Filter plate and high-pressure piston type solid-liquid separation device made of same

A solid-liquid separation, high-pressure piston technology, used in presses, manufacturing tools, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of reducing sludge moisture content, unfavorable sludge dispersion, weak extrusion force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the description of the present invention, "above" includes the original number, that is, "more than two" refers to two or more than two; the terms "first" and "second" are only used for descriptive purposes, and cannot be interpreted as indicating or implying Relative importance or implicit indication of the number of technical features indicated. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features. In the description of the present invention, "several" means two or more, unless otherwise specifically defined.

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

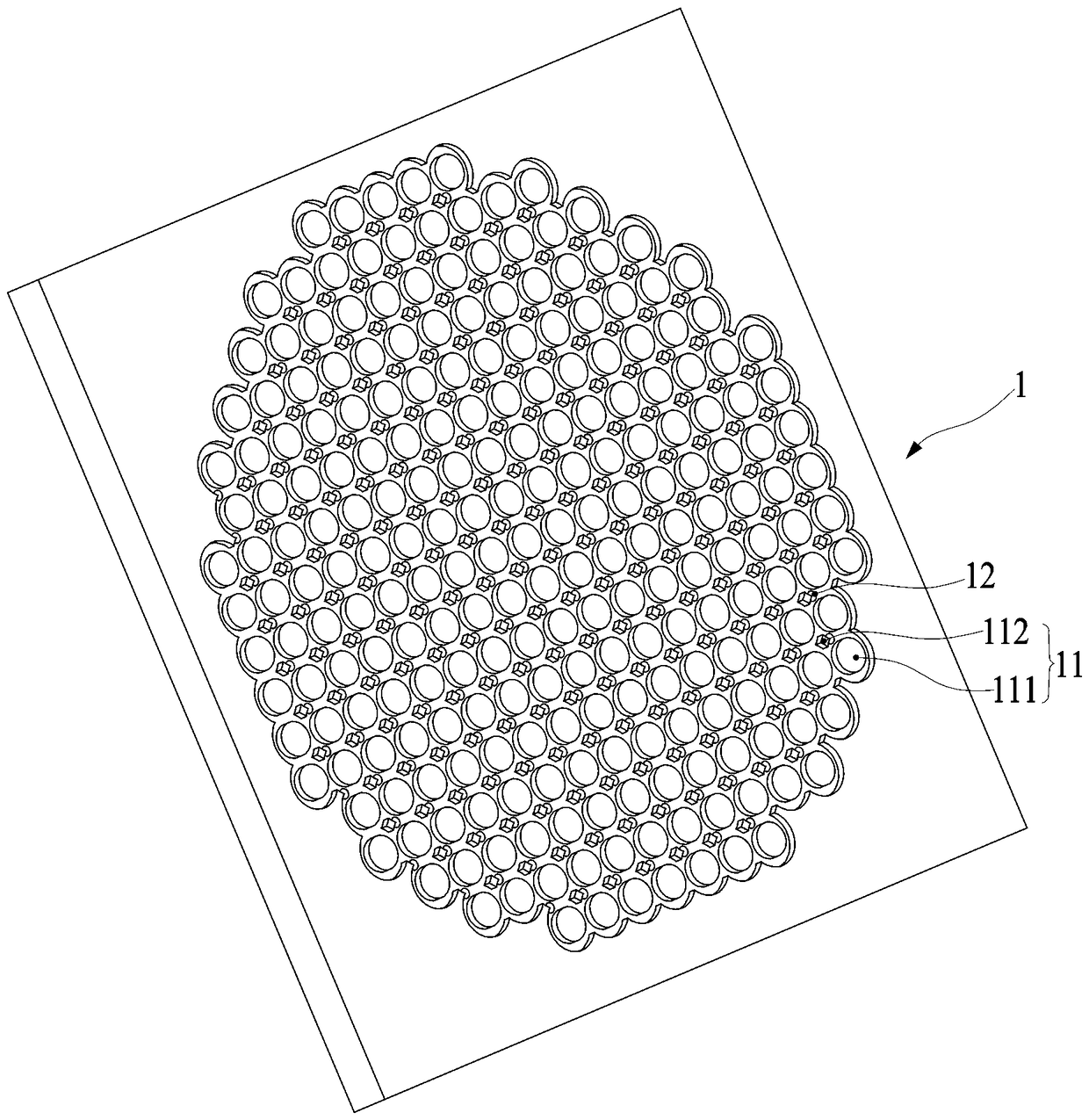

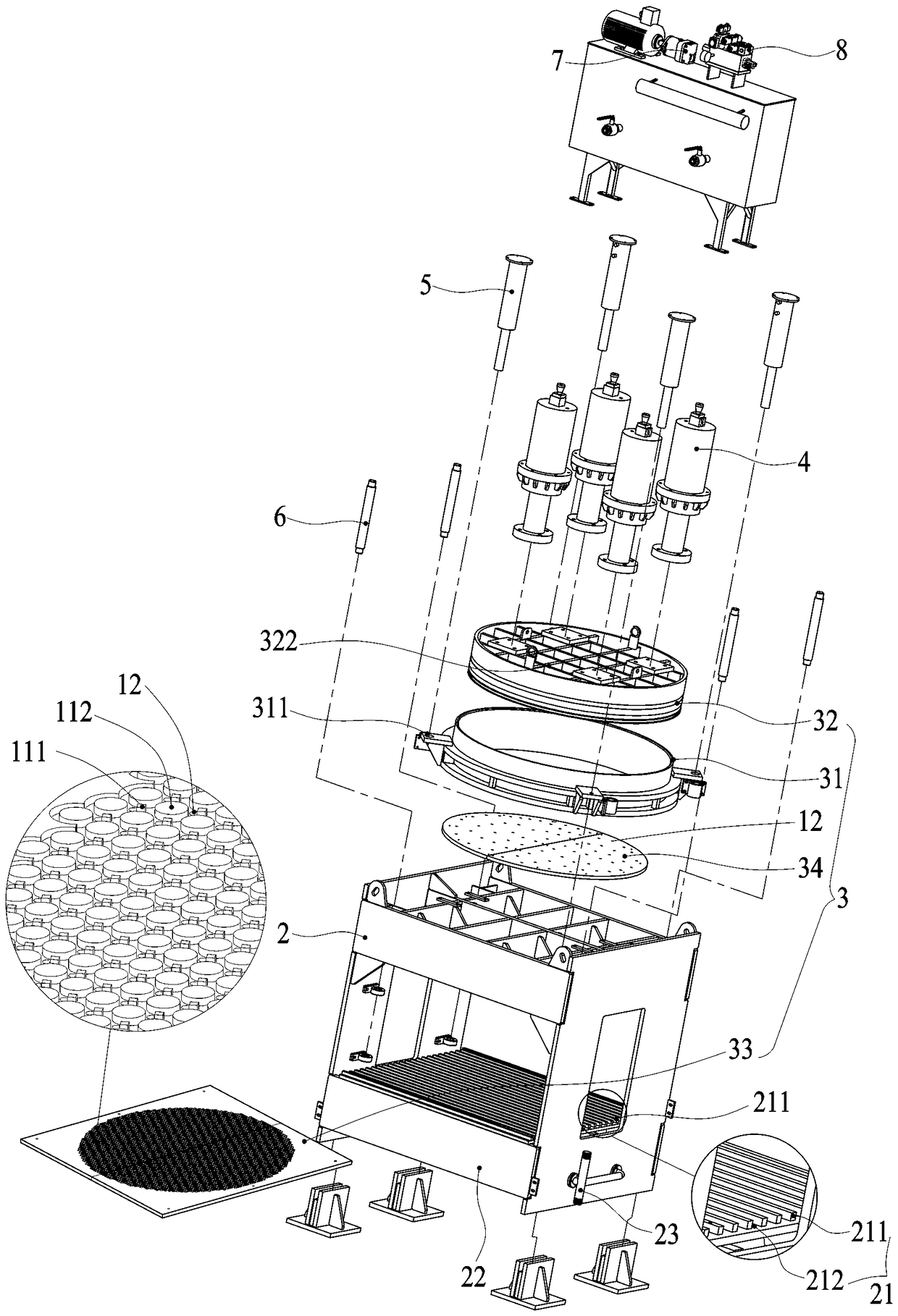

[0032] Such as image 3 , the present invention discloses a filter plate 1 for solid-liquid separation, on the surface of the filter plate 1 facing the object to be filtered, there are criss-cross convex grains 11, and between the convex grains 11 and the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com