Cable type welding wire and method for preparing high-entropy alloy parts with cable type welding wire

A high-entropy alloy, cable-type welding wire technology, applied in welding equipment, welding equipment, arc welding equipment and other directions, can solve the problems of complex process, low forming speed, high yield strength and tensile strength, and achieve simple preparation process and reduce Metallurgical defects, the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

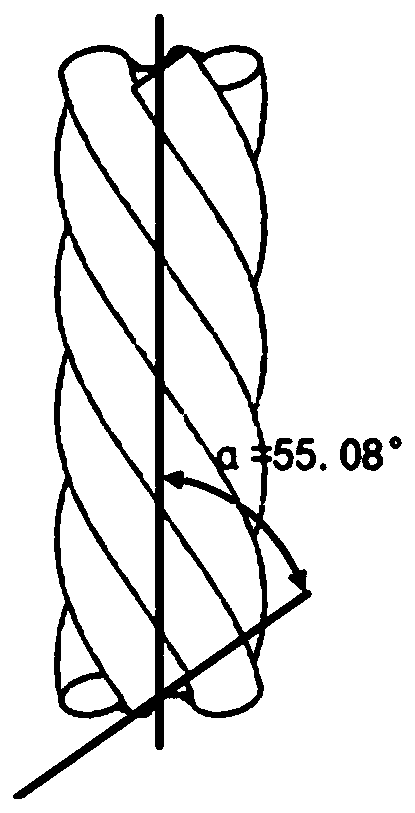

[0036] The welding performance of the cable welding wire is related to the twist length of the peripheral welding wire. The so-called lay length refers to the linear distance between the corresponding two points when the peripheral welding wire rotates around the central welding wire for one revolution (360°). At present, in production practice, the cable-type welding wire is usually regarded as a single-strand raw material, and the lay length of the cable-type welding wire is determined with reference to the standard of a single-strand raw material. That is to say, according to the provisions of the national standard GB / 20118-2008, the lay length of single-strand raw materials = lay length multiple X rope diameter (or strand diameter), the lay length multiple of 1X7 is not greater than 10.5, and the general production plant adopts 6.5-7.0. For the single-strand raw material of 1×7 (i.e. 1+6) with a monofilament diameter of 1mm, its rope diameter is roughly equal to 3, then th...

Embodiment 2

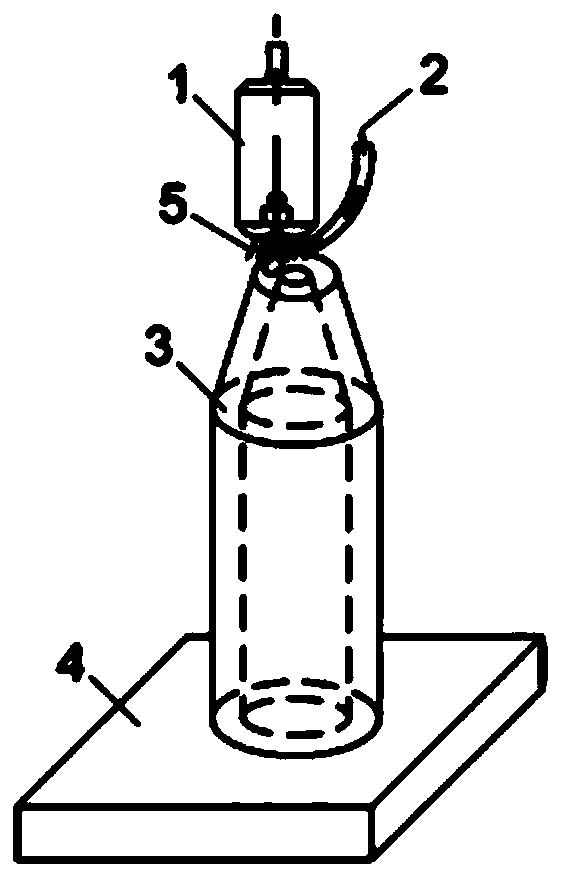

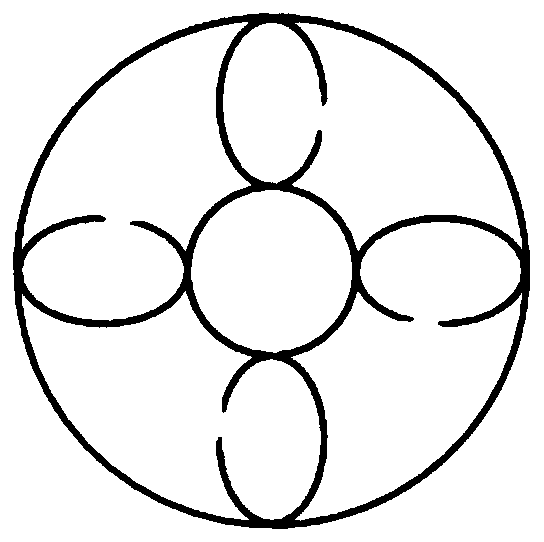

[0066] A cable-type welding wire, used in the field of high-entropy alloy preparation, comprising a central welding wire and several surrounding welding wires, the several surrounding welding wires are helically twisted around the central welding wire, and each adjacent surrounding welding wire is tangent Connection; the diameter of the surrounding welding wire is not greater than the diameter of the central welding wire, and there are at least three surrounding welding wires, and the raw materials for the surrounding welding wire and the central welding wire are selected according to the formula of high-entropy alloy, and the raw materials include metal Silk. The cable-type welding wire can be composed of the following metal wires: Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Sc, Pd, Y, Hf, Ta , W, Al or Sn, etc. Cable type welding wire can also be changed into 1+5 mode.

[0067] Further, the high-entropy alloy includes more than 5 major alloying elements and no more than...

Embodiment 3

[0084] In this embodiment, the additive manufacturing method based on the arc fuse is realized, and the CuCoCrFeNi high-entropy alloy is prepared by using the cable-type welding wire. The diameter of the cable-type welding wire is 0.8mm, and the solid nickel wire is the central welding wire. , iron wire, and chrome wire are peripheral welding wires. The cable-type welding wire adopts the 1+4 mode, that is, one solid nickel wire is used as the central welding wire, and four solid copper wires, cobalt wires, iron wires, and chromium wires are used as peripheral welding wires. Wire combination type. The prepared cable-type welding wire has a diameter of 2.4 mm. The design dimensions of the parts to be produced are as follows: the height of the bottom cylinder is 400mm, the inner diameter is Φ150mm, the top inner diameter is Φ50mm, the wall thickness is 10mm, the total height is 800mm, and the size of the substrate used is 300mm×300mm×20mm. The welding wire is a cable-type weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com