Patents

Literature

67results about How to "Less prone to deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

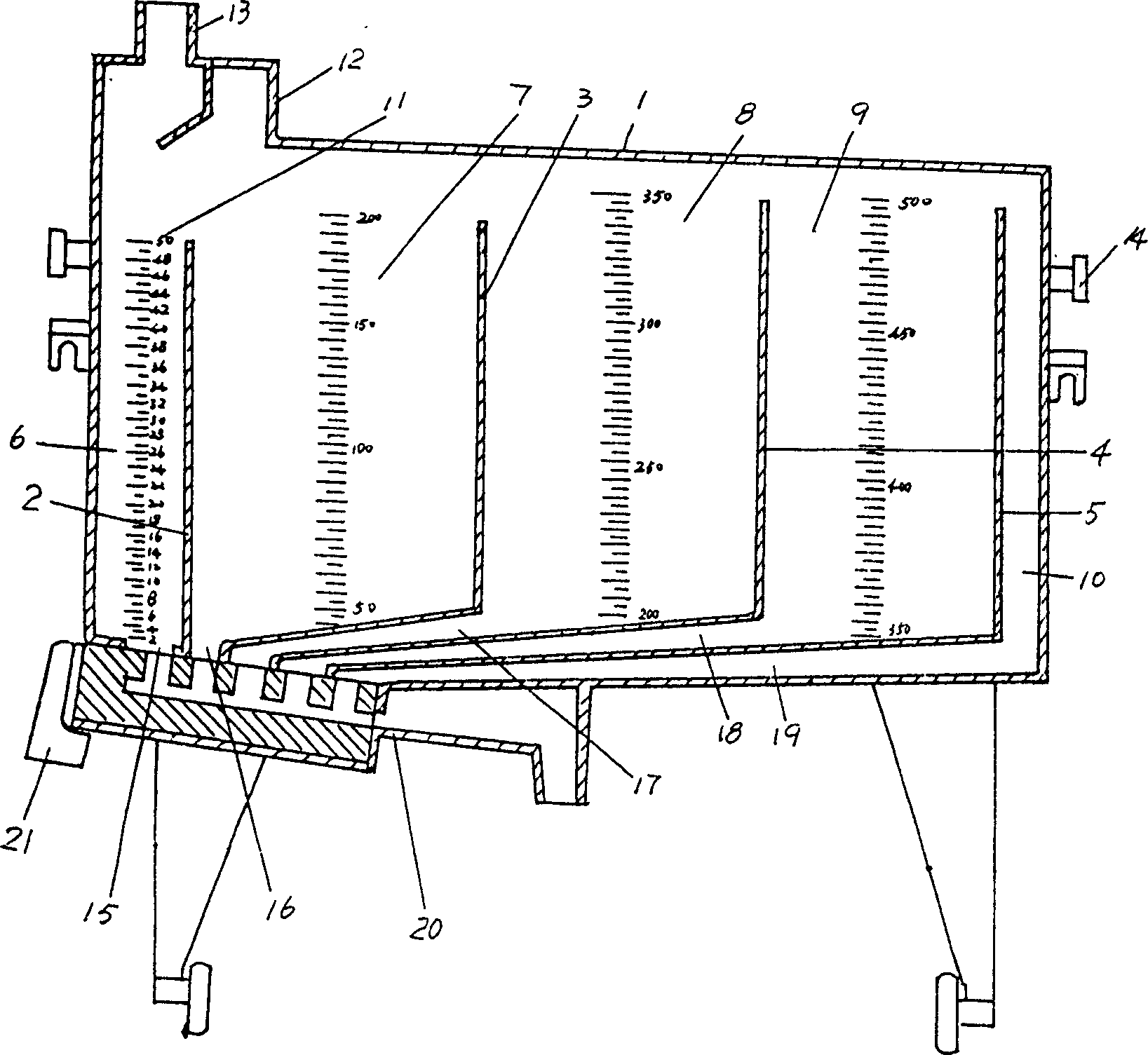

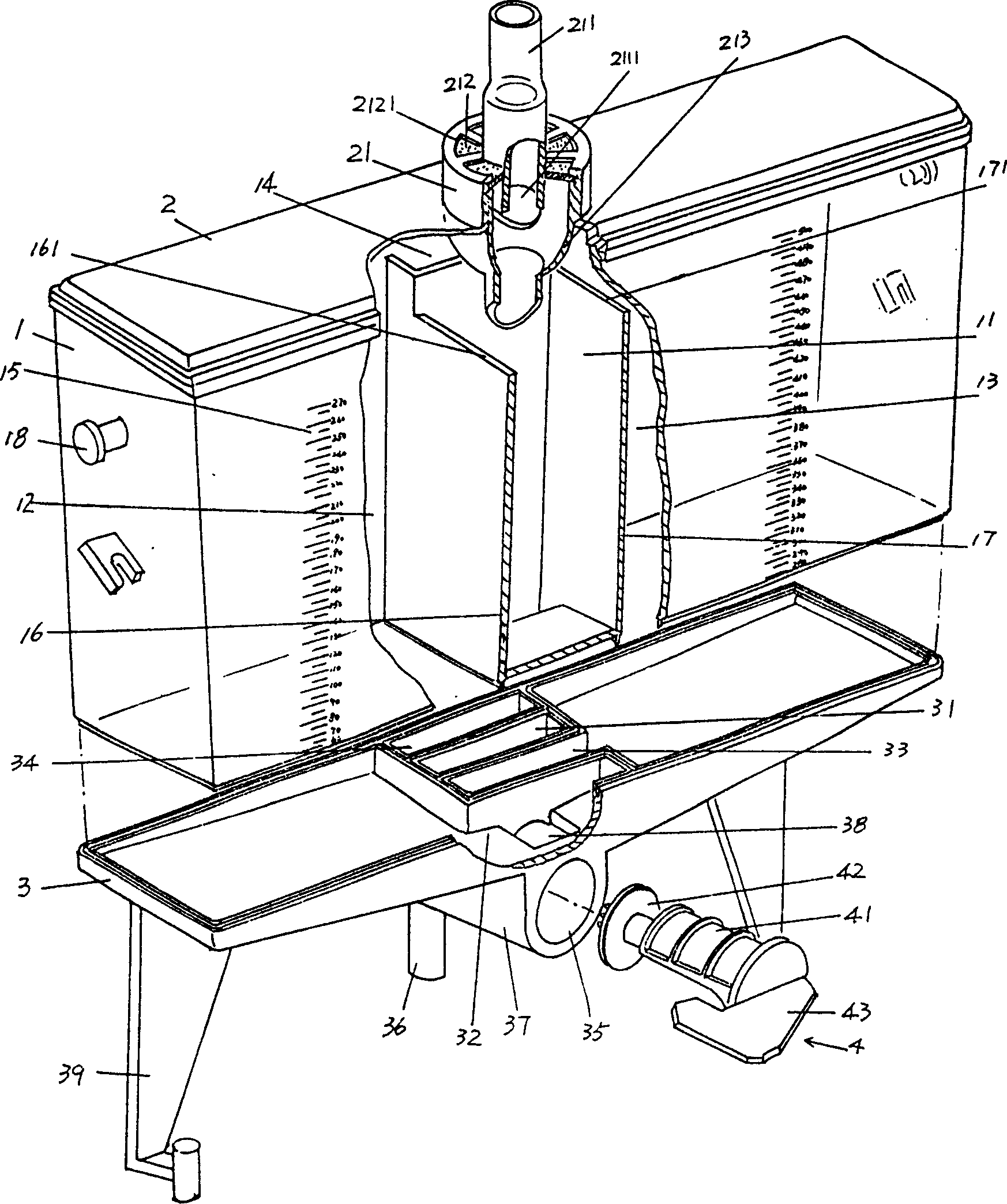

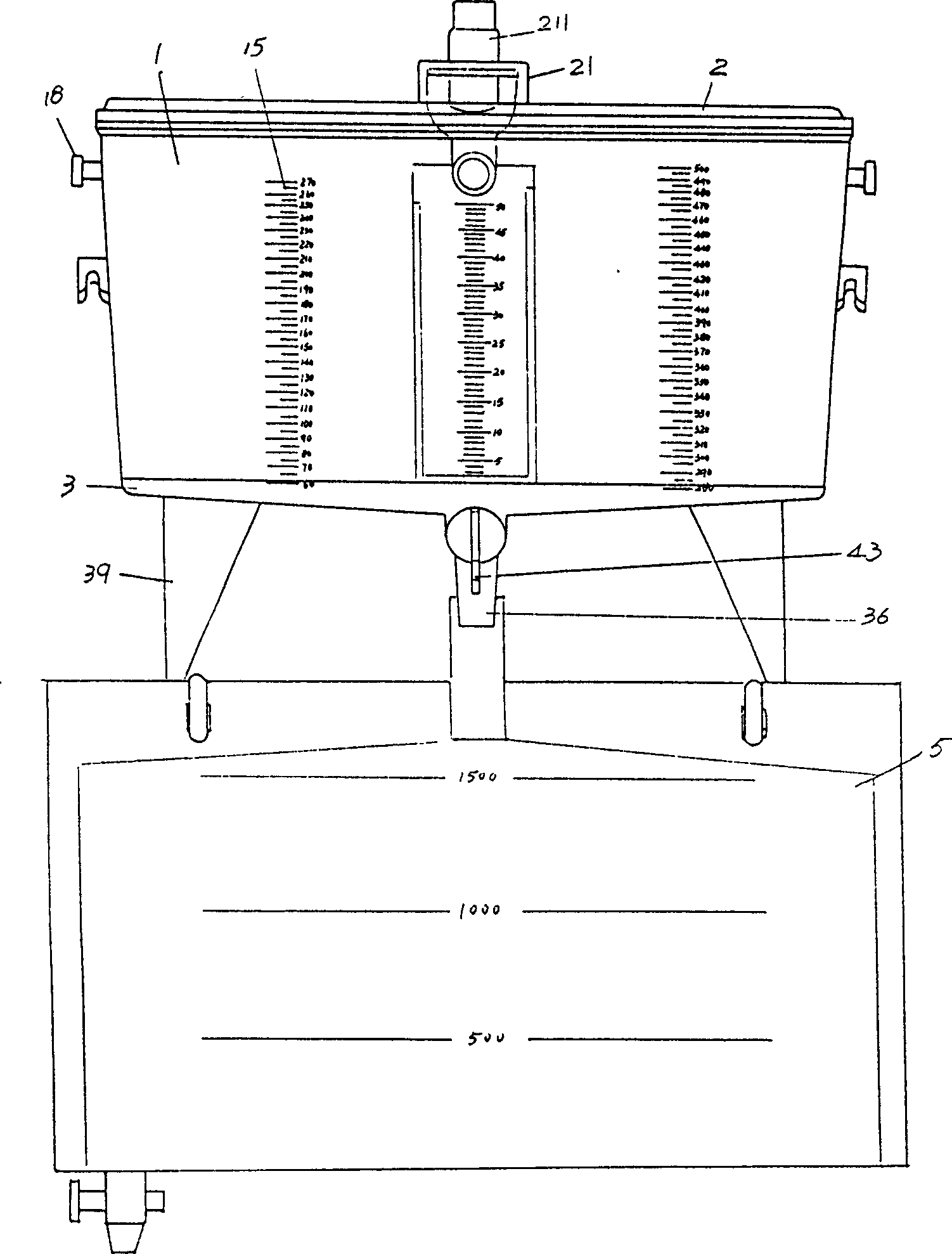

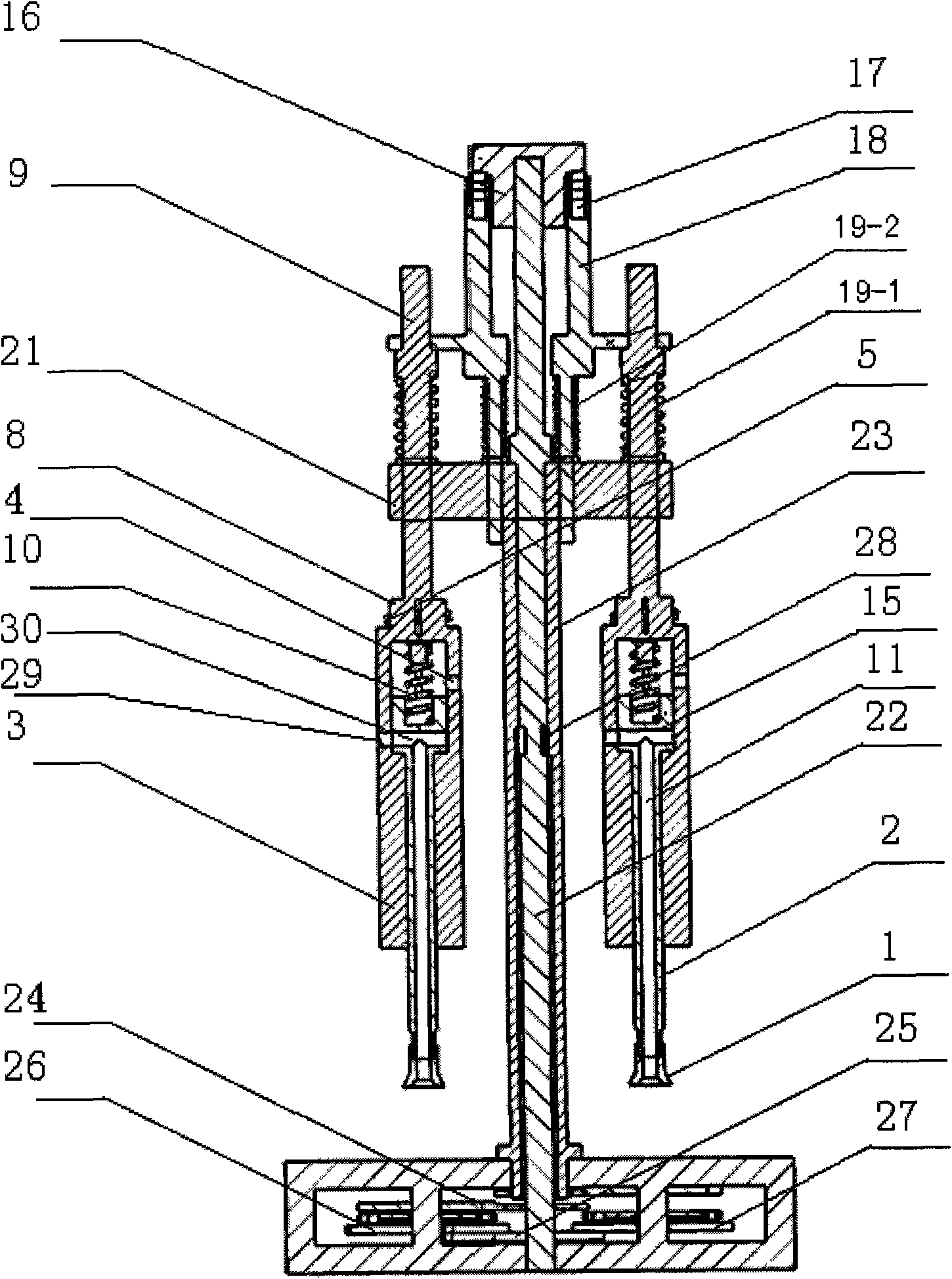

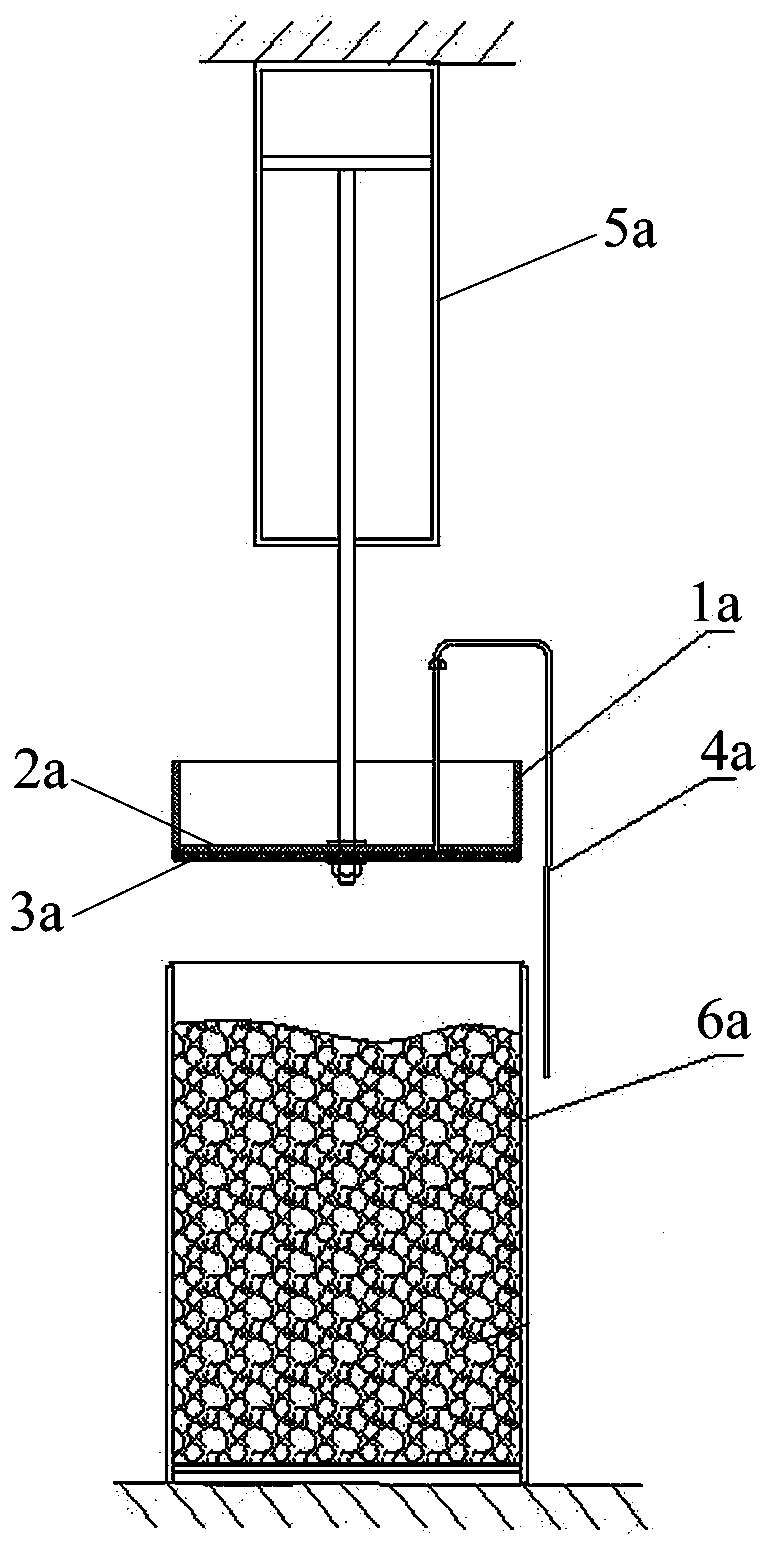

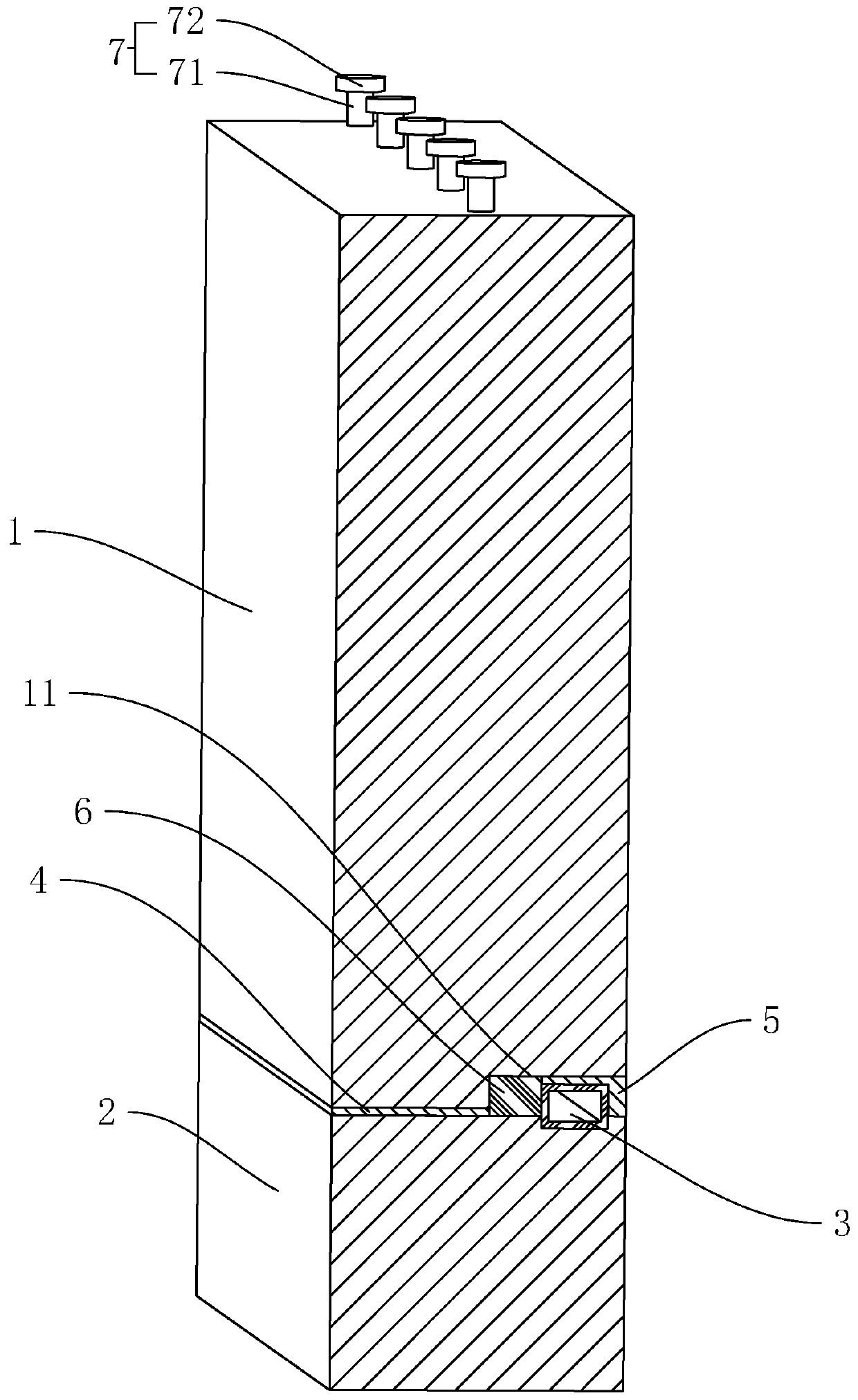

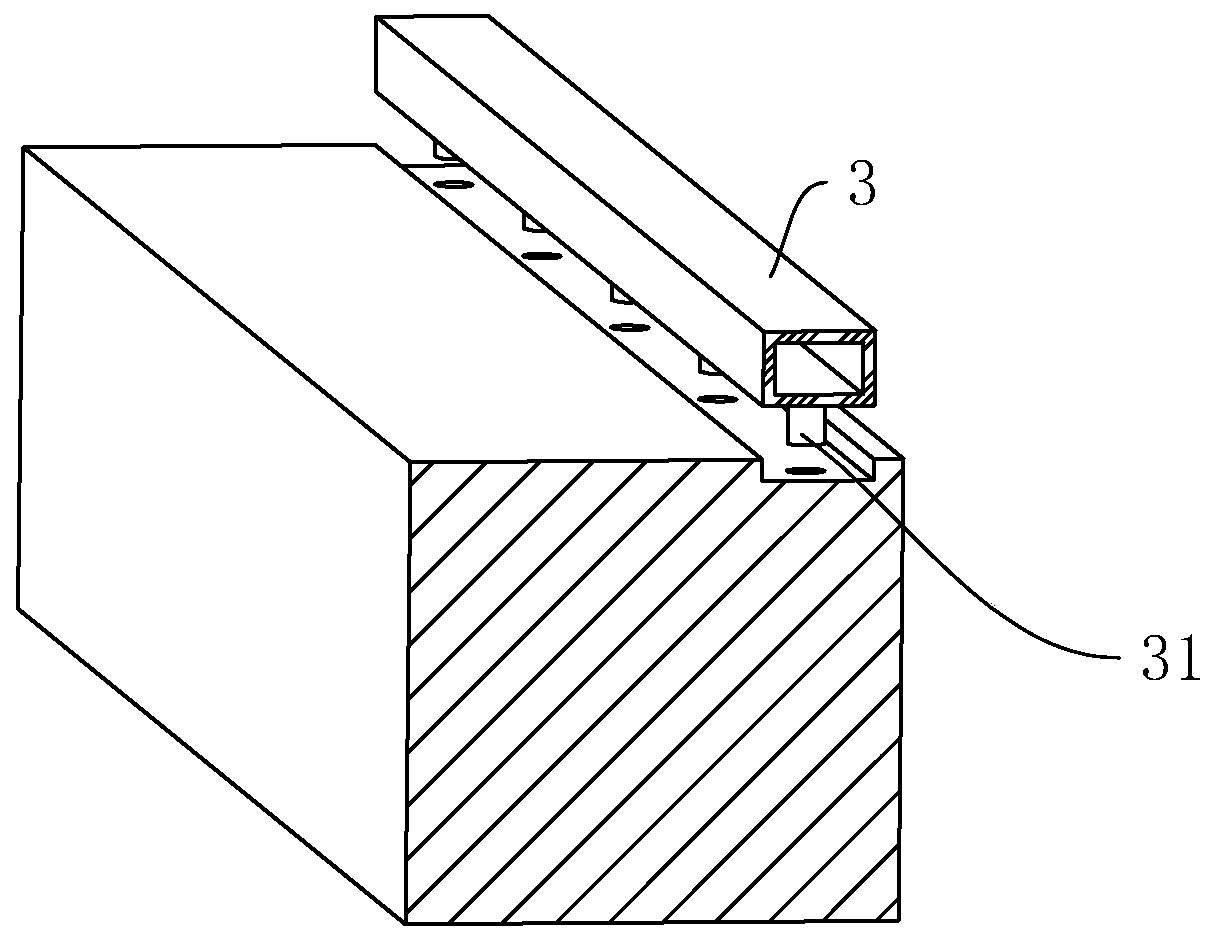

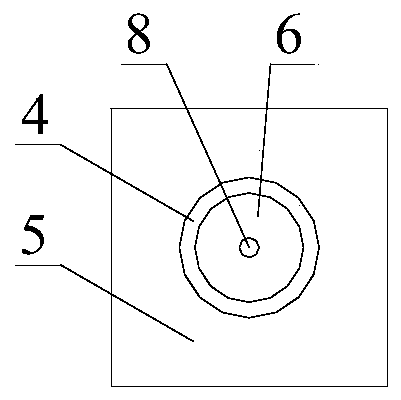

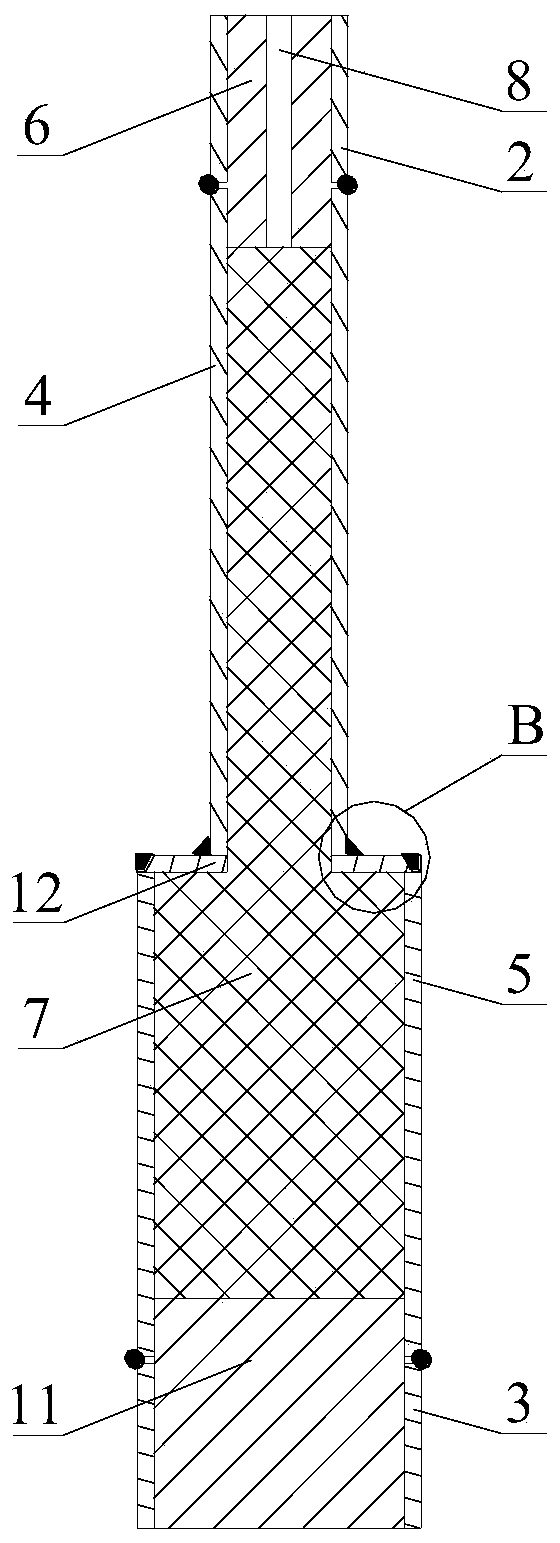

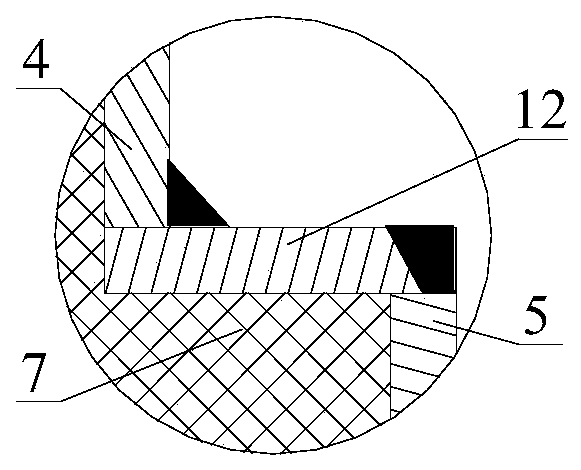

Medical semi-automatic urine metering storing apparatus

InactiveCN1282451CLess prone to deflectionSmooth drainagePharmaceutical containersMedical packagingUrine metersSemi automatic

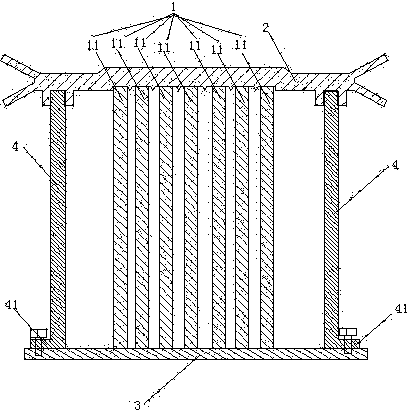

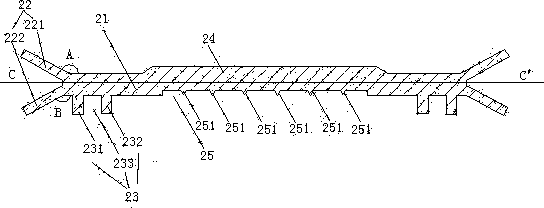

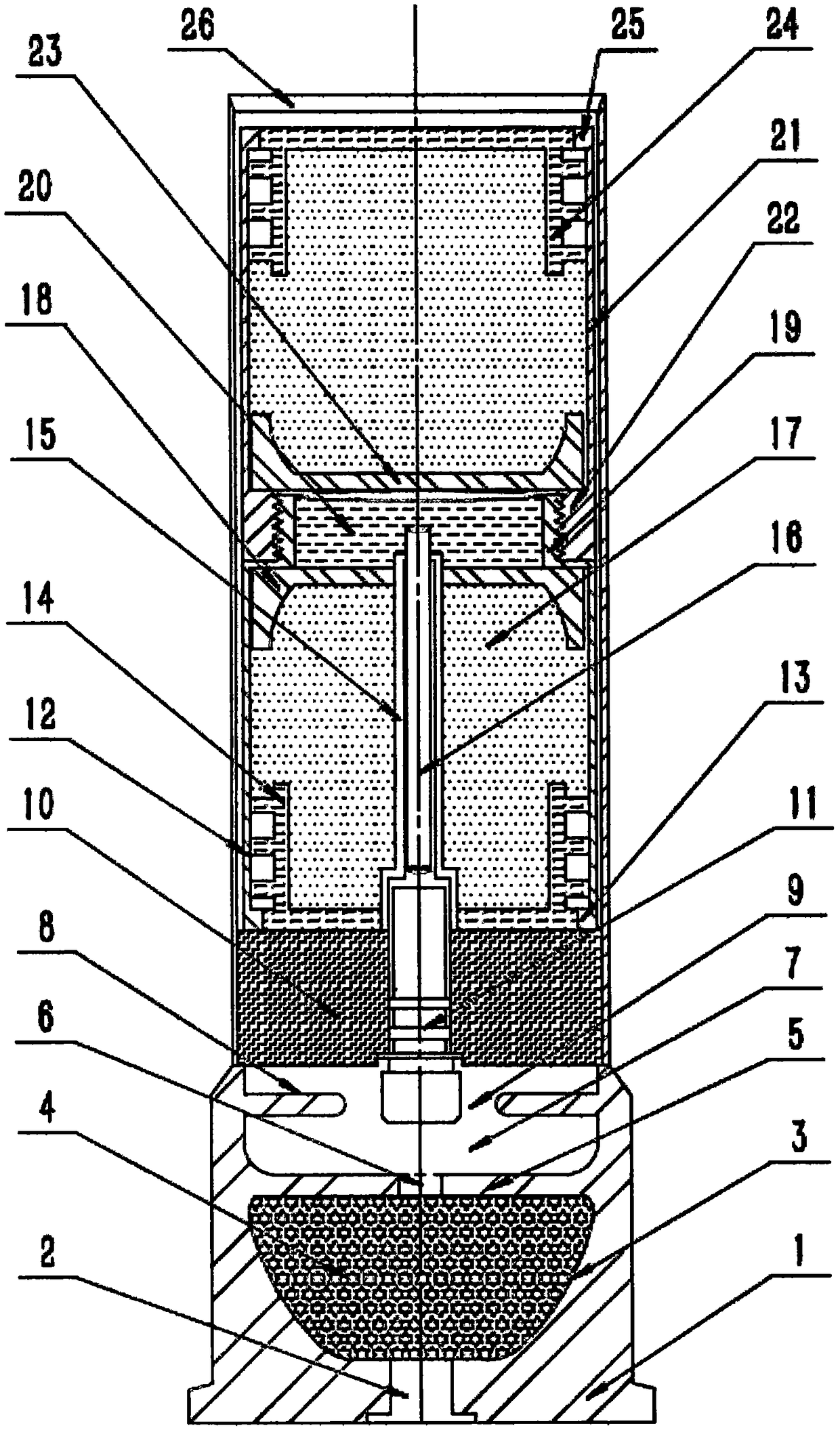

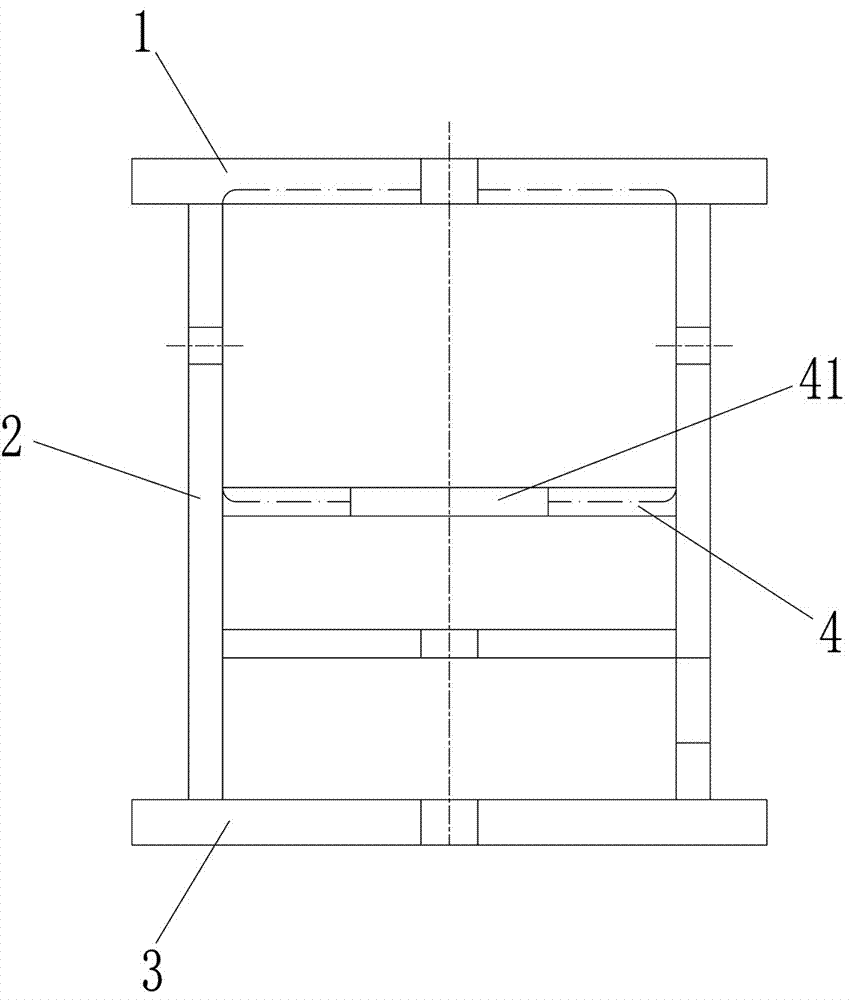

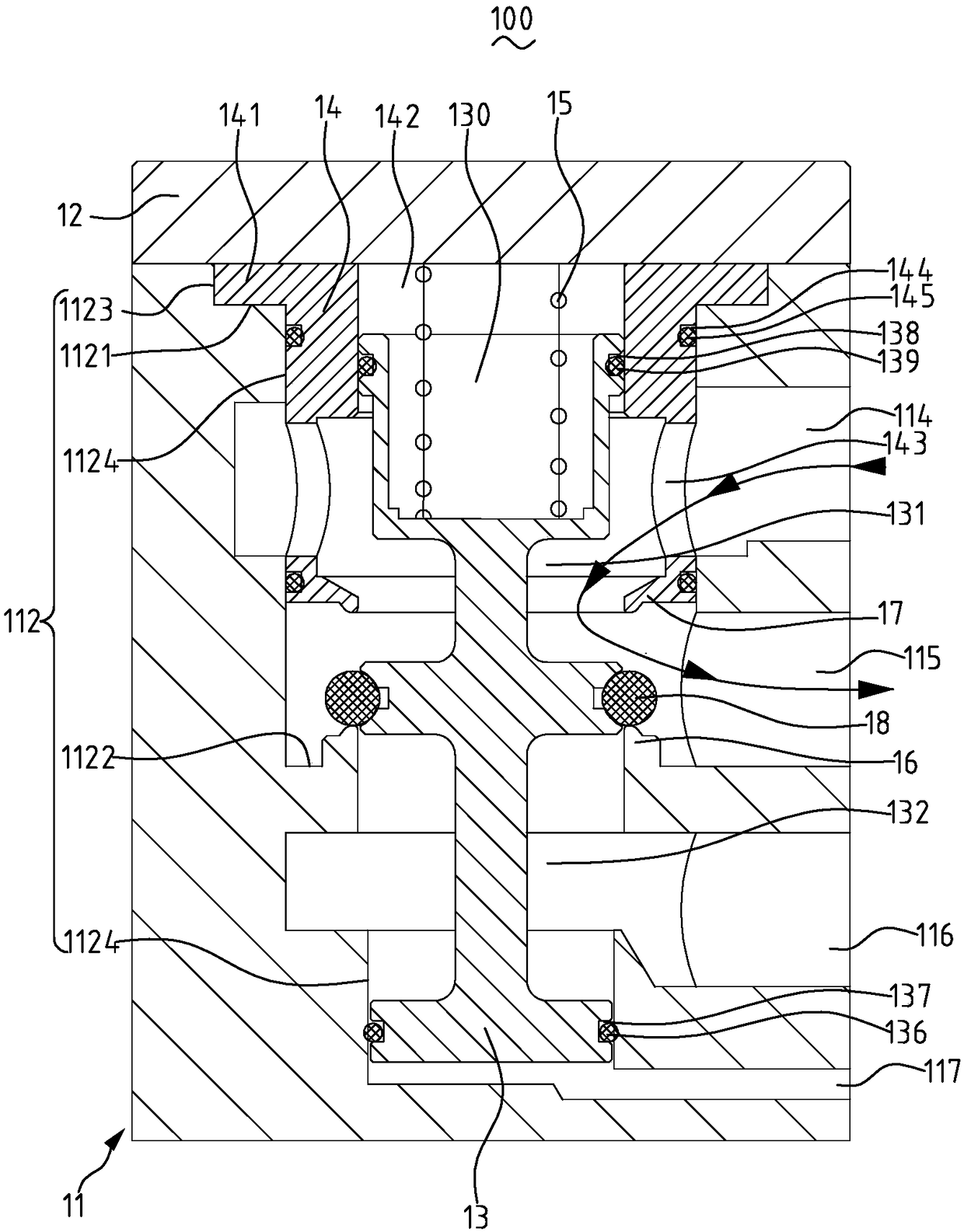

A medical semi-automatic urine metering storage device belongs to the technical field of medical devices. A box body 1 comprising a chamber divided into several urine storage chambers and an overflow chamber 14, a box cover 2 with a catheter interface seat 21 fixed with a catheter interface 211 above the box body 1 and on the box body 1 below is provided with the box bottom cover 3 of the discharge valve 4, the catheter interface seat 21 is located in the middle part of the box body 1, and the open position on the upper part of the catheter interface seat 21 is provided along the periphery of the catheter interface 211. Air film 212, catheter interface 211 is provided with check valve 2111; The diversion channel is provided with a discharge valve seat 37 with a discharge pipe 36 and a valve hole 35 in the middle of the box bottom cover 3; the discharge valve 4 is arranged in the valve hole 35. Advantages: Urine backflow can be prevented when the box body 1 is tilted or even lying down; the liquid can be drained smoothly when the drain valve 4 is opened; the catheter interface seat 21, the diversion channel, and the drain valve 4 are respectively arranged on the box cover 2 and the middle part of the box bottom cover 3, the box body 1 is not prone to deflection, which helps to ensure the accuracy of measurement.

