A kind of production technology of corn pulping fiber

A corn fiber and production process technology, applied in the field of corn pulping fiber production, can solve the problems of low drying efficiency, large air volume, low exhaust temperature, etc., achieve low steam and power consumption, facilitate waste heat recovery, and high drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

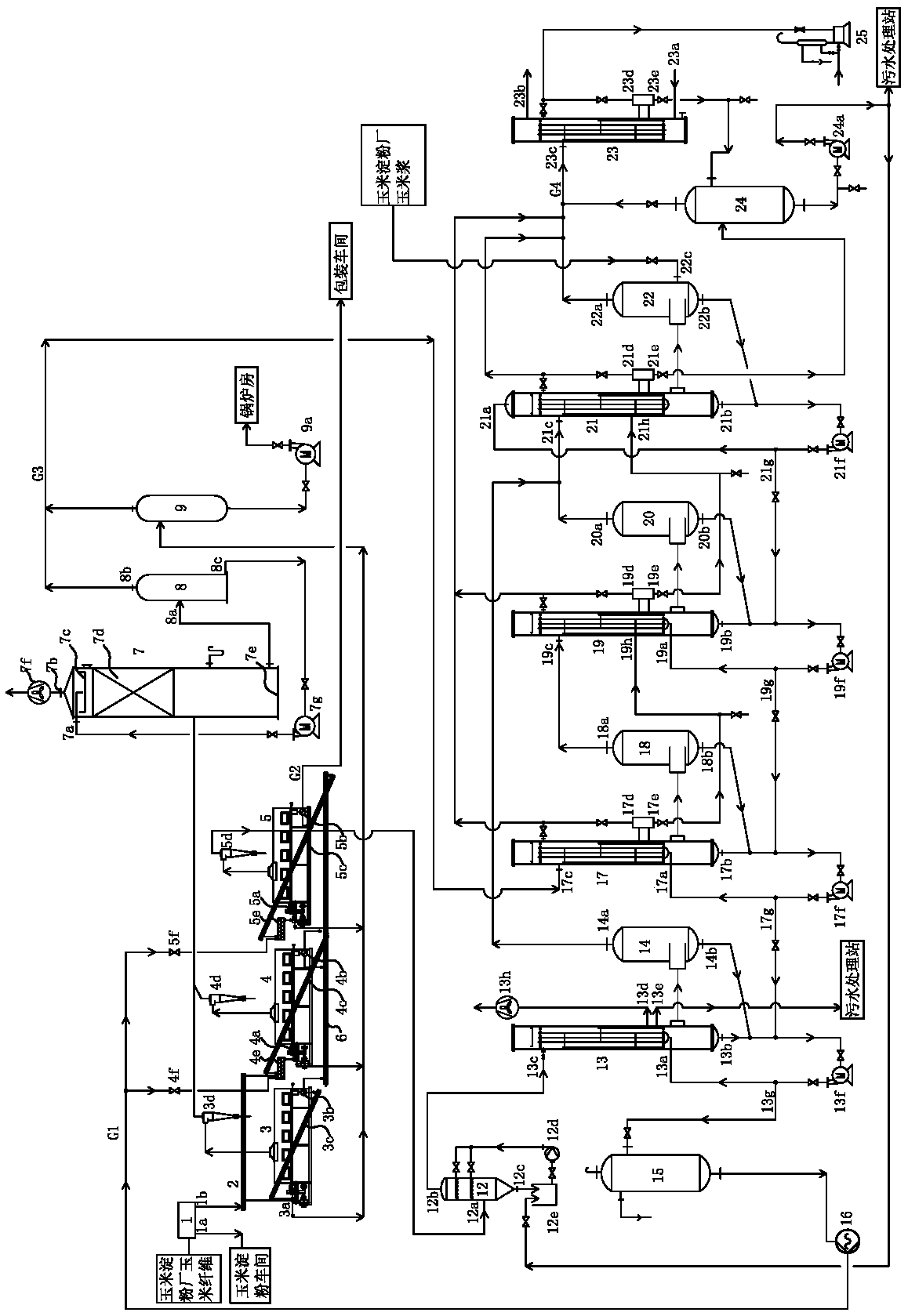

[0020] Such as figure 1 Shown, the production technique of a kind of corn pulping fiber of the present invention, comprises the following steps successively:

[0021] ⑴ The corn fiber in the corn starch factory is separated into dehydrated corn fiber and dehydration liquid by the screw dehydrator 1. The water content of the dehydrated corn fiber is 61-63%, and the dehydration liquid is returned to the corn starch workshop.

[0022](2) Concentrate the corn steep liquor in the corn starch factory to make it into thick corn steep liquor and enter the thick corn steep liquor total addition pipe G1, the above-mentioned dehydrated corn fiber enters the feeding screw conveyor 2 from the dehydrated corn fiber outlet 1b, and part of it enters the feeding screw conveyor 2 from the feeding screw conveyor 2 The first discharge port enters the first feeding screw 3a, and is sent to the first tube bundle dryer 3 by the first feeding screw 3a for primary drying.

[0023] (3) The corn fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com