Ceramic kiln with cooling control structure

A ceramic kiln and control structure technology, applied in the field of ceramic kiln, can solve the problems of increasing temperature field uniformity, uncontrollable temperature and atmosphere, unevenness, etc., to achieve uniform temperature field, reduce temperature difference, and strong automatic adjustment ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

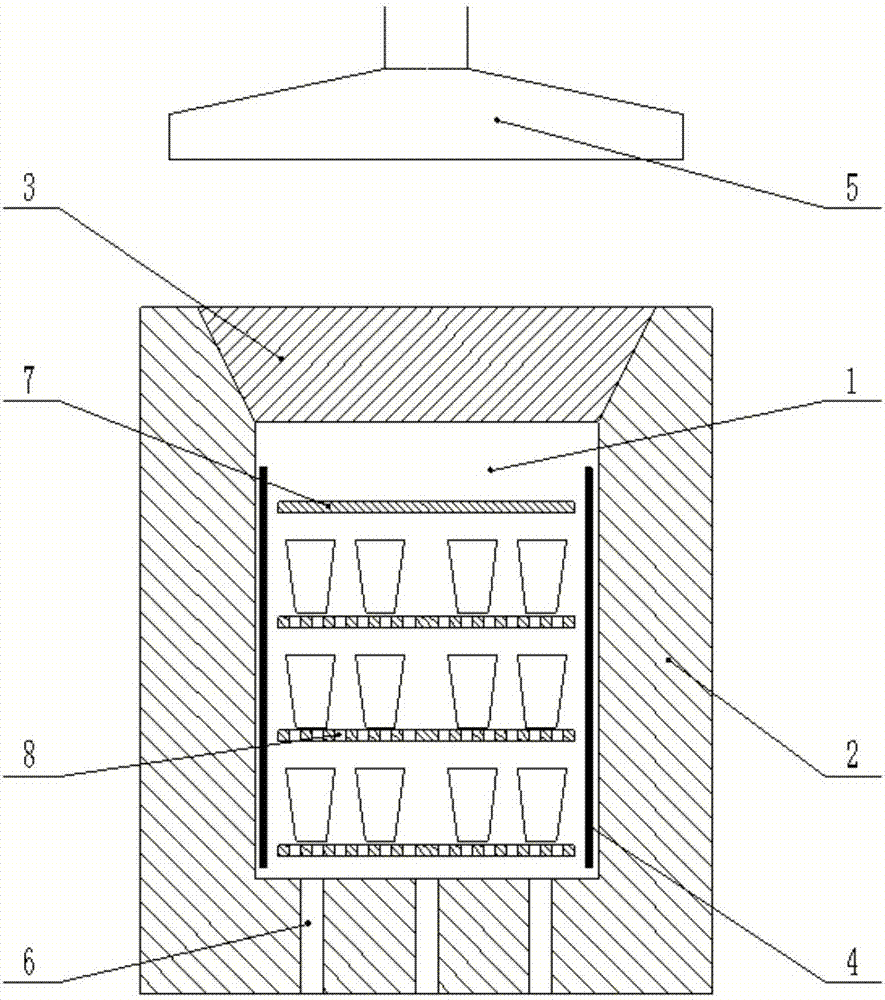

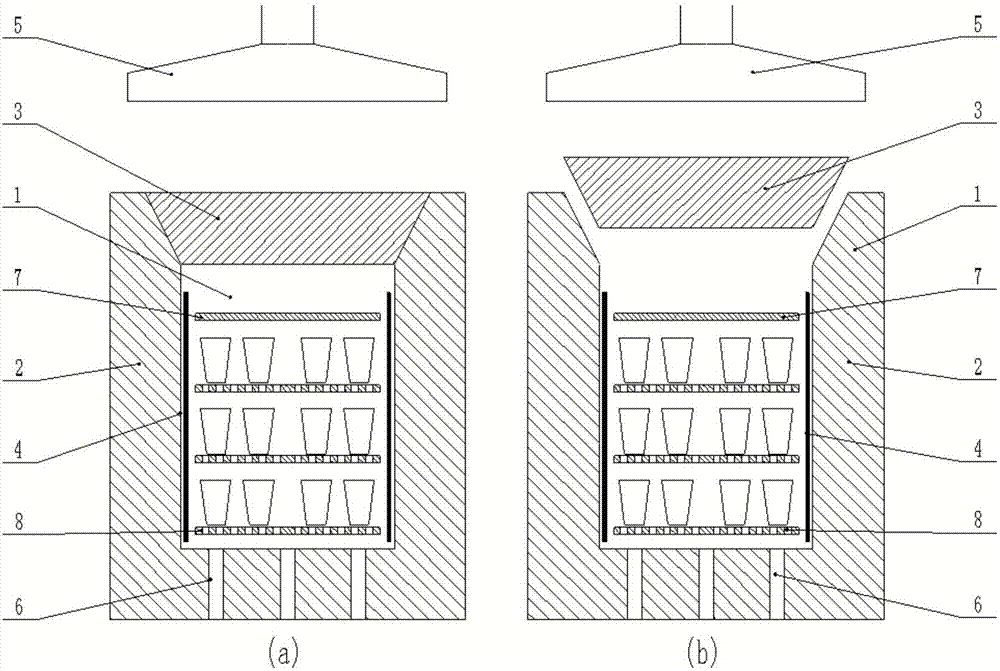

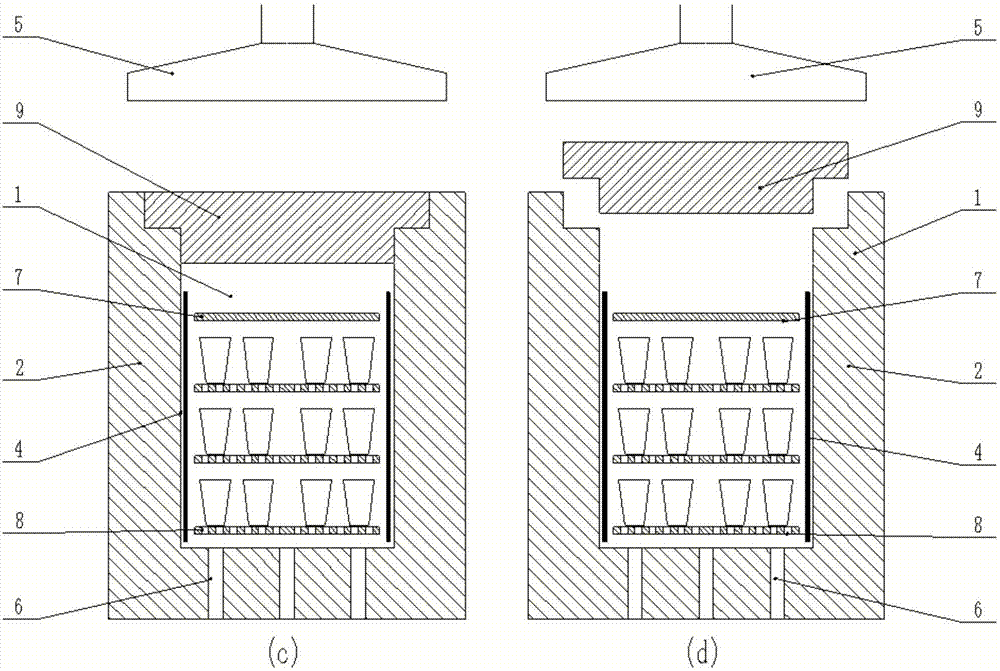

[0018] The ceramic kiln with cooling control structure proposed by the present invention has a structure such as figure 1 As shown, it includes a furnace 1, an outer wall of a kiln 2, a liftable top cover 3, a heater 4, a smoke collection and exhaust hood 5, a controlled air intake pipe 6, a soaking shed 7 and a perforated ventilation shed 8. The heater 4 is arranged on the four walls of the furnace 1, and the perforated ventilation sheds 8 are longitudinally arranged in the furnace 1, and the body to be fired is placed on the perforated and ventilated shelvings 8 . The soaking shed plate 7 is positioned above the uppermost green body to be fired. The lower part of the furnace 1 is provided with a controlled air intake pipe 6 , the upper part of the furnace 1 is provided with a liftable top cover 3 , and a smoke collection and exhaust hood 5 is provided above the liftable top cover 3 .

[0019] In the above-mentioned ceramic kiln with cooling control structure, the liftable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com