Integral purified integration system and process of lignite in cement production through catalytic mild pyrolysis

A technology of pyrolysis upgrading and integrated system, which is applied in the field of lignite catalytic mild pyrolysis upgrading integrated system, which can solve the problems of clogging and upgrading process pipelines, increasing carbon dioxide emissions, and high oxygen content in hot flue gas, so as to reduce costs , Increase water vapor content, reduce the effect of dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

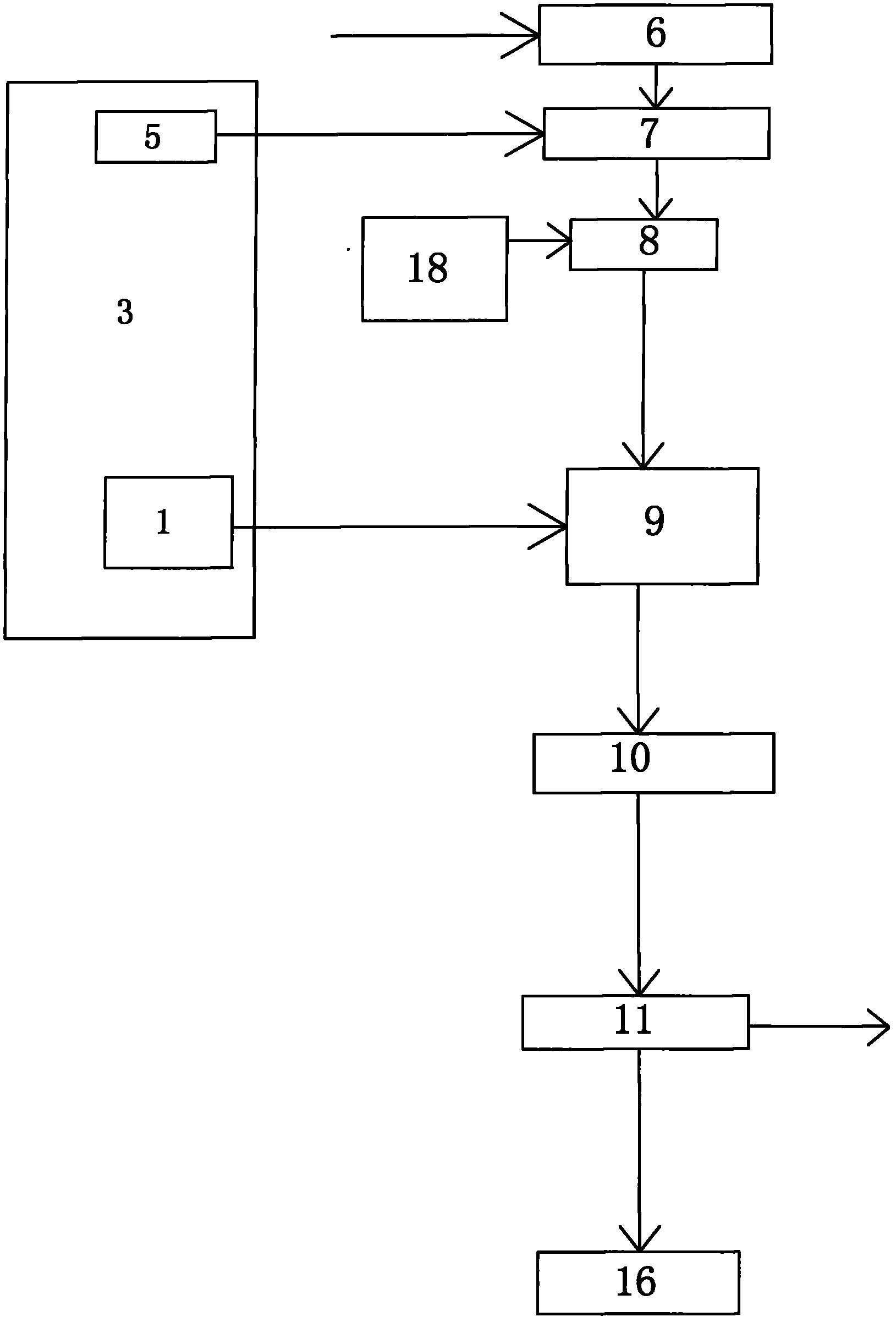

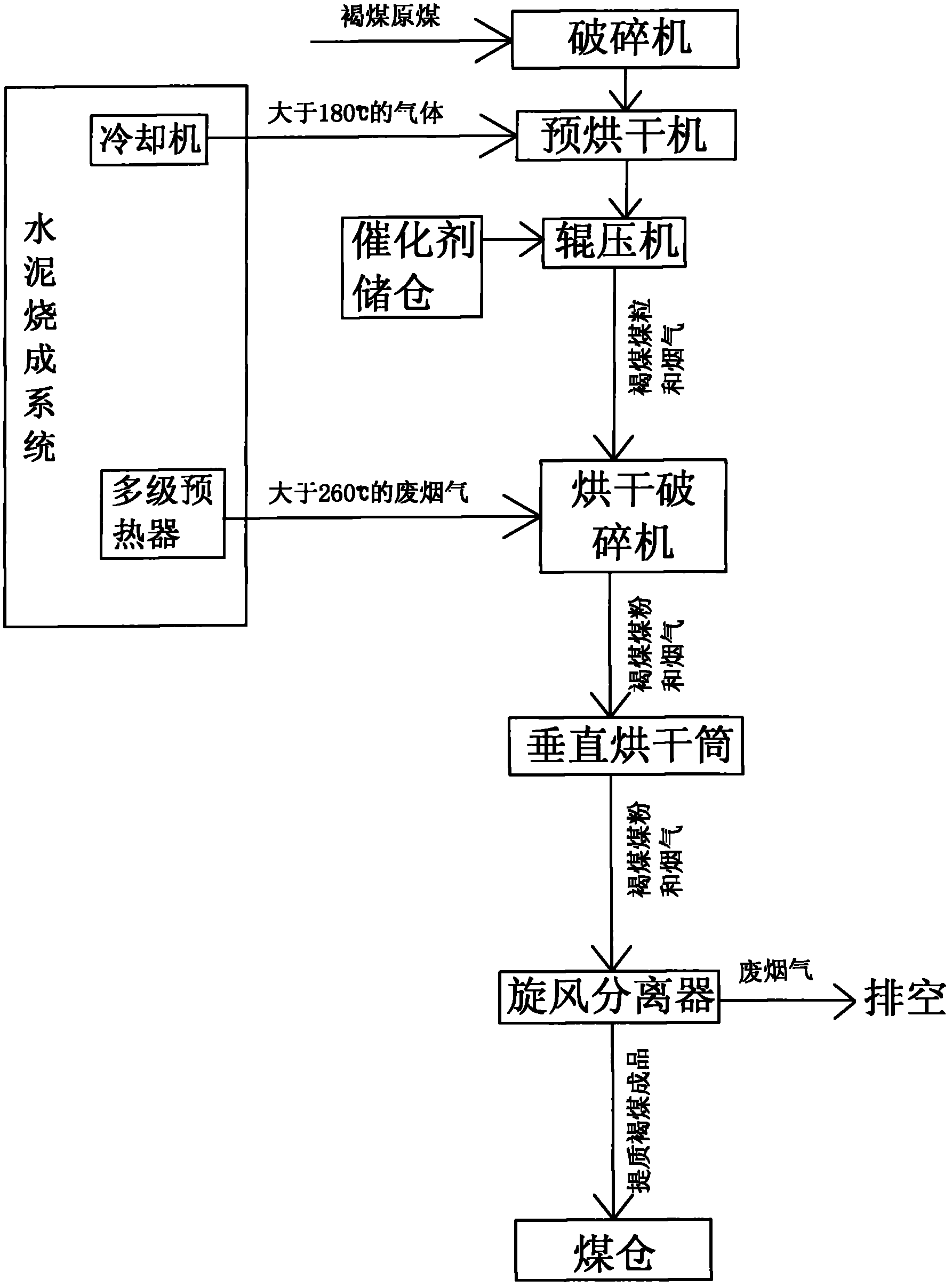

[0030] Embodiment 1: as figure 1 As shown, the integrated lignite catalytic mild pyrolysis upgrading integrated system in cement production includes a cement firing system 3, a crusher 6, a pre-dryer 7, a roller press 8, a catalyst storage bin 18, a drying Crusher 9, vertical drying cylinder 10, cyclone separator 11, coal bunker 16;

[0031] Among them, the cooler for cooling the clinker of the cement burning system 3 - the cooler 5 is connected to the pre-dryer 7 through the pipeline, and the cement kiln tail of the cement burning system 3 - the multi-stage preheater 1 is connected to the drying crusher through the pipeline 9 connections, crusher 6, pre-dryer 7, roller press 8, drying crusher 9, vertical drying cylinder 10, cyclone separator 11, coal bunker 16 are connected in sequence, catalyst storage bin 18 is connected with the roller press 8 phase connections.

[0032]The cement burning system 3 is a suspension preheater kiln, which includes a multi-stage preheater 1, ...

