Patents

Literature

41results about How to "Less metallurgical defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of complex large thin-walled Ni3Al alloy cast

The invention provides a preparation method of a complex large thin-walled Ni3Al alloy cast, and belongs to the technical field of casting. The method comprises the following steps: (1) preparing a wax mould; (2) coating slurry, applying sand, drying to prepare a shell surface layer, preparing shell layers from the second layer to the ninth layer on the surface layer in sequence, and coating slurry; (3) drying to form a shell; (4) removing the wax mould, and preheating in a vacuum condition; (5) pouring Ni3Al alloy fluid in the shell, and controlling the pouring time to be between 5 and 7 seconds; and (6) cooling along with the furnace to the temperature of 650+ / -10 DEG C, naturally cooling in an insulating vessel, removing the shell on the surface, and cutting off the pouring gate part of the cast body. The cast prepared by adopting the method has remarkably reduced metallurgical defects, the problem of bar crack is successfully solved, and the quality is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Aluminum alloy semi-ring for fairing of launch vehicle and preparation method thereof

ActiveCN101760682AGuaranteed performanceLess metallurgical defectsExtrusion control devicesHardnessHigh intensity

The invention discloses an aluminum alloy semi-ring for a fairing of a launch vehicle and a preparation method thereof, relating to an alloy semi-ring and a preparation method thereof. The invention solves a problem that the traditional aluminum alloy semi-ring for the fairing of the launch vehicle has a low intensity and cannot satisfy the application requirements of large-scale launch vehicles. The aluminum alloy semi-ring for a fairing of a launch vehicle is made of Si, Fe, Cu, Mn, Mg, Ni, Zn, Ti and Al. The tensile strength of the semi-ring is 380-450MPa, the percentage elongation after fracture is 6.0-10% and the Brinell hardness is 110N / sq.m-150N / sq.m. The preparation method comprises the following steps of: preparing the raw material, melting, casting, homogenizing annealing, forging, extruding, bending, quenching, coldly compressing to deform, flattening and ageing the raw materials to obtain the aluminum alloy semi-ring for the fairing of the launch vehicle. The aluminum alloy semi-ring for the fairing of the launch vehicle has a high intensity and can be applied to the large-scale launch vehicle.

Owner:NORTHEAST LIGHT ALLOY CO LTD

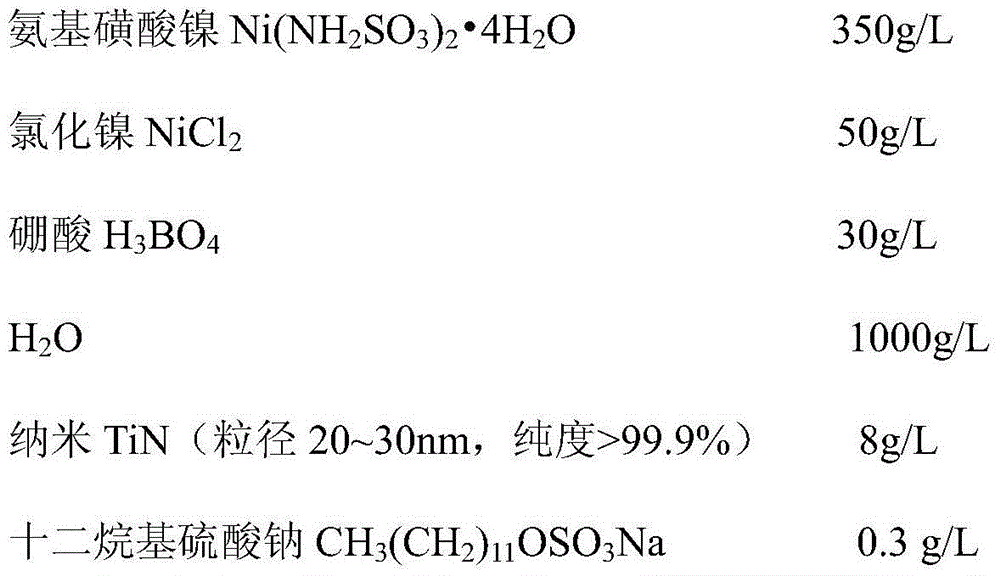

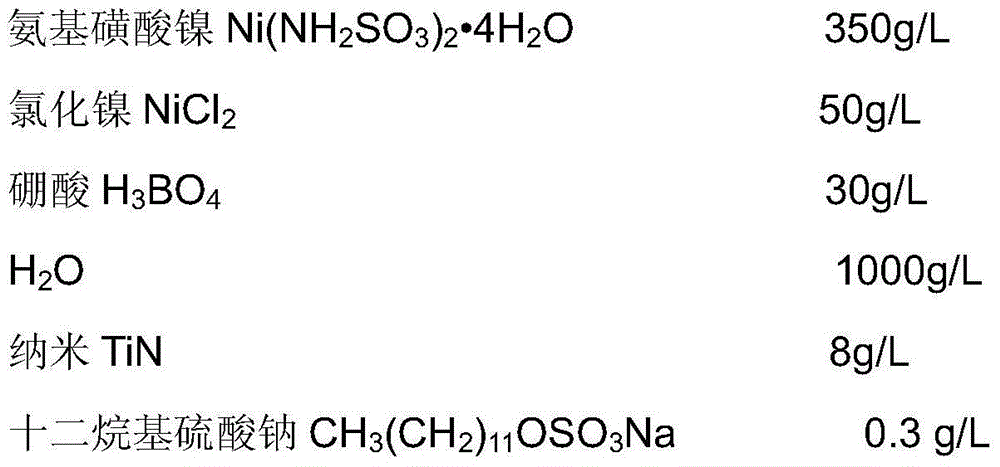

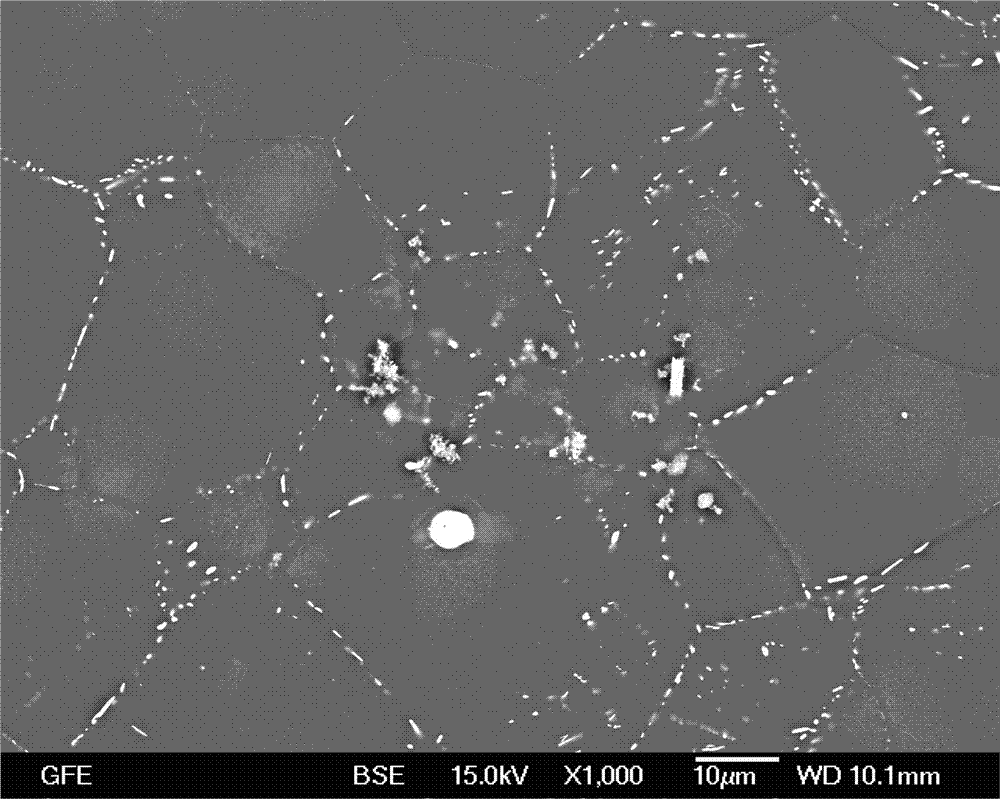

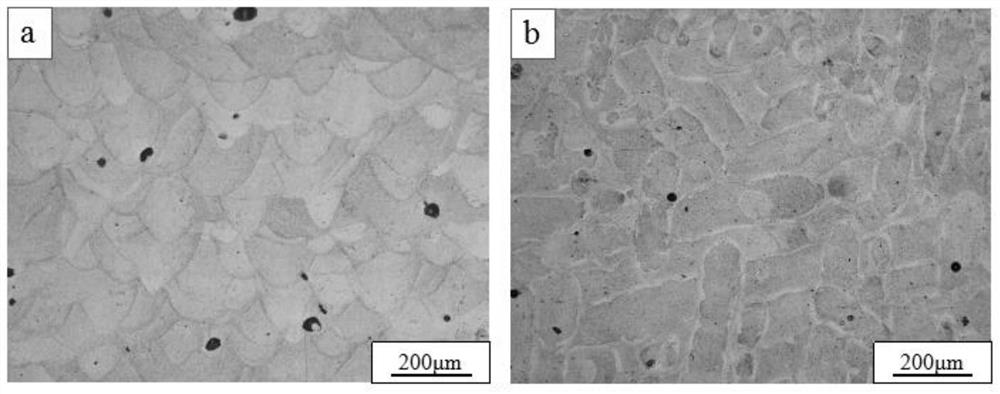

Electrodeposition-laser remelting strengthening process of Ni-nanometer TiN composite layer on surface of nickel base superalloy

InactiveCN104928729ASolve complex processImprove friction resistanceElectrolytic coatingsElectrochemistryPulse power supply

The invention relates to an electrodeposition-laser remelting strengthening process of a Ni-nanometer TiN composite layer on a surface of a nickel base superalloy. The process comprises the following steps: (1) preparation of plating solution: the plating solution comprises such components as nickel aminosulfonate, nickel chloride and water solution of boric acid; (2) preparation of electrodes: the area ratio of an anode to a cathode is 1.5: 1; and the anode and the cathode are arranged in parallel by a distance of 30 mm; (3) composite electrodeposition: a power supply adopts a two-way high-frequency pulse power supply; and (4) laser remelting: a solid pulse laser processor is adopted to perform the one-way laser remelting; and applied power ultrasonic waves, high-intensity magnetic fields and high-frequency pulse current parameters assist the electrodeposition process. The process organically combines the electrodeposition Ni-nanometer TiN composite layer technology with the laser cladding technology, is a new composite processing technology of physics and electrochemistry, and has the advantages of high processing efficiency and quality and wider application range. The process can satisfy the use requirements of nickel base alloy parts under the working conditions of high speed, high temperature, high impact load and corrosion.

Owner:DALIAN UNIV

Aluminum alloy evaporator inner wall thin plate and continuous casting rolling production process thereof

ActiveCN102851551AGood welding performanceLess metallurgical defectsProcess efficiency improvementMetal rolling arrangementsCorrosionAluminium

The present invention discloses an aluminum alloy evaporator inner wall thin plate and a continuous casting rolling production process thereof. The thin plate adopts an aluminum manganese alloy as a base, contains silicon, iron, copper, manganese, magnesium, zinc and titanium, and is prepared by adopting a continuous casting rolling production process. The process comprises the following steps: adding raw materials to a smelting furnace to carry out melting, refining, and residue removing; discharging the resulting material to a cast rolling machine from the furnace to carry out cast rolling; carrying out a first annealing treatment on the cast-rolled plate material to reduce needle-like FeAl3 and influence on mechanical property by a phase composition, wherein the phase composition and the Al-Mn solid solution achieve phase equilibrium; carrying out cold rolling on the first-annealed plate material 5-6 times; carrying out a second annealing treatment on the cold-rolled plate material; and carrying out foil rolling 1-2 times to prepare the aluminum alloy evaporator inner wall thin plate. The technical scheme of the present invention has the following characteristics that: good moldability, good weldability, and good corrosion resistance are provided, structure and performances are uniform, metallurgical defects are less, anisotropy is low, strength is high strength, elasticity is good, and the like.

