A special al-cr heat-resistant alloy powder for 3d printing, preparation method, application and al-cr heat-resistant alloy

A 3D printing, heat-resistant alloy technology, used in additive manufacturing, additive processing, etc., can solve the problems of poor mechanical properties, easy cracking, etc., and achieve the effect of high density, low anisotropy, and good thermodynamic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) configure metal powder, prepare according to the mass percentage content, the composition is as follows: Cr: 4.0wt%, Mg: 1.0wt%, Mn: 0.5%, Sc: 0.7wt%, Zr: 0.35wt%, Si: 0.1% , and the rest are Al;

[0047] (2) Vacuum smelting: Put the pure metal block containing the above components into a vacuum induction furnace for heating and smelting; the vacuum smelting temperature is 850°C, and the air pressure in the smelting furnace is 0.6MPa;

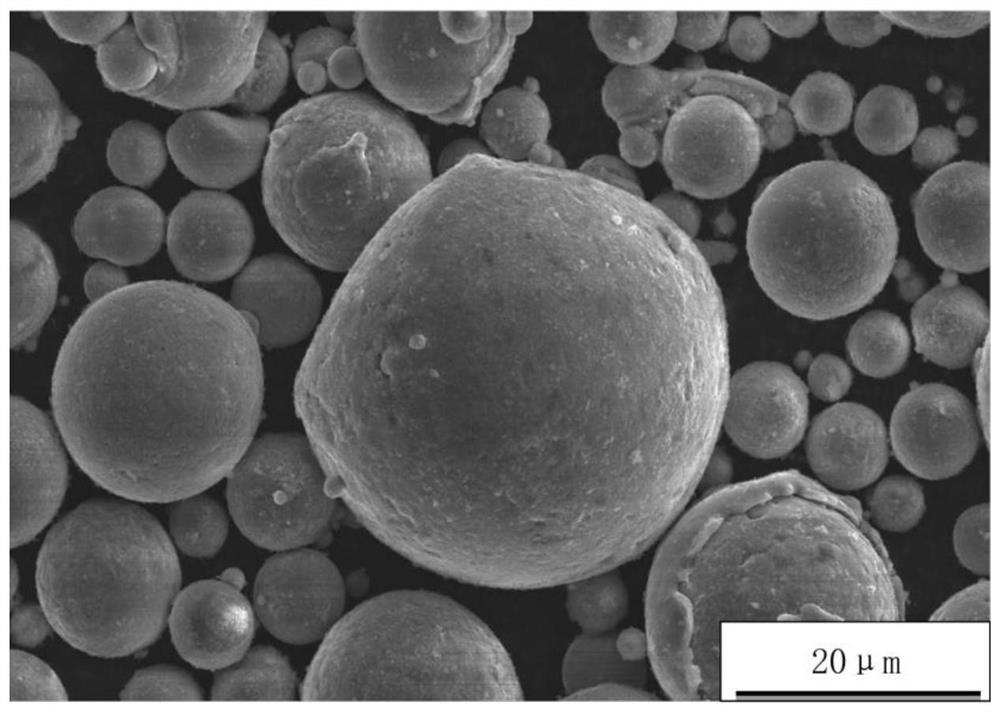

[0048] (3) atomization powder making: using argon gas as the medium to atomize metal droplets, the atomization pressure is 8.5MPa, to obtain pre-alloyed powder;

[0049] (4) Sieving: Sieve and classify the pre-alloyed powder, and sieve the powder of 15-53 μm, which is used as the raw material powder required for 3D printing;

[0050] (5) Drying treatment: place the sieved pre-alloyed powder in a drying oven for drying at a drying temperature of 90°C for 8 hours;

