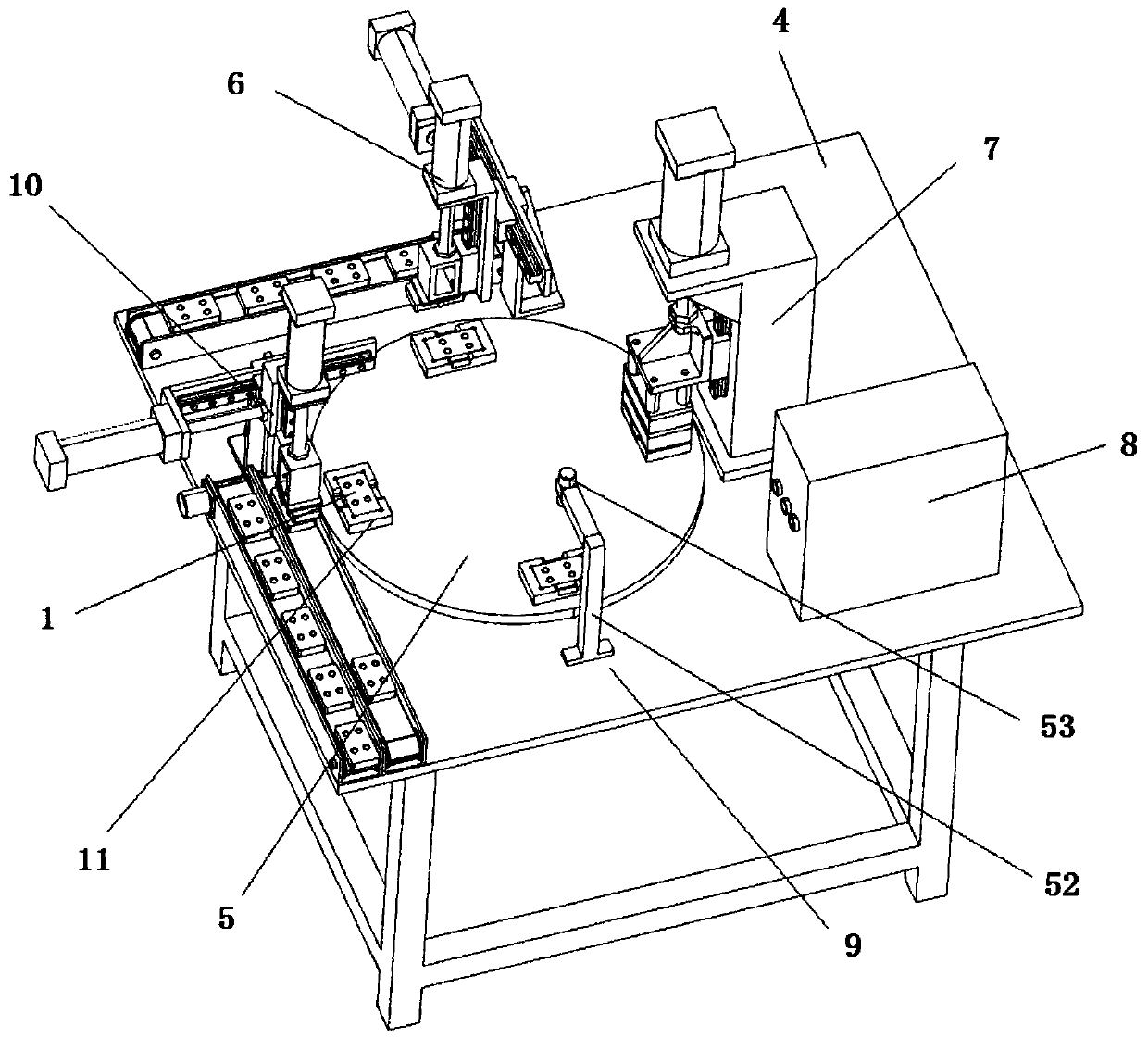

[0042] Such as Figure 3-11As shown in , a fully automatic welding device for a magnetic inductor provided by an embodiment of the present invention includes a frame 1, and the frame 4 is provided with a rotating positioning plate 5, an automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com