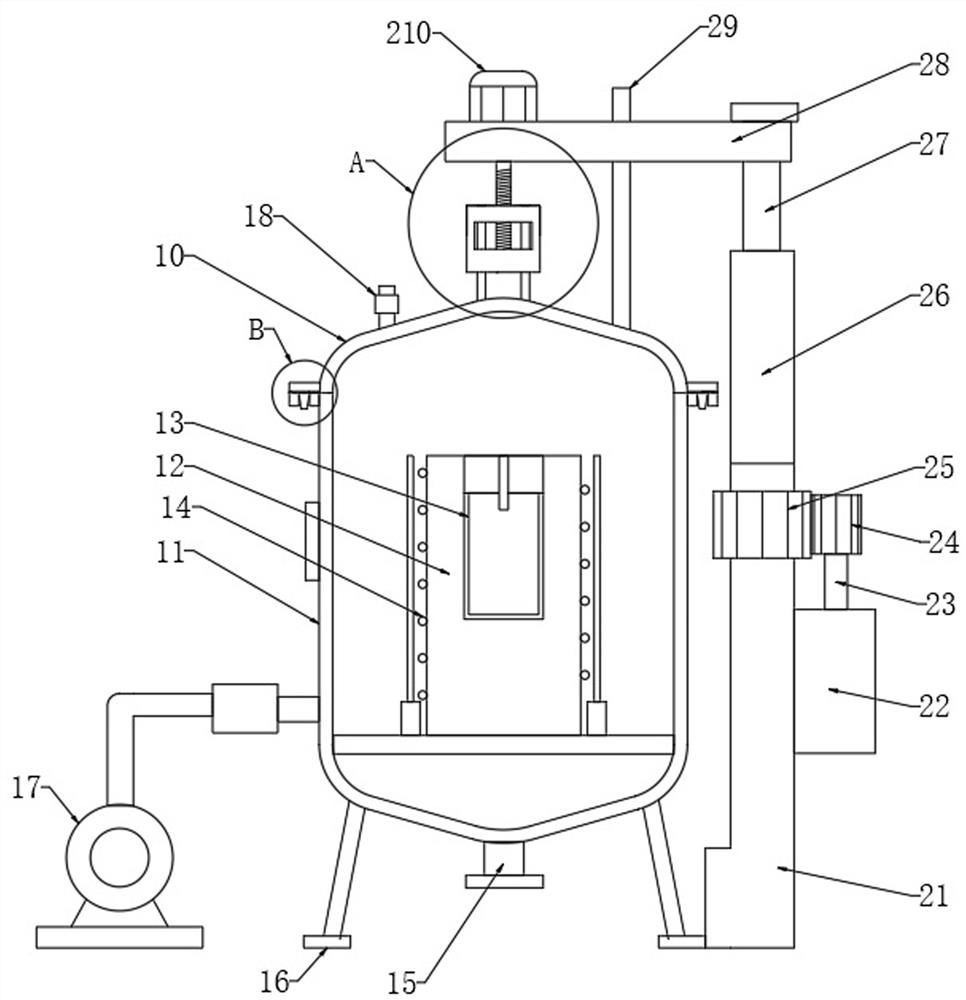

Improvement method and device for prolonging service life of graphite crucible

A graphite crucible and life-span technology, applied in lighting and heating equipment, furnaces, sustainable manufacturing/processing, etc., can solve the problems of graphite oxidation, failure to measure the final temperature, and fracture, so as to increase the fluidity of powder materials and improve the Secondary spraying effect, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