Owner:江阴新仁铝业科技有限公司

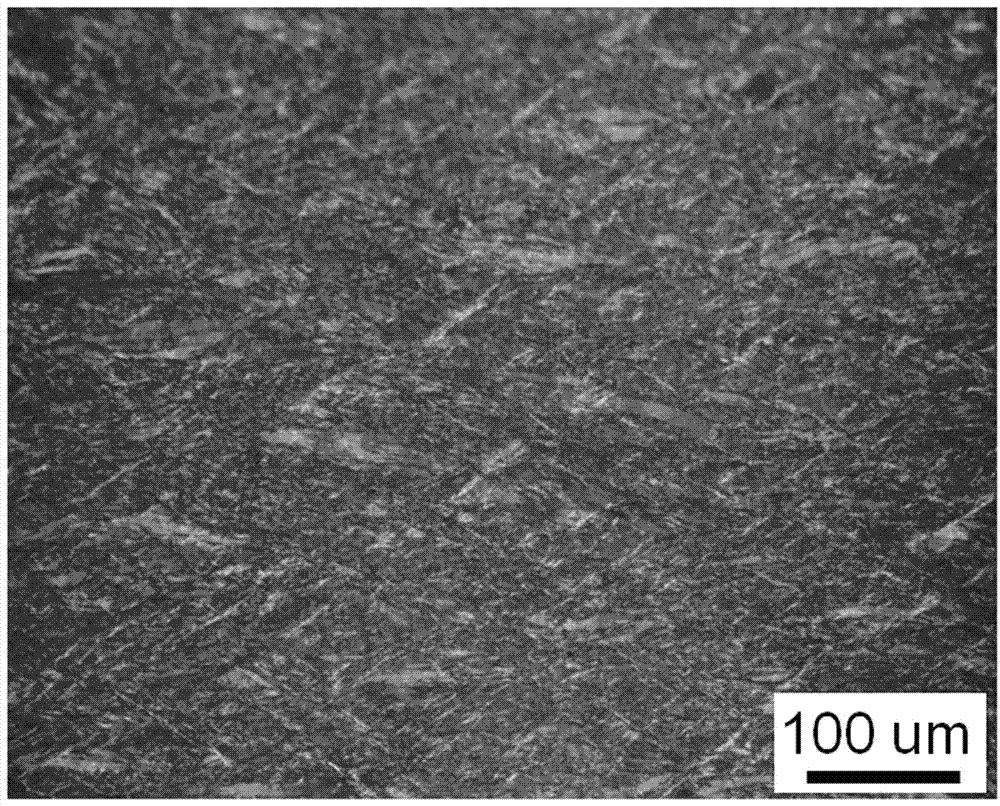

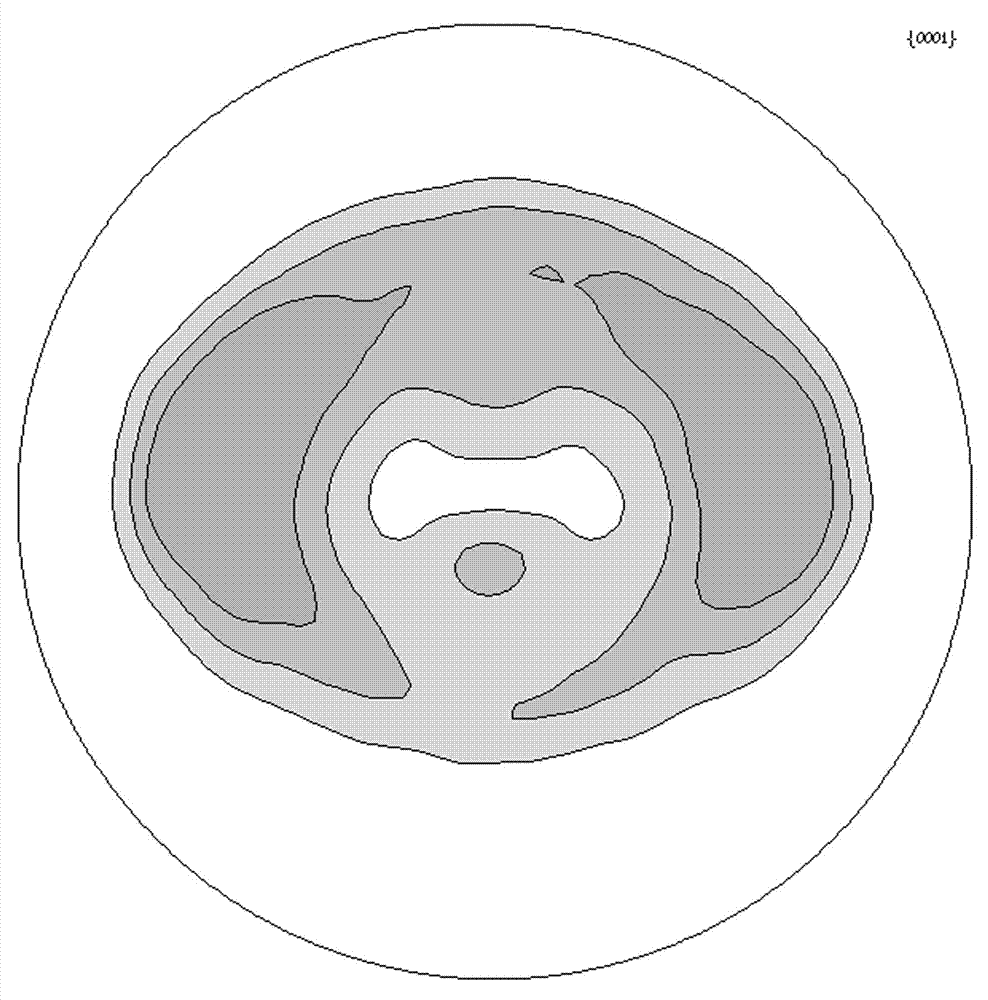

Preparation method of rare earth magnesium alloy and sheet thereof

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is characterized by comprising the following components by mass percent: 0.5 to 4.0% of Zn, 0.1 to 2% of Gd, 0.3 to 0.9% of Zr, and the balance of Mg. The preparation method of the rare earth magnesium alloy sheet comprises the following steps of: treating a rare earth magnesium alloy ingot casting by uniform annealing; cooling with water; milling the surface; preheating a milled blank; rolling for four to eight times; melting down and heating once every two to three times after rolling; continuously rolling, wherein the total rolling reduction is 70 to 95%; annealing the sheet subjected to hot rolling; performing cold rolling for a moderate-thickness sheet subjected to hot rolling for two to four times; and then annealing the sheet subjected to cold rolling to obtain the rare earth magnesium alloy sheet. The invention also provides a preparation method of the rare earth magnesium alloy and the sheet thereof. The rare earth magnesium alloy sheet is high in plasticity and high in heat stability. Compared with hot rolling, cold rolling has the advantage that the magnesium alloy can be prevented from being oxidized into a film during heating; in addition, the prepared sheet is accurate in dimension and uniform in thickness; a thin belt which cannot be produced by hot rolling can be obtained; and mass production and application can be realized.

Owner:GUANGDONG INST OF NEW MATERIALS

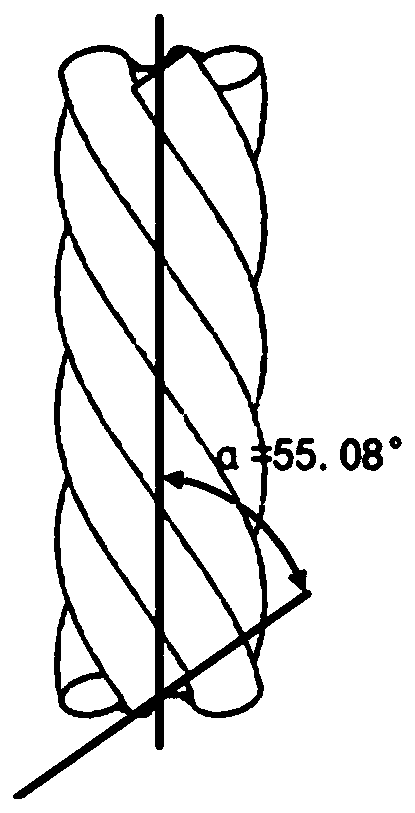

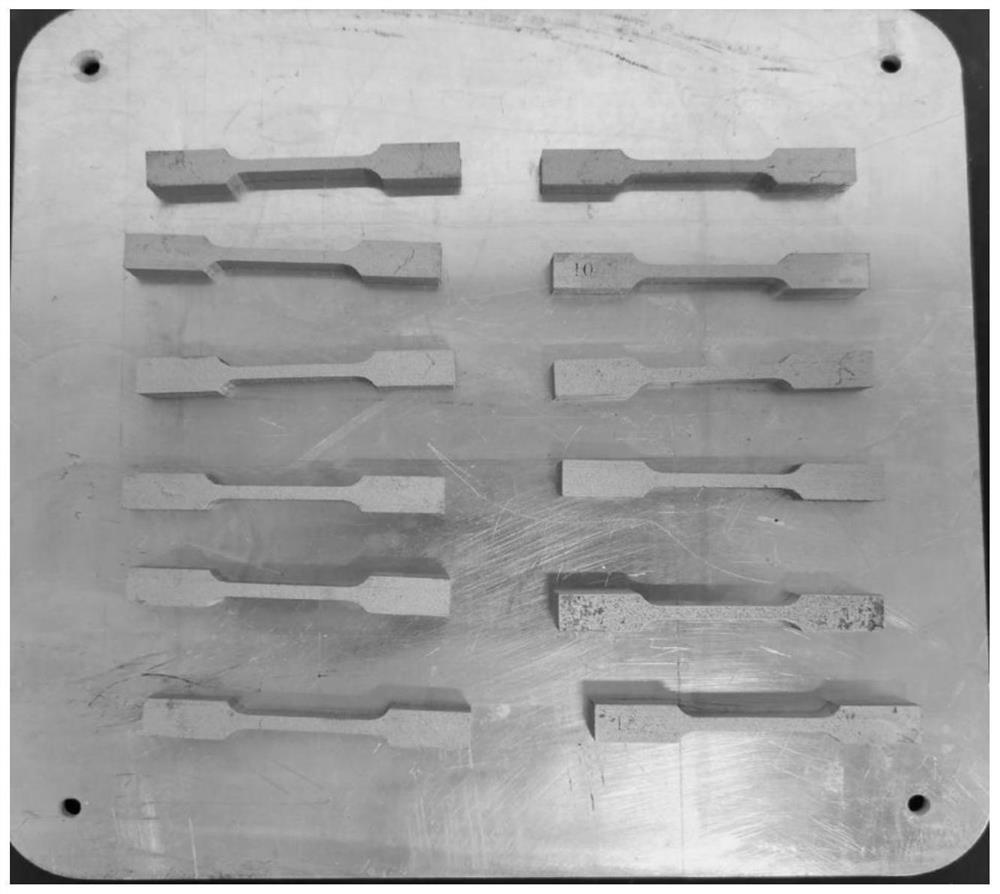

Cable type welding wire and method for preparing high-entropy alloy parts with cable type welding wire

InactiveCN110315237AEasy to overflowLess metallurgical defectsArc welding apparatusWelding/cutting media/materialsHigh rateChemical composition

The invention provides a cable type welding wire which is used in the field of high-entropy alloy preparation. The cable type welding wire comprises a central welding wire body and a plurality of encircling welding wire bodies, wherein the encircling welding wire bodies are spirally wound and twisted around the central welding wire body, and the adjacent encircling welding wire bodies are tangentially connected; the diameter of the encircling welding wire bodies is equal to or less than that of the central welding wire body, and the number of the encircling welding wire bodies is three or more; raw materials of the encircling welding wire bodies and the central welding wire body are selected according to a formula of a high-entropy alloy; and the raw materials comprise metal wires. The invention also provides a method for preparing high-entropy alloy parts by using the cable type welding wire. With the method, the problems of high cost, low preparation efficiency, inconvenient adjustment of alloy components, uneven chemical composition and structure, and high rate of defects such as air holes, cracks, slag inclusion, gaps and shrinkage holes in the prior art are solved.

Owner:FOSHAN UNIVERSITY

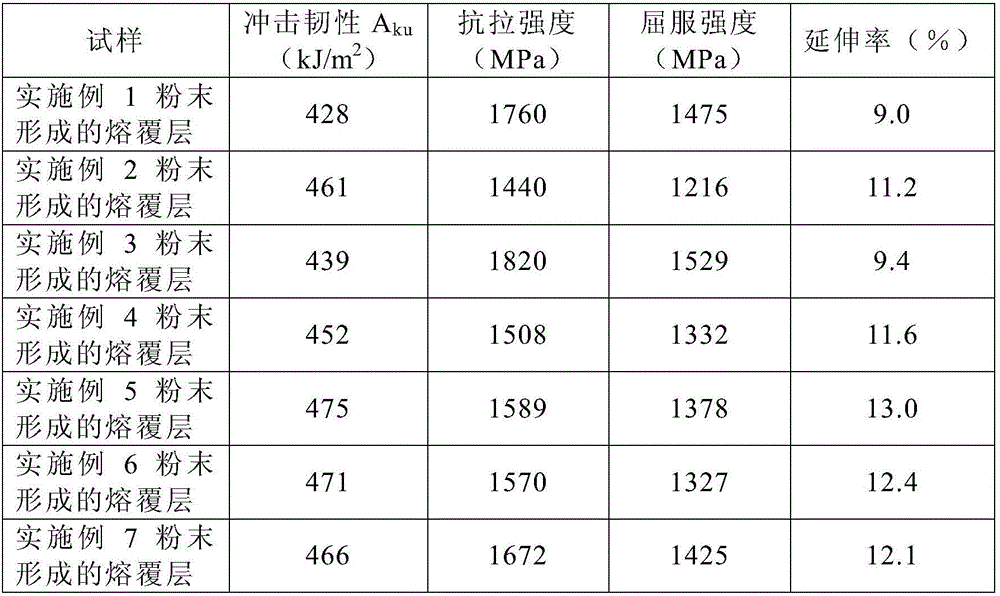

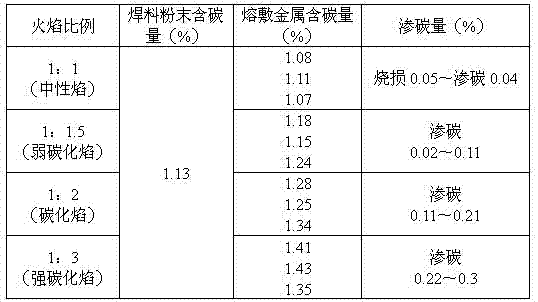

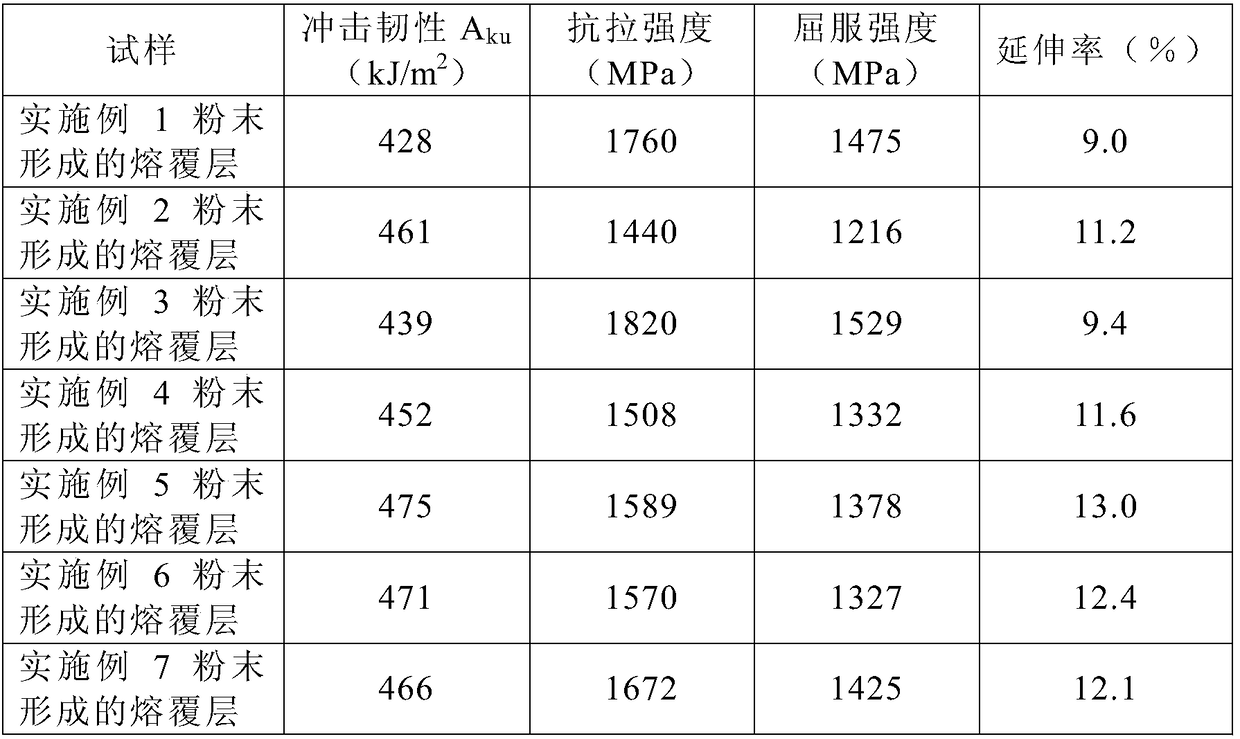

Laser cladding powder for 30CrMnSiNi2A steel and preparation method

ActiveCN106480363AHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthUltimate tensile strength

The invention relates to laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The laser cladding powder is prepared from the following components in weight percent: 0.8% to 1.0% of Cr, 0.75% to 1.10% of Mn, 0.65% to 1.10% of Si, 2.0% to 3.2% of Ni, 0.16% to 0.22% of C, 0.15% to 0.20% of Cu, 0.015% to 0.020% of P, 0.01% to 0.015% of S, 0.001% to 0.015% of rare earth and the balance of Fe. The invention further provides the preparation method of the laser cladding powder, the laser cladding powder is exclusively used in a laser cladding technique of the 30CrMnSiNi2A steel, excellent bonding strength and low metallurgical defects and dilution rate of a cladding interface are guaranteed, the toughness of a cladding layer is increased, the wettability of the cladding powder is improved, the cracking of the cladding layer is inhibited, and the crack growth rate is reduced.

