Gradient ceramic coating on steel substrate and its preparation process

A gradient material and ceramic technology, applied in the field of steel-based ceramic gradient material coating, can solve the problems of low bonding strength, complex spraying process, unstable crystal form, etc., and achieve high temperature oxidation resistance improvement, good physical and chemical matching, High temperature thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

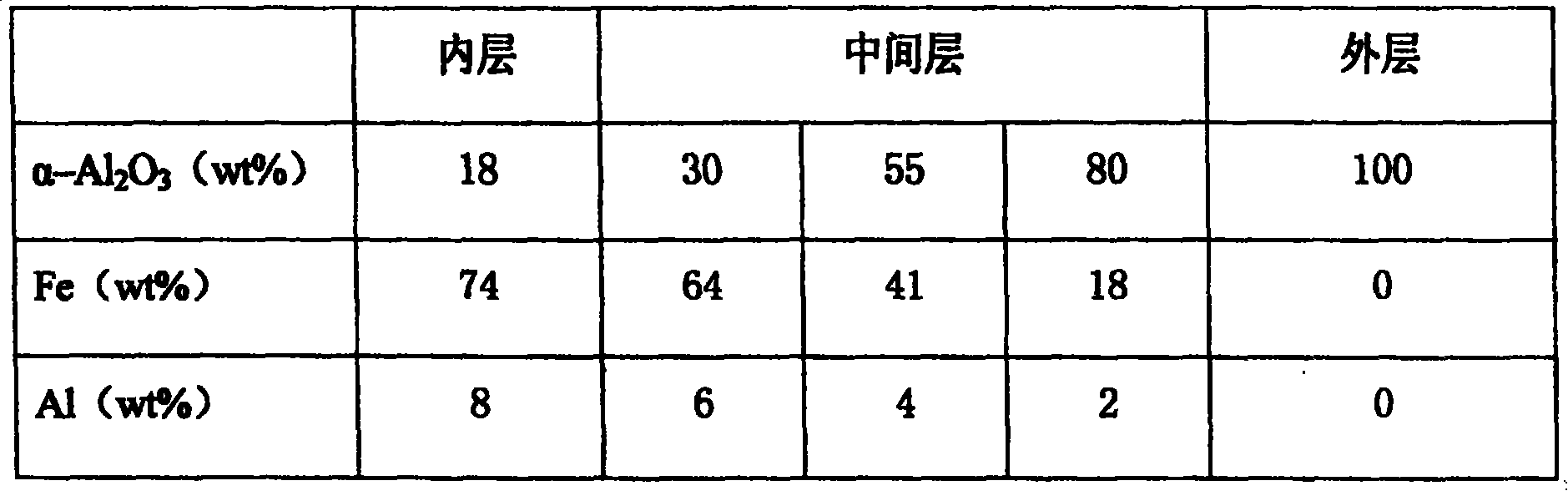

[0027] The steel-based ceramic gradient material coating in this embodiment consists of three layers, from the inside to the outside, the inner layer, the middle layer and the outer layer, and the α-Al in each layer 2 o 3 The weight percentages of , Fe and Al are shown in Table 1 respectively.

[0028] Table 1

[0029] inner layer

middle layer

outer layer

α-Al 2 o 3 (wt%)

15

45

100

Fe(wt%)

80

45

0

Al(wt%)

5

10

0

[0030] The specific process is as follows:

[0031] In this experiment, 45 # Steel is the base material, and its surface is ground and polished. Three layers of Fe-Al / Al were prepared on the steel substrate by spraying method and the combination of spraying method and sol-gel method respectively. 2 o 3 Coating, inner layer and intermediate layer are sprayed with Fe-Al / Al on the steel substrate by spraying method 2 o 3 Mixed slurry, the outermost layer is co...