Owner:常熟市神灵医用器材有限公司

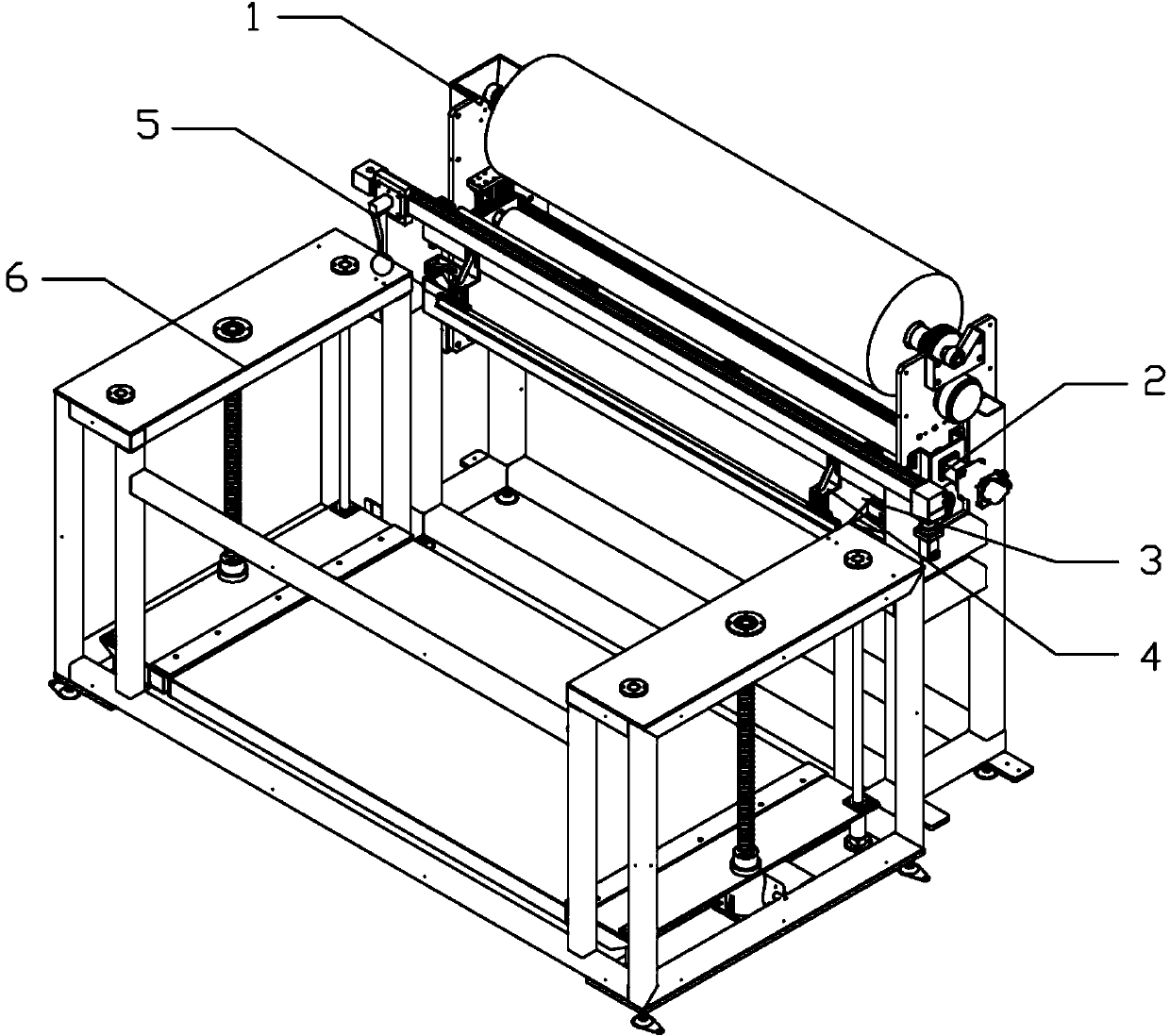

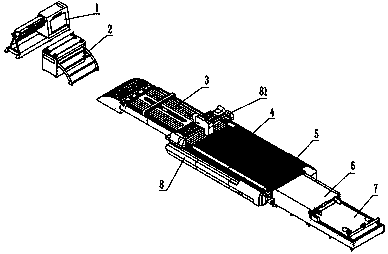

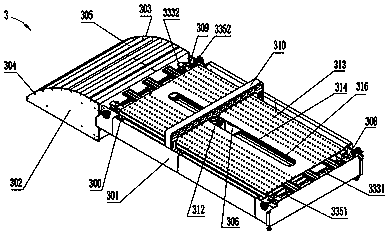

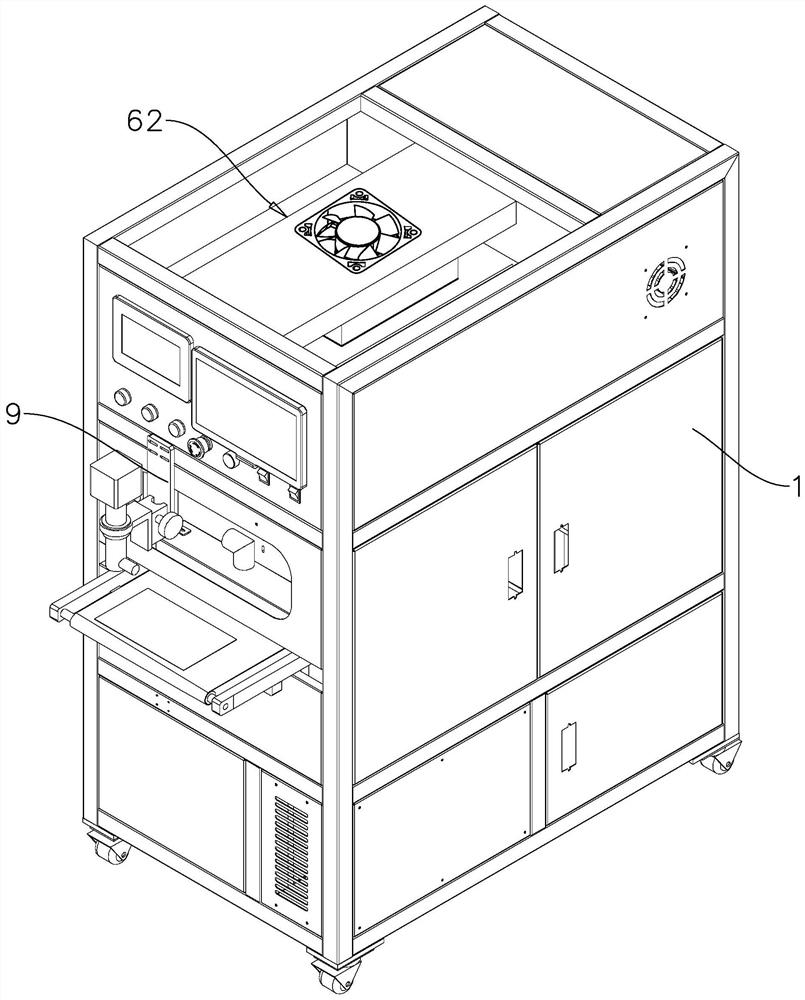

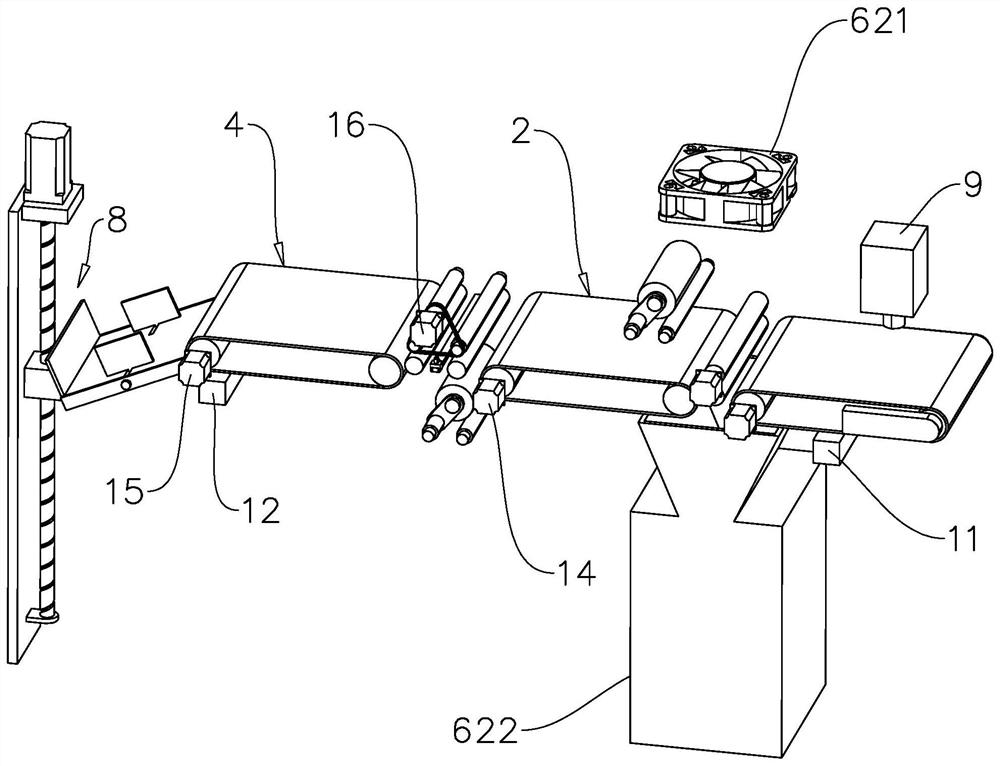

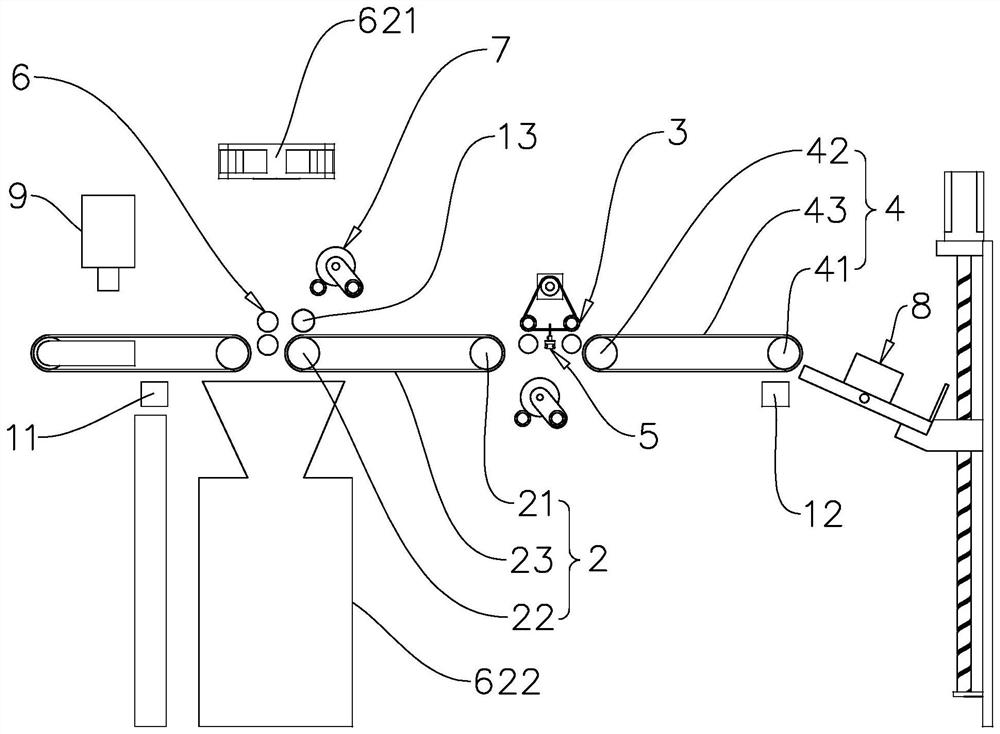

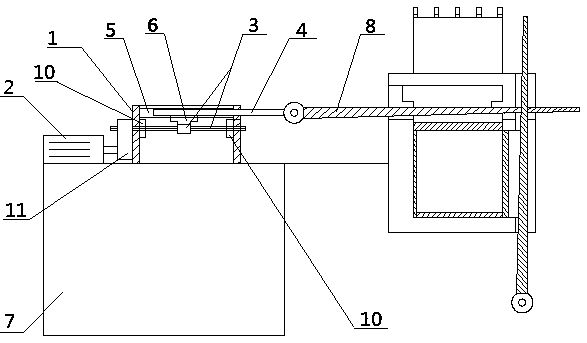

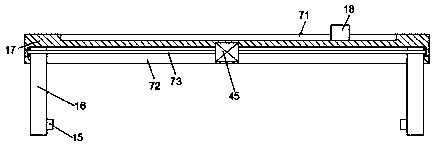

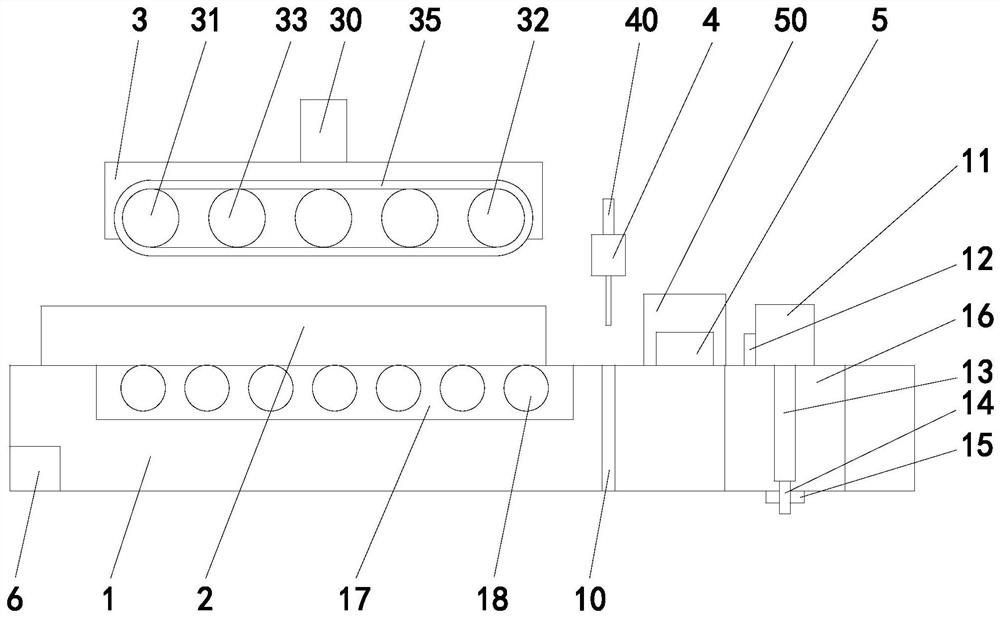

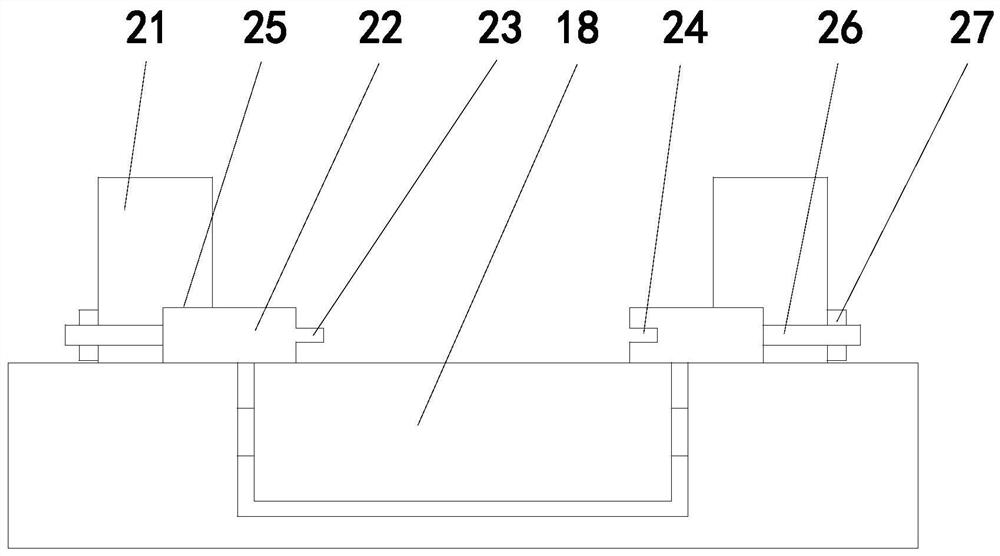

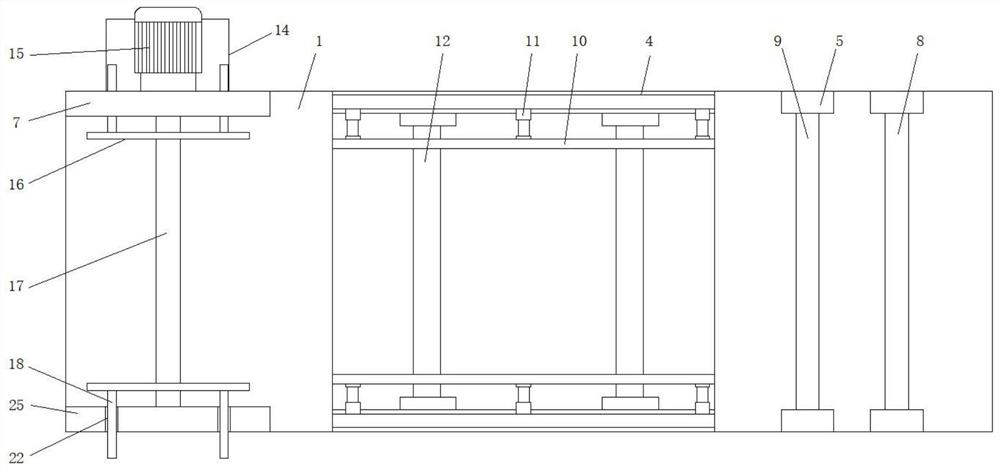

Automatic paper paving machine

ActiveCN103387071AGood compression effectLess prone to deflectionPackagingArticle deliveryPulp and paper industryPaper sheet

The invention relates to an automatic paper paving machine, comprising an unreeling mechanism and a paper conveying mechanism, wherein the output end of the unreeling mechanism is connected with the paper conveying mechanism; the output end of the paper conveying mechanism is connected with a lifting platform; a blowing mechanism is arranged at the output end of the paper conveying mechanism; a paper cutting mechanism is arranged above the blowing mechanism; the paper conveying mechanism comprises a paper sheet thickness adjusting device. According to the automatic paper paving machine with the structure, a drive roller and a driven roller in the paper conveying mechanism are good in a pressing effect, paper sheets conveyed are flat and do not easily deflect, the paper paving precision is high, the driven roller and the drive roller can automatically adapt to the paper sheets with different thickness through a spring, and the universality is strong; the lifting platform is integrated with the paper conveying mechanism, the space is greatly saved, the blowing mechanism is used for assisting in conveying the paper sheets and preventing the paper sheets from flying up or stopping; a paper knife in the paper cutting mechanism is circular, the cutting is very rapid, and the cutting edge of the paper knife is lower than the surfaces of the paper sheets, so that two edges of the paper sheets can be completely cut off.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