Embodiment 2

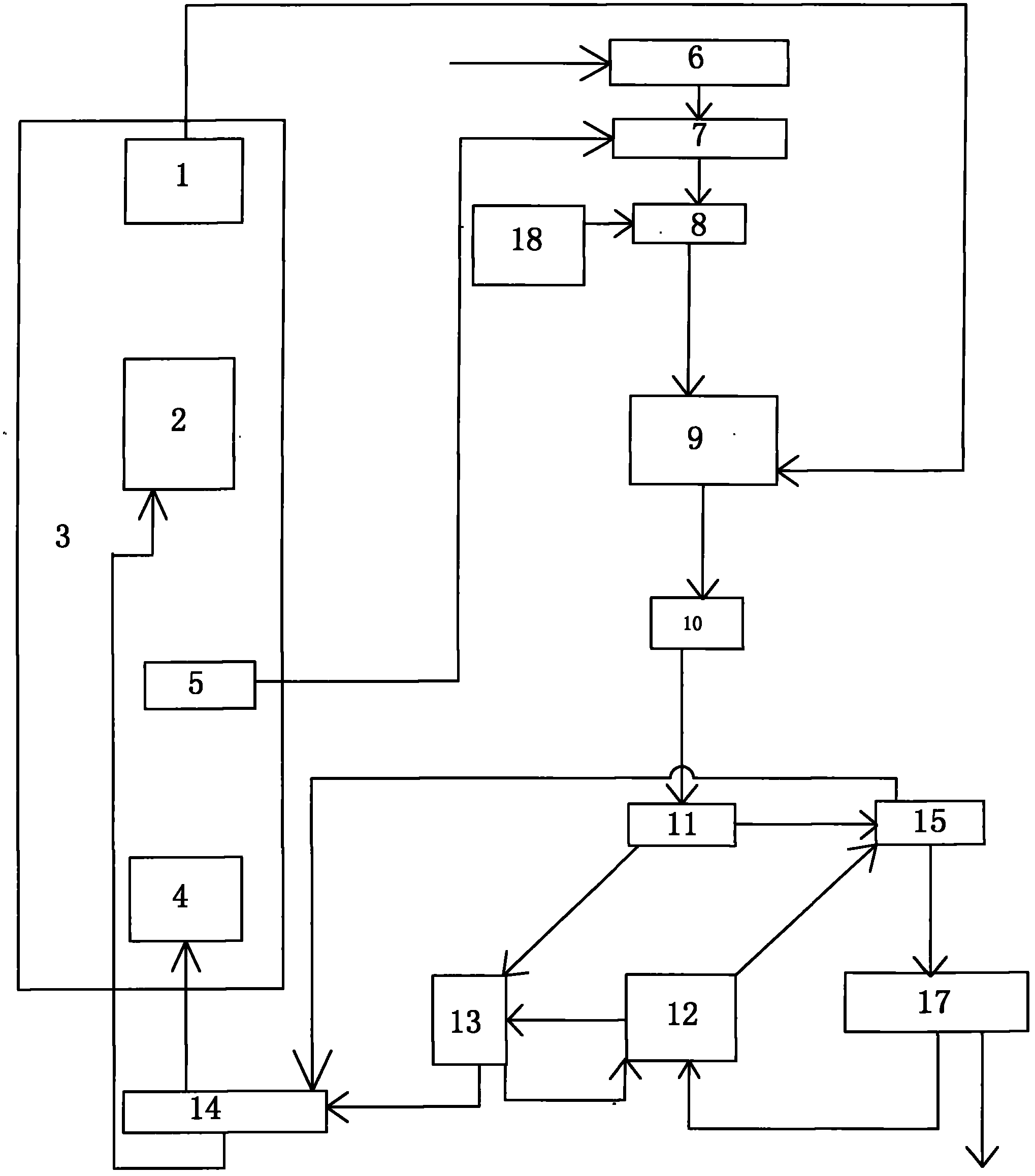

[0040] Embodiment 2: Integrated lignite catalytic mild pyrolysis upgrading integrated system in cement production, which includes cement burning system 3, crusher 6, pre-dryer 7, roller press 8, catalyst storage bin 18, oven Dry crusher 9, vertical drying cylinder 10, cyclone separator 11, grinding device 12, coal particle classification device 13, coal powder feeding device 14, dust collector 15 and water recovery device 17; wherein the cement firing system 3 The cooler for cooling the clinker—the cooler 5 is connected to the pre-dryer 7 through pipelines, the cement kiln tail of the cement firing system 3—the multistage preheater 1 is connected to the drying crusher 9 through pipelines, and the crushers 6, The pre-dryer 7, roller press 8, drying crusher 9, vertical drying cylinder 10, and cyclone separator 11 are respectively connected in sequence, the catalyst storage bin 18 is connected with the roller press 8, the cyclone separator 11, and the coal particle The classifyin...

Embodiment 3

[0054] Embodiment 3: in the integration system of lignite catalytic mild pyrolysis upgrading in the cement production of embodiment 1, the cement firing system can also be a Liboer kiln, which includes a Liboer preheater, a cooling machine and a coal kiln. Powder burner, wherein the clinker cooling cooler of the cement firing system 3 is the cooler of the Liber kiln, and the cement kiln tail of the cement firing system 3 is the Liber preheater.

[0055] The pre-dryer 7 is a vertical dryer.

[0056] In step (2) of Example 1, the catalyst in the catalyst storage bin 18 can also be added to the roller press 8 at a rate of 3% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com