A kind of preparation method of high-purity titanium-nickel-copper shape memory alloy casting ingot

A memory alloy and titanium-nickel-copper technology, which is applied in the field of preparing high-purity titanium-nickel-copper shape memory alloy ingots, can solve the problem that the content of O element in the ingot cannot be reduced, the metallurgical defects cannot be better eliminated, and the coarse grain structure cannot be eliminated. Solve problems such as limited handling, and achieve the effect of good stability of O element content, reduction of metallurgical defects, and fine grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

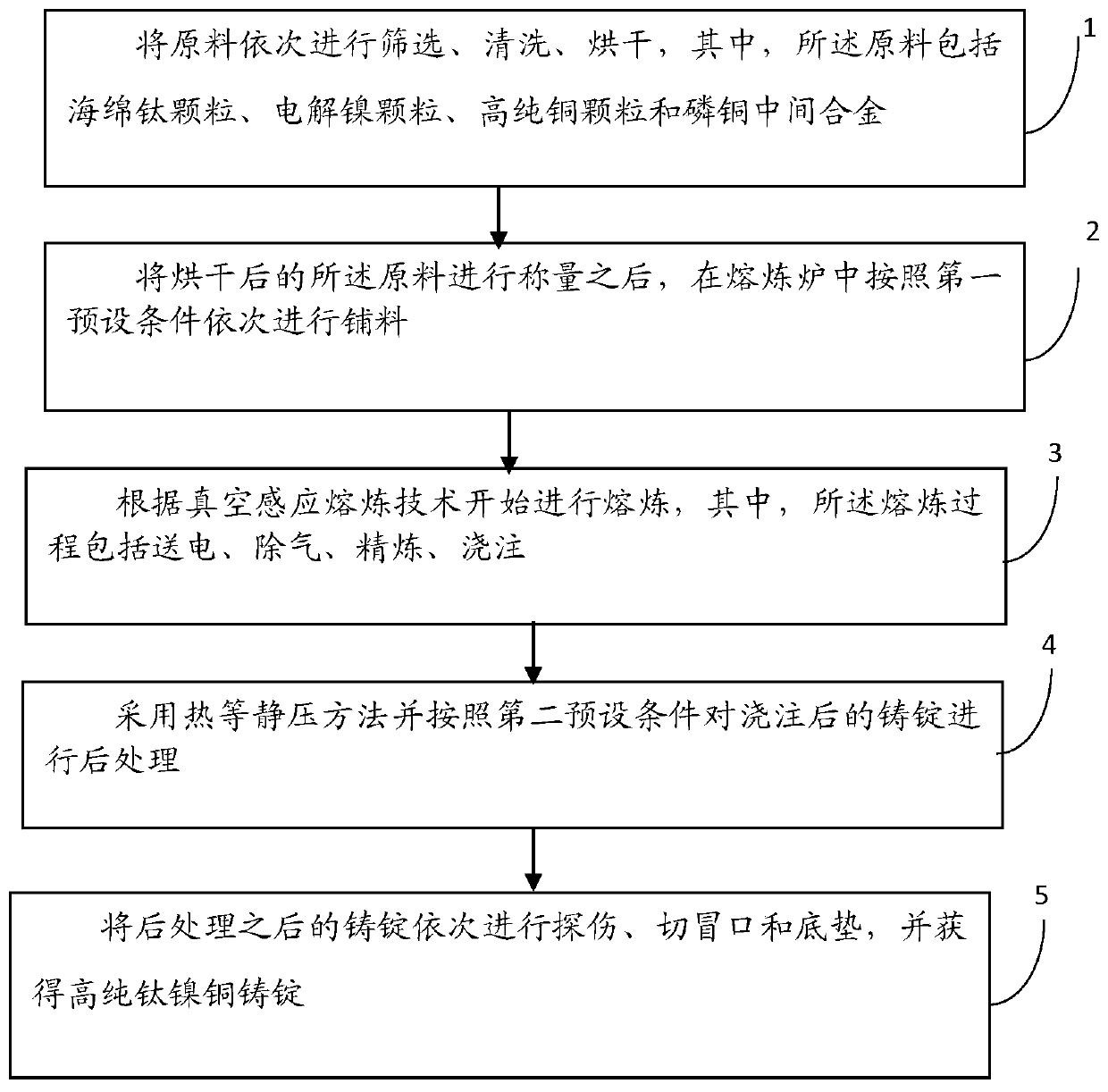

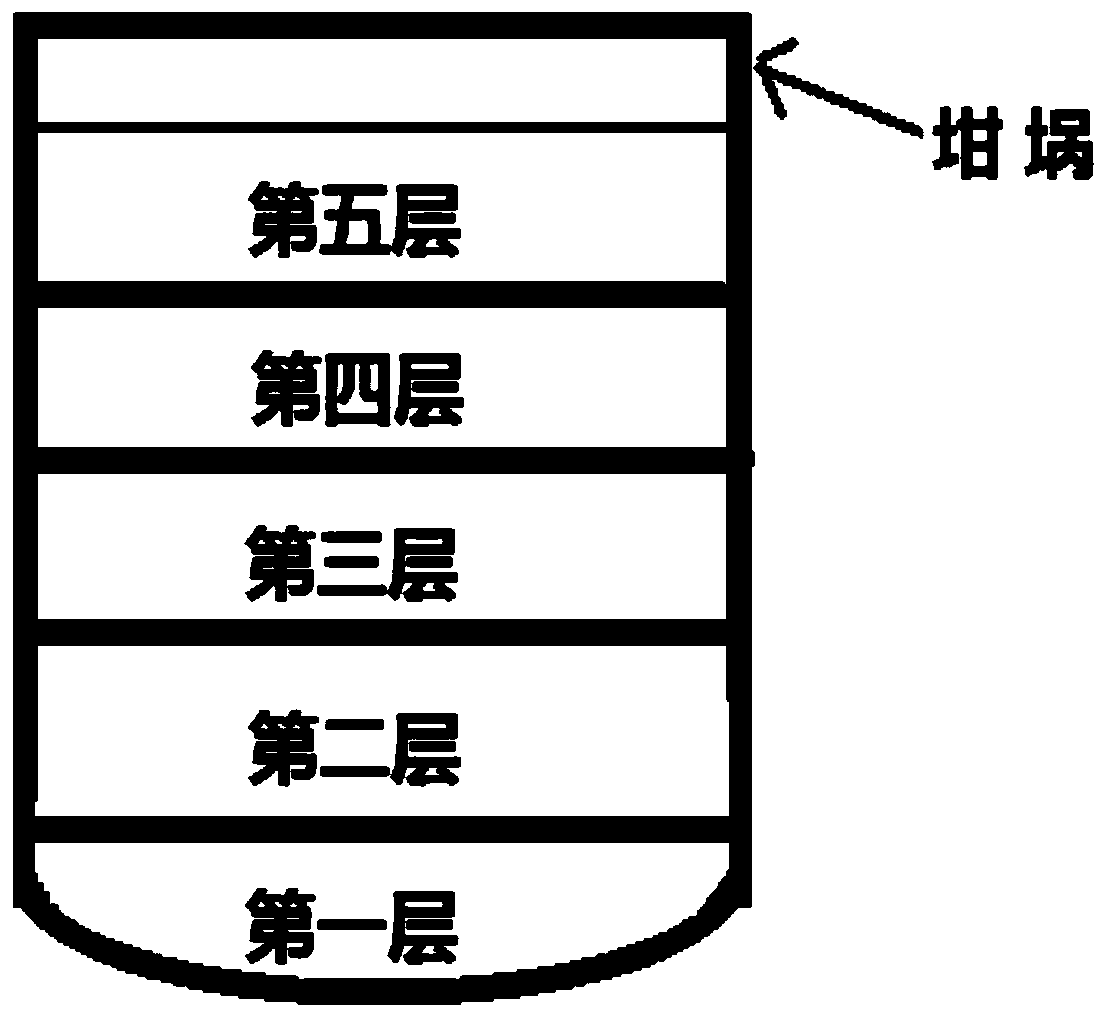

[0023] This embodiment provides a preparation method of high-purity titanium-nickel-copper shape memory alloy ingot, please refer to figure 1 , the preparation method of the high-purity titanium-nickel-copper shape memory alloy ingot comprises:

[0024] Step 1: Screening, cleaning and drying the raw materials in sequence, wherein the raw materials include titanium sponge particles, electrolytic nickel particles, high-purity copper particles and phosphor copper master alloy.

[0025] Further, in the step 1, it also includes: in the raw material screening process, the titanium sponge particles meet the first particle size range, the electrolytic nickel particles and high-purity copper particles meet the second particle size range, the phosphor copper The master alloy satisfies the third grain size range.

[0026] Further, the range of the first particle size is 3-12.7mm.

[0027] Further, the second particle size range is less than or equal to 10×10mm.

[0028] Further, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com