Manufacturing method for low metallurgical defect gh4169 nickel base alloy ingot

A GH4169, nickel-based alloy technology, applied in the direction of improving process efficiency and energy efficiency, can solve problems such as metallurgical defects and affect product quality, and achieve the effects of improving alloy purity, eliminating central defects, and reducing metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

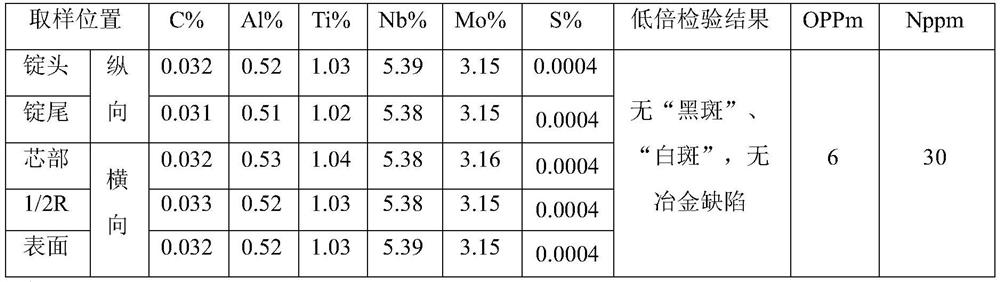

Embodiment 1

[0030] This embodiment uses the manufacturing method of the high-quality GH4169 nickel-based alloy ingot with low metallurgical defects of the present invention, through the steps of vacuum induction melting, protective atmosphere electroslag remelting, homogenization treatment, rapid forging and elongation and vacuum self-consumption remelting, Production of GH4169 alloy ingots with a φ406mm specification.

[0031]Step A VIM smelting: Vacuum induction melting (VIM) is used to precisely control the chemical composition of GH4169 nickel-based alloy. When the content of [S] in the alloy is 5PPm, the content of [O] is 5PPm, and the content of [N] is 25PPm, the steel is tapped and vacuum cast into a diameter of φ360mm. The nickel-based alloy ingot; step B protective atmosphere electroslag remelting: the high-purity GH4169 nickel-based alloy ingot with a diameter of φ360mm obtained in step A is subjected to protective atmosphere electroslag remelting, and the melting rate is control...

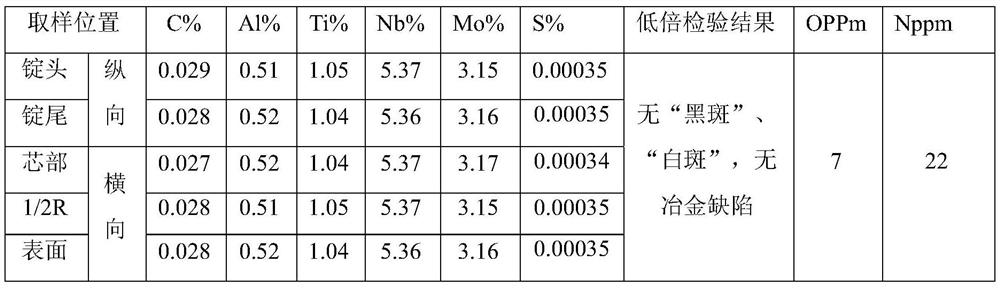

Embodiment 2

[0035] This embodiment uses the manufacturing method of the high-quality GH4169 nickel-based alloy ingot with low metallurgical defects of the present invention, through the steps of vacuum induction melting, protective atmosphere electroslag remelting, homogenization treatment, rapid forging and elongation and vacuum self-consumption remelting, Production of GH4169 alloy ingots with φ508mm specification.

[0036] Step A VIM smelting: Vacuum induction melting (VIM) is used to precisely control the chemical composition of GH4169 nickel-based alloy. The [S] content in the alloy is 4PPm, the [O] content is 7PPm, and the [N] content is 18PPm. The steel is tapped and vacuum cast into a diameter of φ450mm. The nickel-based alloy ingot; step B protective atmosphere electroslag remelting: the high-purity GH4169 nickel-based alloy ingot with a diameter of φ450mm obtained in step A is subjected to protective atmosphere electroslag remelting, and the melting rate is controlled at 5kg / min ...

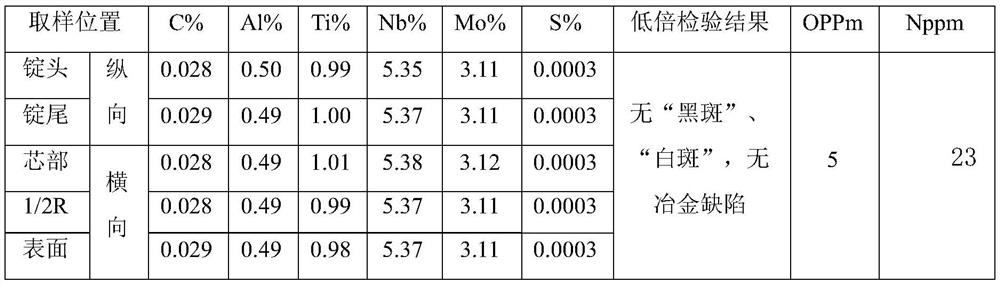

Embodiment 3

[0040] This embodiment uses the manufacturing method of the high-quality GH4169 nickel-based alloy ingot with low metallurgical defects of the present invention, through the steps of vacuum induction melting, protective atmosphere electroslag remelting, homogenization treatment, rapid forging and elongation and vacuum self-consumption remelting, Production of GH4169 alloy ingots with φ508mm specification.

[0041] Step A VIM smelting: Vacuum induction melting (VIM) is used to precisely control the chemical composition of GH4169 nickel-based alloy. When the content of [S] in the alloy is 3PPm, the content of [O] is 5PPm, and the content of [N] is 22PPm, the steel is tapped and vacuum cast into a diameter of φ450mm. The nickel-based alloy ingot; step B protective atmosphere electroslag remelting: the high-purity GH4169 nickel-based alloy ingot with a diameter of φ450mm obtained in step A is subjected to protective atmosphere electroslag remelting, and the melting rate is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com