Owner:国营芜湖机械厂

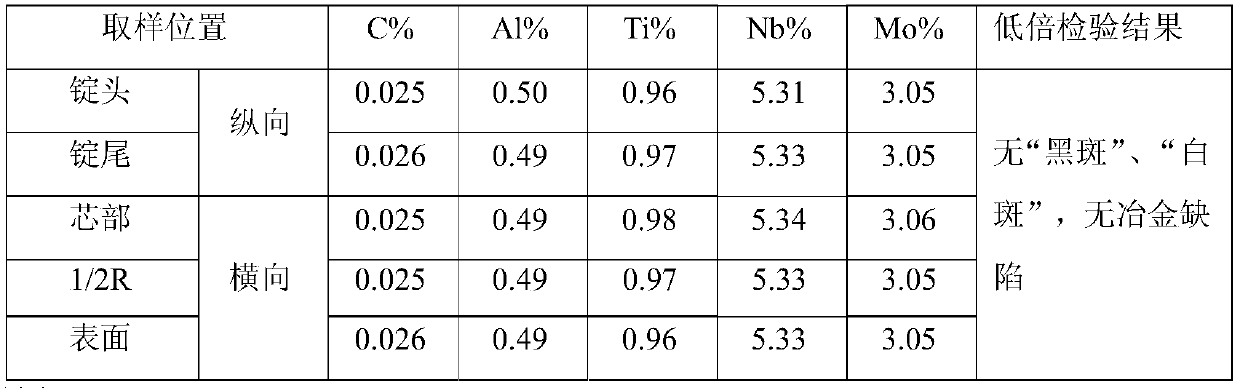

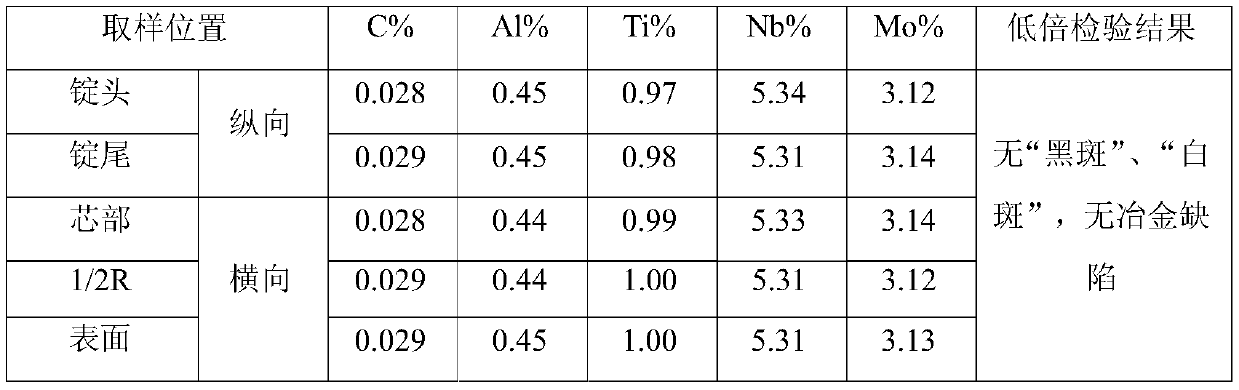

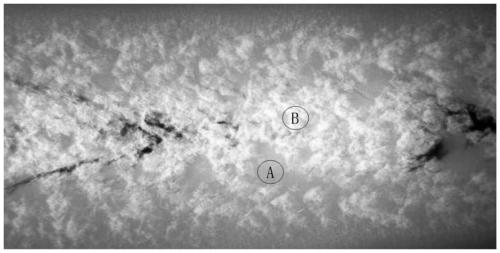

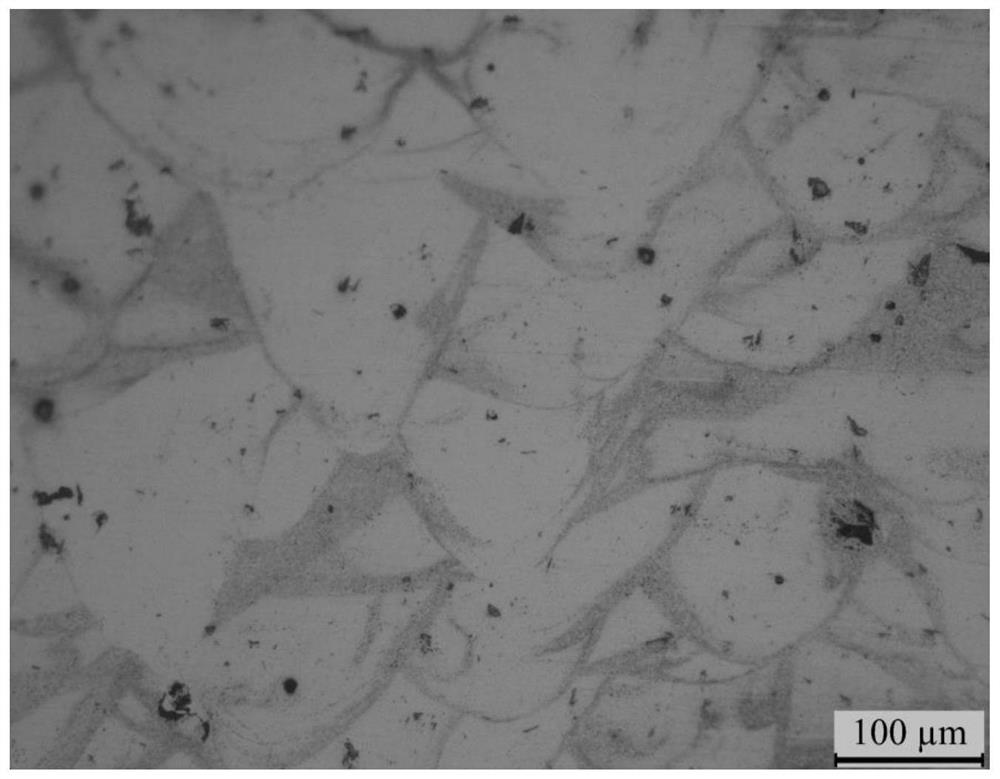

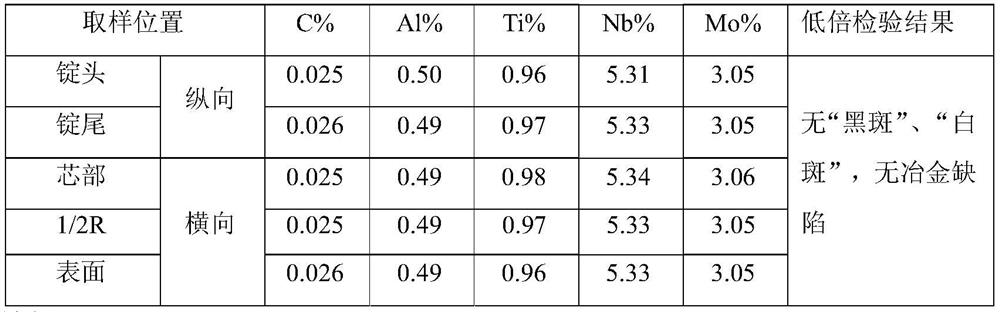

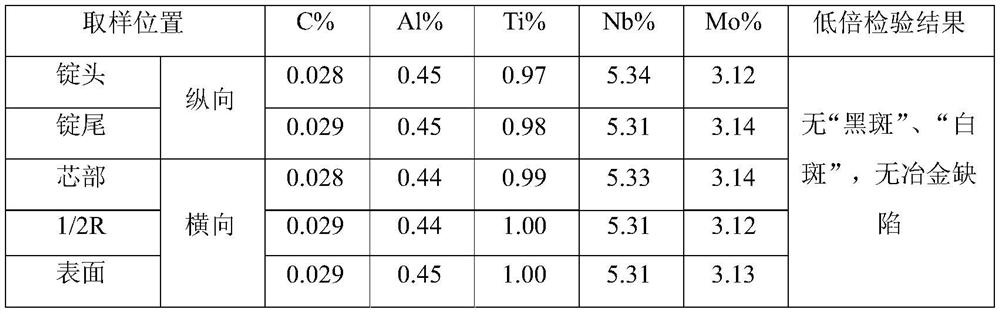

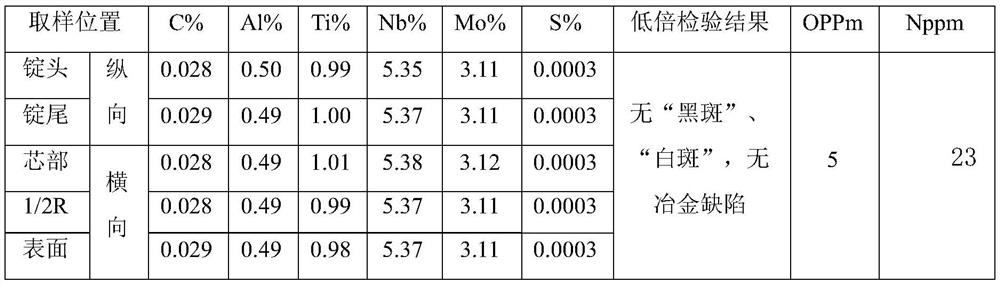

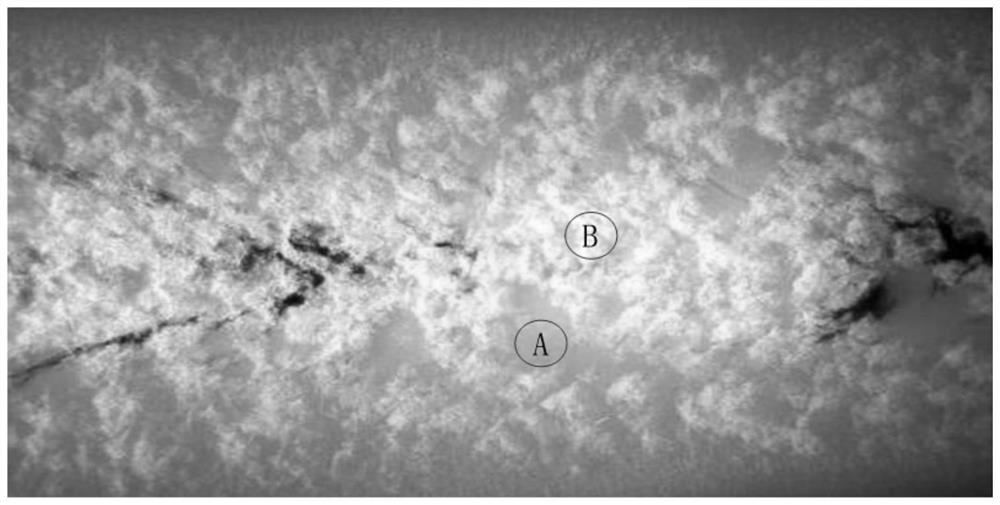

Technological method of reducing number of metallurgical defects of GH4169 nickel base alloy ingot

The invention discloses a technological method, particularly discloses a technological method of reducing the number of metallurgical defects of a GH4169 nickel base alloy ingot, belongs to the technical field of nickel base alloy remelting production technologies, and provides the technological method of reducing the number of the metallurgical defects of the GH4169 nickel base alloy ingot. The quality defects of a finished product of the technological method are few. According to the technological method, the GH4169 nickel base alloy molten ingot which is obtained through vacuum induction melting serves as a basic ingot, and the purpose that the number of the metallurgical defects of the GH4169 nickel base alloy ingot is reduced is achieved through one-time homogenization treatment, one-time high-speed forging, upsetting and pulling operation and one-time remelting operation.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

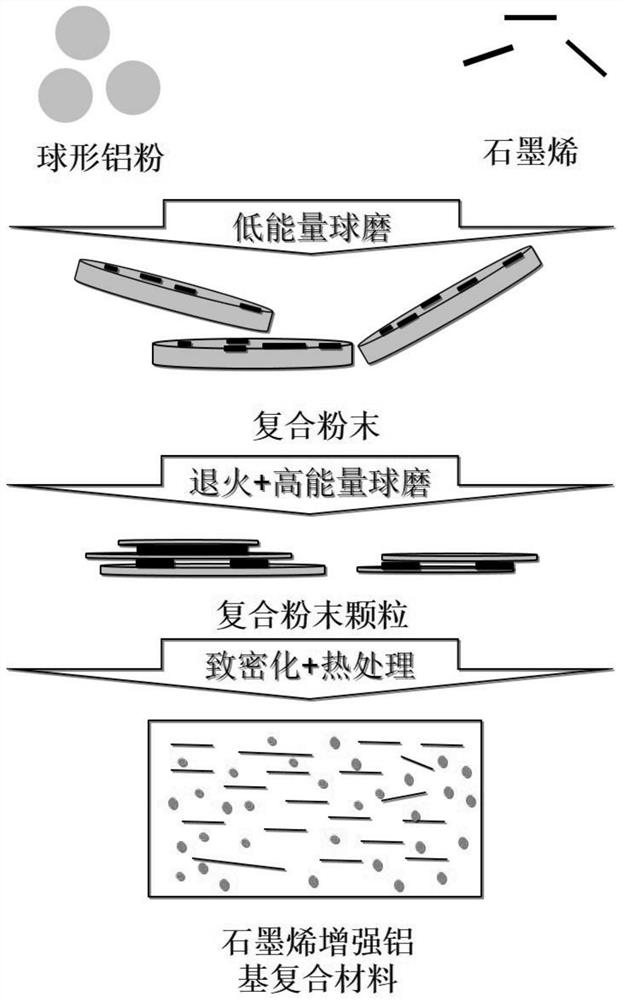

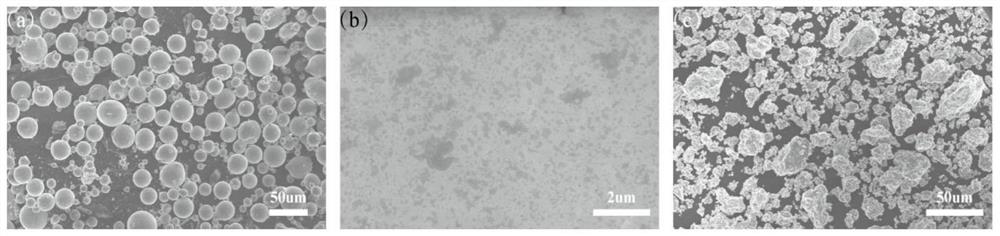

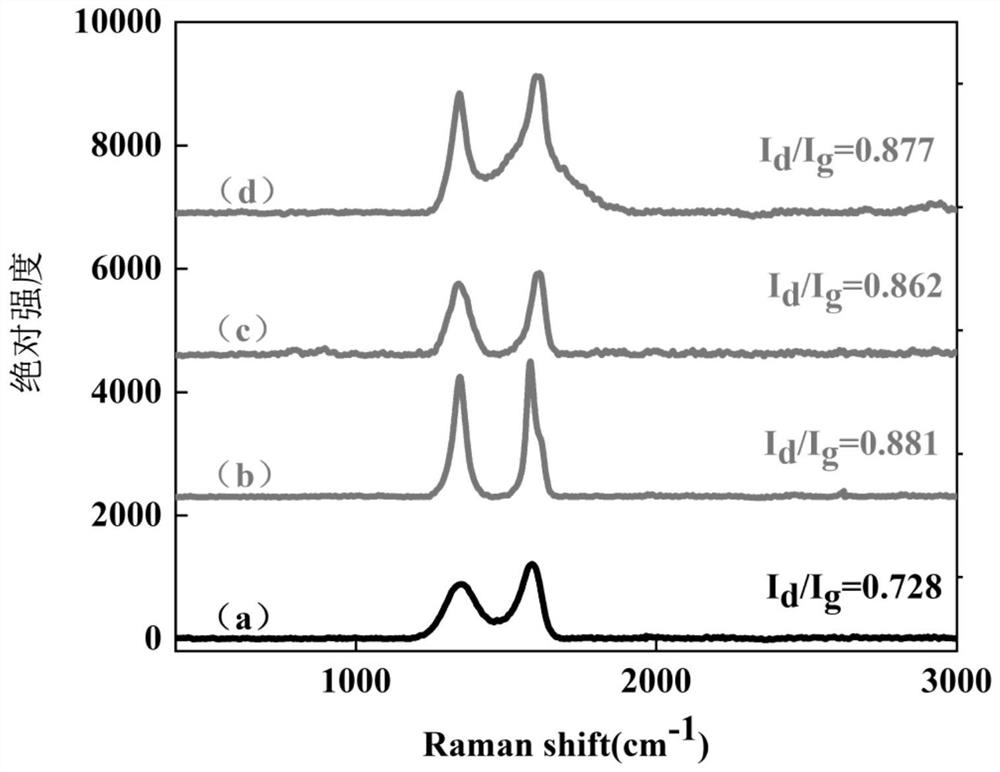

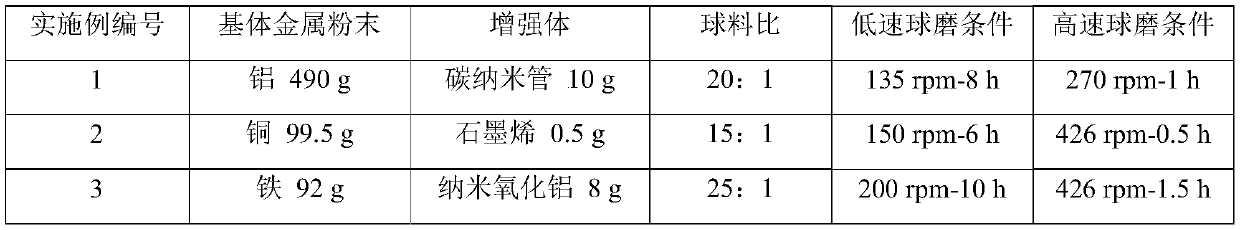

Powder metallurgy preparation method of graphene reinforced aluminum-based composite material

InactiveCN112725660AEvenly dispersedImproves Structural IntegrityTransportation and packagingMetal-working apparatusHigh energyGraphite

The invention provides a powder metallurgy preparation method of a graphene reinforced aluminum-based composite material, which comprises the following steps: preparing graphene-aluminum composite powder by long-time low-energy ball milling in advance, annealing, and carrying out short-time high-energy ball milling, densification processing and heat treatment to finally obtain the composite material. Uniform compounding of matrix powder and graphene is achieved through long-time low-energy ball milling, meanwhile, interface reaction can be avoided, and the structural integrity of graphene is protected; the annealed composite powder can improve the plastic deformation capacity of the composite powder while improving the quality of the graphene; short-time high-energy ball milling is performed, so that composite powder is welded into particles, and the quality of graphene is not damaged; and in addition, for the composite material of a aluminum alloy matrix, the uniformly dispersed graphene promotes the precipitation of fine dispersed precipitated phases in the matrix, and the mechanical properties of the composite material are further improved. The method is beneficial to protecting the integrity of the graphene structure to the maximum extent, exerts the graphene strengthening potential, saves energy and time, and is suitable for batch preparation and production.

