Circular rotary heating furnace for long aluminum bars

A technology of rotary heating and heating furnace, applied in the field of aluminum profile processing, can solve the problem of easy jamming and high energy consumption of square heating furnace, and achieve the effects of uniform heating, high degree of automation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further descriptions will be made below in conjunction with the accompanying drawings and specific embodiments, and the combinations and improvements made by the present invention can be achieved without violating the idea and essence of the present invention. Should fall within the protection scope of the present invention.

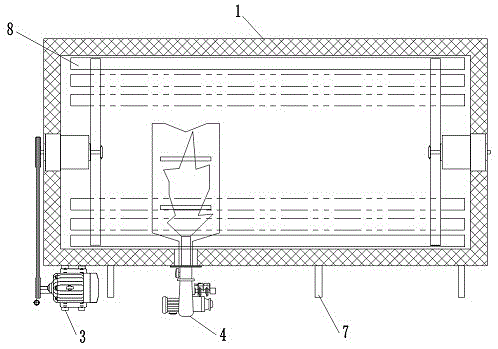

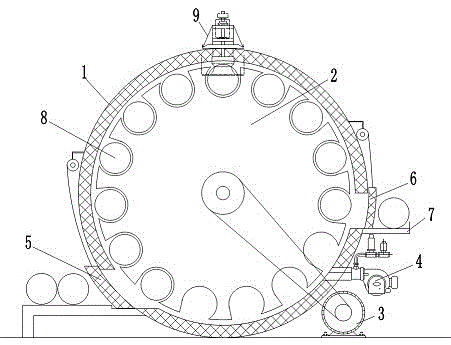

[0013] Such as Figure 1-2 As shown, a circular long aluminum rod rotary heating furnace, the main body is a furnace body 1 with a cylindrical structure, and an insulation layer is provided outside the inner chamber. On both sides of the furnace body, there are strip-shaped feeding furnace door 5, discharging furnace door 6 and discharging table 7 respectively, wherein the discharging furnace door 6 and the discharging table 7 are arranged on the right side of the furnace body and are connected with each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com