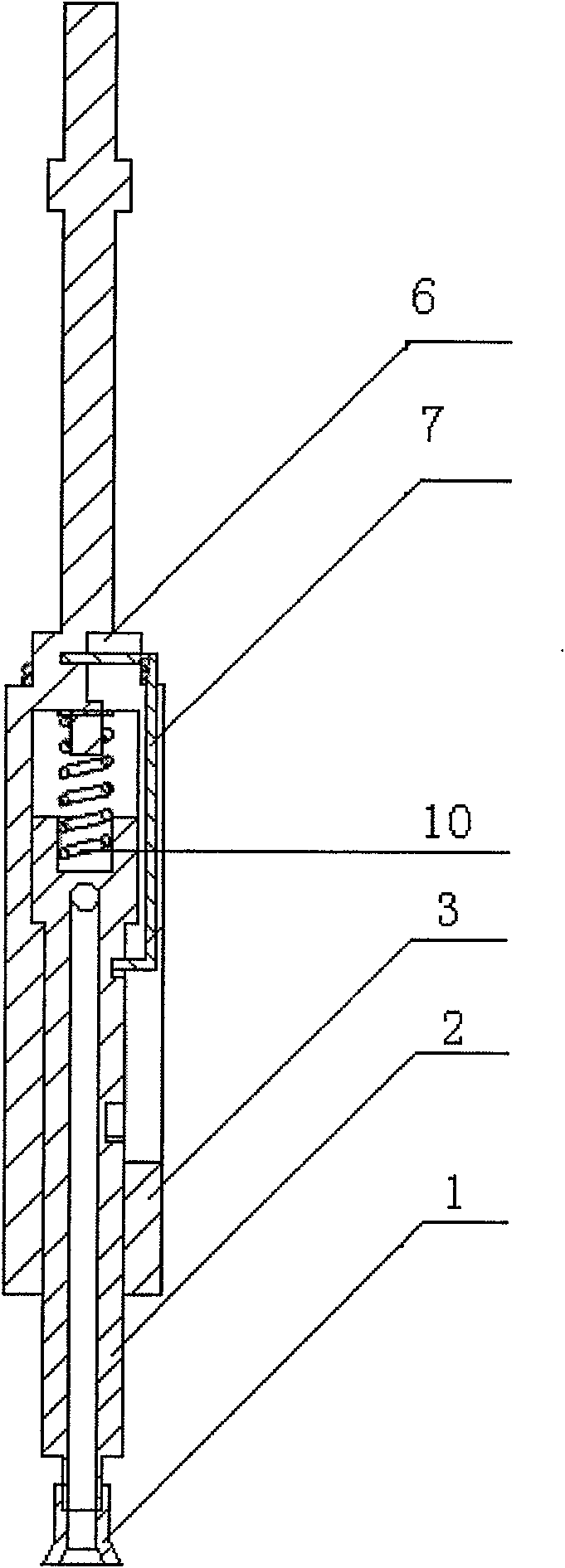

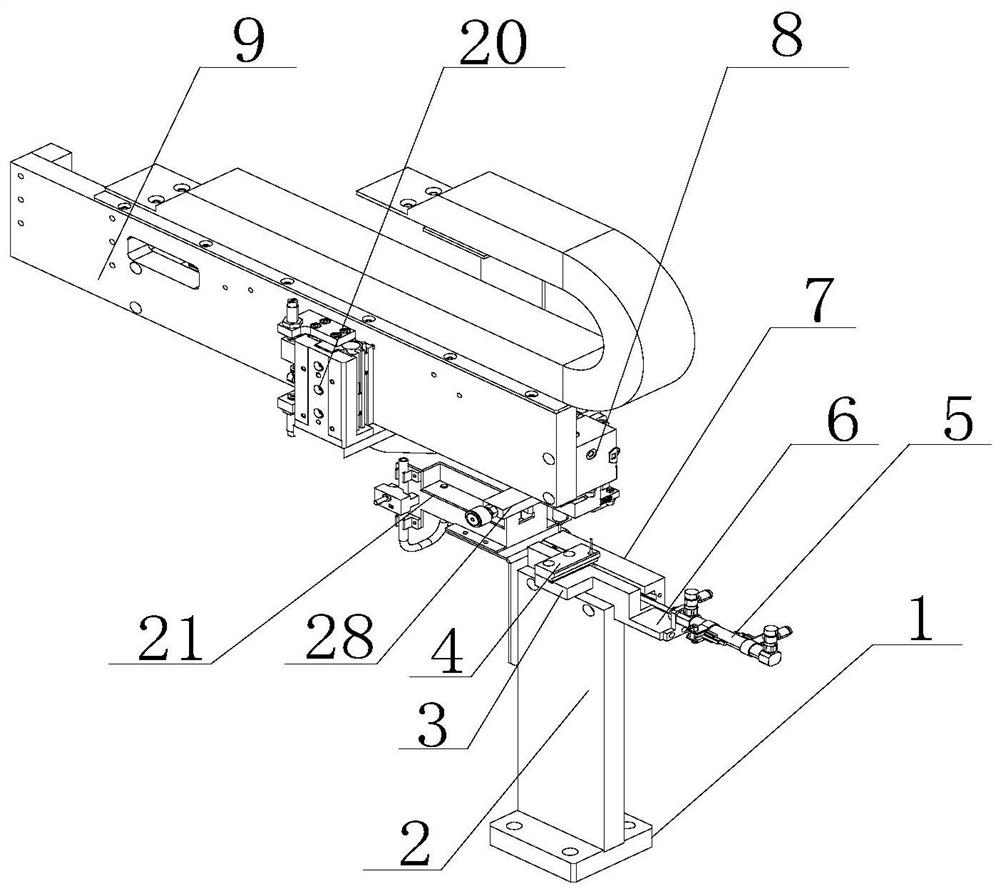

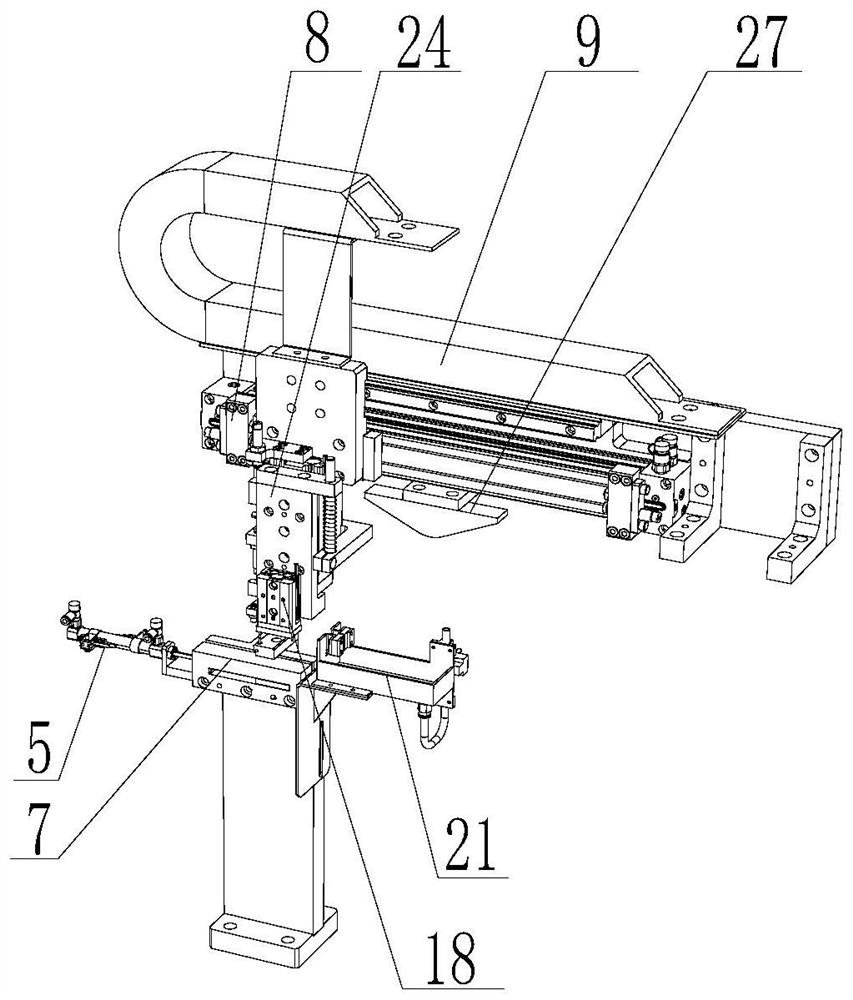

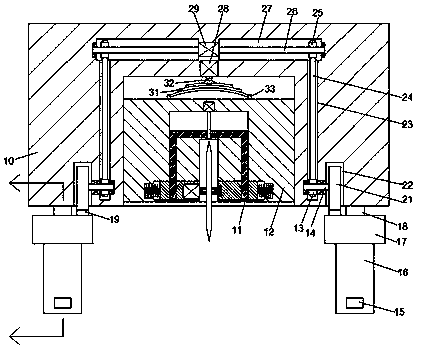

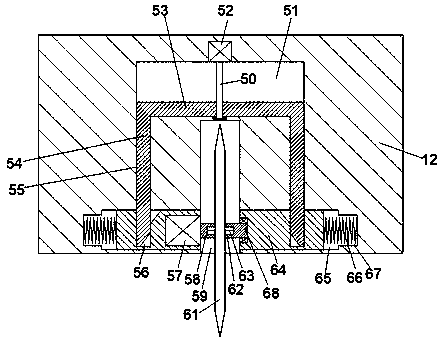

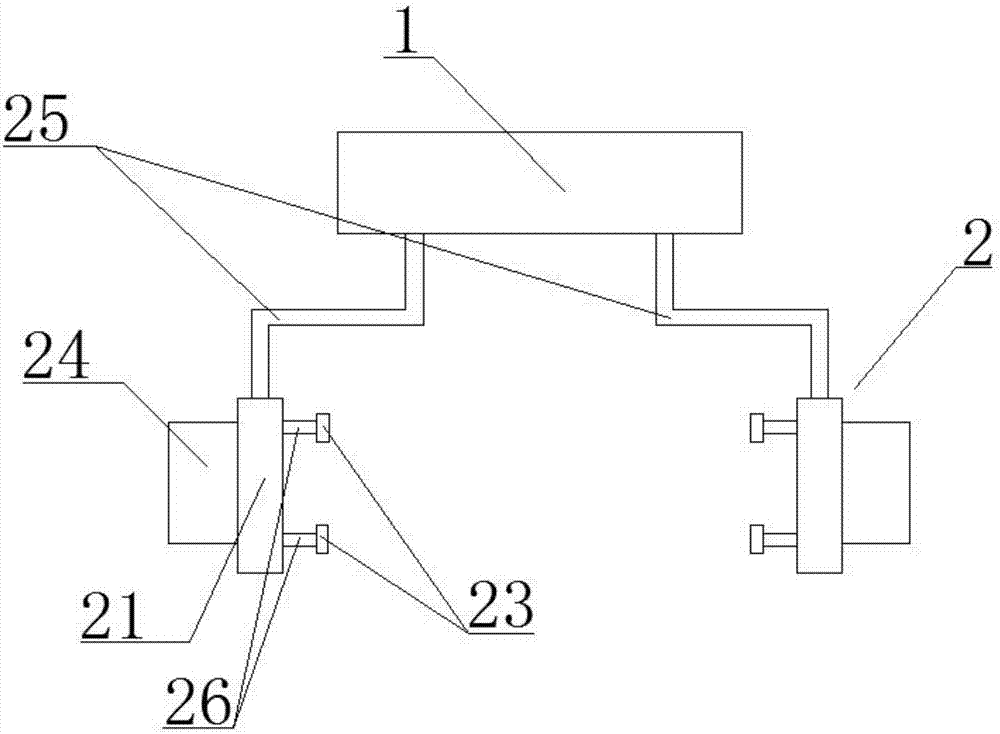

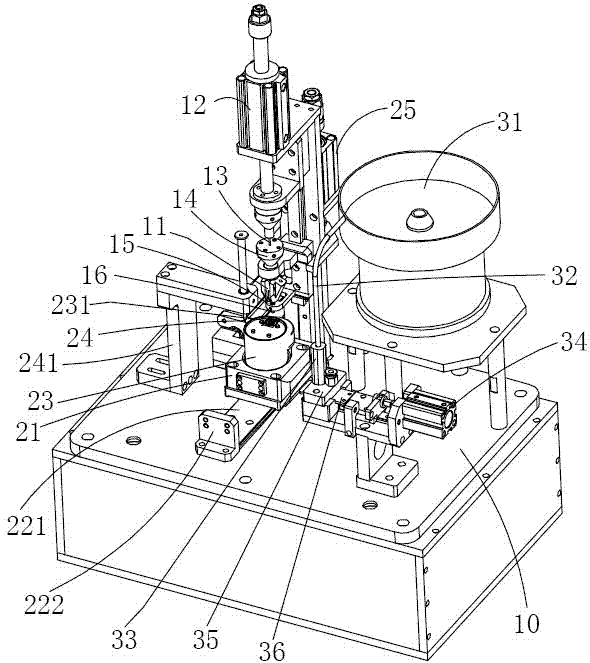

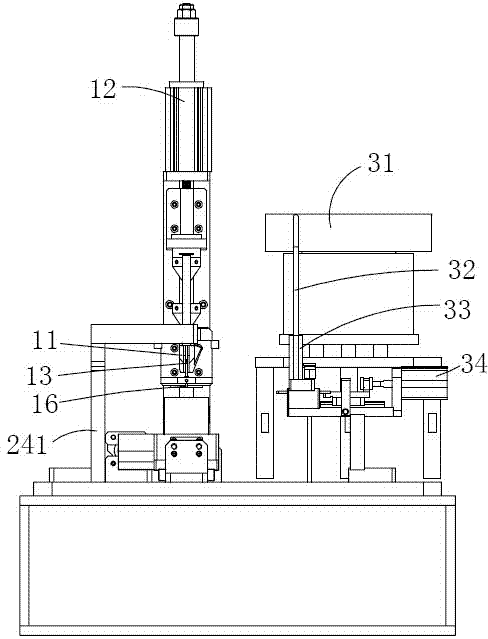

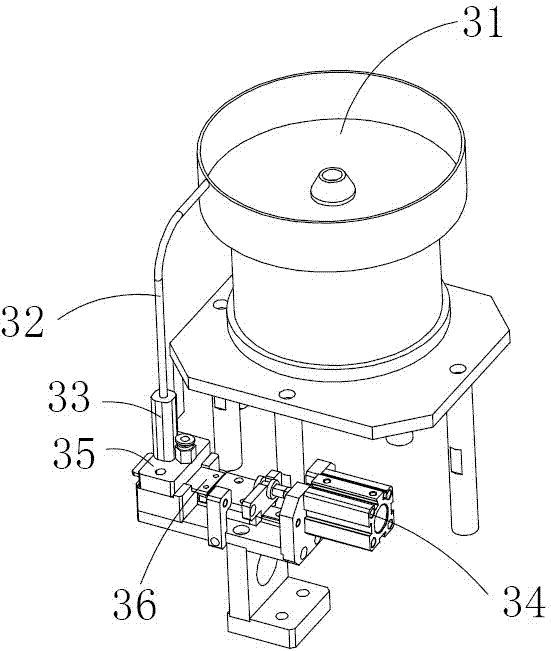

Device for taking and placing chaton automatically

InactiveCN101590643AFor precise pick and placeRealize continuous pick and placeGripping headsGearingBiomedical engineering

Owner:ZHEJIANG UNIV

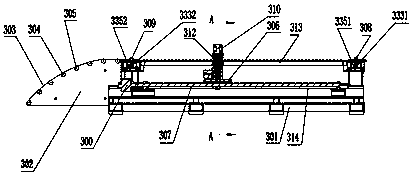

Laser cutting device

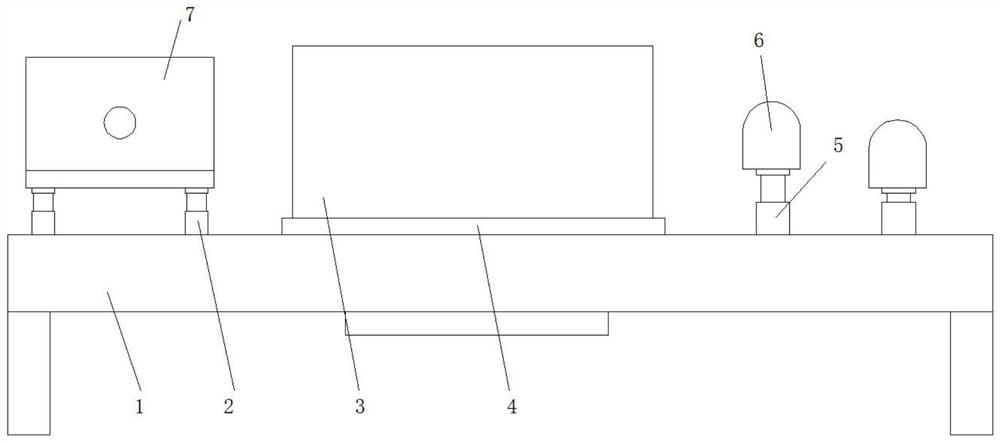

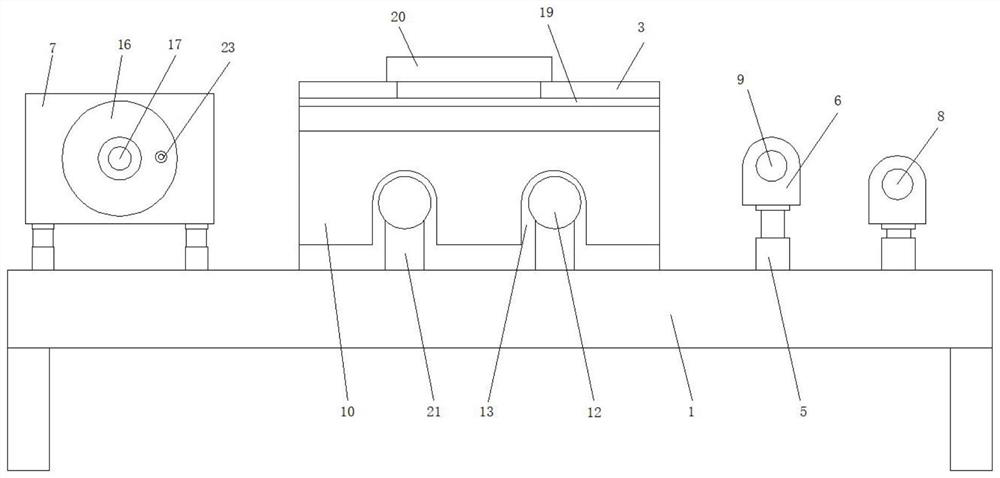

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

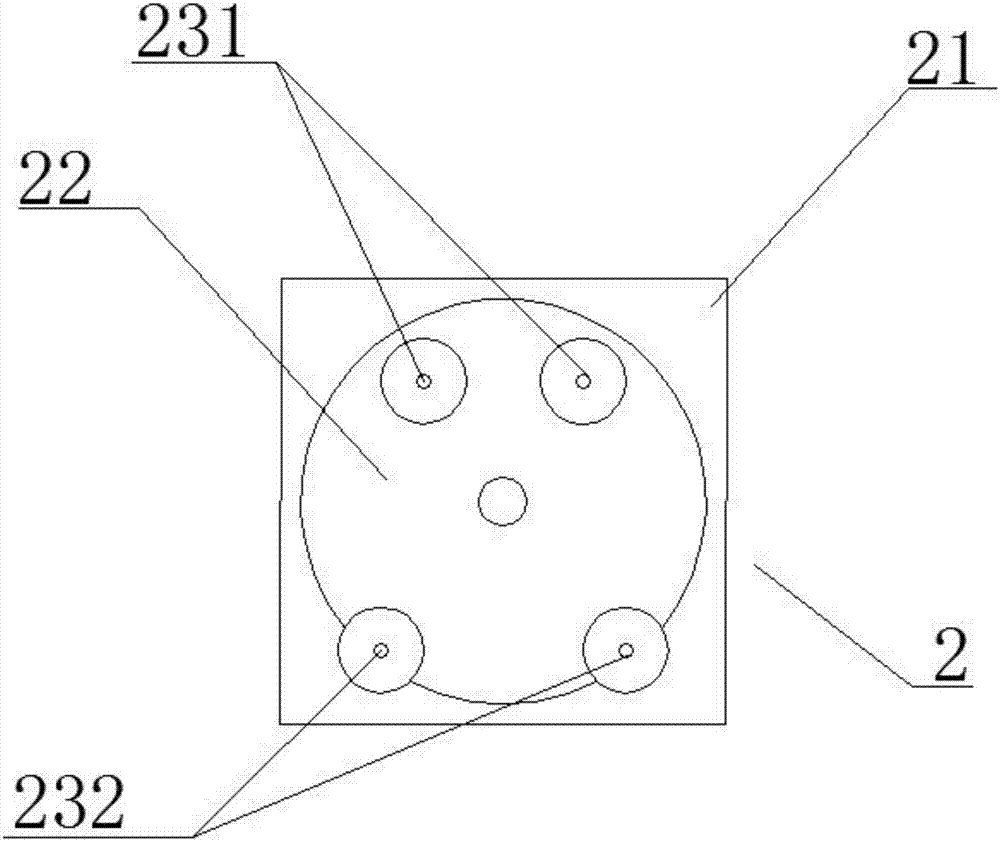

Porous clamping device capable of automatically centering and drilling long-thin steel-sheet type parts

ActiveCN102950312ANot easy to deflectLess prone to deflectionPositioning apparatusMetal-working holdersIsosceles trapezoidPunching

A porous clamp device capable of automatically centering and drilling long-thin steel-sheet type parts relates to a porous centering and drilling clamp device for long-thin steel sheets, and solves the problem that a porous processing mold for the long-thin steel sheets is complex in structure, long in processing period, high in cost, low in punching accuracy and the like. A claw and a sliding top block are slidingly matched with two first sliding chutes on a base, two nuts are arranged in two second sliding chutes on the base and slidingly matched with the second sliding chutes and fixed with the claw and the sliding top block, a stop plate is arranged on the claw which is detachably connected with a slide plate, an inverted isosceles trapezoid groove and a long groove for storing drilling parts are formed between the claw and the sliding top block, a mold is inverted in the isosceles trapezoid groove, a fastening screw leans on the mold, a drill bushing is inlaid in a drilling bushing hole of the mold, a positioning block of a screw rod is arranged in a screw rod support seat on the base, and two ends of the screw rod are connected with the two nuts in a threaded manner. The porous clamp device is used for clamping and fixing in drilling of the long-thin steel-sheet type parts.

Owner:HARBIN JIANCHENG GRP

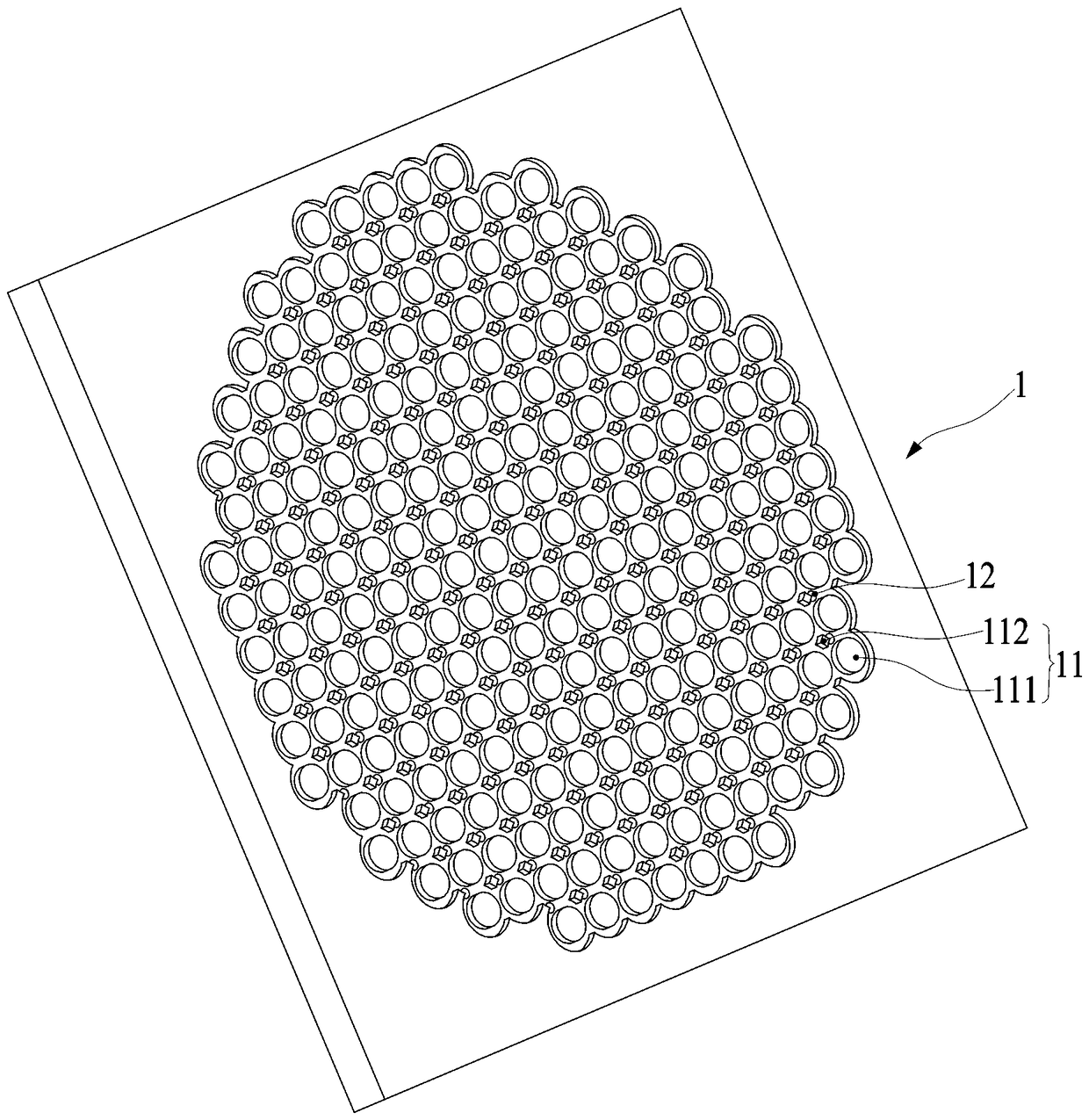

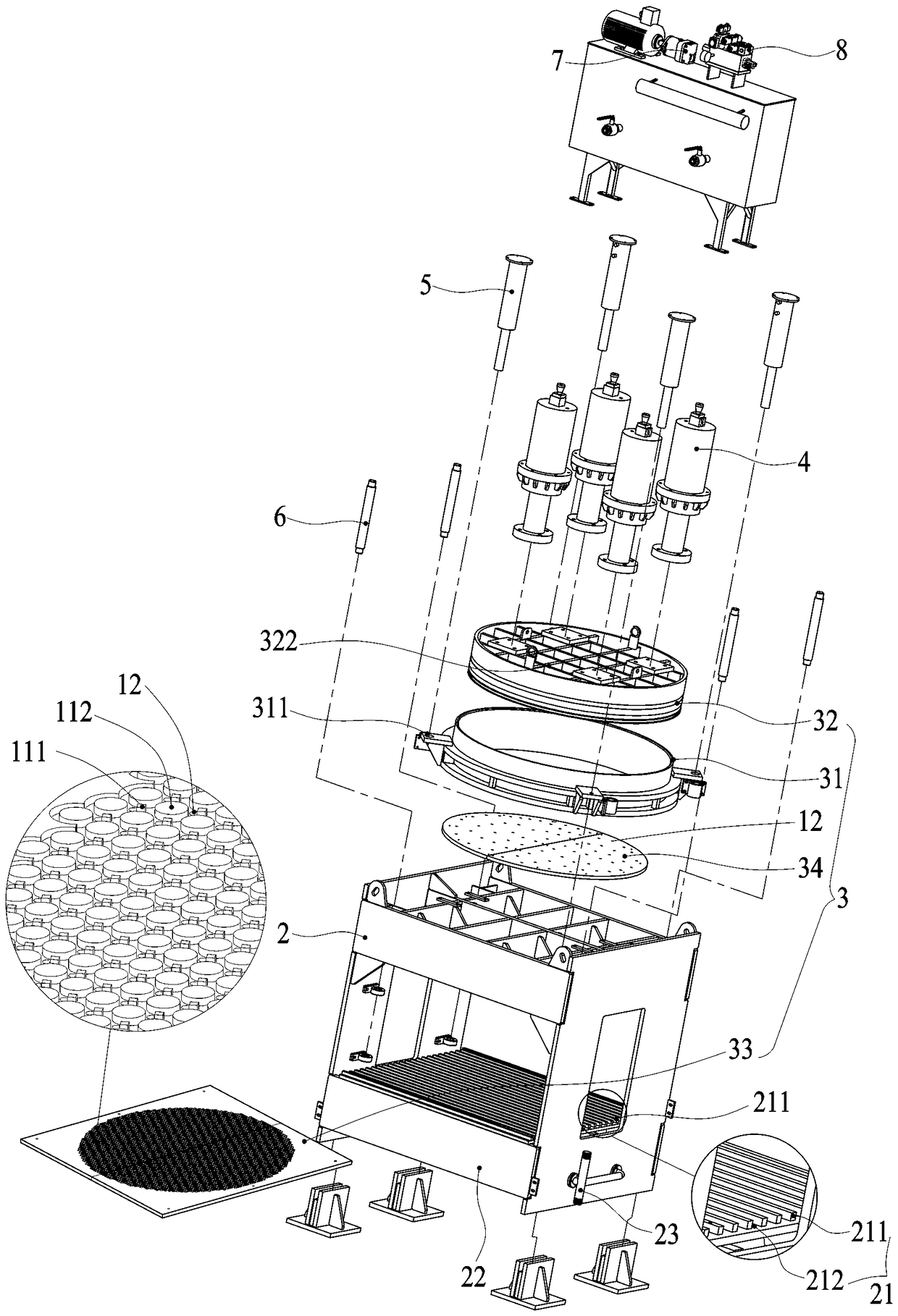

Filter plate and high-pressure piston type solid-liquid separation device made of same

PendingCN108859213AIncrease contact areaIncrease the number ofSludge treatment by de-watering/drying/thickeningPressesControl systemEngineering

The invention discloses a filter plate and high-pressure piston type solid-liquid separation device made of the same. Vertical and horizontal staggered projecting particles are arranged on the surfaceof the filter plate facing filtered objects, and water passing through holes penetrate the filter plate and are formed among the projecting particles. The high-pressure piston type solid-liquid separation device comprises a frame, a filter component, a piston oil cylinder, a lifting oil cylinder, a guide rod, an oil pump and a control system, the lifting oil cylinder drives a filter cylinder to vertically move along the guide rod, the piston oil cylinder drives a piston to vertically move along the filter cylinder, a first filter plate body and a second filter plate body are provided with thefilter plate, and the projecting particle surfaces of the first filter plate body and a second filter plate body are oppositely arranged. By the aid of the scheme, the extruding surface of the filterplate is provided with point-like distributed projecting particles, the contact areas among the filter plate and the filtered objects are greatly increased, more moisture can be extruded by the filter plate under the same extruding force, and solid-liquid separation effects are good.

