Electrodeposition-laser remelting strengthening process of Ni-nanometer TiN composite layer on surface of nickel base superalloy

A nickel-based superalloy and composite electrodeposition technology, applied in coatings, electrolytic coatings, etc., can solve the problems of difficult parameter control, stress deformation, poor surface flatness, etc., and achieve long service life, enhanced friction resistance, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Processing requirements: Prepare a Ni-nano TiN strengthening layer on the ring-cone working surface of Ni80A parts (high-power diesel engine valves), the thickness of the strengthening layer is 150 μm, the surface microhardness reaches 1100HV0.5, and the surface roughness value reaches Ra0.8μm.

[0029] The processing method steps are as follows:

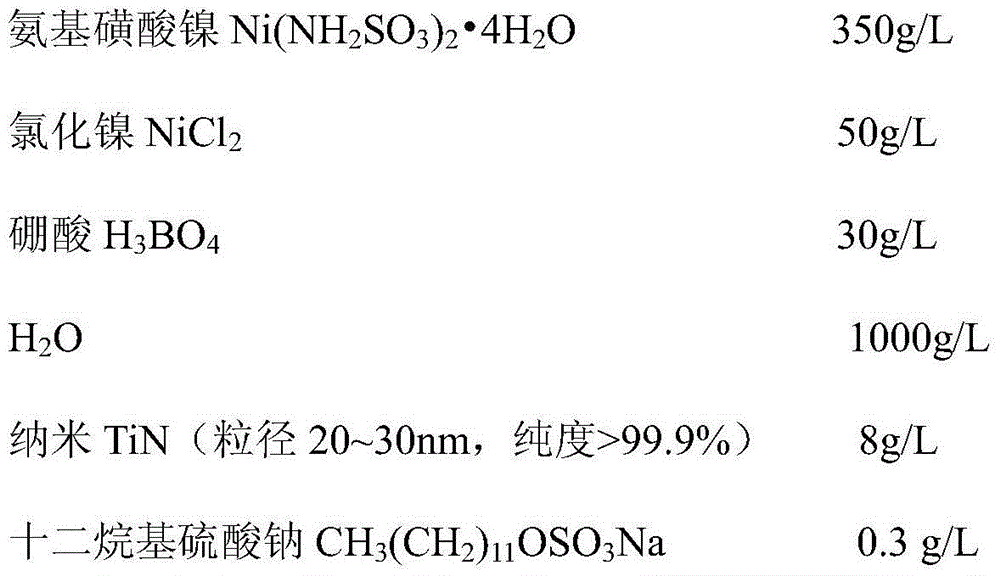

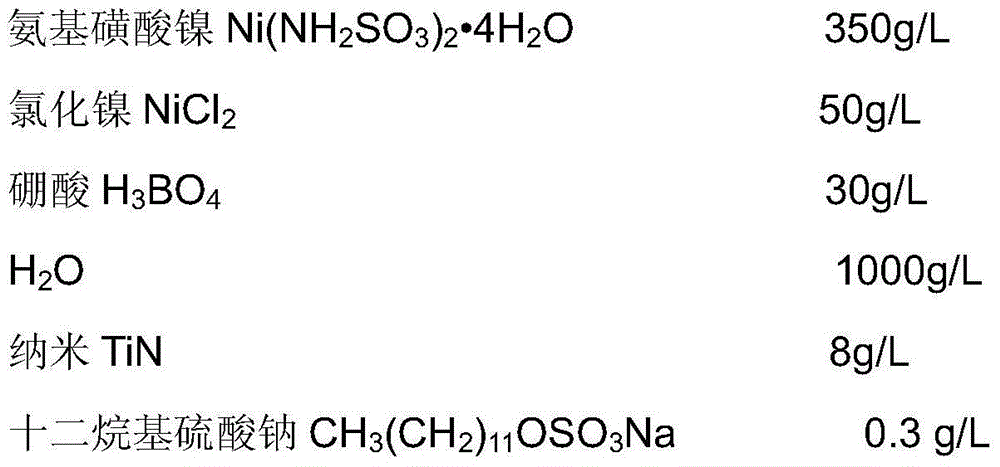

[0030] 1) Composite electrodeposition

[0031] (1) Configure the plating solution according to the following formula: nickel sulfamate (350g / L), nickel chloride (50g / L), boric acid (30g / L), nano-TiN (particle size 20-30nm, purity >99.9%) , 8g / L), sodium lauryl sulfate (0.3g / L), the pH value of plating solution=4.2, temperature T=45 ℃. The prepared plating solution was placed in an ultrasonic cleaning tank heated by a water bath at 45°C for mechanical stirring at a stirring rate of 200 rpm for 30 min.

[0032] (2) The anode used in the electrodeposition process is an electrolytic nickel plate (purity>99.9%), the cathode is t...

Embodiment 2

[0039] Processing requirements: Prepare a Ni-nano TiN strengthening layer on the working surface of KGH95 parts (a wear-resistant ring for large displacement corrosion-resistant centrifugal pumps), the thickness of the strengthening layer is 170 μm, the surface microhardness reaches 1000HV0.5, and the surface roughness value reaches Ra0. 4 μm.

[0040] The processing method steps are as follows:

[0041] 1) Composite electrodeposition

[0042] (1) Configure the plating solution according to the following formula: nickel sulfamate (350g / L), nickel chloride (50g / L), boric acid (30g / L), nano-TiN (particle size 20-30nm, purity >99.9%) , 8g / L), sodium lauryl sulfate (0.3g / L), the pH value of plating solution=4.2, temperature T=45 ℃. The prepared plating solution was placed in an ultrasonic cleaning tank heated by a water bath at 45°C for mechanical stirring at a stirring rate of 200 rpm for 30 min.

[0043] (2) The anode used in the electrodeposition process is an electrolytic n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com