Owner:SHANGHAI JIAO TONG UNIV

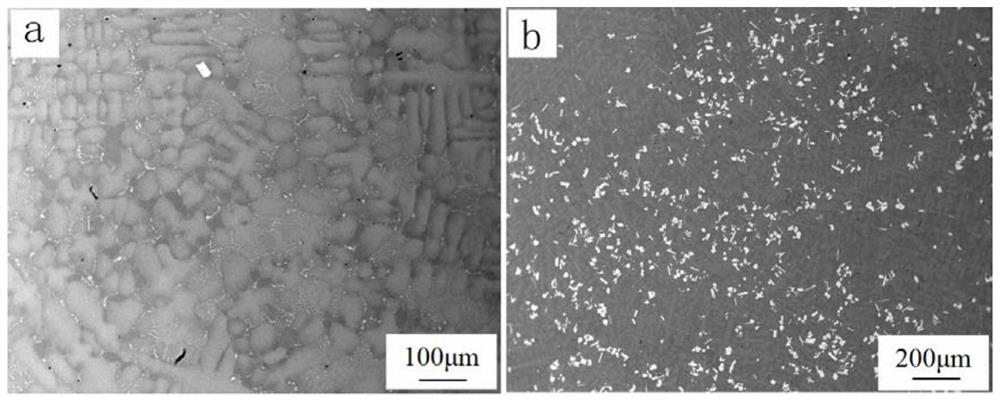

Preparation process of nickel-based high temperature alloy with high-content refractory elements

ActiveCN109913702AImprove melting efficiencyImproves ingredient uniformityIncreasing energy efficiencyRefractoryLow density

The invention discloses a preparation process of a nickel-based high temperature alloy with high-content refractory elements, and belongs to the technical field of alloy preparation. According to theprocess, a vacuum induction melting (VIM) and electroslag remelting (ESR) process is adopted for preparing the alloy containing the high-content refractory elements. During the vacuum induction melting stage, by controlling the feeding mode, increasing the refining temperature, prolonging the refining time, accelerating the solidification rate and the like, the segregation phenomena of refractorymetal and low-density alloy elements are effectively suppressed, and the composition uniformity of upper and lower parts of a parent alloy ingot is improved. Through electroslag remelting, secondary shrinkage in the alloy ingot is eliminated, the impurity content is reduced, and the metallurgical quality is improved. The preparation process can significantly reduce the microsegregation and macrosegregation phenomena of the high-content refractory elements and can effectively reduce the content of harmful gas elements such as O and N in the high-temperature alloy, the purity of the alloy is improved, the degree of segregation of the high-specific gravity elements is reduced, the heredity of alloy anomalous tissues is improved, and the overall mechanical properties of the alloy are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

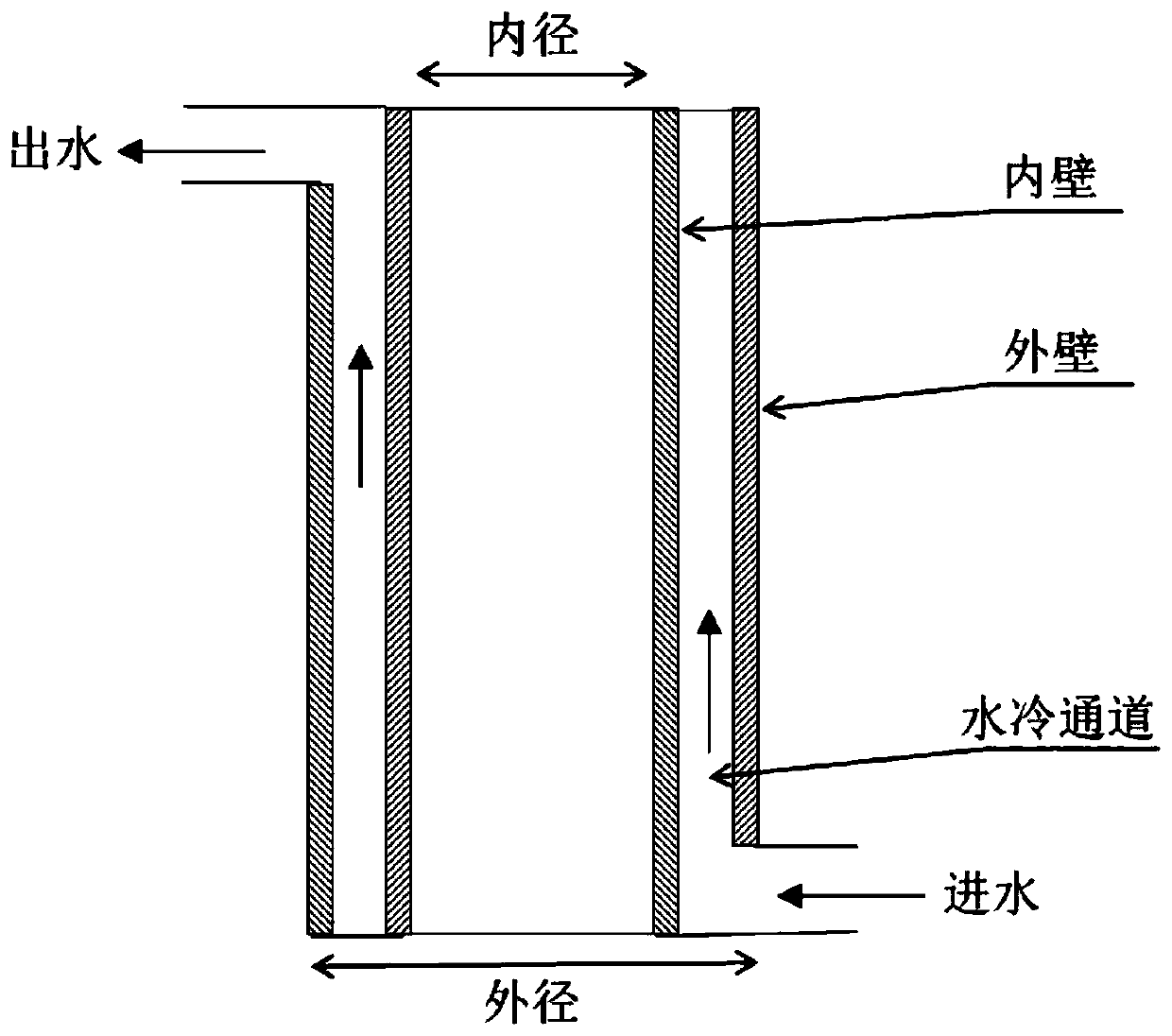

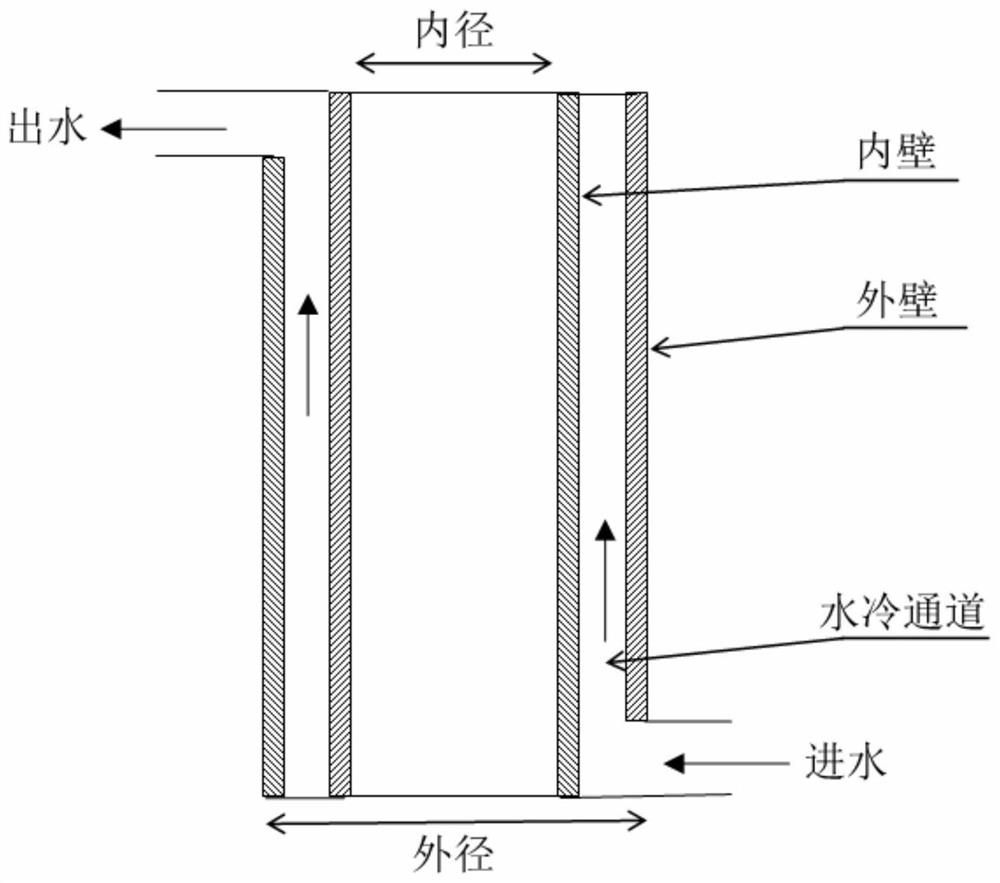

Vacuum consumable remelting method of deformed high-temperature alloy GH4169

ActiveCN111394590AOptimizing the consumable remelting processImprove processing stabilitySuperalloyElectro-slag remelting

The invention belongs to the technical field of high-quality deformed high-temperature alloy preparation for aero engines, and relates to a vacuum consumable remelting method of a deformed high-temperature alloy GH4169. The vacuum consumable remelting method specifically comprises the steps of preparing consumable electrodes by electroslag remelting, electrode ingot high-temperature stress reliefannealing, machining, electrode welding, centering charging, three-stage control consumable remelting and the like. The vacuum consumable remelting method has the outstanding advantages that the riskof segregation metallurgical defects generated in the process of high-niobium deformed high-temperature alloy vacuum consumable remelting can be reduced, and meanwhile, the batch stability and usage reliability of prepared deformed high-temperature alloy materials are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Continuous rolling method of evaporator inner wall aluminum alloy foils

InactiveCN107893202AGood formabilityGood welding performanceMetal rolling arrangementsIngotContinuous rolling

The invention discloses a continuous rolling method of evaporator inner wall aluminum alloy foils, and relates to the field of material molding, in particular to the continuous rolling method of the evaporator inner wall aluminum alloy foils. The method comprises the following steps: firstly, needed raw materials are prepared; wastes in the raw materials adopt pure aluminum; the total input of thewastes is not more than 35%, wherein the second-grade waste input is not more than 30%, and raw aluminum ingots are not less than 65%; the raw materials are fed in a smelting furnace for melting; themolten raw materials are stirred and slagged, and components of the raw materials are adjusted; the slagged raw materials are refined in the smelting furnace; the refined raw materials are transferred into an insulation furnace for secondary refining and standing; and the secondarily refined raw materials are discharged into a degassing box for degassing and slagging. The production process is simple; the production efficiency can be improved; and produced final foils are excellent in molding property, welding property and corrosion resistance, uniform in structure and performance, few in metallurgy defect, low in anisotropy and more suitable for serving as evaporator inner walls.

Owner:SHAANXI QIYUAN TECH DEV

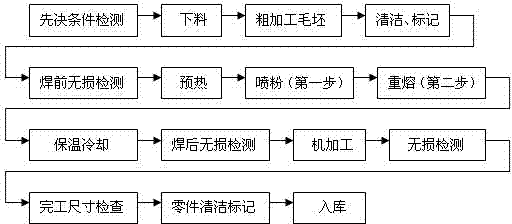

Claw assembly with long service life and production process thereof

InactiveCN104751921AReduce meltingSelf-fluxingNuclear energy generationReactors manufactureNuclear reactorWear resistance

The invention discloses a claw assembly with long service life and a production process thereof, which are used for manufacturing parts with mutual friction in an operation process of the claw assembly of a nuclear reactor control rod driving mechanism. The process comprises the following steps which are carried out in sequence: discharging, roughly machining and machining a wear-resisting layer on the surface. The step of discharging is to machine blanks of all parts according to design requirements; the step of machining the wear-resisting layer on the surface is to spray and weld the wear-resisting layer on the surface of each blank; and the step of spraying and welding the wear-resisting layer comprises the following steps which are carried out in sequence: pre-heating, spraying powder and re-melting, and cooling. In the claw assembly disclosed by the invention, the sprayed and welded wear-resisting layer or the surfaced wear-resisting layer is arranged on the surface of each part with the friction in the operation process. The invention provides the claw assembly with the long service life and a corresponding manufacturing process, and the obtained claw assembly meets the requirements on the wear resistance under a high-frequency working condition within a 60-year service period.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

Laser cladding iron-based alloy powder for repairing steam turbine rotor journal and preparation and application thereof

InactiveCN112063934AHigh bonding strengthImprove toughnessMetallic material coating processesManganeseUltimate tensile strength

The invention provides iron-based alloy powder. The iron-based alloy powder is prepared from the following components in percentage by mass: 0.04%-0.07% of C, 0.90%-1.20% of Cr, 0.4%-0.9% of Mo, 0.4%-0.7% of Si, 0.5%-0.8% of Mn, 0-0.6% of B and the balance of Fe. A laser cladding layer obtained through the alloy powder has excellent bonding strength, low metallurgical defects and a low dilution rate, the toughness and hardness of the cladding layer are improved, the use requirements are met, and the defects on the surface of a 30Cr2Ni4MoV steam turbine rotor journal can be effectively repaired.