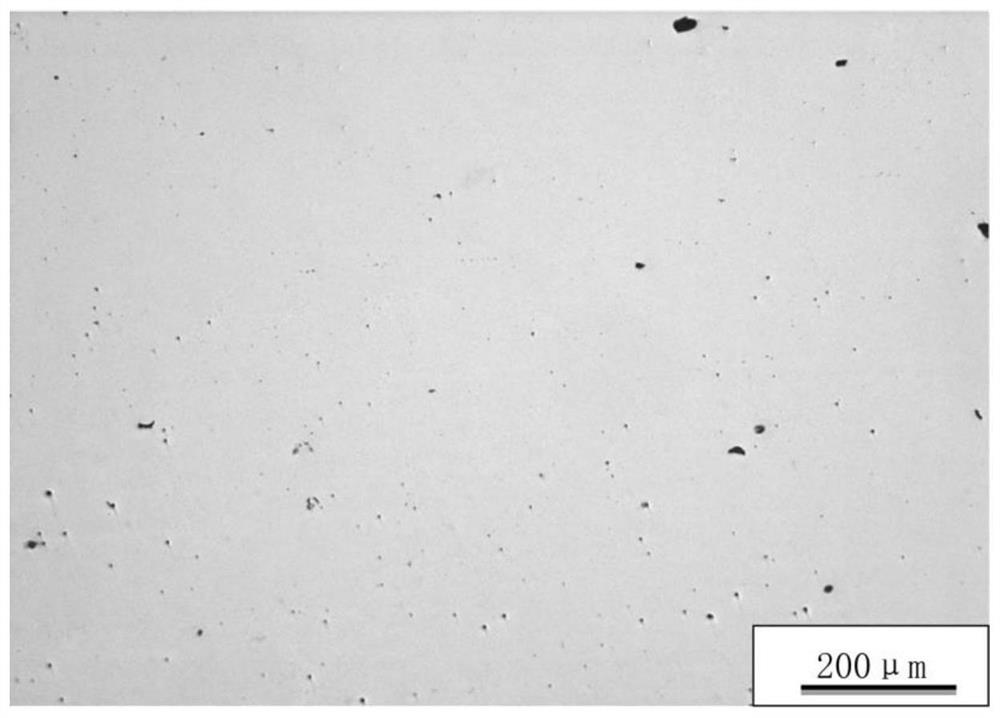

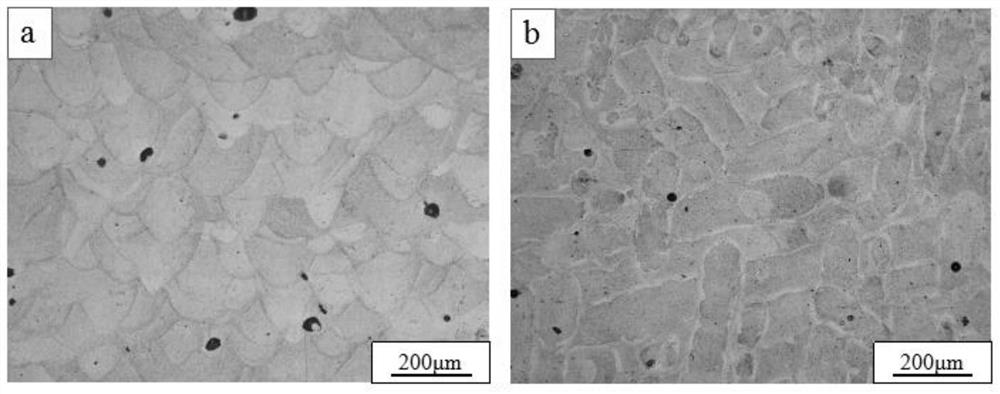

[0051] (6) 3D printing: the above 3D printed aluminum alloy powder i...

Embodiment 2

[0060] (1) configure metal powder, prepare according to the mass percentage content, the composition is as follows: Cr: 4.0wt%, Mg: 0.7wt%, Mn: 0.3%, Sc: 0.7wt%, Zr: 0.35wt%, Si: 0.1% , and the rest are Al;

[0061] (2) Vacuum smelting: Put the pure metal block containing the above components into a vacuum induction furnace for heating and smelting; the vacuum smelting temperature is 850°C, and the air pressure in the smelting furnace is 0.6MPa;

[0062] (3) atomization powder making: using argon gas as the medium to atomize metal droplets, the atomization pressure is 8.5MPa, to obtain pre-alloyed powder;

[0063] (4) Sieving: Sieve and classify the pre-alloyed powder, and sieve the powder of 15-53 μm, which is used as the raw material powder required for 3D printing;

[0064] (5) Drying treatment: place the sieved pre-alloyed powder in a drying oven for drying at a drying temperature of 90°C for 8 hours;

[0065] (6) 3D printing: the above 3D printed aluminum alloy powder i...

Embodiment 3

[0069] (1) configure metal powder, prepare according to the mass percentage content, the composition is as follows: Cr: 2.5wt%, Mg: 0.8wt%, Mn: 0.5%, Sc: 0.5wt%, Zr: 0.2wt%, Si: 0.1% , and the rest are Al;

[0070] (2) Vacuum smelting: Put the pure metal block containing the above components into a vacuum induction furnace for heating and smelting; the vacuum smelting temperature is 850°C, and the air pressure in the smelting furnace is 0.6MPa;

[0071] (3) atomization powder making: using argon gas as the medium to atomize metal droplets, the atomization pressure is 8.5MPa, to obtain pre-alloyed powder;

[0072] (4) Sieving: Sieve and classify the pre-alloyed powder, and sieve the powder of 15-53 μm, which is used as the raw material powder required for 3D printing;

[0073] (5) Drying treatment: place the sieved pre-alloyed powder in a drying oven for drying at a drying temperature of 90°C for 8 hours;

[0074] (6) 3D printing: the above 3D printed aluminum alloy powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com