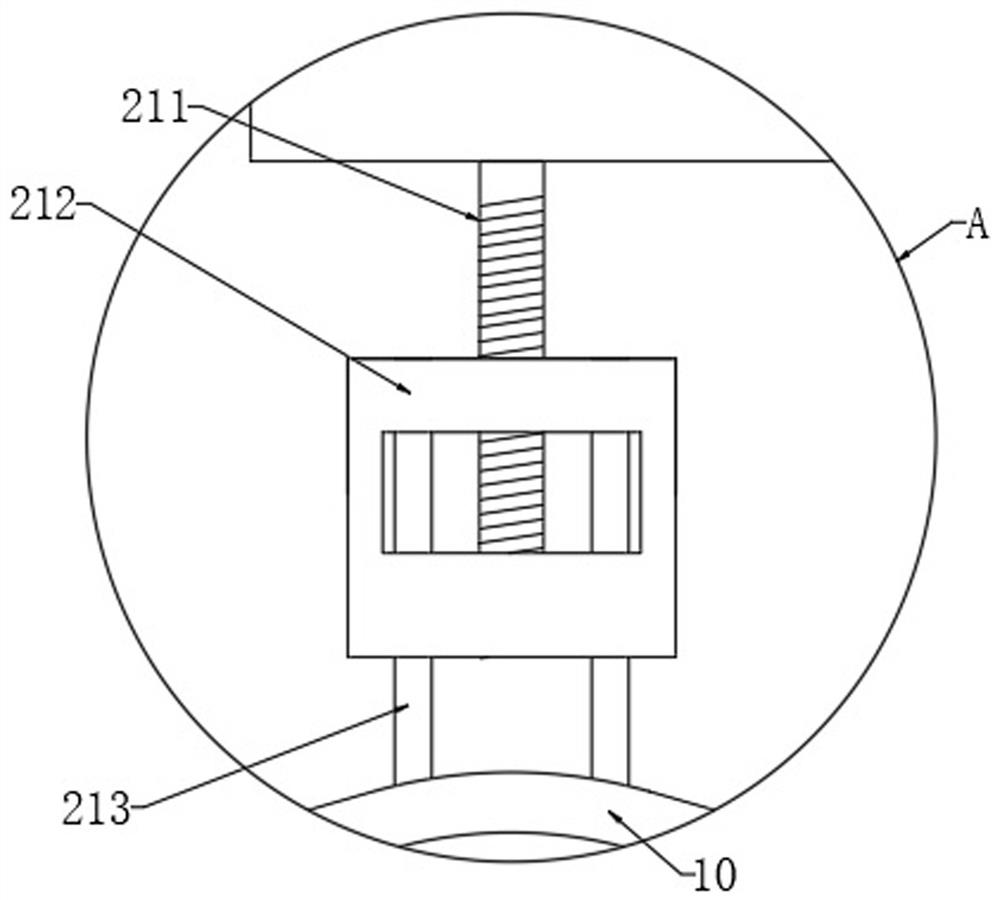

[0050] An improvement method for improving the life of graphite crucible, including the following steps:

[0051] (1) Mixed powder preparation: Tungsten oxide, Si powder, C powder and chloride are mixed in mass 45: 15: 10: 30, resulting in mixed powder;