Owner:ZHEJIANG UNIV OF TECH

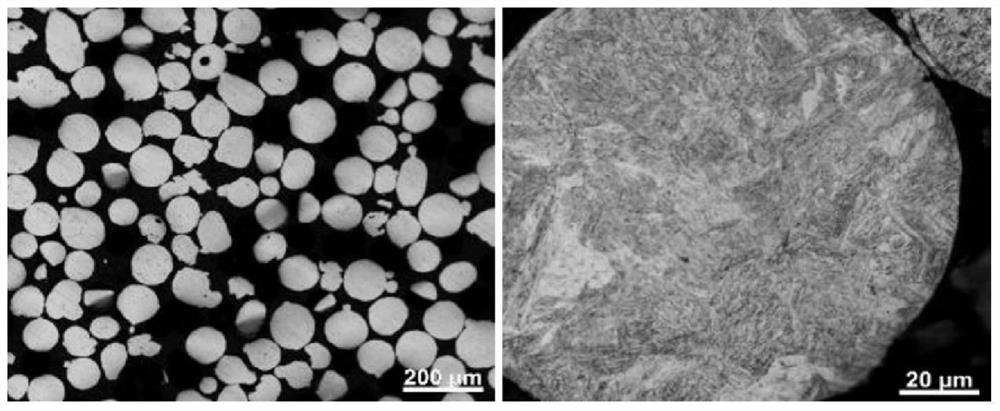

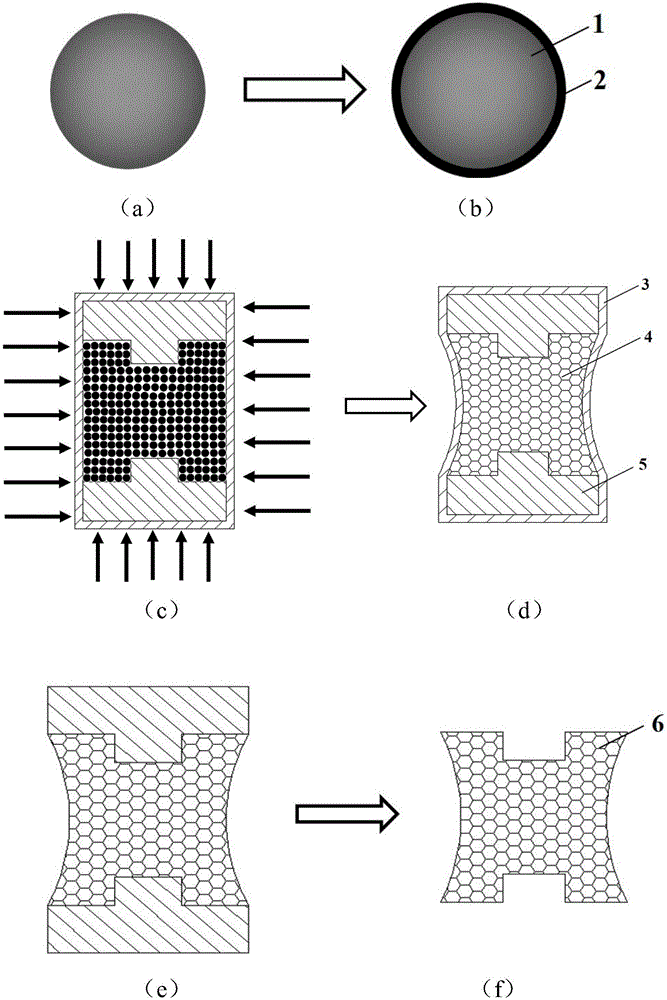

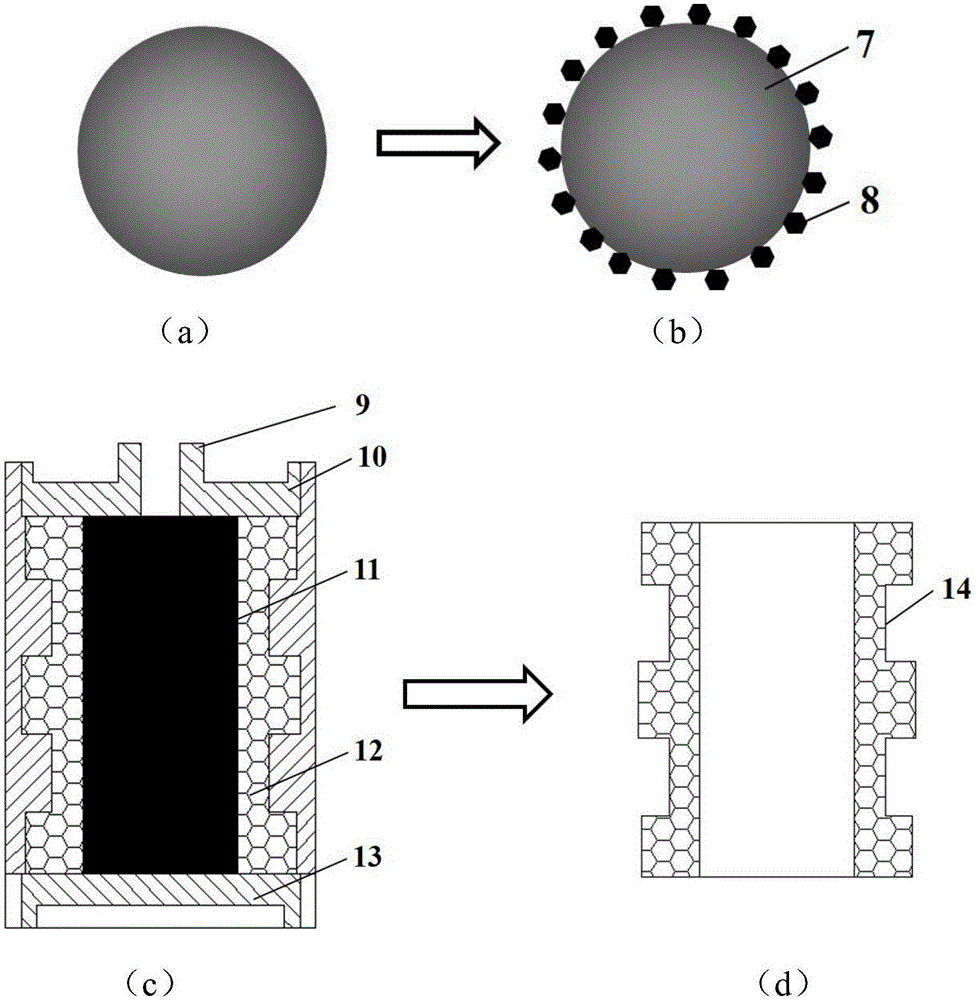

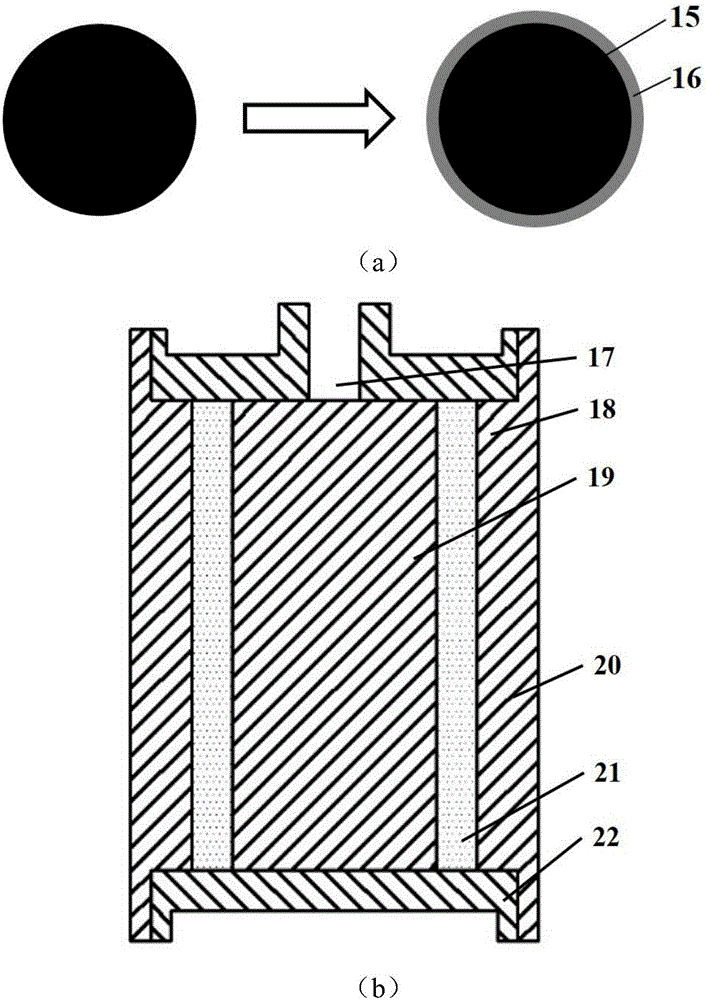

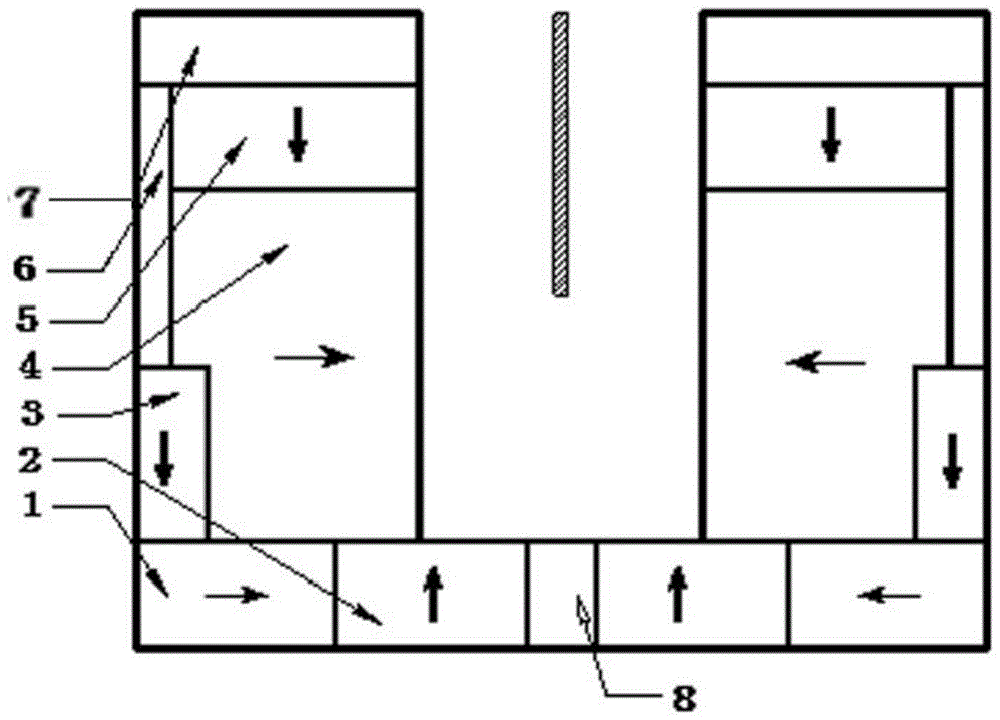

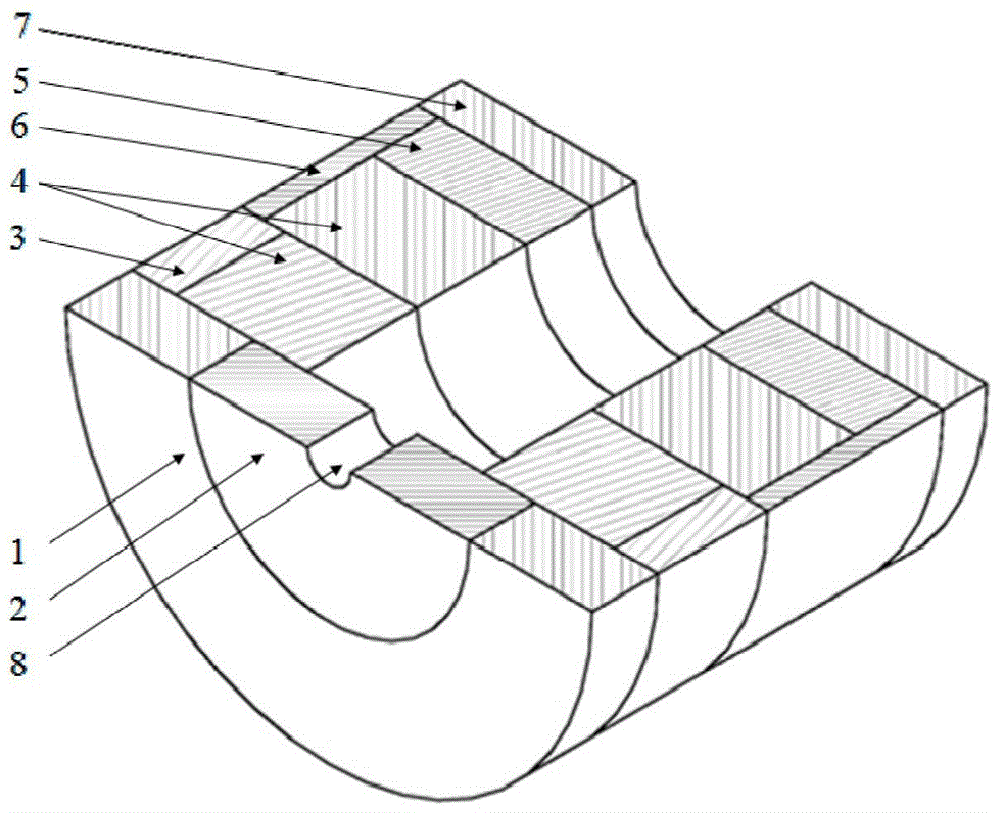

Hot-isostatic-pressing forming method for in-situ generation of continuous spatial net structure

The invention discloses a hot-isostatic-pressing forming method for in-situ generation of a continuous spatial net structure. According to the hot-isostatic-pressure forming method for in-situ generation of the continuous spatial net structure, the surface of a powder base material is covered with a layer of reinforcing materials before hot-isostatic pressing according to the reinforcing requirement of the base material during actual application, and the base material and the reinforcing material are subjected to an in-situ reaction under the effect of high temperature and high pressure of hot-isostatic pressing, so that a new compound with a reinforcing effect is generated, and the compound exists on the boundary of an original powder particle in the form of the continuous spatial net structure. Metallurgical defects caused by an oxide layer on the surface of the original powder particle are effectively reduced through the spatial net structure, and the metallurgical bonding strength between different kinds of powder is improved; and in addition, through a newly-generated reinforcing phase, relevant performance of the base material can be improved, the service life of a hot-isostatic-pressed workpiece is prolonged, and the safety of the hot-isostatic-pressed workpiece is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