Embodiment 2

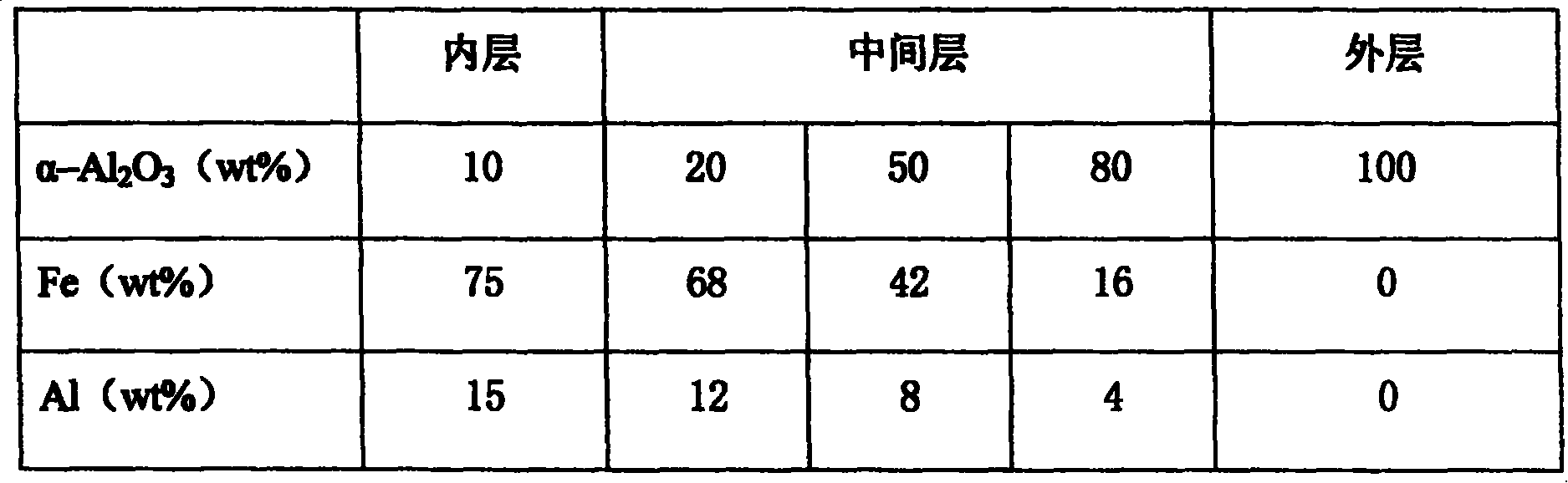

[0036] The steel-based ceramic gradient material coating in this embodiment is composed of an inner layer, a middle layer and an outer layer in sequence from the inside to the outside, and the middle layer is further divided into three layers, totaling five layers. Al in each layer 2 o 3 The weight percentages of , Fe and Al are shown in Table 2 respectively.

[0037] Table 2

[0038]

[0039] Its preparation is basically the same as in Example 1.

Embodiment 3

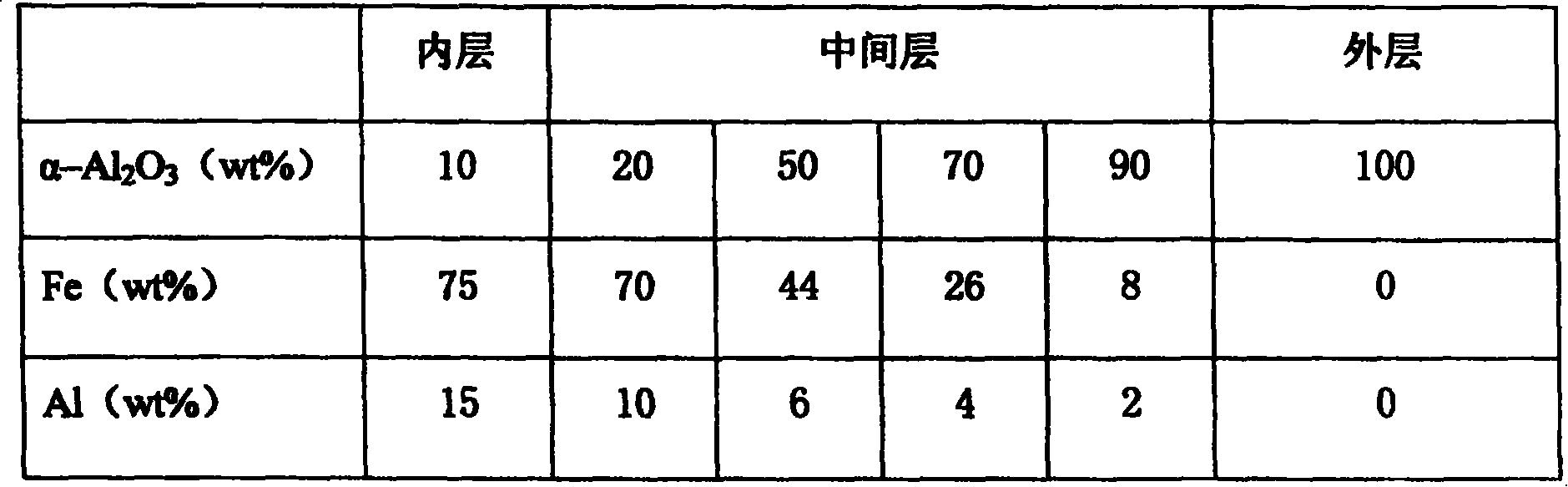

[0041] The steel-based ceramic gradient material coating in this embodiment is composed of an inner layer, a middle layer and an outer layer in sequence from the inside to the outside, and the middle layer is further divided into three layers, totaling five layers. Al in each layer 2 o 3 The weight percentages of , Fe and Al are shown in Table 3 respectively.

[0042] table 3

[0043]

[0044] Its preparation is basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com