Underground no pillar recovery method of coal mine

A recovery method and a coal pillar-free technology, which is applied in mine/tunnel ventilation, ground mining, mining equipment, etc., can solve problems such as retaining lanes, high cost of digging lanes, immature coal pillar recovery technology, waste of coal resources, etc. Achieve the effect of reducing the amount of roadway excavation engineering and maintenance, and improving the recovery rate of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

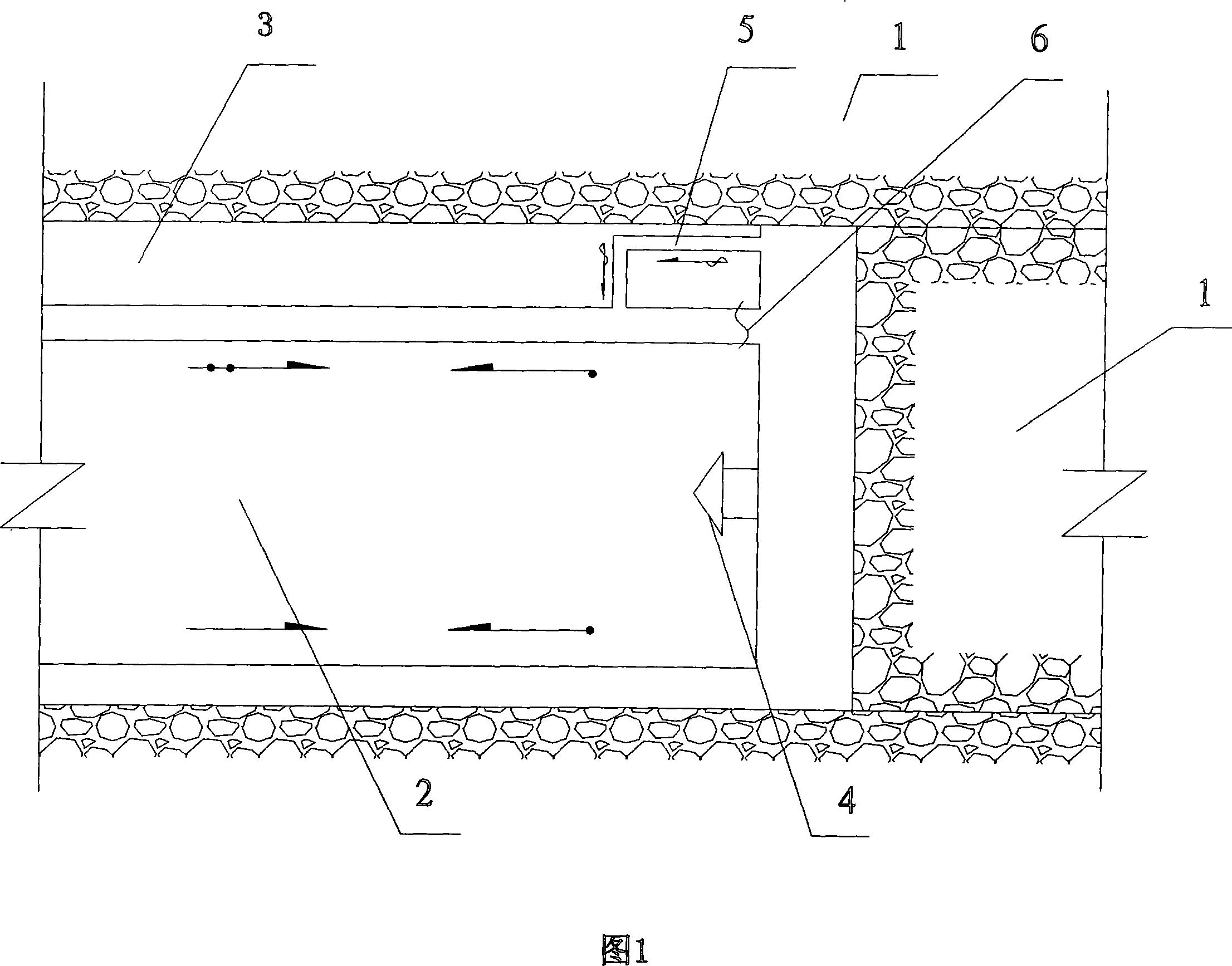

[0017] As shown in FIG. 1 , a roadway layout diagram of a method for recovering coal pillars in an underground coal mine according to the present invention. Ventilation boreholes are arranged along the edge of goaf 1, which can avoid and weaken the influence of fixed support pressure, and replace goaf retention and gob entry. These include the following processes:

[0018] 1. Set coal pillars: In order to avoid the influence of large support pressure in the track level entry in the lower section, section coal pillars 3 should be reserved. Since the reserved section coal pillars will eventually be recycled, in order to facilitate roadway maintenance, coal The column size can be as large as 25-30m;

[0019] 2. Drilling along the goaf: 1 to 3 circular holes with a diameter of 1000mm are constructed at the tail of the working face along the goaf edge of the mined working face as return air holes of the mining face. This method utilizes the edge pressure of the goaf For smaller f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com