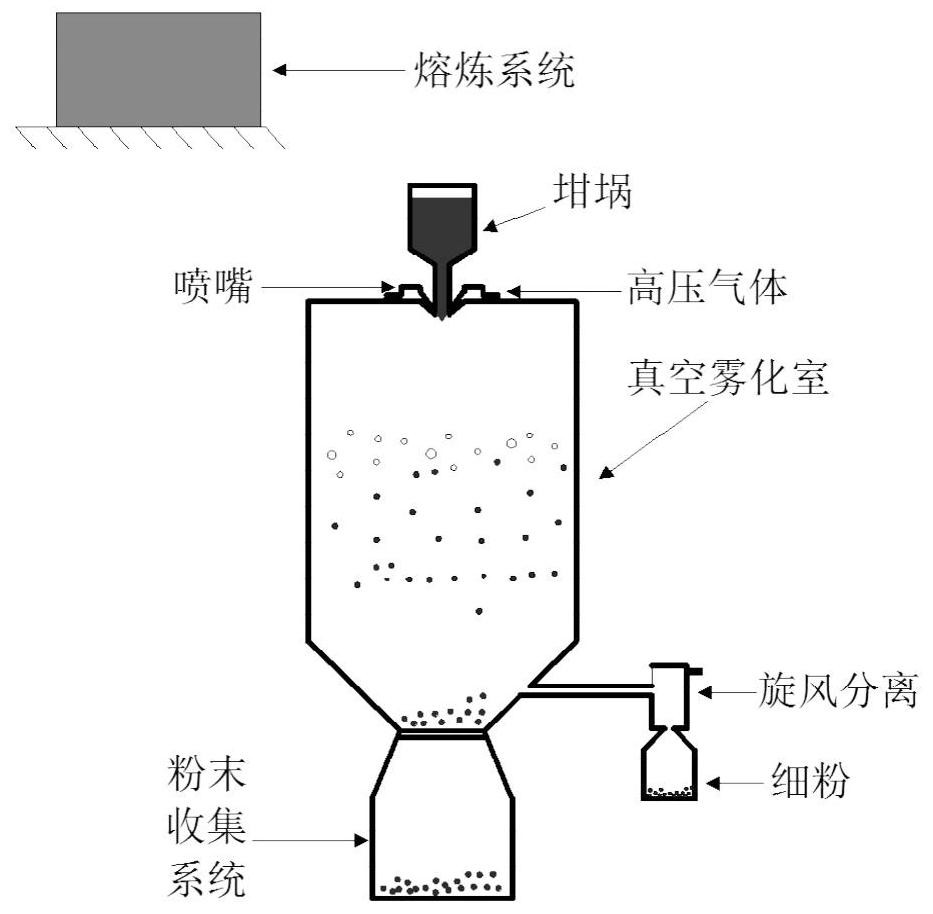

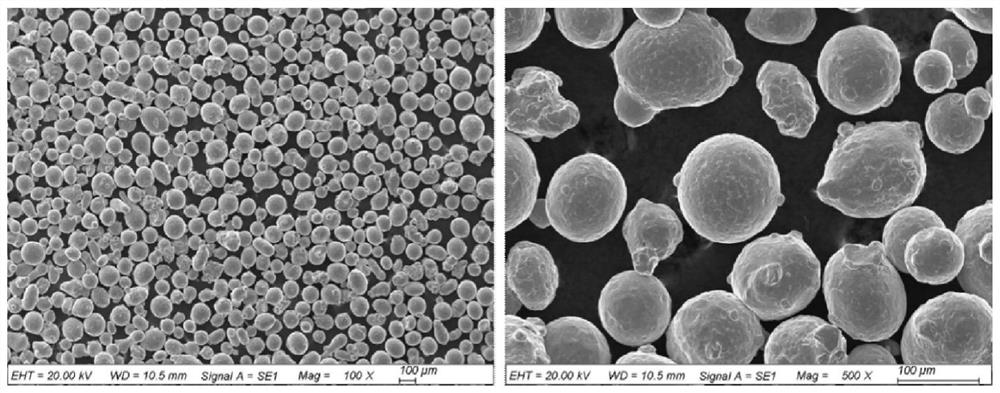

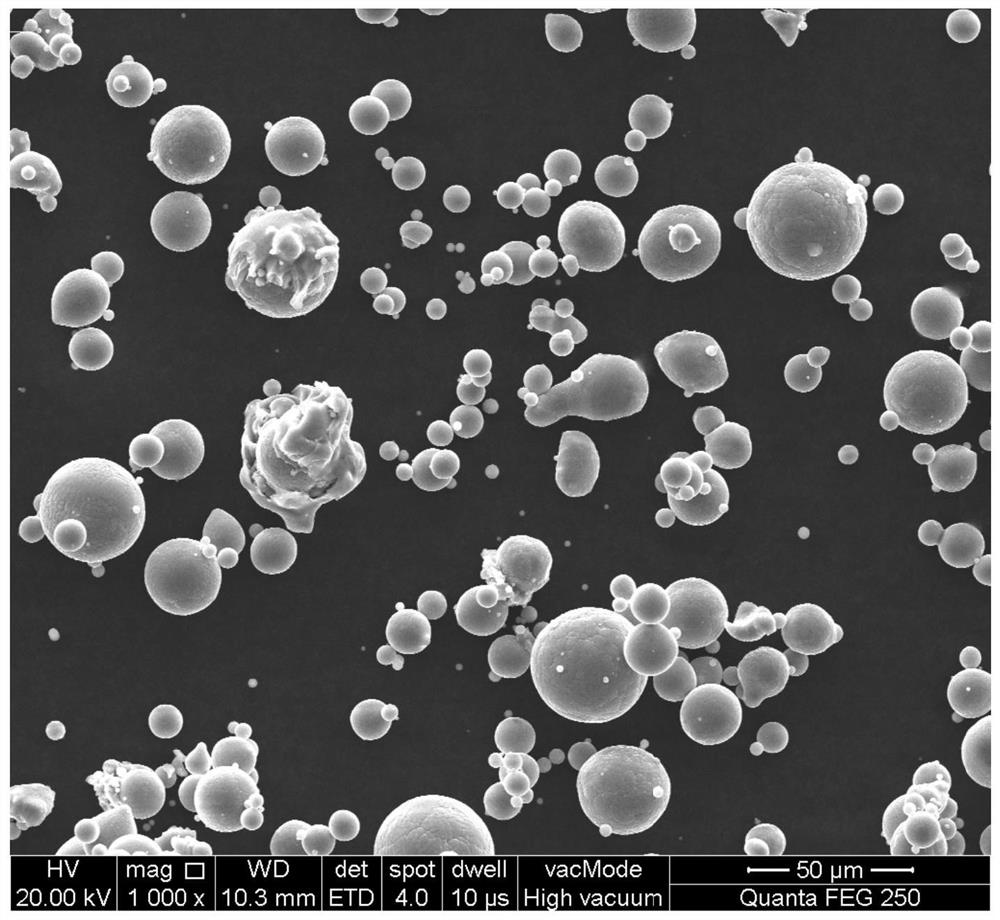

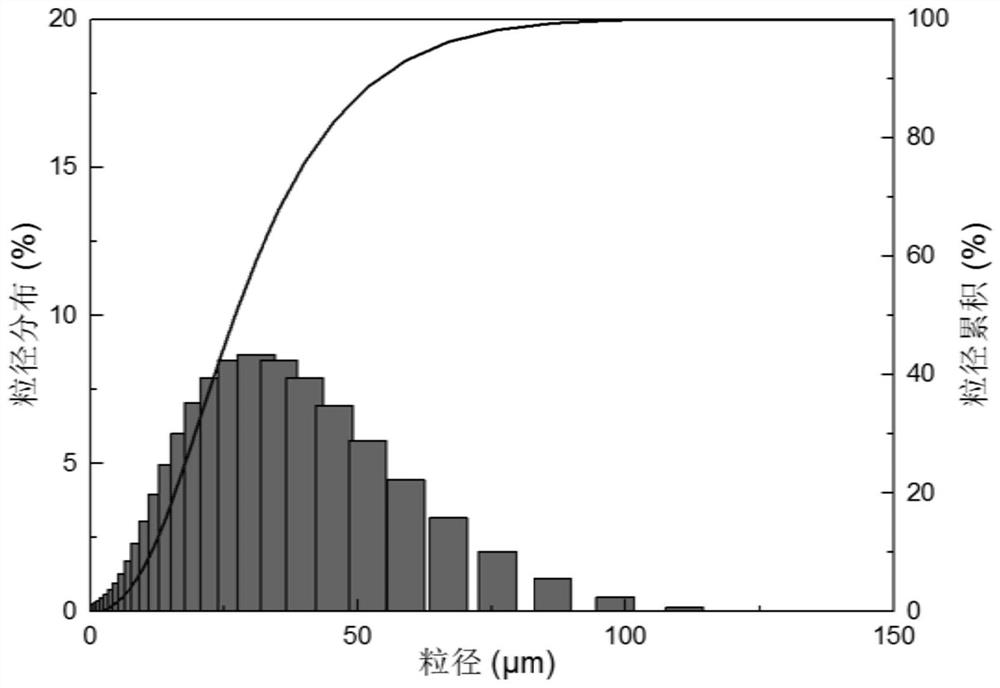

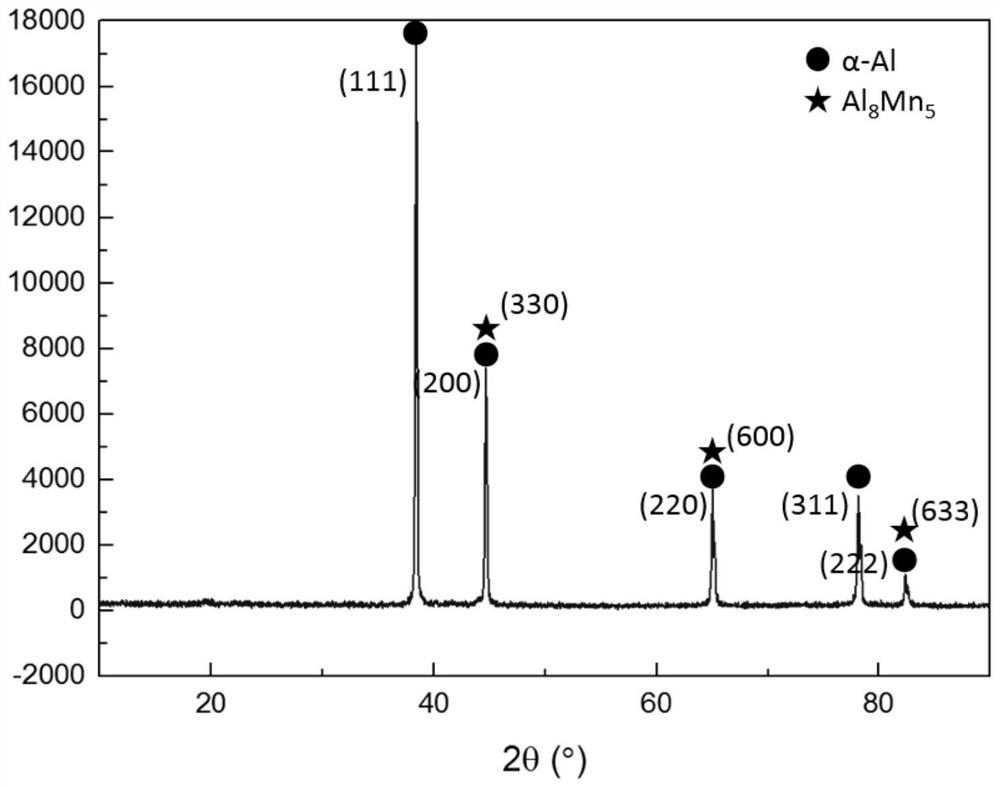

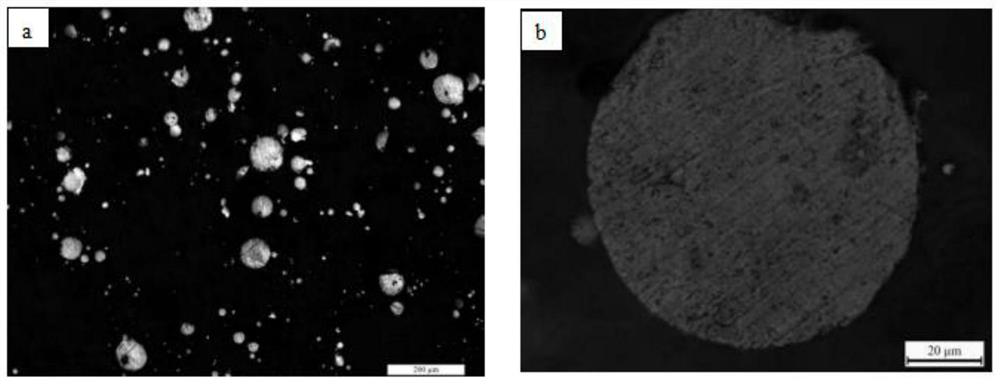

A special aluminum-manganese alloy powder formula for 3D printing and its preparation method and printing method

ActiveCN109576536BAccelerated corrosionImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiency3d printHigh density

The invention discloses a special aluminum-manganese alloy powder formula for 3D printing, a preparation method and a printing method thereof, wherein the alloy powder is a pre-alloy, and in terms of mass percentage, it includes: Mn: 1.0-5.5wt%; Sc : 0.3~0.6wt%; Zr: 0.1~0.3wt%; Mg: 0.8~1.2wt%; Si: 0.2~0.25wt%; Fe: 0.2~0.25wt%, Cu: 0.1~0.2wt%; Zn: 0.1 ~0.2wt%, the rest is Al. The parts of the Al-Mn alloy composition of the present invention after laser 3D printing have no cracks, high density, corrosion resistance, high mechanical properties, and low anisotropy; it solves the problem that the traditional casting and forging Al-Mn alloy composition can be directly used in 3D printing The problem of easy cracking and low mechanical properties. After the alloy composition of the invention is 3D printed, the tensile strength is higher than that of the traditional cast and forged aluminum-manganese alloy. At the same time, compared with other mature 3D printing Al-Si alloys, the alloy of the present invention has higher corrosion resistance and mechanical properties.

Owner:CENT SOUTH UNIV

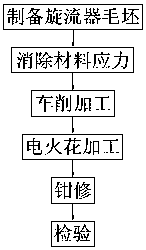

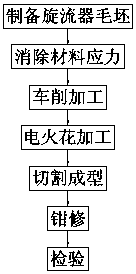

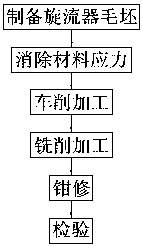

Technical method for manufacturing aero-engine cyclone through special processing technology

The invention relates to the field of aero-engines and gas turbines, and particularly relates to a technical method for manufacturing an aero-engine cyclone through a special processing technology. The method comprises the step of manufacturing a cyclone blank, wherein the cyclone bank is manufactured through a cylindrical forging piece. The method further comprises the step of manufacturing semi-finished cyclone and the step of finishing through pincers; the step of manufacturing the semi-finished cyclone is that the cyclone blank is sequentially subjected to turning processing and electric spark processing to obtain the semi-finished cyclone; the step of finishing through the pincers is that the semi-finished cyclone is finished based on the requirement on a finished cyclone so as to obtain the finished cyclone. According to the method, the forging piece is outstanding in mechanical property, and two processing modes are provided, so that the manufactured cyclone product is high in strength and toughness; the yield is increased; and the processing cost and the processing period are reduced; the manufactured cyclone product can stably run for a long time in an aero-engine combustion chamber; and the service life of the aero-engine combustion chamber cannot be influenced by the quality of the cyclone.

Owner:广汉天空动力机械有限责任公司

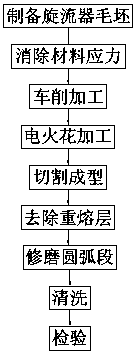

TOPTIG electric arc material increasing device and method for modifying aluminum alloy

PendingCN114769796AOptimize chemical compositionImproved metallurgical propertiesAdditive manufacturing apparatusArc welding apparatusAdditive layer manufacturingAluminium alloy

The invention discloses a TOPTIG electric arc additive material device for modifying aluminum alloy. The TOPTIG electric arc additive material device comprises a nozzle, a clamping sleeve is arranged on a nozzle sleeve, a tungsten electrode is located in the clamping sleeve, the nozzle is located over a workpiece, the nozzle is connected with a powder feeder through a powder feeding pipe, and a powder heating box for heating powder is arranged on the powder feeding pipe; a wire feeder is arranged on the side wall of the nozzle, and the bottom end of the wire is located at the front end of the tungsten electrode. The invention further discloses a material adding method of the TOPTIG electric arc material adding device for modifying the aluminum alloy. By the adoption of the TOPTIG electric arc material increasing device and method for modifying the aluminum alloy, the problems that the forming efficiency of existing material increasing manufacturing is low, and the performance of the formed aluminum alloy is poor can be solved.

Owner:河北金融学院

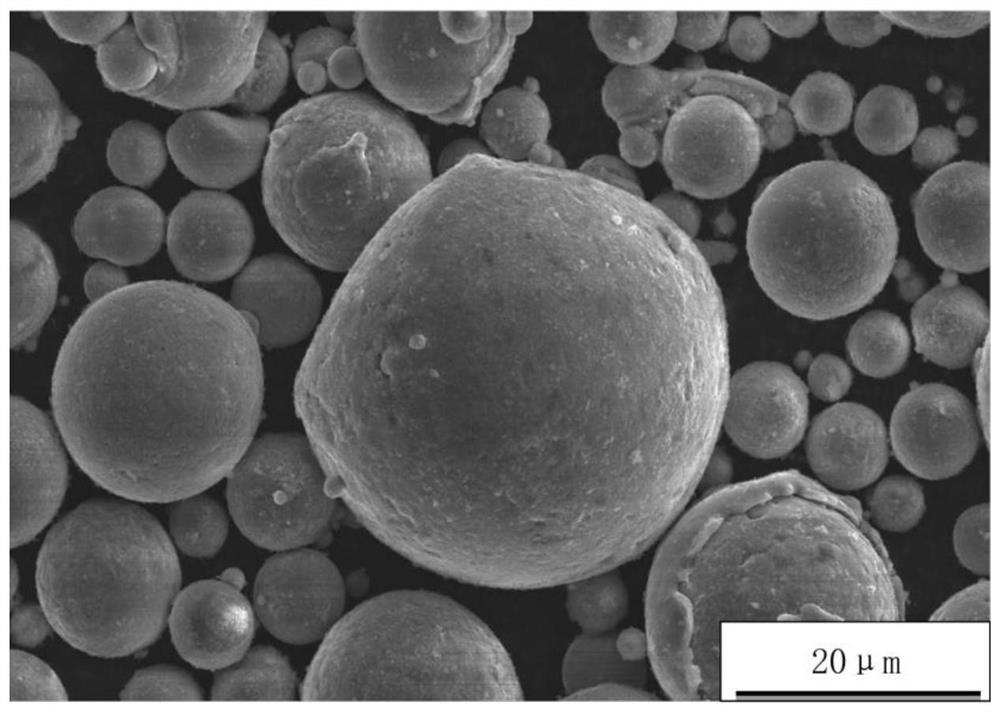

High-strength Al-Fe-Sc alloy capable of being used for laser additive manufacturing

ActiveCN112813310AImprove mechanical propertiesHigh densityAdditive manufacturing apparatusTransportation and packagingSupersaturated solid solutionLaser additive manufacturing

The invention discloses a high-strength Al-Fe-Sc alloy capable of being used for laser additive manufacturing. A preparation method of the high-strength Al-Fe-Sc alloy capable of being used for laser additive manufacturing comprises the steps that according to the composition proportion, raw materials are weighed to be prepared into a mixture, and vacuum melting and argon atomization are carried out. The raw materials comprise the following components in percentage by mass: 2.5-5.5 wt% of Fe; 0.3-0.6 wt% of Sc; 0.1-0.3 wt% of Zr; 0.1-0.15% of Ti; 0.2-0.28 wt% of Si; 0.3-0.5% of Mn; 0.3-0.5 wt% of Mg; 0.2-0.3 wt% of Cu; and the balance Al. The 3D printing Al-Fe alloy is a supersaturated solid solution, Fe elements are almost completely dissolved in Al crystal lattices, the maximum solid solubility of the Fe elements can reach 5.5 wt%, the problem that a traditional Al-Fe alloy cannot be subjected to supersaturated solid solution is solved, and compared with an existing Al-Fe alloy prepared through smelting casting and forging, the 3D printing Al-Fe alloy is good in mechanical property, high in yield strength and low in anisotropy.