Owner:厦门厦工重工有限公司

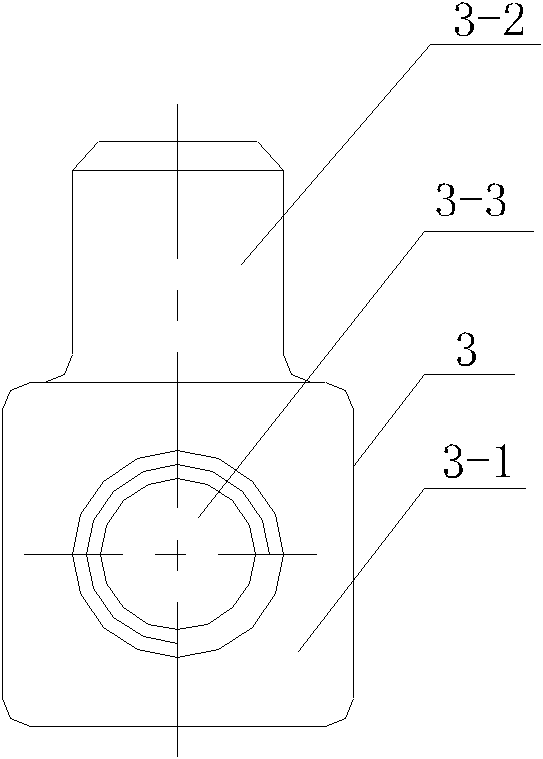

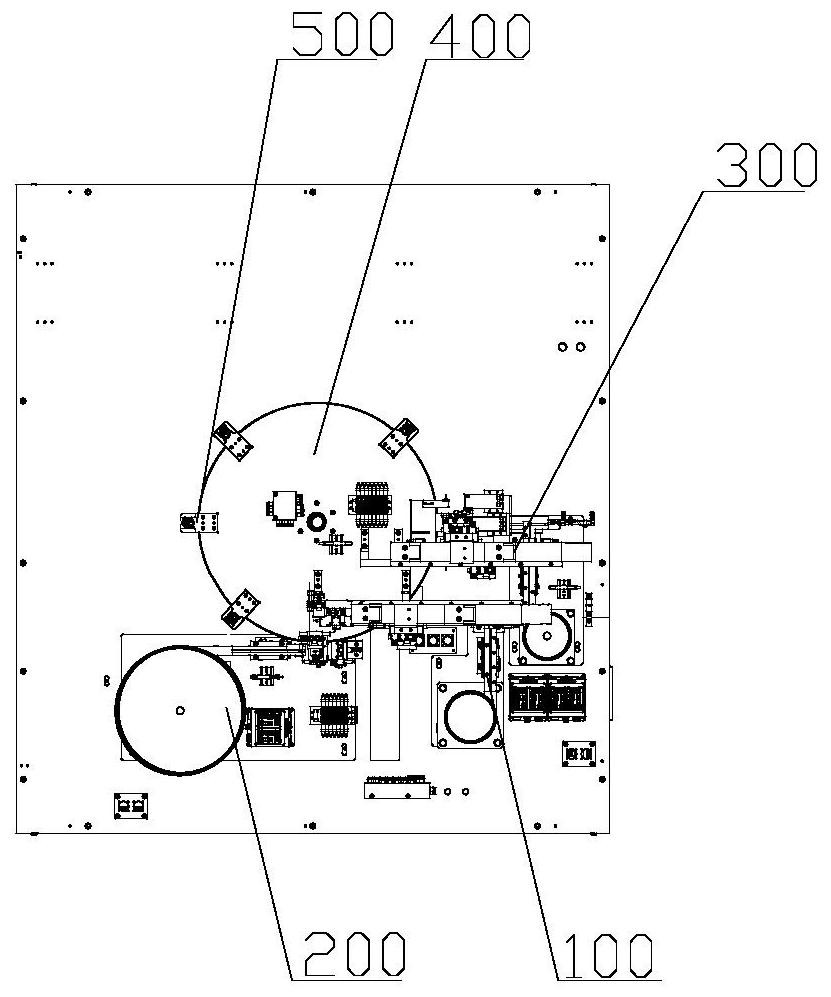

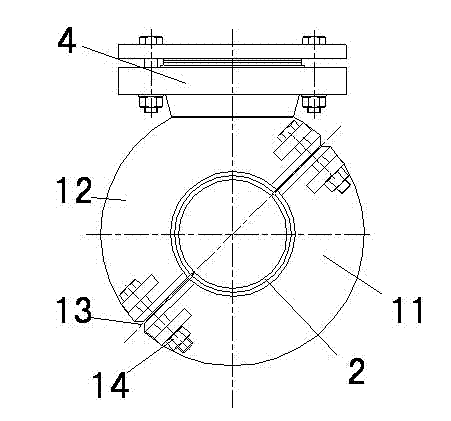

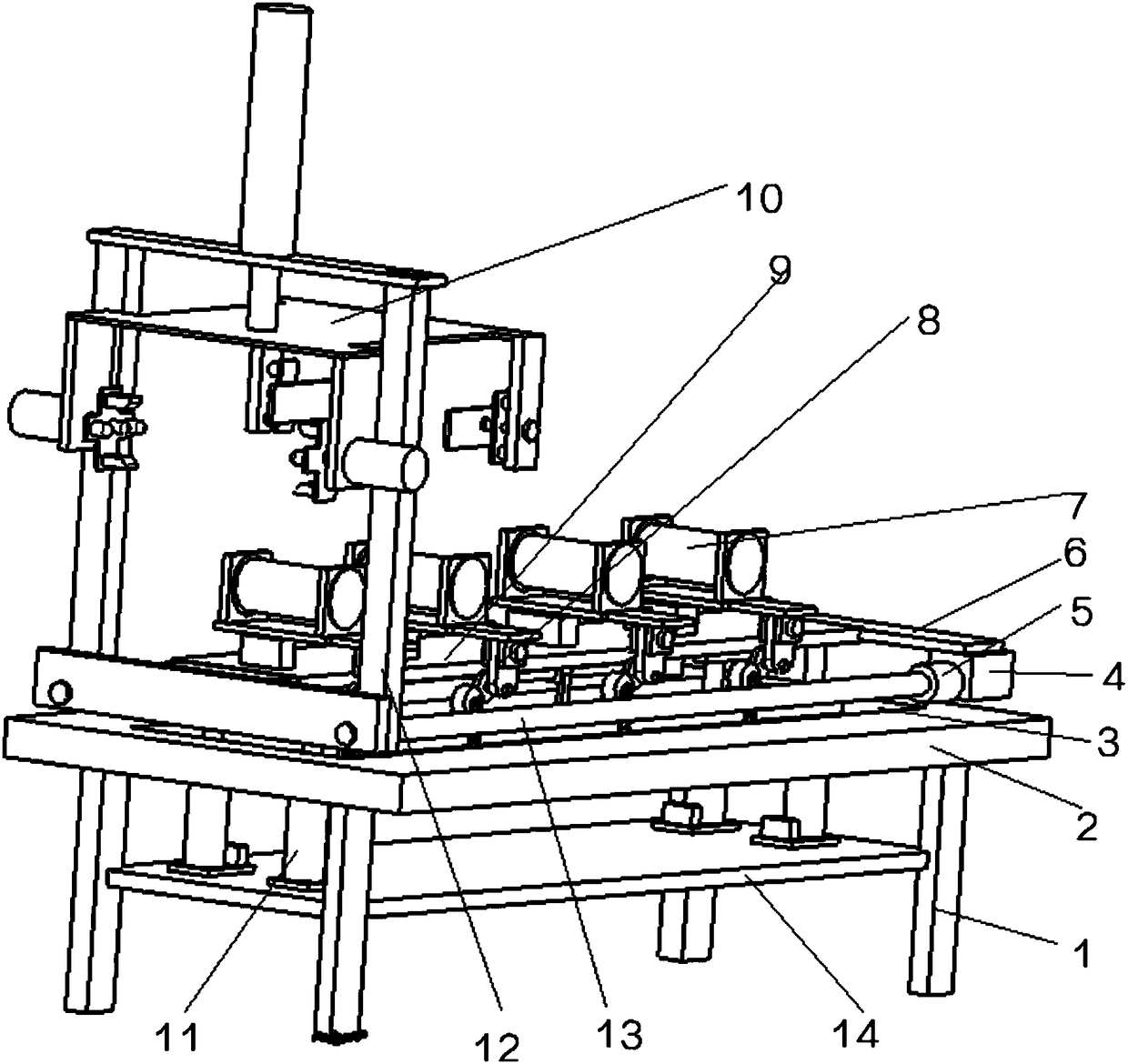

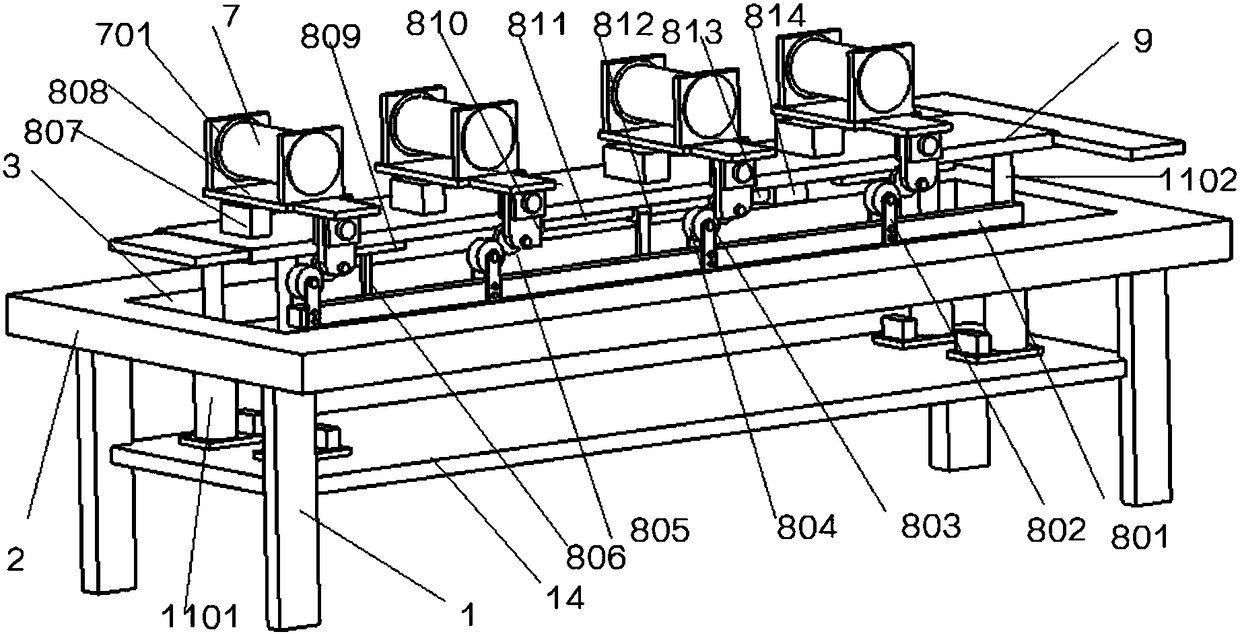

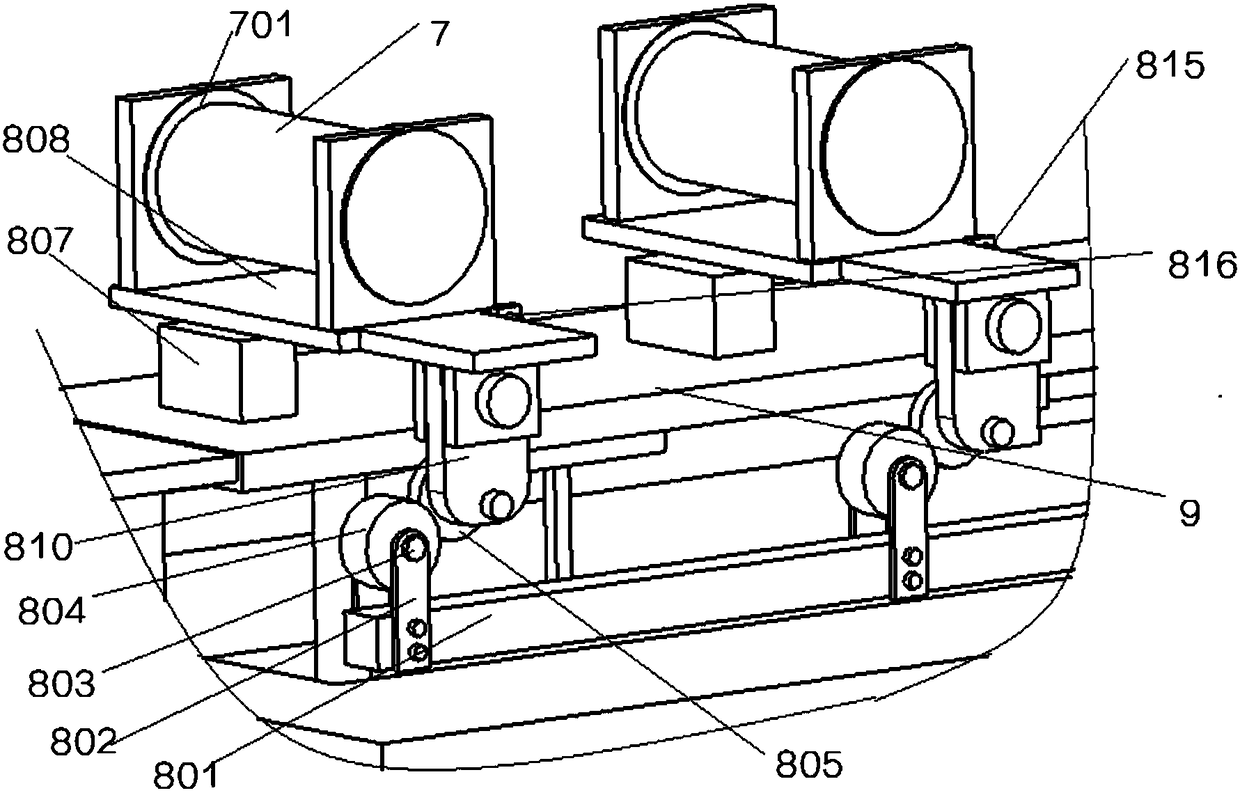

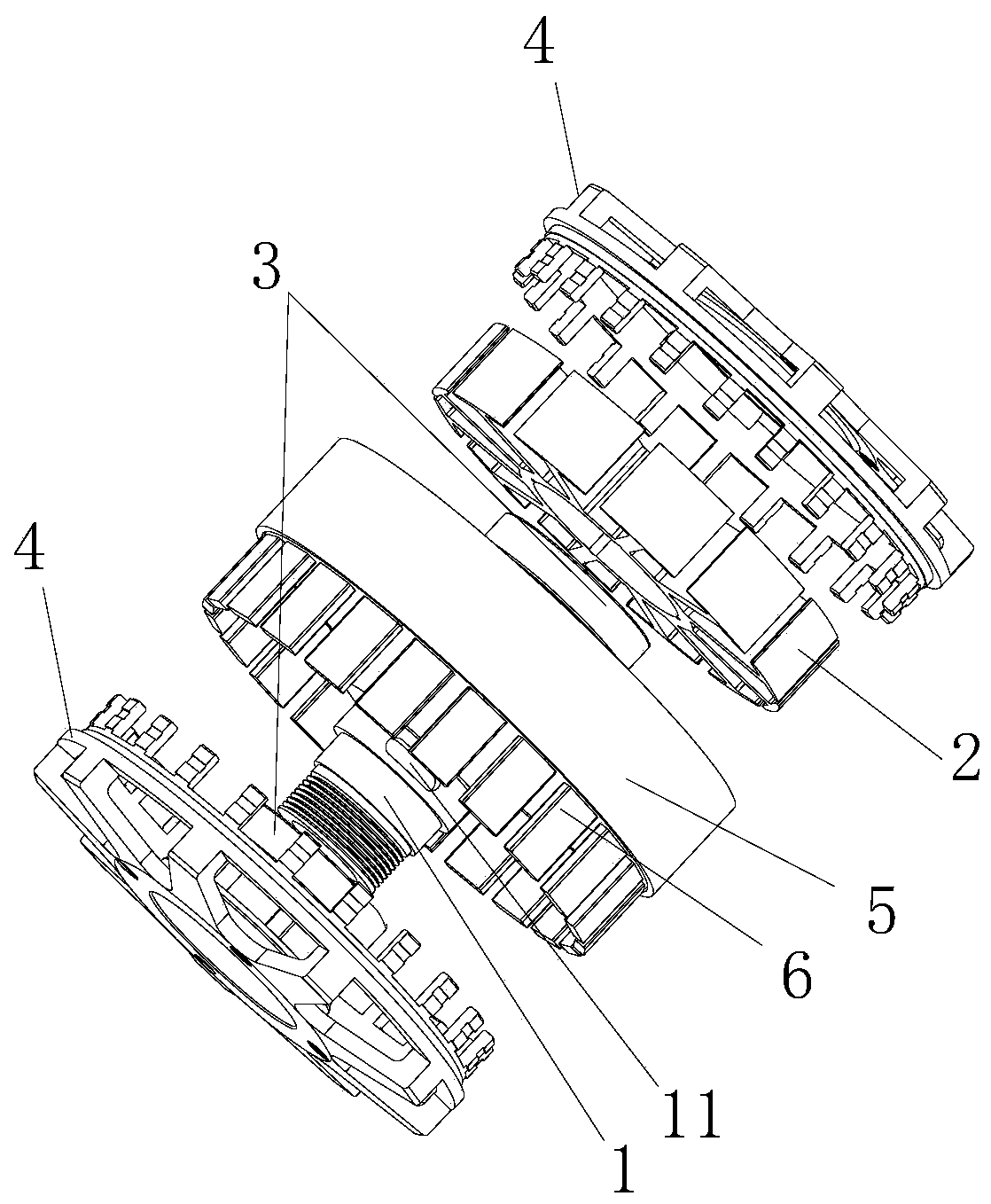

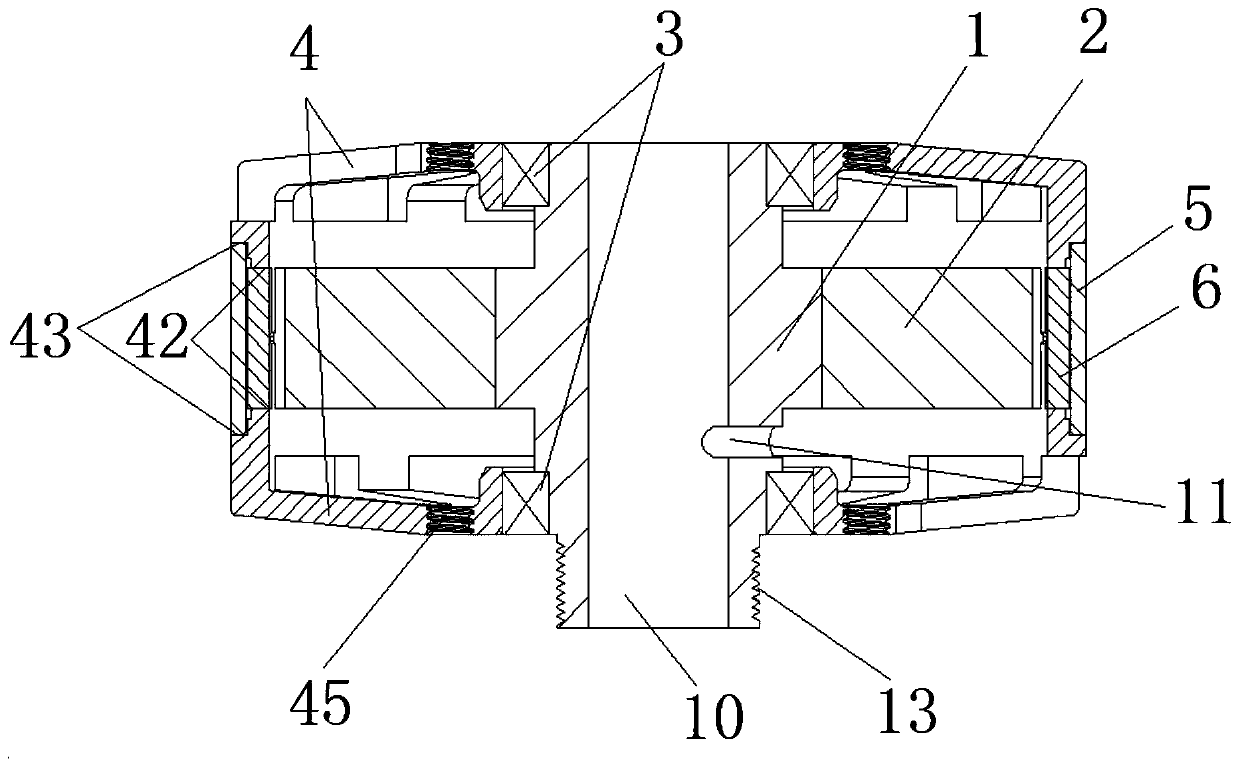

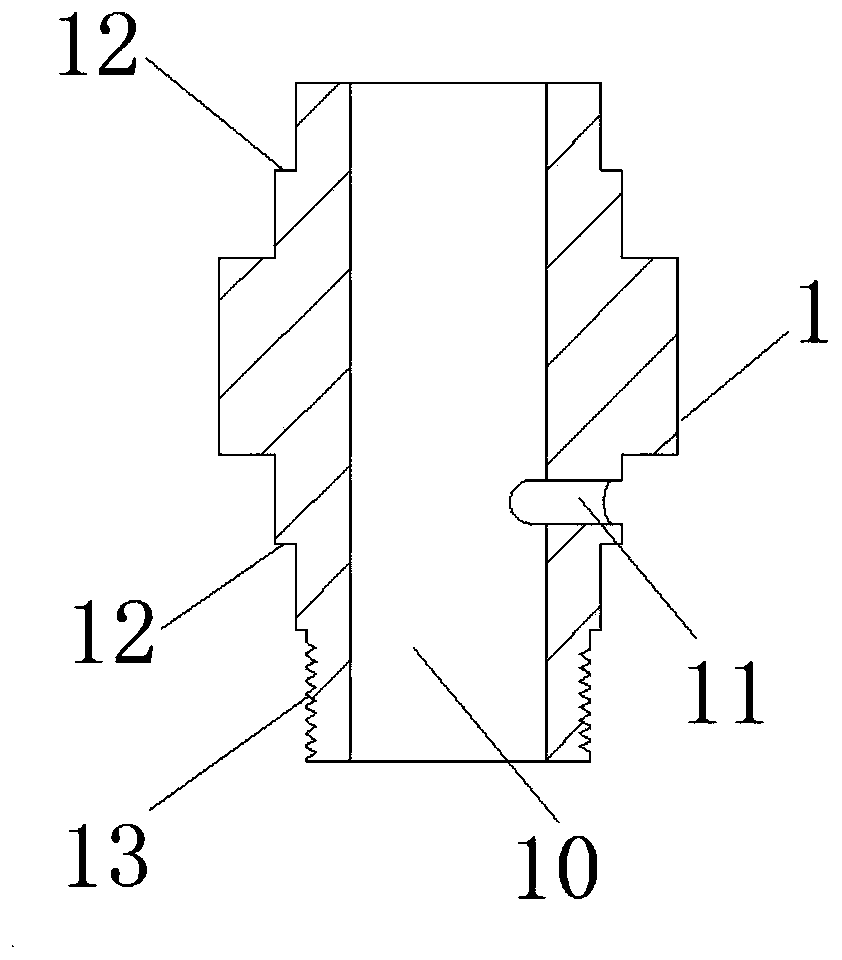

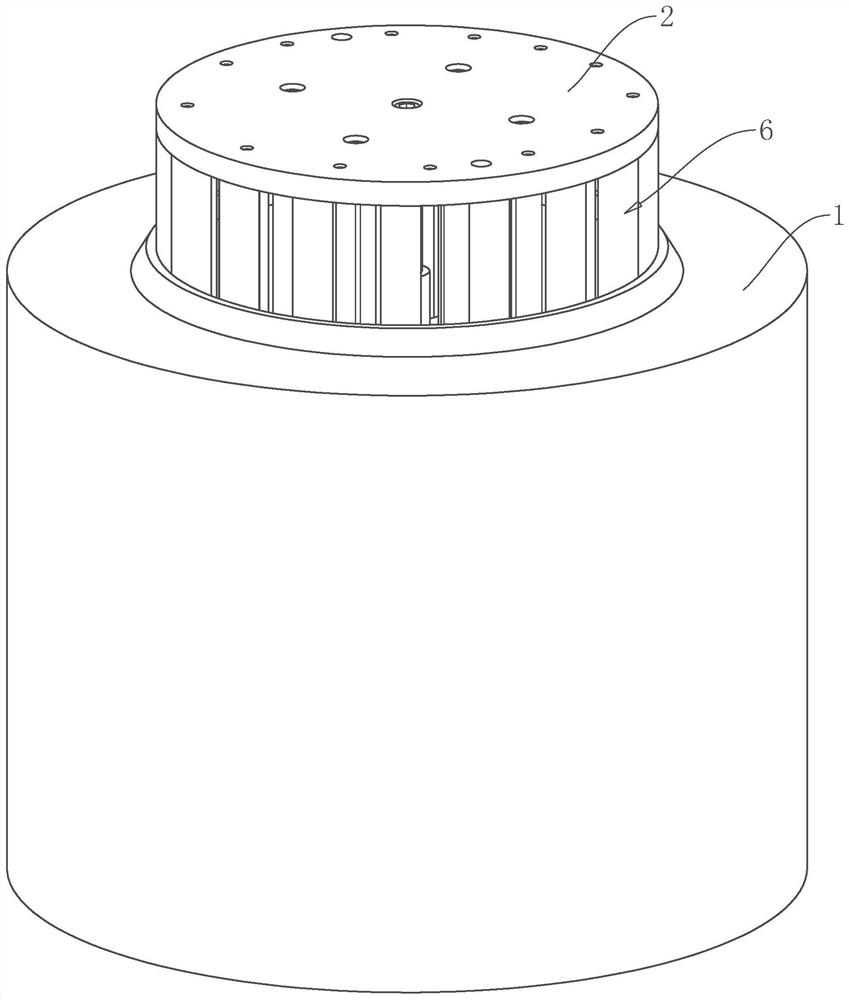

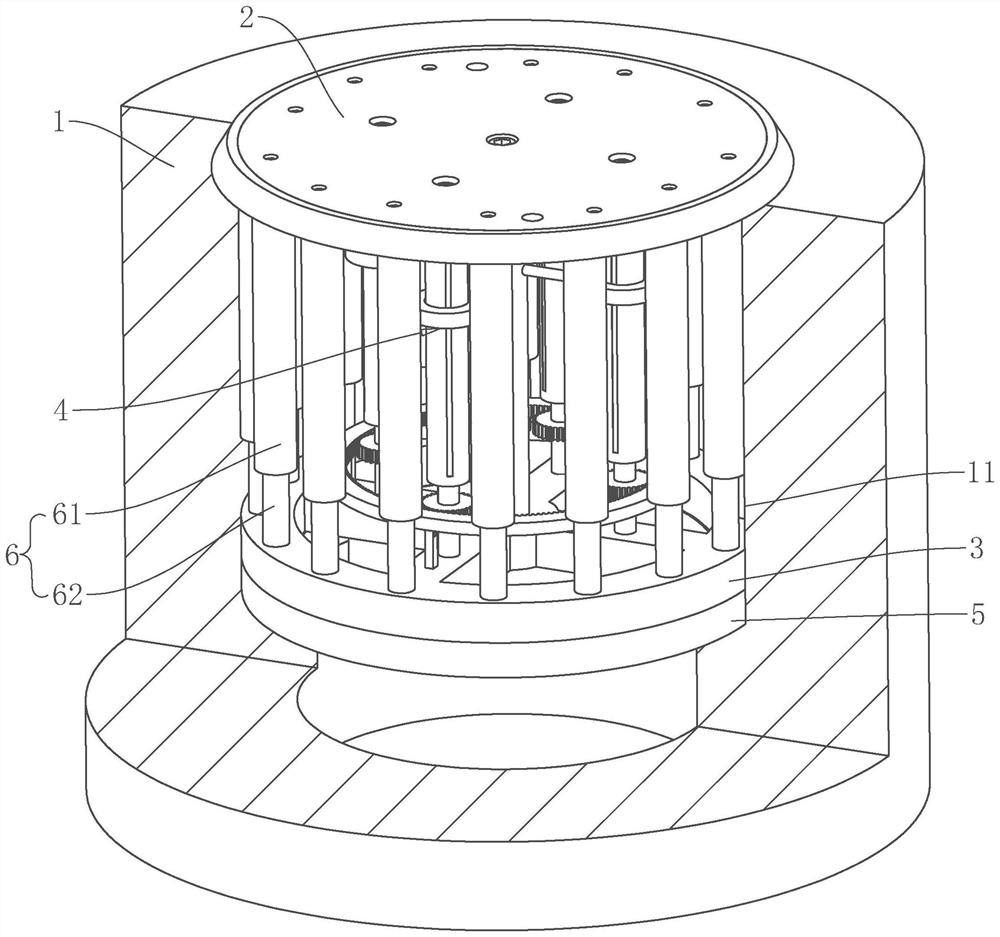

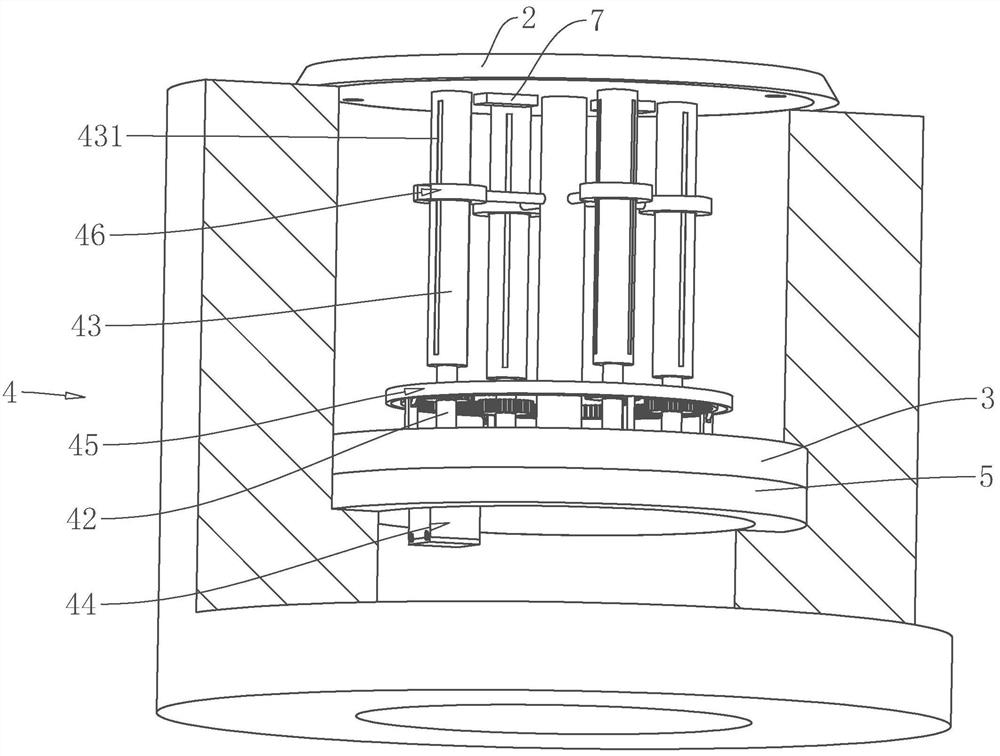

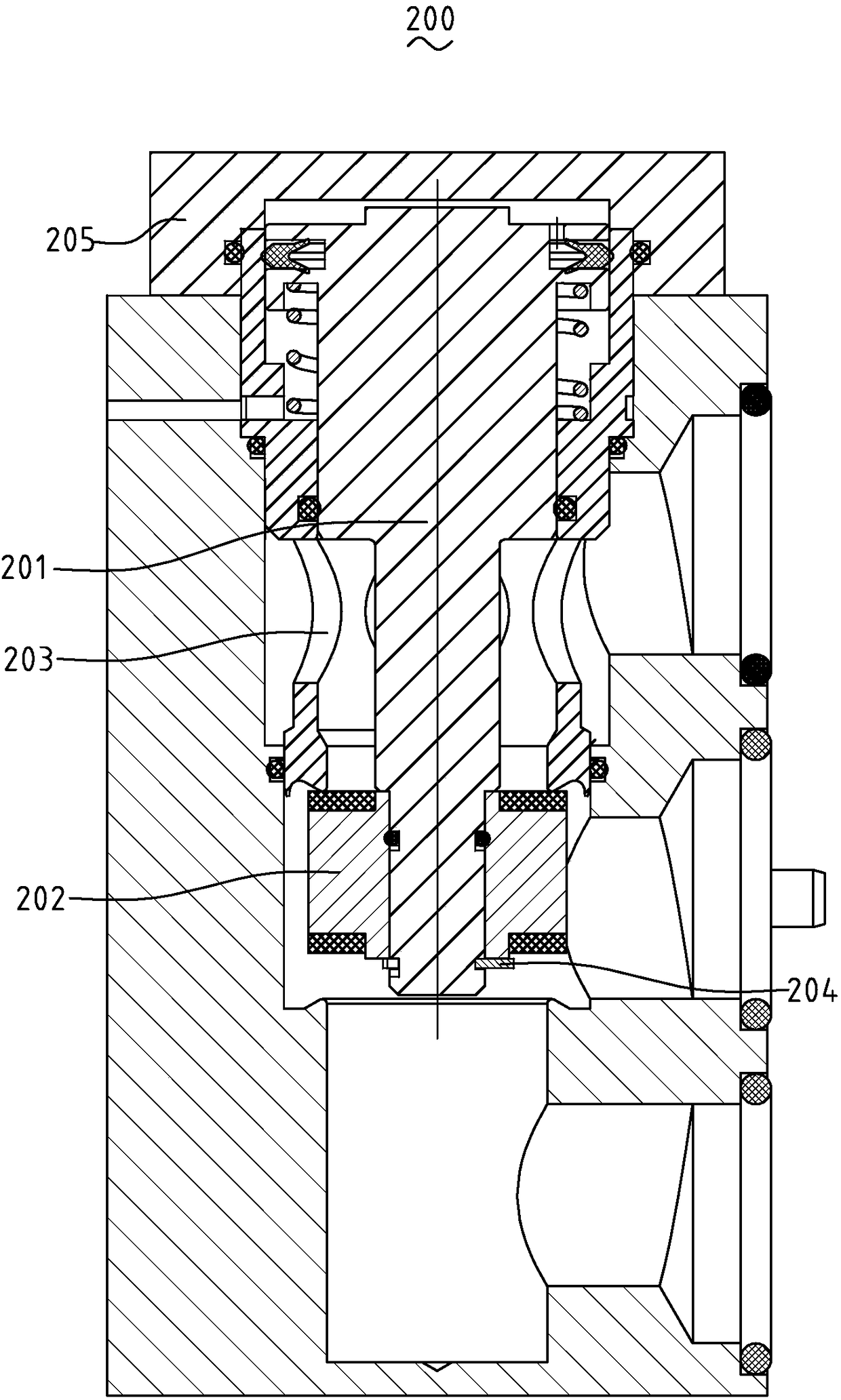

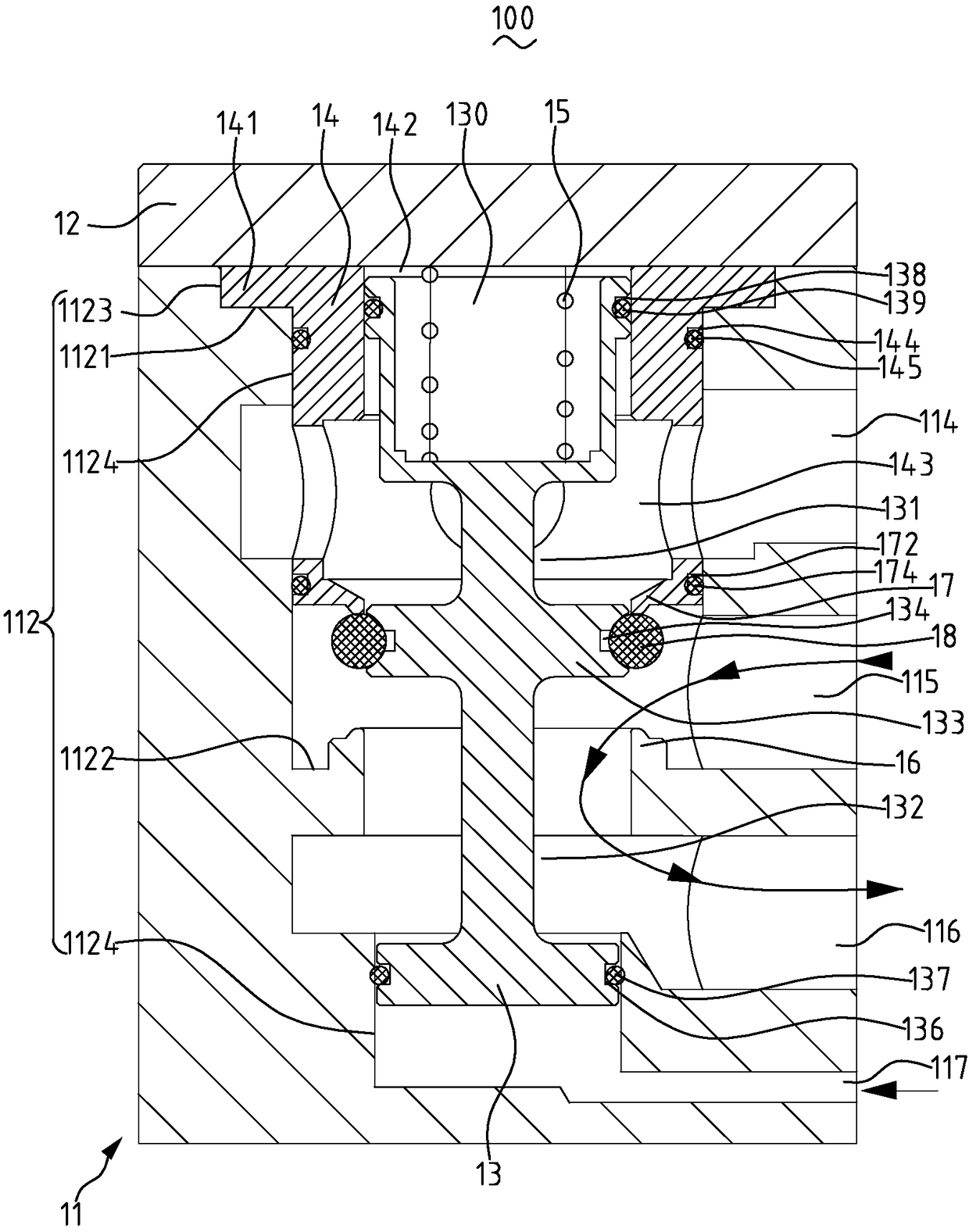

Internet of Things intelligent gas meter speed reducer output end installation system and method

PendingCN113492314ARealize automated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusReduction driveControl engineering

The invention discloses an Internet of Things intelligent gas meter speed reducer output end installation system which comprises an index plate, the index plate can rotate clockwise around the axis of the index plate, and a plurality of clamps used for containing a speed reducer shell are further arranged on the index plate. The system further comprises a movable sealing ring assembling mechanism, a movable sealing ring plug assembling mechanism and a swing frame assembly assembling mechanism. The movable sealing ring assembling mechanism is used for assembling a movable sealing ring into the speed reducer shell. The movable sealing ring plug assembling mechanism is used for assembling a movable sealing ring plug into the speed reducer shell provided with the movable sealing ring. The swing frame assembly assembling mechanism is used for assembling a swing frame assembly into the speed reducer shell provided with the movable sealing ring plug, and the movable sealing ring assembling mechanism, the movable sealing ring plug assembling mechanism and the swing frame assembly assembling mechanism are sequentially distributed on the circumferential face of the index plate in the rotating direction of the index plate. According to the Internet of Things intelligent gas meter speed reducer output end installation system, automatic assembly of the output end of a speed reducer can be achieved, and the assembly efficiency and the assembly quality of the speed reducer are improved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

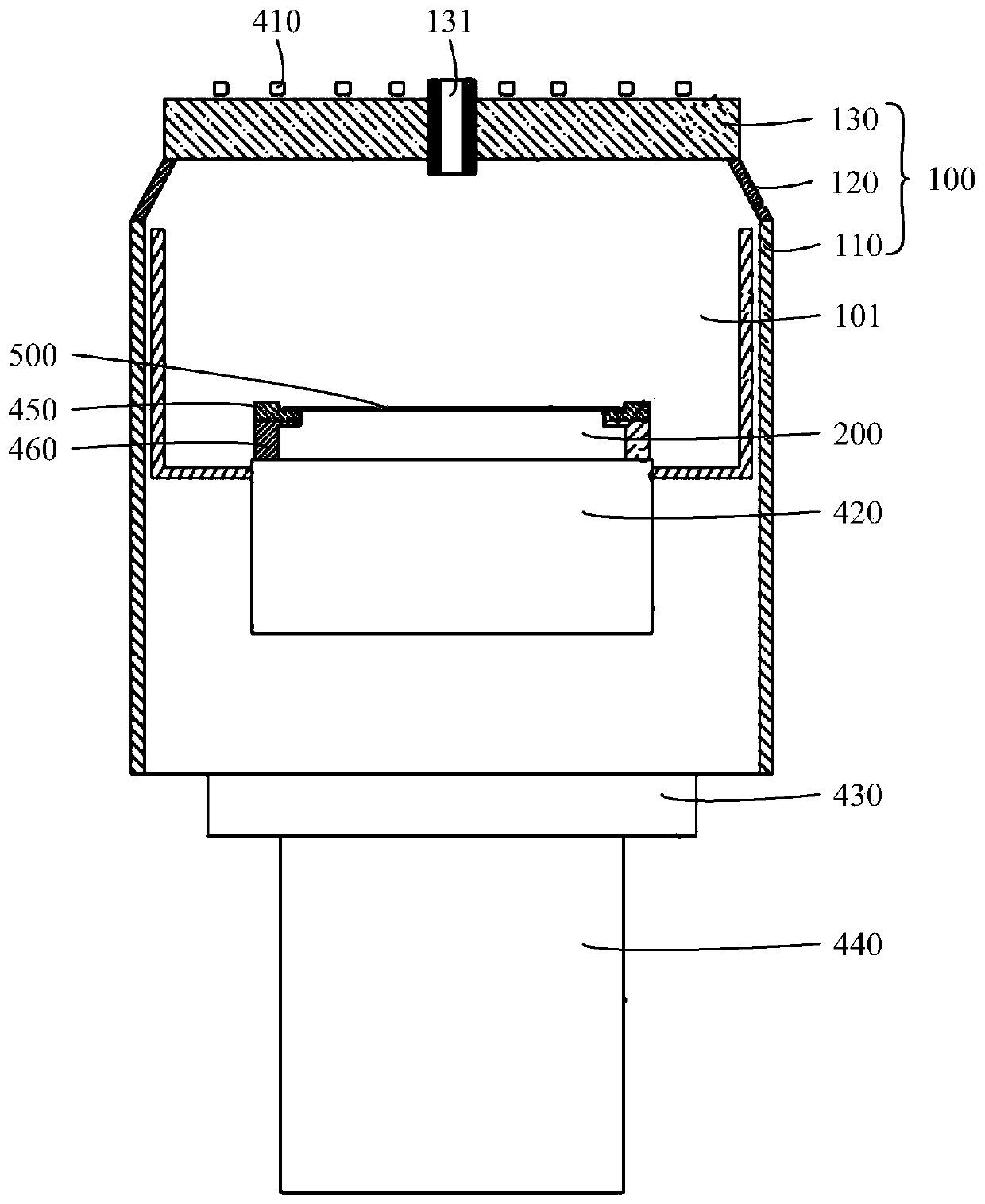

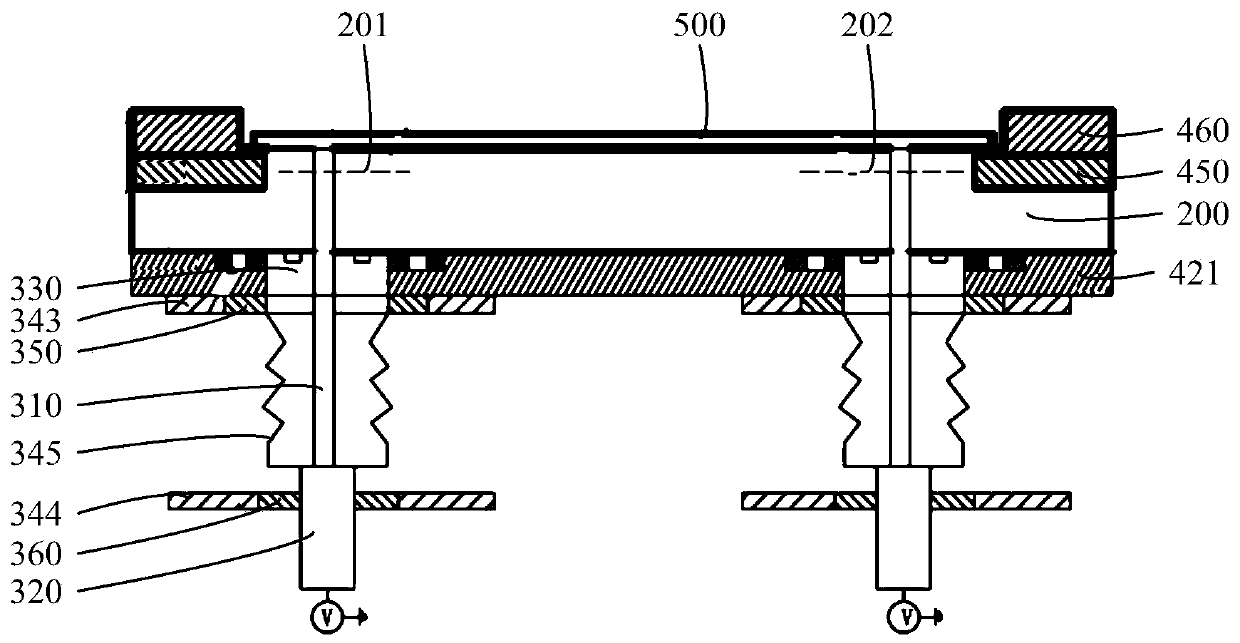

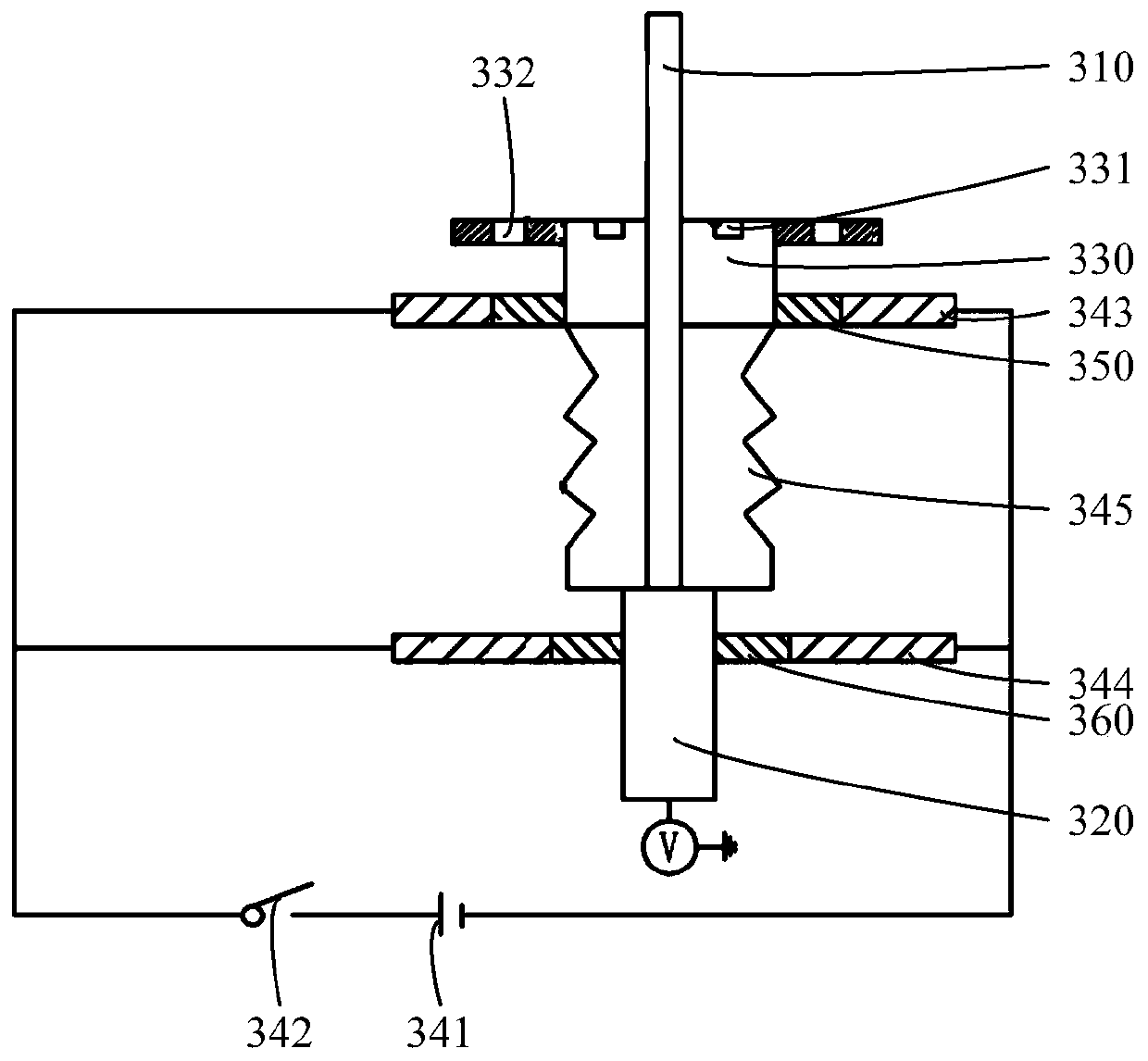

Reaction chamber of semiconductor equipment and semiconductor equipment

ActiveCN111446199AImprove securityImprove reliabilityElectric discharge tubesFinal product manufactureWaferElectrical connection