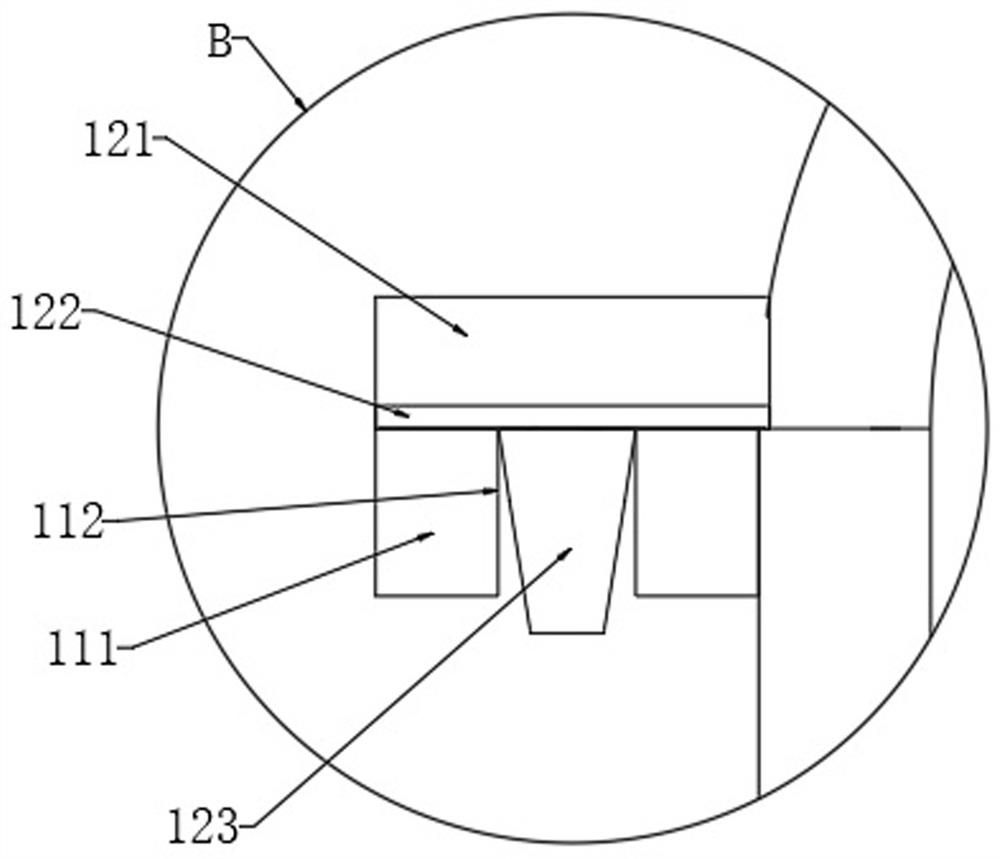

[0052] (2) Preprocessing: Specifically, the graphite crucible substrate is roughened, and then ultrasonically cleaned in anhydrous ethanol, and then immersed in a sodium carbonate solution, then soaked in the nitric acid solution, then washed, finally placed Dry or dry in the air;

[0053] (3) Elementary bath: The activated graphite crucible was carried out in the mixed powder to obtain a graphite crucible having a primary tungsten coating; specifically, the activated graphite crucible was buried in a mixed powder into a high temperature vacuum graphite. The furnace was held at 3,000 ° C under an argon gas atmosphere, and then the surface of the coating was placed flat with sandpaper and dried to obtain a graphite crucible having...

Embodiment 2

[0057] An improvement method for improving the life of graphite crucible, including the following steps:

[0058] (1) Mixed powder preparation: Tungsten oxide, Si powder, C powder and chloride are mixed in mass 60: 30: 25: 5: 50: 25: 5, resulting in mixed powder;

[0059] (2) Preprocessing: Specifically, the graphite crucible substrate is roughened, and then ultrasonically cleaned in anhydrous ethanol, and then immersed in a sodium carbonate solution, then soaked in the nitric acid solution, then washed, finally placed Dry or dry in the air;

[0060] (3) Elementary bath: The activated graphite crucible was carried out in the mixed powder to obtain a graphite crucible having a primary tungsten coating; specifically, the activated graphite crucible was buried in a mixed powder into a high temperature vacuum graphite. The furnace was injected at 3500 ° C for 1.5 h at an argon gas atmosphere, and then the surface of the coating was placed flat and dried to obtain a graphite crucible h...

Embodiment 3

[0064] An improvement method for improving the life of graphite crucible, including the following steps:

[0065] (1) Mixed powder preparation: Tungsten oxide, Si powder, C powder and chloride are mixed in mass 50: 20: 15: 20, resulting in mixed powder;

[0066] (2) Preprocessing: Specifically, the graphite crucible substrate is roughened, and then ultrasonically cleaned in anhydrous ethanol, and then immersed in a sodium carbonate solution, then soaked in the nitric acid solution, then washed, finally placed Dry or dry in the air;

[0067] (3) Elementary bath: The activated graphite crucible was carried out in the mixed powder to obtain a graphite crucible having a primary tungsten coating; specifically, the activated graphite crucible was buried in a mixed powder into a high temperature vacuum graphite. The furnace was insulated at 3200 ° C for 1.2 h under an argon gas atmosphere, and then the surface of the coating was placed flat and dried, and the graphite crucible having a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com