End slope coal bed remote control excavating mining method

A technology of remote control and mining method, which is applied in the field of hillside outcrop and shallow surface coal seam mining, open-pit coal mine end side and residual coal, which can solve the problems of inefficient recovery of coal resources, high labor intensity, waste of resources, etc., and improve the recovery of coal resources. High efficiency, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

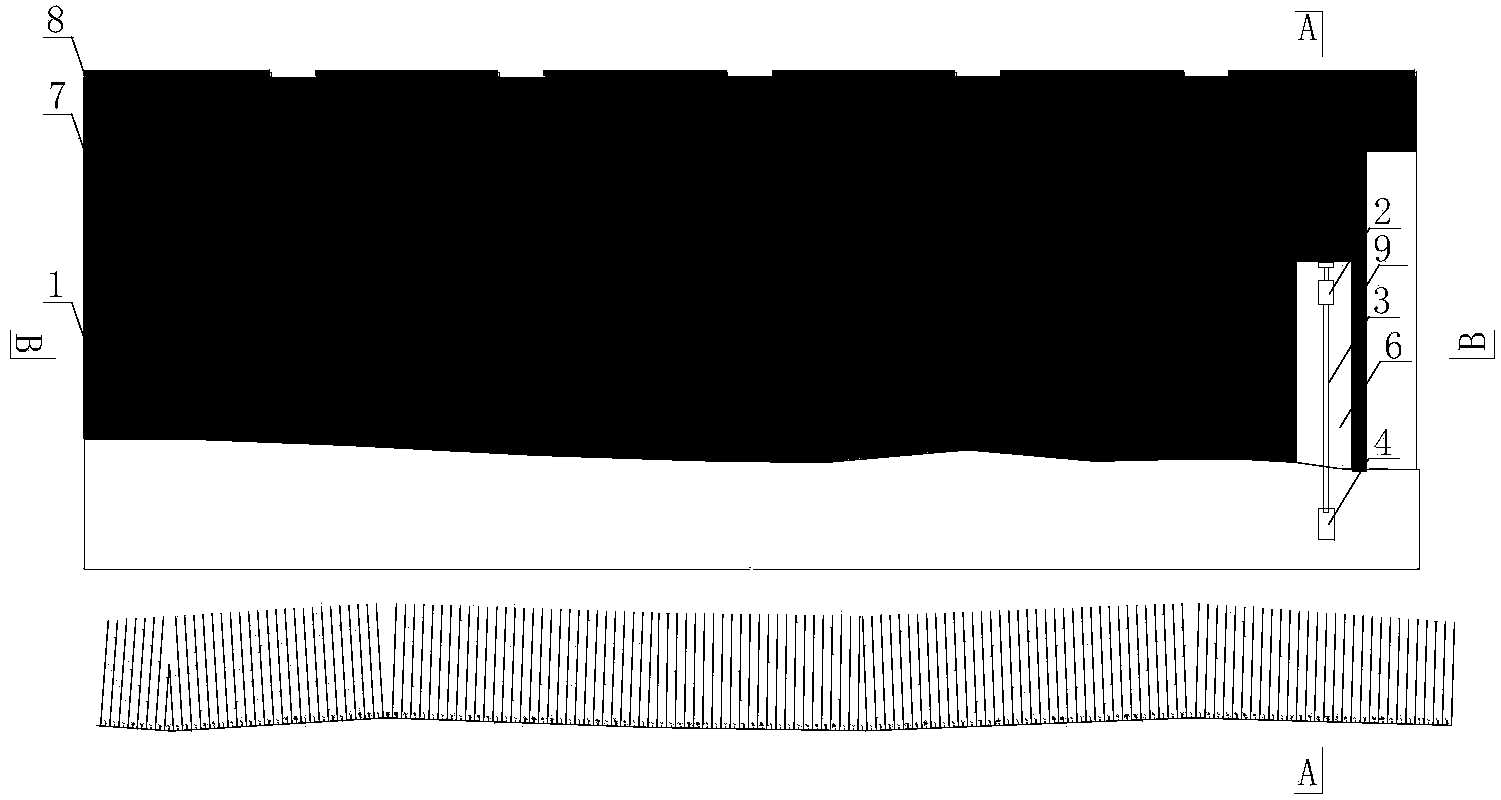

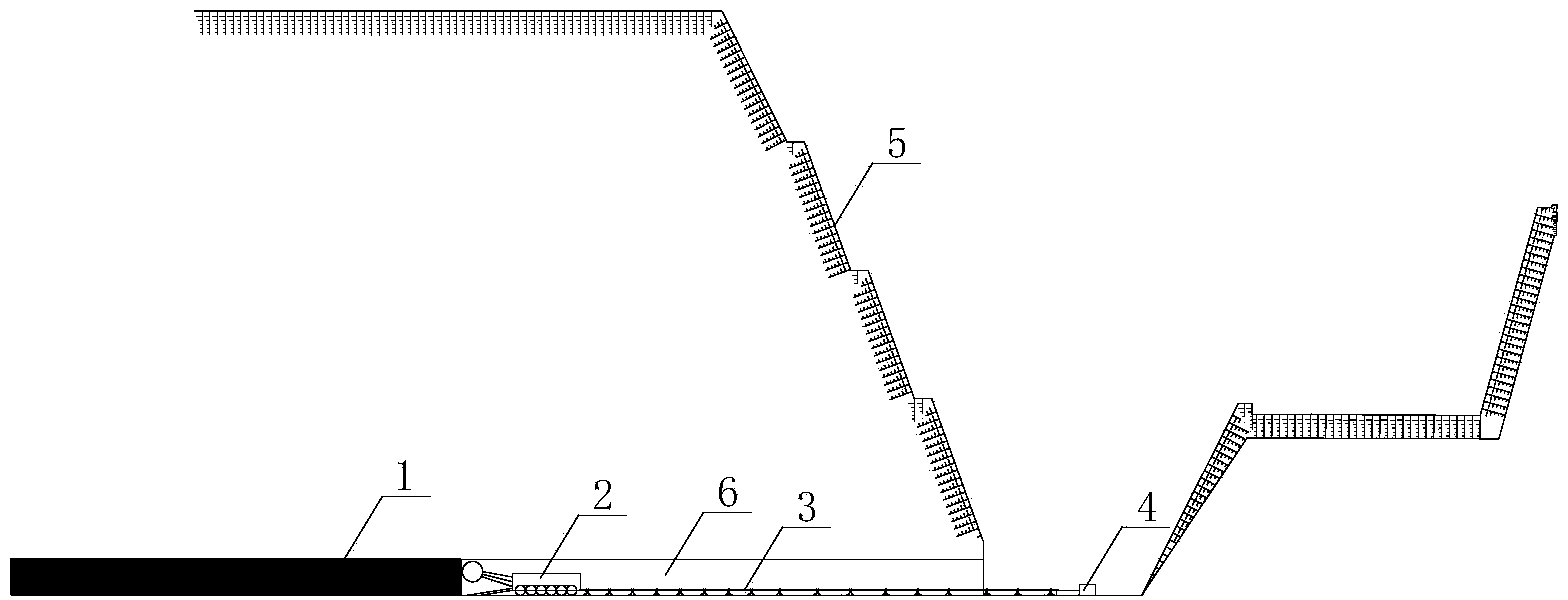

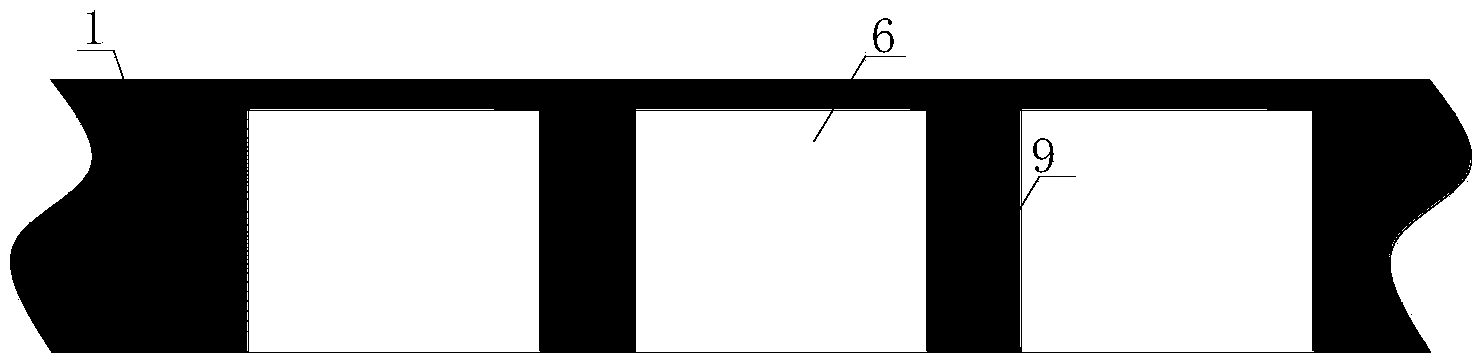

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] In the method for remote-controlled tunneling and mining of end-side coal seams of the present invention, the main coal mining system uses a remote-controlled roadheader system, which includes a roadheader 2 and a remote control room. The control equipment consists of three parts: roadheader electric control box, roadheader electric control box, and operation console. It has the function of remote wired control operation, realizes the separation of man and machine, and operates in a safe operation room during coal mining. The main process of mining includes preparing for cleaning and selecting the initial mining roadway 6, roadheader 2 driving and cutting coal, roadheader coal loading, belt extension, belt conveyor 3 to transport coal outward, loader 4 stacking, excavation to stop production line 7 exit Alleyway 6. Withdraw equipment, overhaul, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com