The invention discloses a reaction chamber of semiconductor equipment and the semiconductor equipment. The reaction chamber comprises a chamber body, and an electrostatic chuck, a compensation voltagedetection device and a lower electrode which are arranged from top to bottom. The chamber body is provided with a reaction cavity; the electrostatic chuck, the compensation voltage detection device and the lower electrode are arranged in the reaction cavity, and the electrostatic chuck is used for supporting a wafer; one end of the compensation voltage detection device penetrates through the electrostatic chuck, is in contact with the wafer and is electrically connected with the wafer, and the other end of the compensation voltage detection device is connected with the lower electrode; and the compensation voltage detection device is used for measuring the voltage of the wafer and compensating the adsorption voltage of the electrostatic chuck according to the detected voltage of the wafer. According to the scheme, the problem of relatively low safety and reliability of the semiconductor equipment due to unbalanced adsorption force of the electrostatic chuck to the wafer can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

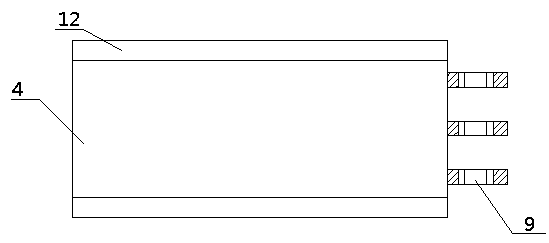

Novel bus duct

InactiveCN104184091AImprove securityEasy to useTotally enclosed bus-bar installationsPulp and paper industry

The invention provides a novel bus duct. The top of a bus bar is provided with a cover plate, the bottom of the bus bar is provided with a bottom plate, the two sides of the bus bar are provided with lateral plates, the two ends of a cover plate body are respectively provided with a dustproof mechanism, the two ends of the bottom of the cover plate body are respectively provided with a lateral plate positioning mechanism, the center of the top of the cover plate body is provided with a reinforced protrusion portion, the center of the bottom of the cover plate body is provided with a bus positioning groove, a plurality of positioning edges are arranged in the bus positioning groove, the tops of the lateral plates are embedded into lateral plate positioning grooves, the lateral plates and the cover plate can be fixed through the lateral plate positioning grooves, the bottoms of the lateral plates are provided with flangings outwards, and the flangings are fixed to the top of the bottom plate through bolts. The bus bar comprises a plurality of buses, the buses are installed in the bus duct through the bus positioning groove in the cover plate, and the buses can be positioned in a spaced mode through the positioning edges. The novel bus duct is good in dustproof effect, convenient to install, simple in operation, high in deformation resistant capacity and high in safety coefficient; heat dissipation can be conducted conveniently.