Owner:CENT SOUTH UNIV

A special al-cr heat-resistant alloy powder for 3d printing, preparation method, application and al-cr heat-resistant alloy

The invention discloses a special Al-Cr heat-resistant alloy powder for 3D printing, a preparation method, an application and an Al-Cr heat-resistant alloy. The Al-Cr heat-resistant alloy powder is a pre-alloyed powder, which includes Cr : 3~4.5%, Mg: 0.5~1.2%, Mn: 0.3~0.5%, Sc: 0.3~0.8%, Zr: 0.1~0.4%, Si: 0.05~0.55%, and the rest is Al; the 3D printing The special Al-Cr heat-resistant alloy powder is screened and dried; after the drying process, the coaxial powder feeding 3D printing is carried out. The density of the Al-Cr heat-resistant alloy obtained by the present invention exceeds 99%, and the average hardness reaches 150HV 0.2 , The tensile strength at 200 ° C is nearly 300Mpa, the structure is fine and uniform, the density is high, the anisotropy is low, and it has excellent room temperature performance and high temperature performance.

Owner:CENT SOUTH UNIV

Laser cladding powder for 30crmnsini2a steel and its preparation method

ActiveCN106480363BHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthToughness

The invention relates to a laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The amount of each component in the laser cladding powder is Cr 0.8%-1.0%, Mn 0.75%-1.10%, Si 0.65% by weight percentage ‑1.10%, Ni2.0%‑3.2%, C0.16%‑0.22%, Cu0.15%‑0.20%, P0.015%‑0.020%, S0.01%‑0.015%, Rare earth 0.001%‑0.015% , the remainder is iron. The present invention further proposes a preparation method of the cladding powder. The laser cladding powder is specially used in the laser cladding technology of 30CrMnSiNi2A steel, so as to ensure the excellent bonding strength of the cladding interface, lower metallurgical defects and reduced dilution rate, and improve the fusion rate. The toughness of the cladding layer improves the wettability of the cladding powder, inhibits the cracking of the cladding layer and delays the crack growth rate.

Owner:国营芜湖机械厂

Process method for reducing metallurgical defects of gh4169 nickel-base alloy ingot

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Aluminum alloy evaporator inner wall thin plate and continuous casting rolling production process thereof

ActiveCN102851551BGood molding effectUniform thicknessProcess efficiency improvementMetal rolling arrangementsManganeseMechanical property

Owner:江阴新仁铝箔科技有限公司

Nanophase/metal composite powder and powder metallurgy preparation method of bulk material

ActiveCN106363185BLess metallurgical defectsEnhancement effect is goodMetal powderUltimate tensile strength

The invention discloses a powder metallurgy preparation method of nanophase / metal composite powder and a block material thereof. The method comprises the steps of carrying out low-speed ball milling on nanophase powder and metal powder for a long time, and uniformly dispersing nanophases on the surface or inside the flake metal powder, so as to obtain nanophase / metal flake composite powder; and carrying out high-speed ball milling for a short time to weld the nanophase / metal flake composite powder to obtain nanophase / metal granular composite powder. According to the preparation method, the problems of uniform dispersion and interface bonding of the nanophases in a metal matrix can be solved through only adjusting the speed of ball milling; compared with traditional constant-speed ball milling, the ball milling method has the advantages that dispersion of the nanophases is more uniform, the interface bonding strength is higher, and the prepared material is more excellent in performance; and the preparation method is simple and efficient in technology and applicable to batch preparation.

Owner:SHANGHAI JIAOTONG UNIV

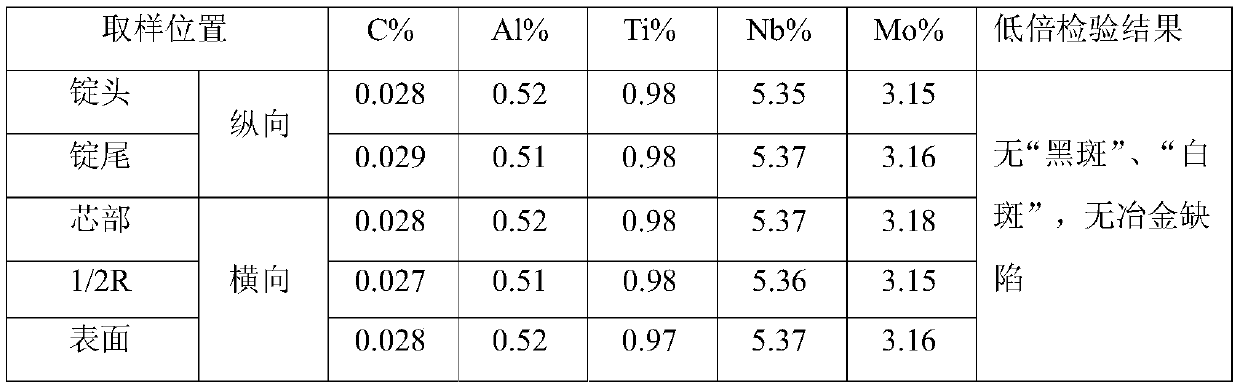

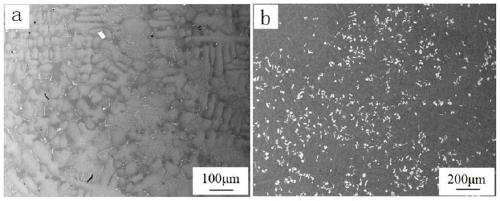

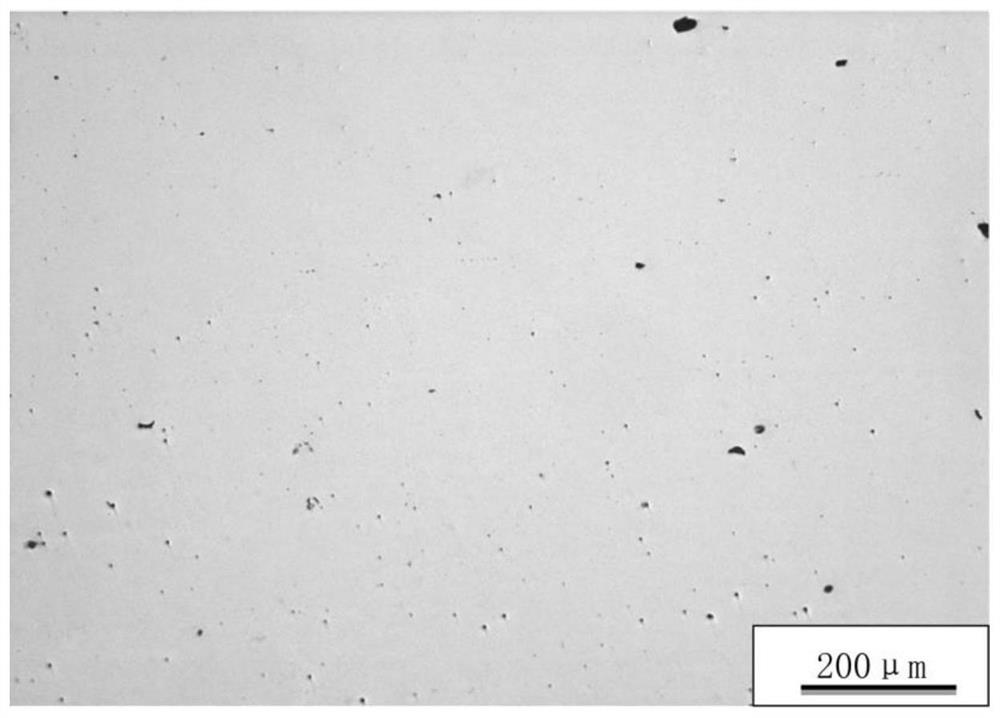

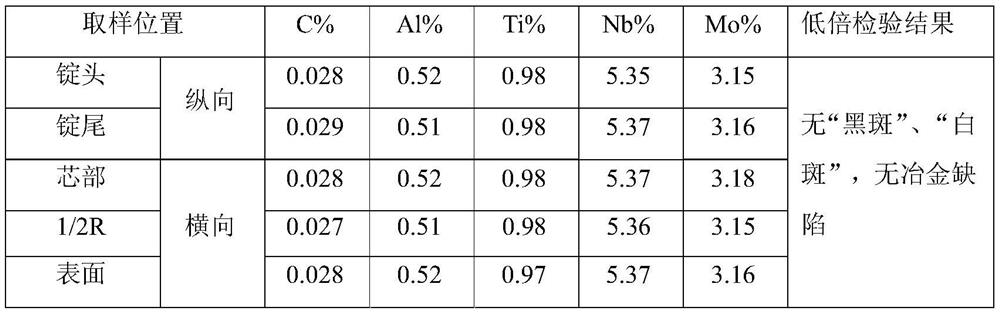

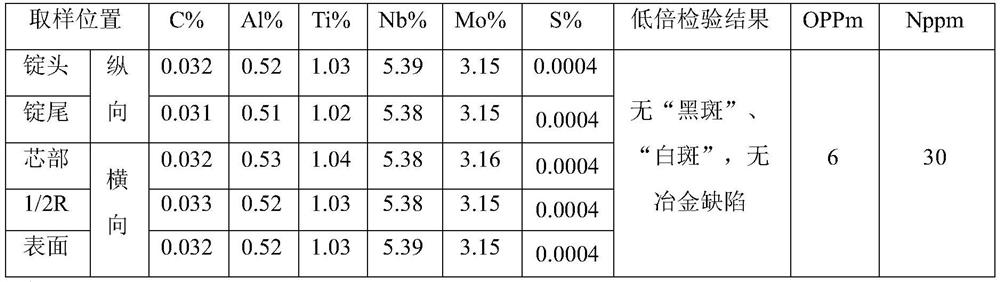

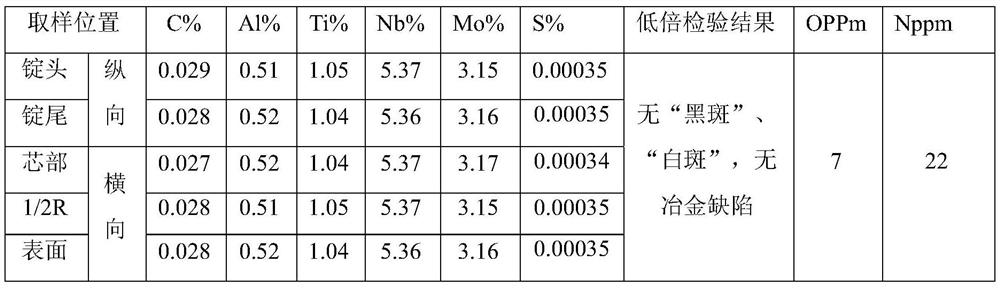

Manufacturing method for low metallurgical defect gh4169 nickel base alloy ingot

ActiveCN110468292BImprove purityUniform chemical compositionIncreasing energy efficiencyIngotVacuum induction melting

The invention discloses a manufacturing method, in particular discloses a manufacturing method for a GH4169 nickel-based alloy ingot with low metallurgical defects, and belongs to the technical field of nickel-based alloy remelting production technology. Provided is a method for manufacturing a GH4169 nickel-based alloy ingot with low metallurgical defects, which can significantly reduce the metallurgical defects of the GH4169 nickel-based alloy ingot. The manufacturing method uses the GH4169 nickel-based alloy ingot obtained by vacuum induction melting as the base ingot, and obtains the GH4169 nickel-based alloy ingot with low metallurgical defects through two remelting, one homogenization treatment and one rapid forging and drawing, wherein, The sequence of the homogenization treatment and the rapid forging and drawing process is arranged between two remelting processes.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

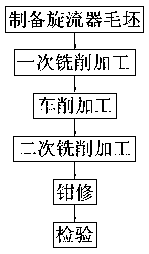

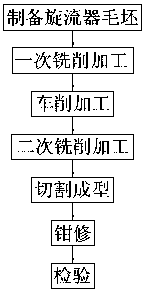

A high-efficiency processing method for aeroengine swirlers

The invention relates to the field of aeroengines and gasoline turbines, in particular to a technological method of a high-efficient machining swirler for an aeroengine. The method comprises a step ofpreparing a swirler blank, wherein the swirler blank is manufactured by columnar forging pieces, and the columnar forging pieces are manufactured by aviation materials; the method also comprises a step of preparing a swirler semi-finished product and a step of gripping and repairing; the step of preparing a swirler semi-finished product comprises the following steps: turning the swirler semi-finished product at least one time and milling the swirler semi-finished product at least one time so as to prepare the swirler semi-finished product; and the step of gripping and repairing comprises thefollowing steps: trimming a profile surface of the swirler semi-finished product according to a finished product requirement of the aeroengine so as to prepare a swirler finished product. By adoptinga matched machining way of turning and milling, a machining period is shortened; and by matching with a gripping and repairing operation, a finished product ratio is increased, so that the manufactured swirler finished product has the advantages of stable metal quality and longer service life, and the manufactured swirler finished product meets a high-standard requirement on the aeroengine.

Owner:广汉天空动力机械有限责任公司

Preparation process of a nickel-based superalloy with high content of refractory elements

ActiveCN109913702BImprove melting efficiencyImproves ingredient uniformityIncreasing energy efficiencySlagSuperalloy

The invention discloses a preparation process of a nickel-based superalloy with high content of refractory elements, and belongs to the technical field of alloy preparation. The process adopts vacuum induction melting (VIM) + electroslag remelting (ESR) process to prepare alloys with high content of refractory elements. During vacuum induction melting, by controlling the feeding method, increasing the refining temperature and prolonging the refining time, and accelerating the solidification rate, etc., the segregation of refractory metals and low-density alloy elements can be effectively suppressed, and the composition uniformity of the upper and lower parts of the master alloy ingot can be improved. Electroslag remelting eliminates secondary shrinkage cavities in alloy ingots and reduces impurity content to improve metallurgical quality. The invention can not only significantly reduce the micro-segregation and macro-segregation of high-content refractory elements, but also effectively reduce the content of harmful gas elements such as O and N in superalloys, thereby improving the purity of the alloy and reducing the degree of segregation of high-density elements. Improve the heredity of the abnormal structure of the alloy and improve the comprehensive mechanical properties of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

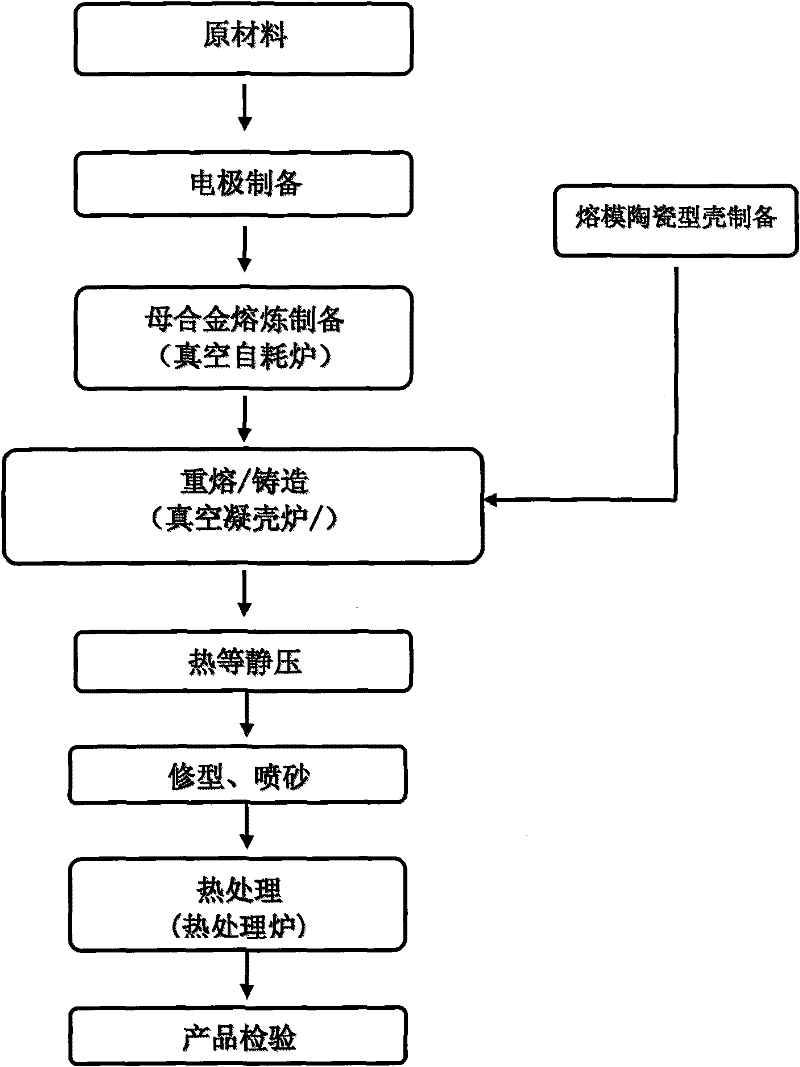

Technique for producing precision castings of zirconium and zirconium alloy pumps/valves

InactiveCN101590511BGuaranteed purityImprove overall utilizationFoundry mouldsFoundry coresWaxWeld seam

The invention provides a technique for producing precision castings of zirconium pump and valves. The technique is characterized in that the precision castings of zirconium pumps and valves are produced by adopting the methods of lost-wax ceramic-shell precision casting and hot isostatic pressing, wherein the lost-wax ceramic-shell precision casting refers to near-net-shape casting adopting a lost-wax ceramic shell for casting in a vacuum self-consuming skull furnace; the lost-wax ceramic shell is formed through reproduction according to a wax pattern consistent with the geometric shape and size of a pump and valve component; the first two layers of the shell of the inner surface of the lost-wax ceramic shell is made from special oxide; the whole shell is manufactured through the process links of wax pressing, painting, shell hanging, dewaxing, roasting and the like; and the hot isostatic pressing is to place a to-be-treated casting in a container which ishermetic and resistant to high pressure and can be heated to high temperature, vacuumize the container, fill the container with high-pressure inert gas and heat the container to a preset temperature. The technique has the advantage of solving the problem of low material utilization rate and hidden trouble caused by no welding seams at high temperature and high isostatic pressure in all directions, high surface finish of the casting, few internal defects of the casting, pure composition and stable performance.