Owner:JIANGSU HENLEY ELECTRIC

Detonation type tear bomb

ActiveCN108759587AReduce training stressPromote rapid formationAmmunition projectilesProjectilesDetonationFire - disasters

The invention discloses a detonation type tear bomb. The detonation type tear bomb comprises a cartridge case, a primer, a propellant, a push disc, a projectile body, delay tubes, an explosion expanding explosive, OC stimulating powder, stimulating powder pushing discs, a guide rail, a blasting plug and a sealing identification pad, wherein the primer is riveted to the axis of the bottom end faceof the cartridge case, the push disc is used for pushing the projectile body to move, the projectile body comprises a lower projectile body and an upper projectile body, the delay tubes comprise a first-stage delay ignition tube and a second-stage delay ignition tube, the explosion expanding explosive is ignited and used for pushing the upper stimulating powder pushing disc and the lower stimulating powder pushing disc to move towards the two sides and are punched out of the blasting plug so as to achieve rapid spraying of the OC stimulating powder, and the sealing identification pad is used for sealing the cartridge case. According to the detonation type tear bomb, the design is ingenious, the situations that when the propellant is invalid or is subjected to neglected loading, the primerdirectly ignites the explosion expanding explosive so as to induce the bore premature, spraying is completed, the stimulating powder pushing discs are cut off, no flames are sprayed out, then accidental fire disasters or explosion accidents can be effectively avoided, the safety performance is relatively high, relatively large explosion sound is generated at the moment when the blasting plug is punched out, the deterrent performance is good, emission is carried out through an anti-riot gun, and the range is relatively long.

Owner:ENG UNIV OF THE CHINESE PEOPLES ARMED POLICE FORCE

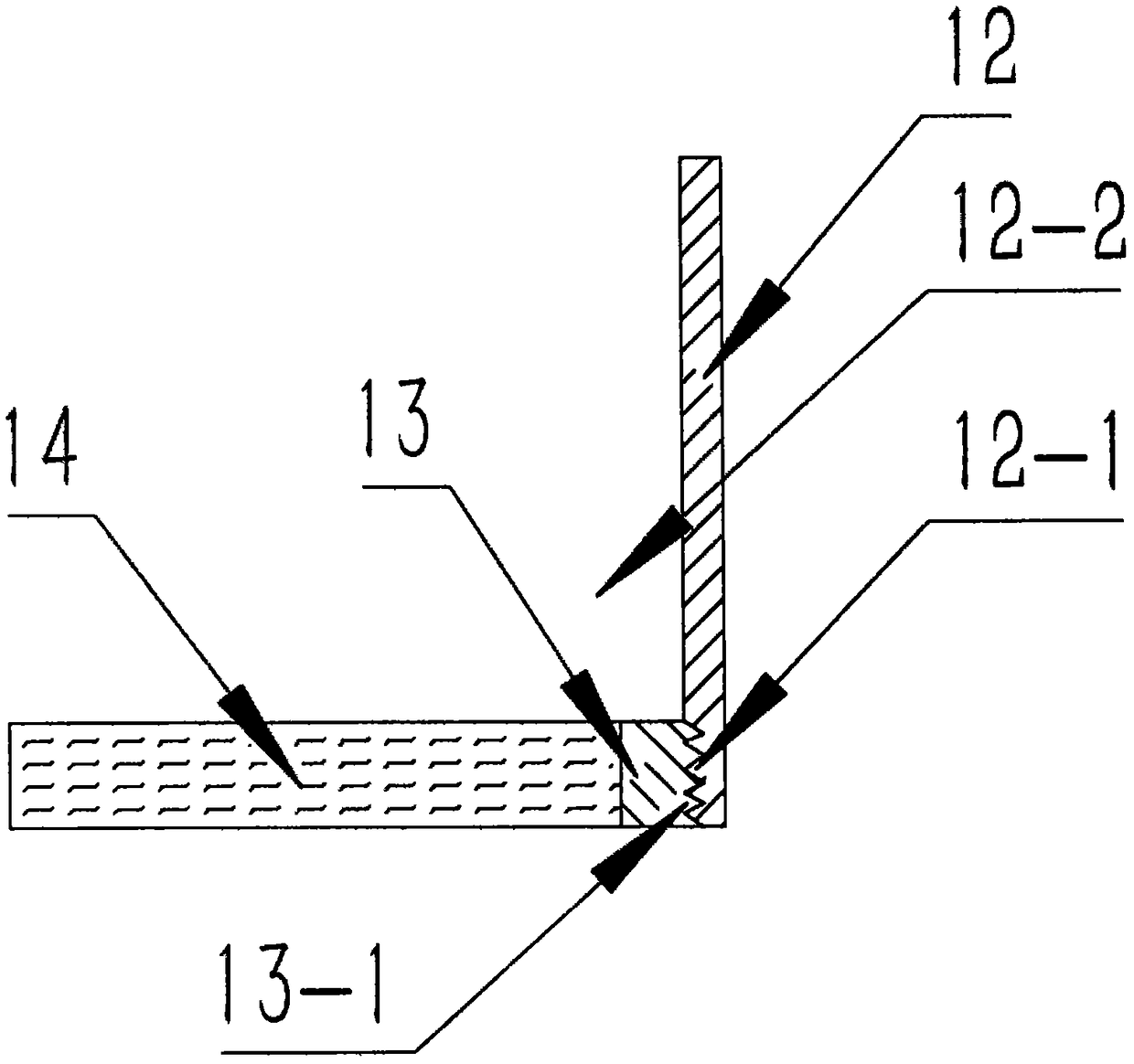

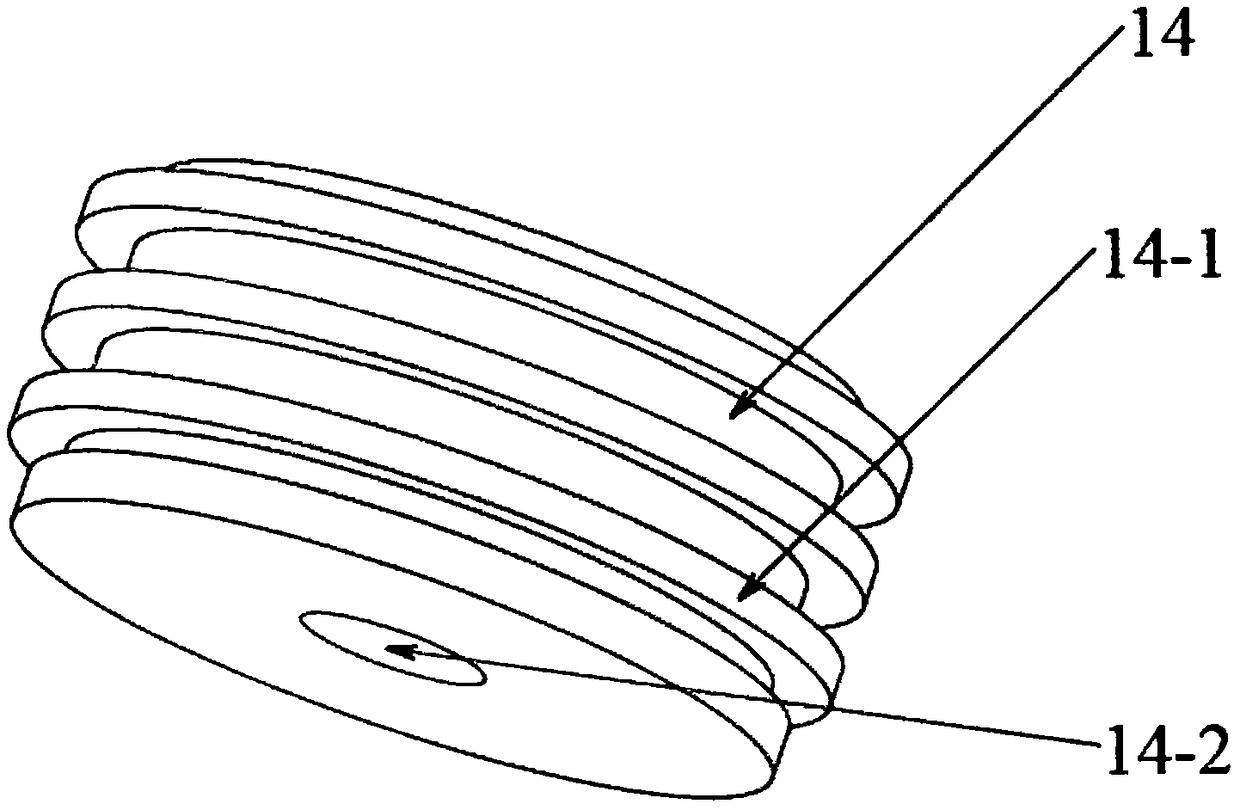

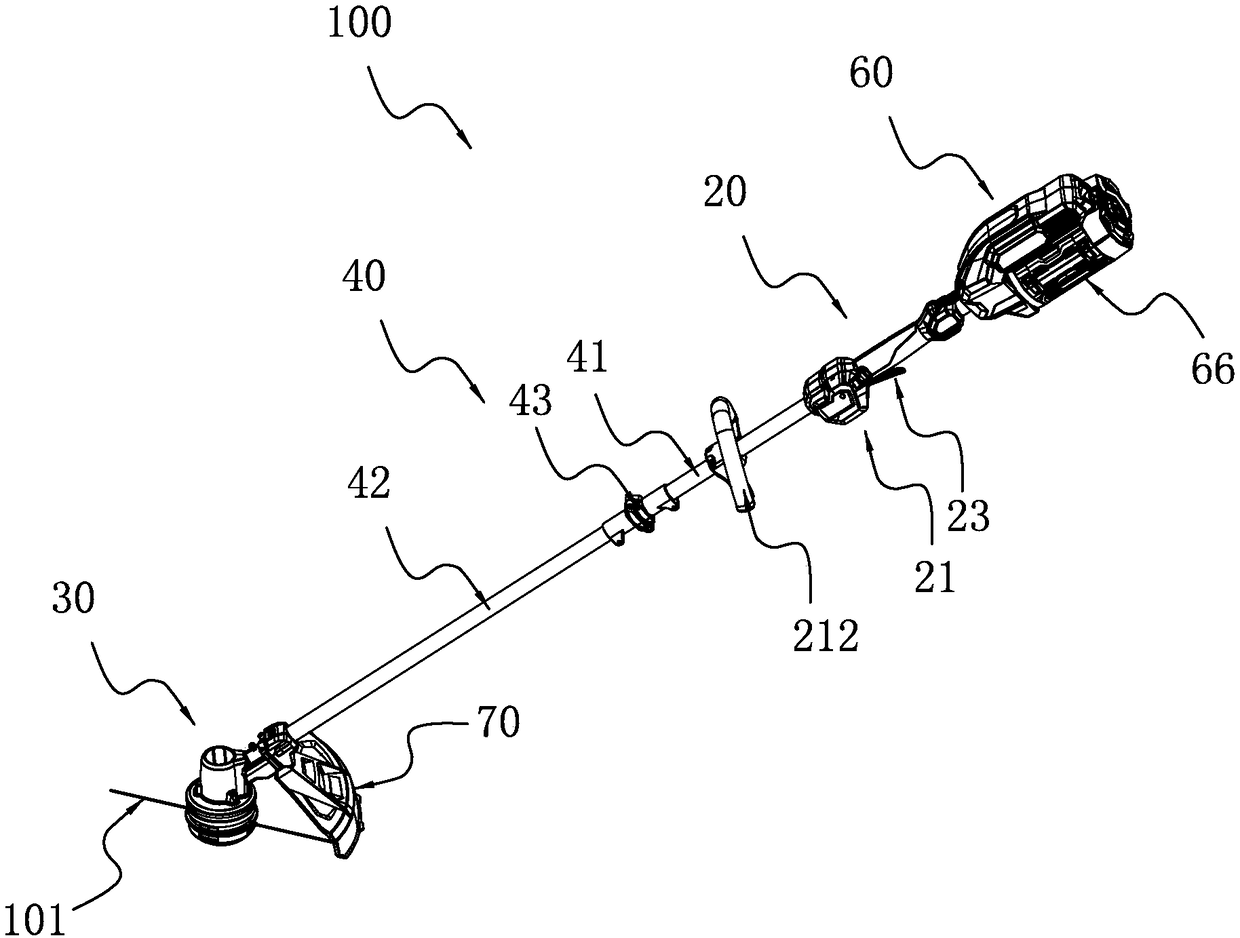

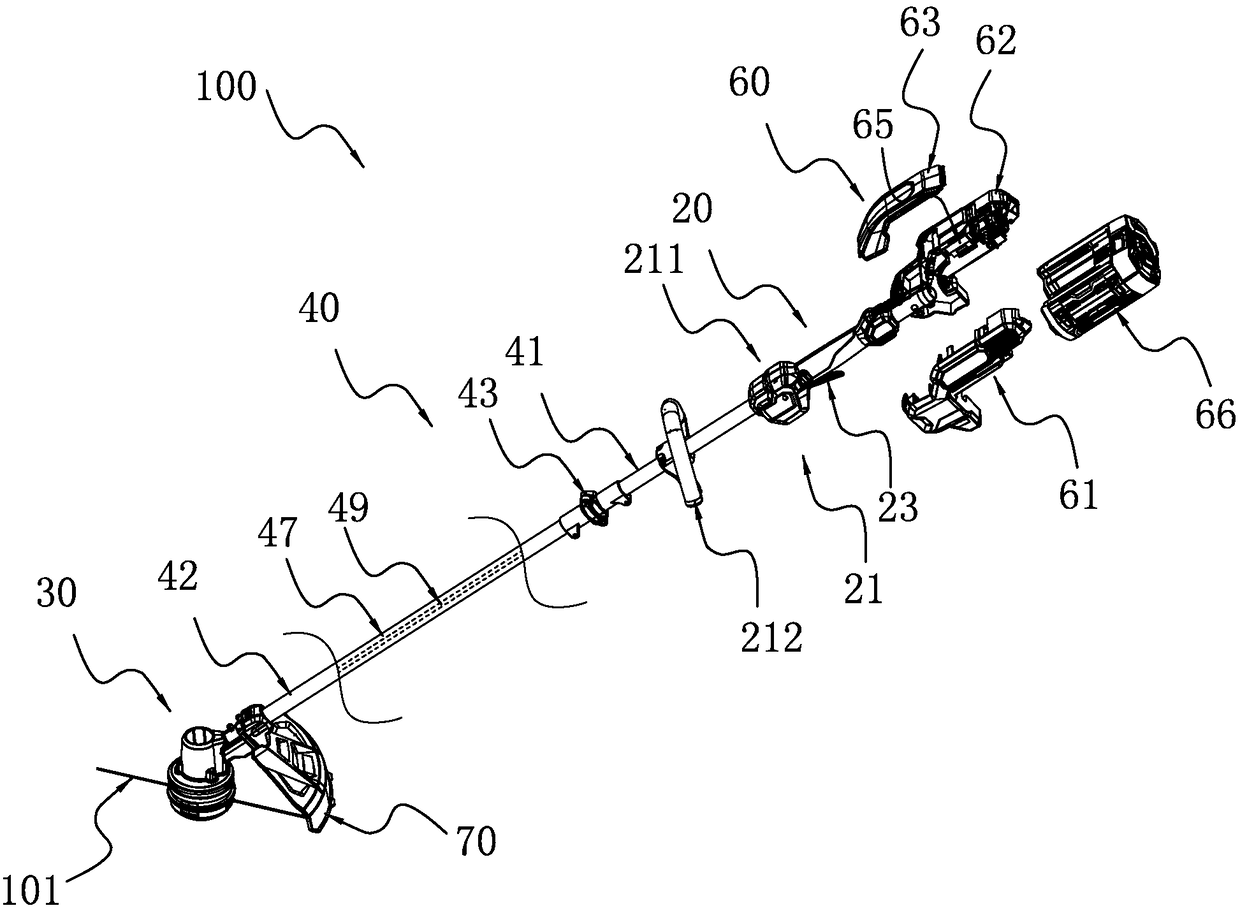

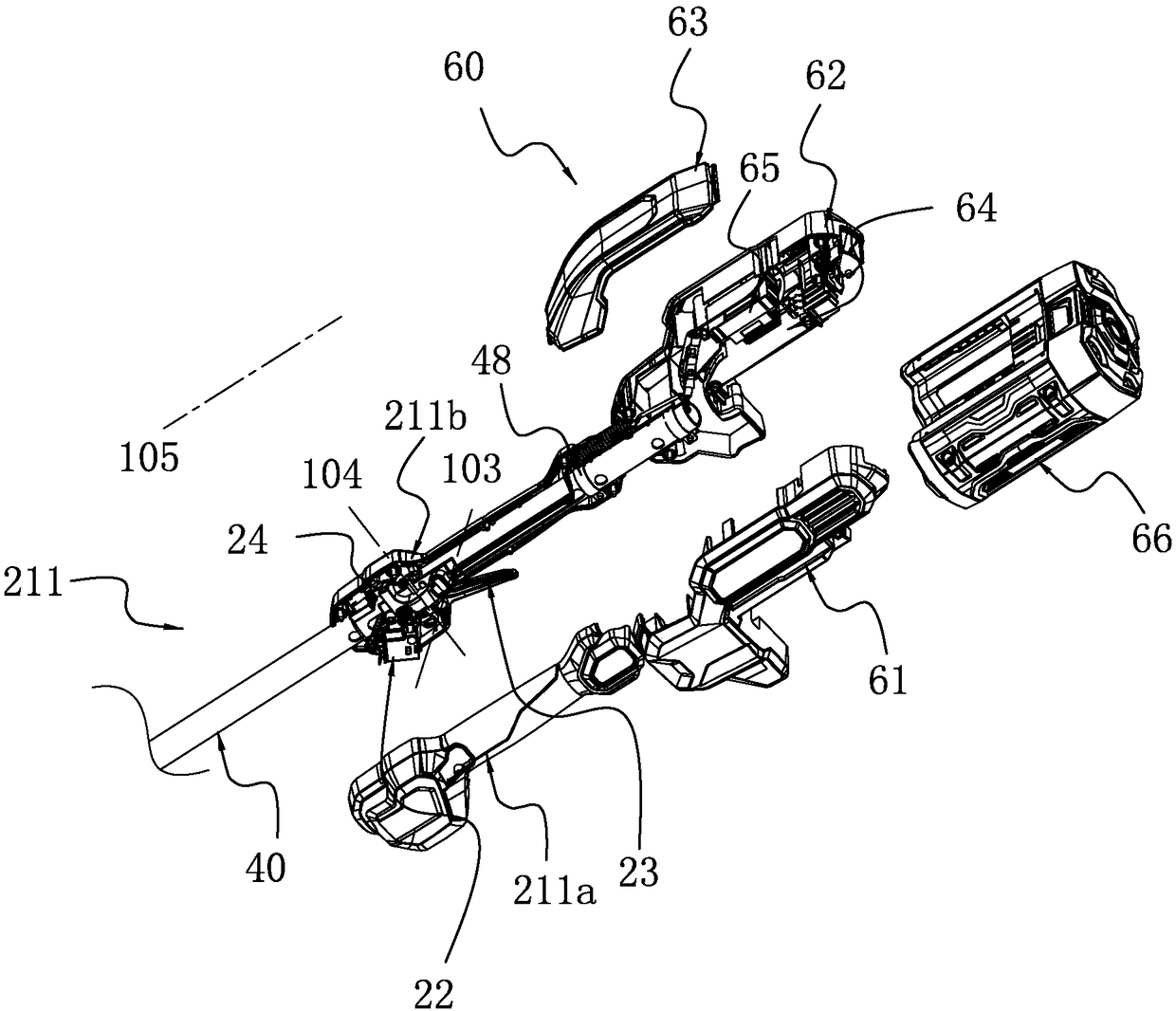

Grass trimmer and grass trimming head

The invention discloses a grass trimmer and a grass trimming head thereof. The grass trimmer comprises: a grass trimming head; a motor which drives the grass trimming head to rotate; in a cutting mode, the motor rotates forwardly to drive the grass trimming head to rotate in one direction; in an automatic winding mode, the motor reversely rotates to drive one of a spool or shell component to rotate in the opposite direction relative to the other; the grass trimming head comprises a shell component which is formed with an outer threading hole; the shell component comprises a shell and a threadoutlet buckle sleeve; the shell forms a shell cavity; the thread outlet buckle sleeve is fixed to the shell and forms the outer threading hole; the spool is provided with an inner threading hole through which a grass trimming rope penetrates; the inner threading hole is arranged in a flange part; and the distance from the thread outlet buckle to the flange part is smaller than the maximum outer diameter of the grass trimming rope. According to the invention, the grass trimming rope can be automatically wound to the spool under the action of the motor, the grass trimming rope can be directly inserted into the inner threading hole from the outer threading hole, deflection is not easy to occur, and the installation process of the grass trimming rope is convenient and fast.