Owner:SHENYANG NORTH TITANIUM IND

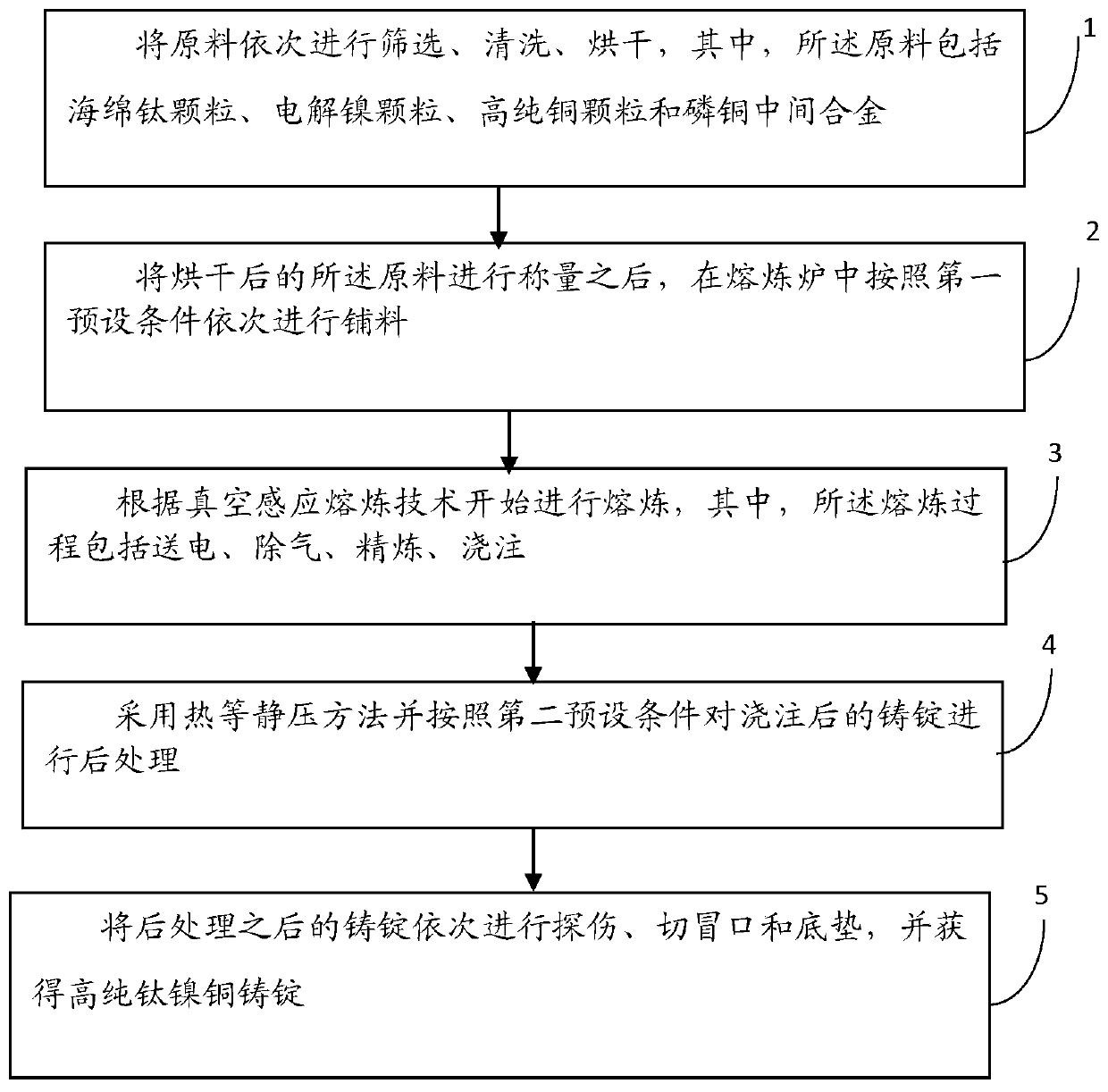

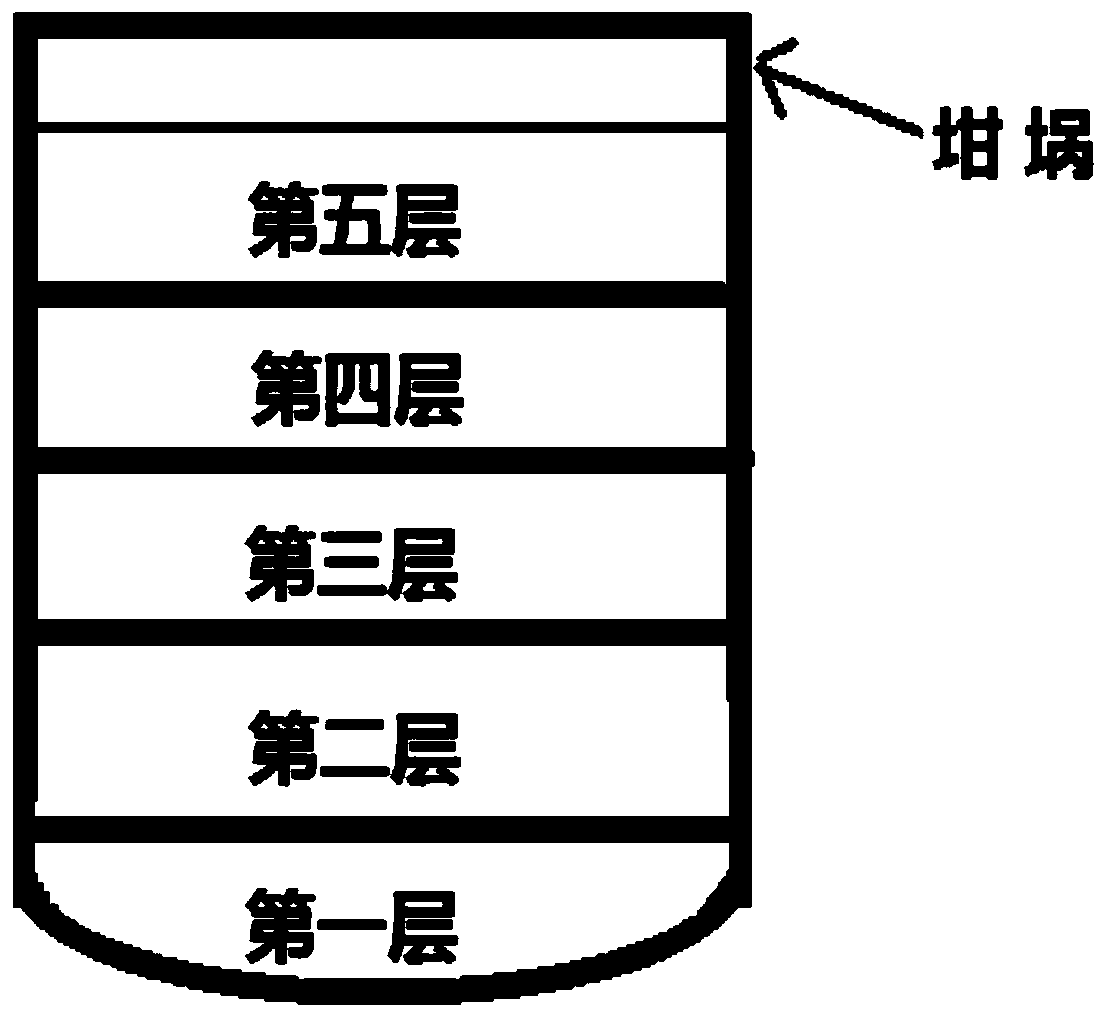

A kind of preparation method of high-purity titanium-nickel-copper shape memory alloy casting ingot

The invention discloses a preparation method for high-purity titanium nickel copper shape memory alloy ingots, and relates to the technical field of shape memory alloy preparation. Raw materials are screened, cleaned and dried; the raw materials comprise sponge titanium particles, electrolytic nickel particles, high-purity copper particles and phosphorus copper intermediate alloys; after the driedraw materials are weighed, the materials are paved in a smelting furnace in sequence according to a first preset condition; the materials are smelted according to a vacuum induction smelting technology, wherein the smelting process comprises power supply, degassing, refining and casting; the aftertreatment is performed on ingots after casting according to a second preset condition by adopting a hot isostatic pressing method; and then, the flaw detection, the riser cutting and the bottom cushioning are performed on the ingots after aftertreatment in sequence to obtain high-purity titanium nickel copper ingots. The preparation method achieves the technical effects of convenience to prepare the ingots, controllable and lower content of impurity element O, high content stability of the O element, fine grain structure and great reduction of metallurgy defects.

Owner:西安斯塔克材料科技有限公司

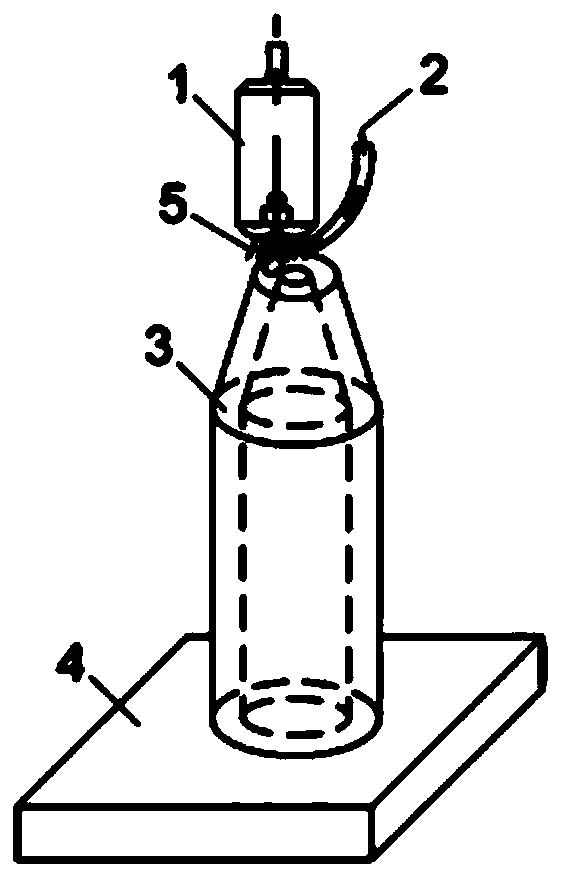

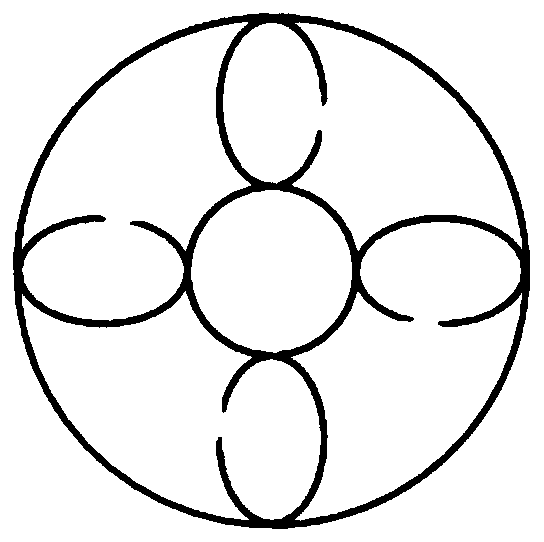

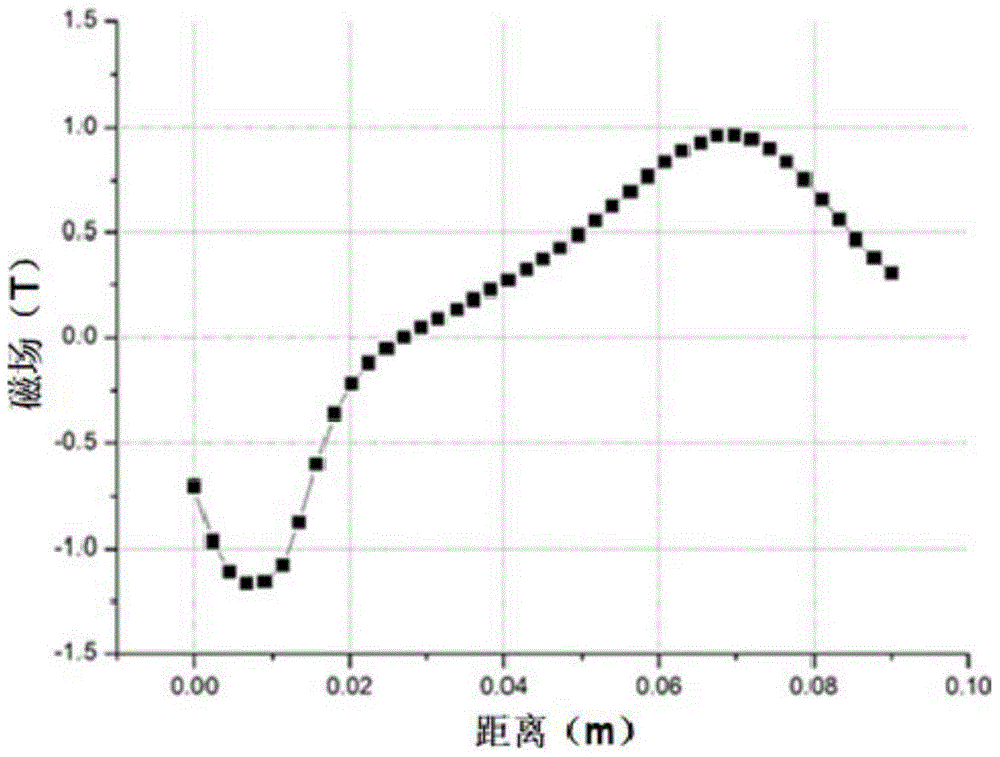

A kind of NdFeB permanent magnet material and its preparation method and magnetic field assisted direct casting device

ActiveCN103894587BSimple designLow costMagnetsMagnetic materialsCircular discCondensed matter physics

The invention discloses a neodymium-iron-boron permanent magnet material, a preparation method and a magnetic field auxiliary direct casting device. A main magnet of the device is a circular-ring-shaped magnet which is magnetized in a radial mode. A first disc-shaped repulsion magnet with the magnetic field direction being axially upward is arranged below the center of the main magnet, and a second disc-shaped repulsion magnet which is magnetized in a radial mode is arranged on the periphery of the first repulsion magnet. A regulating magnet is arranged at the upper end of the main magnet, second soft iron is arranged on the upper portion of the regulating magnet, first soft iron is arranged outside the regulating magnet, and a circular-ring-shaped magnet guide magnet which is magnetized downwards in the axial direction is arranged outside the main magnet. The chemical general formula of the neodymium-iron-boron permanent magnet material is [Nd (85-x-y) CoxFeyAlzB (15-z)] (100-a) Ma, wherein in the formula, x+y is larger than or equal to 30 and smaller than or equal to 70, z is larger than or equal to 0 and smaller than or equal to 10, and a is smaller than and equal to 4. Compared with a material prepared without adding magnetic fields, the performance of the neodymium-iron-boron permanent magnet material is greatly improved, the preparation process is simple, cost is low, products are dense, and the neodymium-iron-boron permanent magnet material is suitable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com