Owner:NANJING CHERVON IND

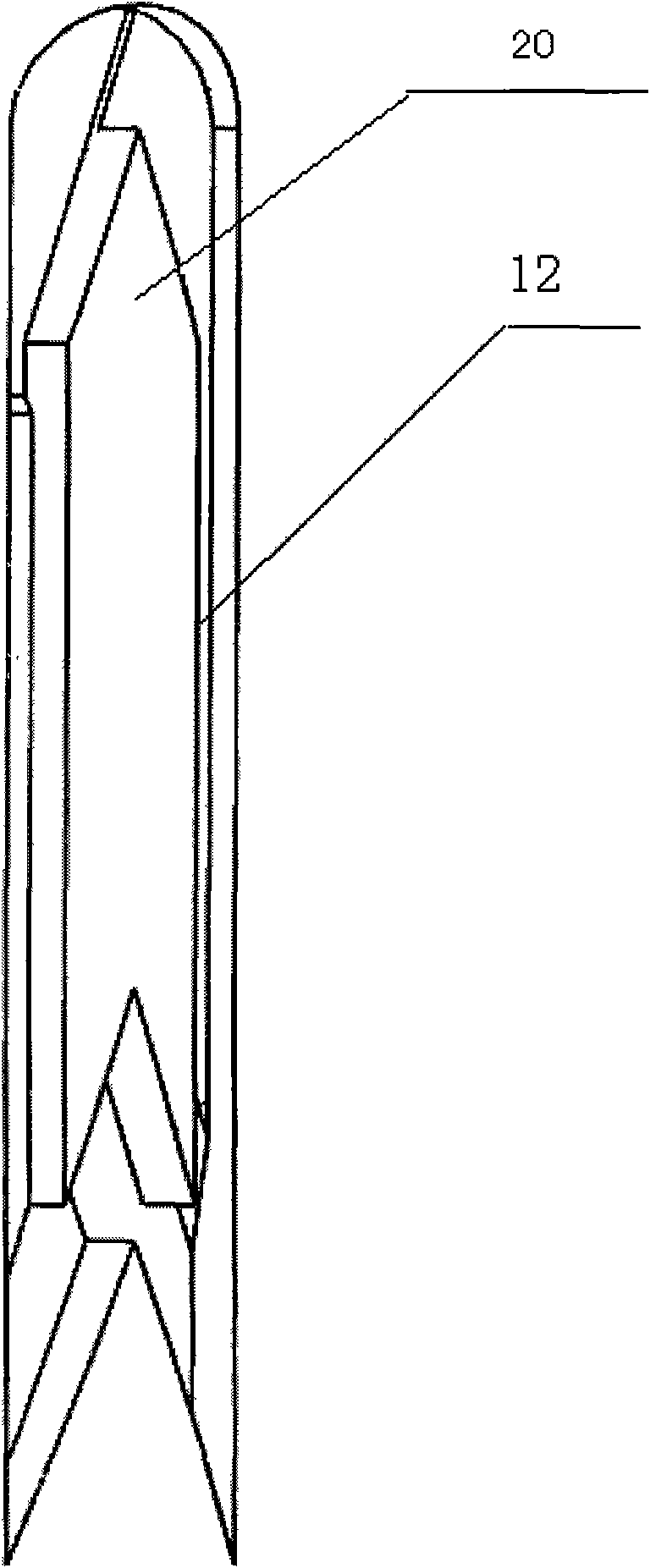

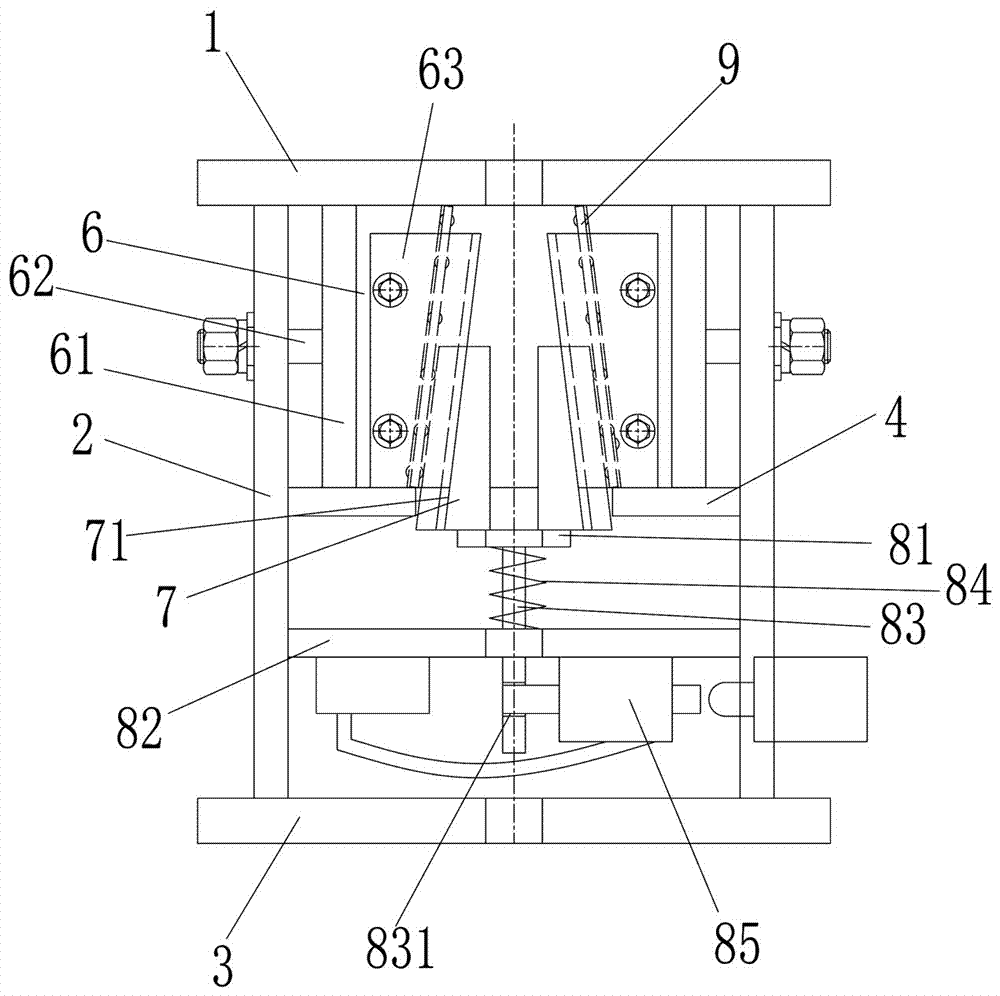

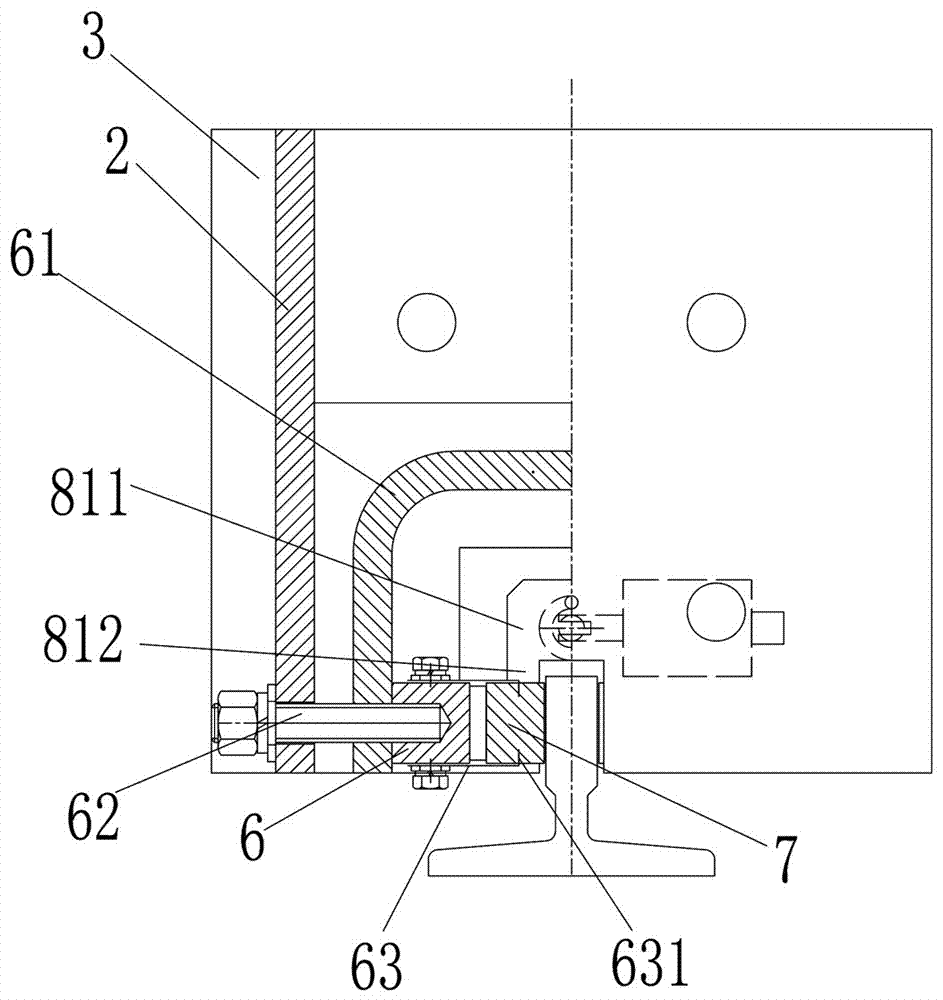

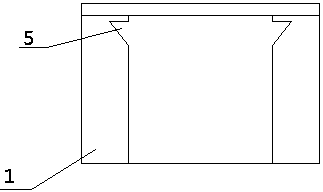

Elevator safety clamp device

ActiveCN107473049ASmooth brakingLess prone to deflectionBrake actuating mechanismsElevatorsStructural engineeringSTI Outpatient

The invention belongs to the field of elevators, and particularly relates to an elevator safety clamp device. The device comprises a clamp body and a wedge block assembly arranged in the clamp body, wherein the clamp body comprises a top plate, two side plates, a bottom plate and a middle guide plate which are sequentially arranged from top to bottom; the upper end of each side plate is fixedly connected with the top plate and the lower end of each side plate is fixedly connected with the bottom plate; the front sides of the top plate, the bottom plate and the middle guide plate are correspondingly provided with a guide rail channel used for allowing an elevator guide rail to pass through in the up-down direction; the middle guide plate is arranged between the two side plates; the part, corresponding to the guide rail channel, of the middle guide plate is provided with a guide opening, and the caliber of the guide opening is larger than the guide rail channel; and the wedge block assembly comprises two horizontal wedge blocks and two up-down wedge blocks symmetrically arranged on the two sides of the guide rail channel. According to the elevator safety clamp device, an up-down braking structure is started in emergency, so that the up-down wedge blocks slide upwards along the horizontal wedge blocks to clamp the guide rail passing through the guide rail channel so as to realize braking.

Owner:HENGDA FUJI ELEVATOR

Quick moving and assembling rig

ActiveCN105178875AHigh degree of modular integrationMeet the transportation conditionsConstructionsDerricks/mastsWinchPetroleum

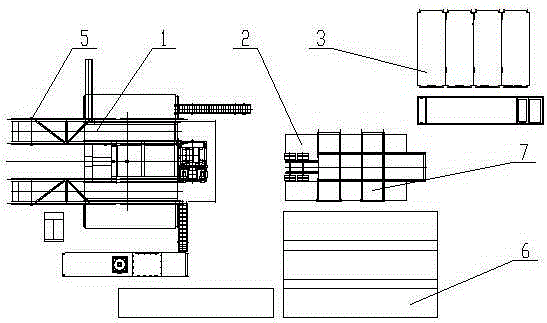

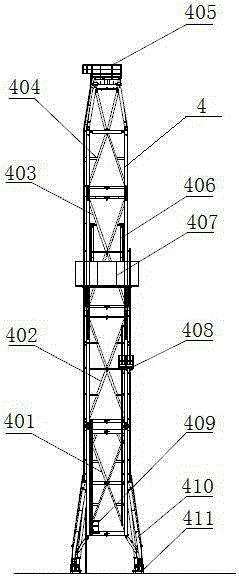

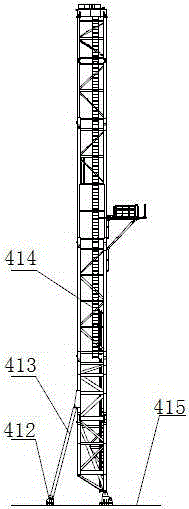

The invention relates to the technical field of petroleum drilling equipment and discloses a quick moving and assembling rig. The quick moving and assembling rig comprises an equipment module, a slurry module and a power module, wherein the equipment module comprises a derrick and a base; the slurry module comprises a slurry tank and a slurry pump; the derrick is sequentially divided into four segments from bottom to top; a front supporting leg and a rear supporting leg are arranged on two opposite sides of the bottom of the first segment of the derrick; each segment of the derrick is vertically divided into an inverted-L-shaped rear segment and an inverted-L-shaped front segment; during connection of two segments of the derrick, the rear segments are connected through hooks, and the front segments are connected through pin ear plates; and the base consists of base modules, wing-room modules, an independent winch module, a pipe setback and beam module, a turntable and turntable independent driving beam module and base accessories, and matched structural part quick mounting, connecting and locking devices are arranged at the connecting parts of the base modules, the wing-room modules, the independent winch module, the pipe setback and beam module and turntable and turntable independent driving beam module. The quick moving and assembling rig can be mounted and dismounted conveniently and quickly, can not only meet the road transportation rule requirements to be moved in long distance but also directly move between short-range well sites on the whole, and therefore is improved in transition efficiency.

Owner:LANZHOU LS PETROLEUM EQUIP ENG CO LTD

Novel professional light guide plate CCD film laminating machine

InactiveCN112974401AImprove cutting effectThe film covering process is green and environmentally friendlyCleaning using gasesLight guideDust control

The invention relates to a novel professional light guide plate CCD film laminating machine. The novel professional light guide plate CCD film laminating machine comprises a machine frame, a first conveying mechanism, a transition mechanism, a second conveying mechanism and a cutting mechanism, the first conveying mechanism, the transition mechanism and the second conveying mechanism are sequentially arranged on the machine frame in the conveying direction of a light guide plate, and the transition mechanism comprises two clamping and pressing conveying assemblies. The cutting mechanism is arranged between the two clamping and conveying assemblies, each clamping and conveying assembly comprises an upper roller and a lower roller, and the upper rollers and the lower rollers clamp and convey the light guide plate. A first electrostatic rod and a dust removal mechanism are arranged at the feeding end of the machine frame, a second electrostatic rod and a material collecting mechanism are arranged at the discharging end of the machine frame, one installation mechanism is arranged at the position, close to the feeding end, of the machine frame, the other installation mechanism is also arranged at the position, close to the discharging end, of the machine frame, and the two installation mechanisms are used for installing a reflecting film and a bright enhancement film correspondingly. A pressing roller is arranged at the position, close to the first conveying mechanism, of the machine frame. The novel professional light guide plate CCD film laminating machine has the effect of improving the film laminating production stability of the light guide plate.

Owner:DONGGUAN YUANLI ELECTRONICS TECH

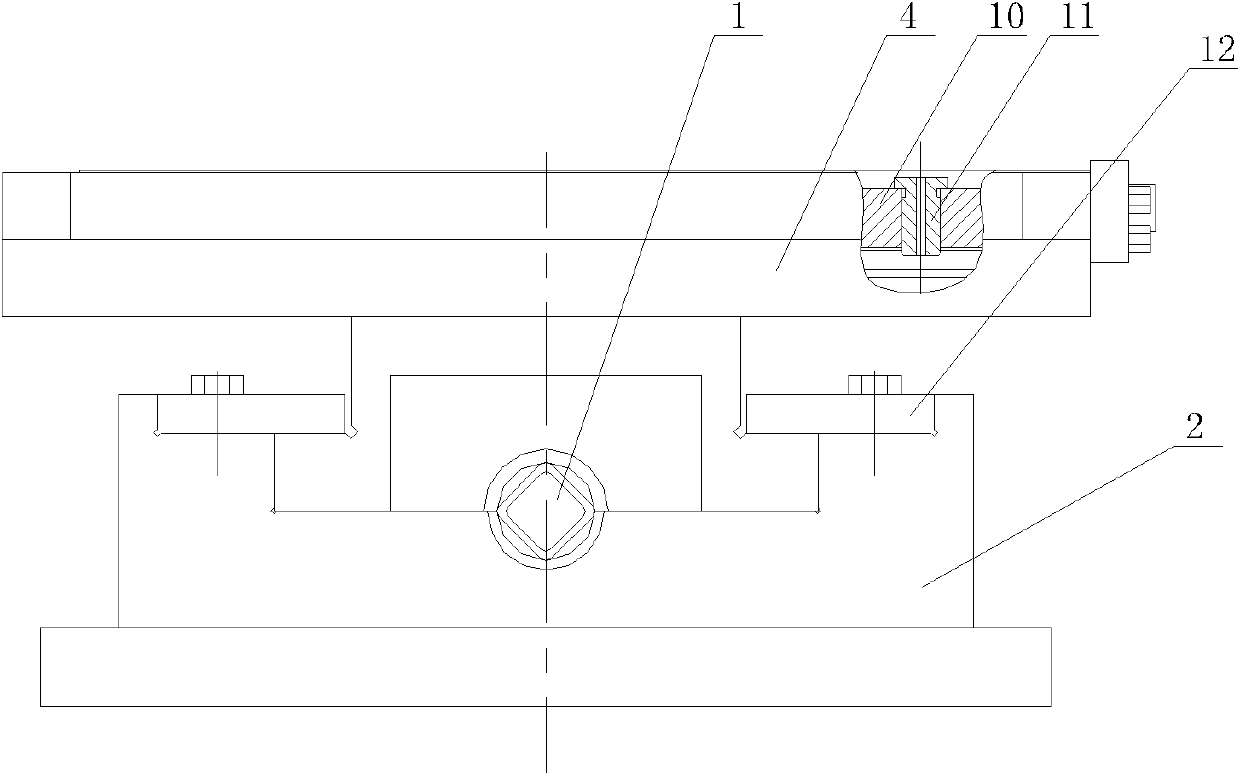

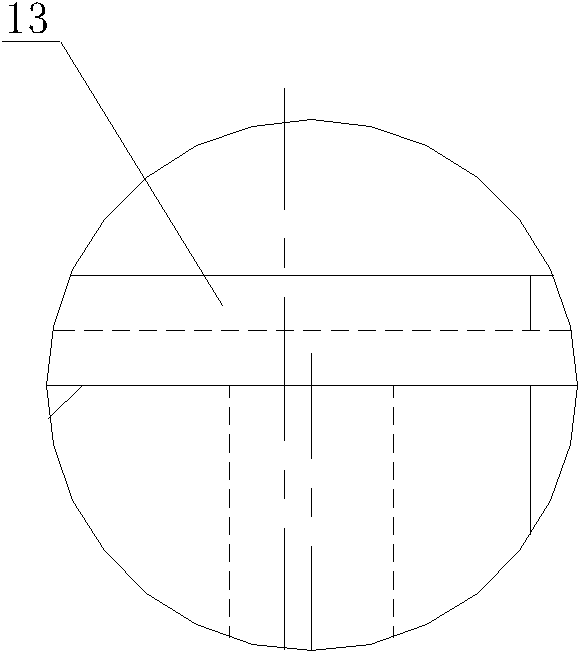

Lead screw transmission structure for target plate three-way confining press

The invention relates to a lead screw transmission structure for a target plate three-way confining press. The structure comprises a support frame, a driving motor, a lead screw nut pair and a drivingplate; the support frame is fixedly mounted on a frame of the target plate three-way confining press; parallel guide rail grooves are formed in the support frame; the lead screw nut pair is mounted in the support frame through a shaft base; the driving motor is mounted on the frame at the left end of the support frame, and is connected with a lead screw of the lead screw nut pair through a speedreducing mechanism; the driving plate is mounted in the guide rail grooves of the support frame, and is operated in the guide rail grooves; the bottom surface of the driving plate is fixedly connectedwith a connecting plate of the lead screw nut pair; and the right side end of the driving plate is hinged with a loading plate of the confining press through a pin shaft. The structure has the following beneficial effects: the structure is simple; the deflection is easily generated in transmission; and the separation of the transmission structure from the loading plate can be realized in the experimental process to effectively prevent damage of the transmission structure by the blasting vibration.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

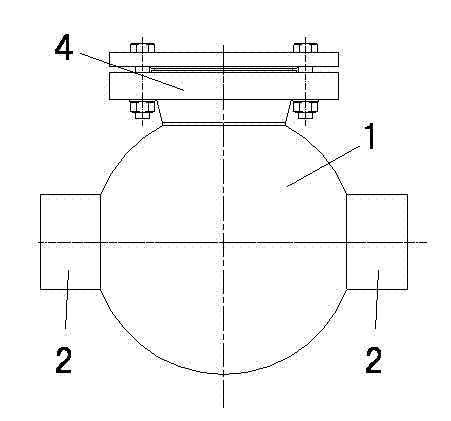

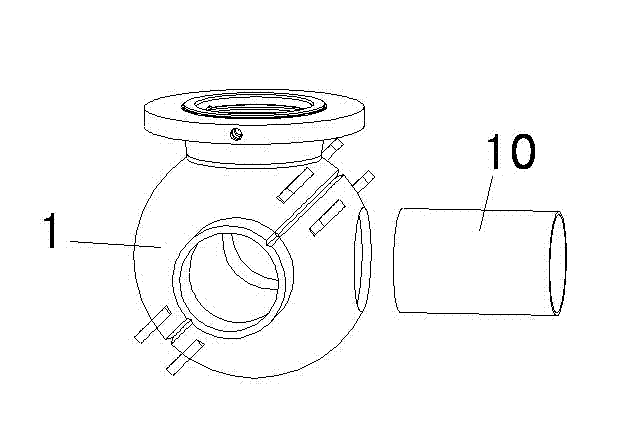

Spherical pipe connector

InactiveCN103486382AImprove securityConvenient welding operationPipe elementsBranching pipesLine tubingClassical mechanics

The invention discloses a spherical pipe connector. The spherical pipe connector comprises a pipe connector body; the pipe connector comprises a sphere; the sphere is provided with an encircling pipe and a hubbed flange; the hubbed flange is used for being connected with a perforating and sealing equipment; the encircling pipe is used for encircling pipelines being continuously used for carrying out perorating and sealing; the sphere comprises an upper semi-sphere and a lower semi-sphere; encircling-pipe upper half portions are arranged at the two ends of the upper semi-sphere, and encircling-pipe lower half portions are arranged at the two ends of the lower semi-sphere; the encircling-pipe upper half portions and the encircling-pipe lower half portions are combined to form the encircling pipe; connecting positions of the upper semi-sphere and the lower semi-sphere are fixed through bolt assemblies respectively; a branch connecting pipe of the spherical pipe connector can be horizontally arranged on the sphere, is located in the same horizontal plane with a main pipeline and can also be arranged at the bottom of the sphere; further having perorating performance and sealing performance, the spherical pipe connector can save half operation cost and operation time and can be applied to pipelines with all kinds of hole diameters and burying depths and improve perforating or sealing operation safety under the conditions that pipelines are continuously conveyed.

Owner:SUZHOU GAS EQUIP & VALVES MFG

External wall assembling structure of fabricated building and construction method of external wall assembling structure

InactiveCN110777977ASeismic performance is not easyLess prone to deflectionWallsWall plateExternal cladding

Owner:深圳市正知建筑技术有限公司

Ventilating duct construction method

InactiveCN109158685AImprove construction efficiencyEasy to replaceTube shearing machinesShearing machine accessoriesArchitectural engineeringEngineering

The invention discloses a ventilating duct construction method. According to the method, a construction frame body and a clamping and fixing assembly installed on the lower side of the construction frame body are involved, wherein a containing cavity is formed in the end surface of the bottom of the construction frame body, a cutting machine body is installed in the containing cavity in a slidingfit mode, convex blocks are bilaterally symmetrically and fixedly arranged on the end surface of the top of the cutting machine body, a buffering elastic piece is installed on the convex blocks, a piston rod is fixedly arranged in the right center of the top end of the buffering elastic piece, the top end of the piston rod is in power fit connection with an air pressure cylinder, the air pressurecylinder is fixedly arranged in the top wall of the containing cavity, concave cavities are bilaterally symmetrically formed in the positions, on the left side and the right side of the containing cavity, in the bottom end surface of the construction frame body, vertical transmission cavities are arranged in the positions, on the inner sides of the containing cavity, in the construction frame bodyin an up-and-down extension mode, the tail ends of the tops of the vertical transmission cavities communicate with transverse transmission cavities extending leftwards and rightwards, and a driving motor is fixedly arranged between the transverse transmission cavities on the left side and the right side.

Owner:俞耀

Novel seamless steel pipe blank pushing machine

ActiveCN108057723AGuarantee push demandHigh adjustment accuracyMetal rolling arrangementsEngineeringMaterial Perforation

The invention provides a novel seamless steel pipe blank pushing machine. The novel seamless steel pipe blank pushing machine comprises a support and a workbench arranged on the support. The workbenchis provided with a square cavity. A base which is parallel to the workbench is arranged on the portion, at the bottom of the workbench, of the support. An adjusting device penetrating through the square cavity is arranged on the base and comprises a lifting mechanism and an adjusting mechanism which are arranged on the base. The lifting mechanism is provided with a cushion plate. The cushion plate is connected with a guide roller through the adjusting mechanism. Extension plates are arranged on the two sides of the cushion plate. Sliding rods rotationally connected with the extension plates are arranged at the positions, between the two extension plates, of the bottoms of the extension plates. The two sliding rods are connected through a frame. A sizing device is arranged on the frame. According to the novel seamless steel pipe blank pushing machine, the secondary perforation material pushing demand is met, the feeding stability and feeding efficiency are ensured, meanwhile, pushing of different pipe diameters is achieved, the adjusting precision is high, rapidness and convenience are achieved, the perforation precision is ensured, and the application range is wide.

Owner:天津腾飞钢管有限公司

Steel structure sand core, manufacturing method of steel structure sand core and bolt hole casting method

PendingCN110640091AQuality improvementImprove casting qualityFoundry mouldsFoundry coresMechanical engineeringSteel tube

The invention belongs to the technical field of casting, and relates to a steel structure sand core, a manufacturing method of the steel structure sand core and a bolt hole casting method. The steel structure sand core comprises a sand core body shell, a molding sand filling body and an exhaust hole, and the manufacturing method of the steel structure sand core comprises the steps that steel pipewelding is adopted, molding sand is filled, drying is carried out, and manufacturing of the finished steel structure sand core is finished. The bolt hole casting method adopts the finished steel structure sand core for finishing the casting molding of a bolt hole. According to the bolt hole casting method, the finished steel structure sand core is adopted for finishing the casting molding of the bolt hole. According to the steel structure sand core, during manufacturing, the working procedure is simple, operation is convenient, the manufacturing difficulty is low, and manufacturing is facilitated. During bolt hole casting, the casting quality of a casting can be improved, the construction period can be shortened, the bolt hole position precision is ensured, the later-period grinding workloads of the bolt hole can be reduced, the casting surface quality and the inherent quality of the casting can be improved, the production efficiency of the casting can be improved, and the constructionperiod can be shortened.

Owner:SHANDONG IRON & STEEL CO LTD

An Outer Rotor Brushless Motor

ActiveCN107508445BAvoid displacementAvoid vibrationMagnetic circuit rotating partsSupports/enclosures/casingsBrushless motorsElectric machine

Owner:GOERTEK ROBTICS CO LTD

Rapid drainage system for highway road

ActiveCN113668665ADrain fastReduce labor intensitySewerage structuresClimate change adaptationEnvironmental resource managementRoad surface

The invention relates to a rapid drainage system for a highway road, and relates to the field of road drainage. The rapid drainage system comprises a drainage pipeline, a drainage well lid arranged on the drainage pipeline, supporting rings arranged below the drainage well lid at intervals, a lifting mechanism arranged between the supporting rings and the drainage well lid and used for controlling the drainage well lid to ascend and descend, a flow monitoring switch arranged in the drainage pipeline and used for controlling the lifting mechanism to operate and a filtering mechanism arranged between the supporting rings and the drainage well lid and used for filtering garbage. A mounting groove is formed in the inner side wall of the drainage pipeline, and the supporting rings abut against the interior of the mounting groove. The rapid drainage system for the highway road has the effects that the drainage well is automatically opened and closed according to the rainfall, and accumulated water on the road surface is rapidly drained.

Owner:廊坊市拓峰建设工程有限公司

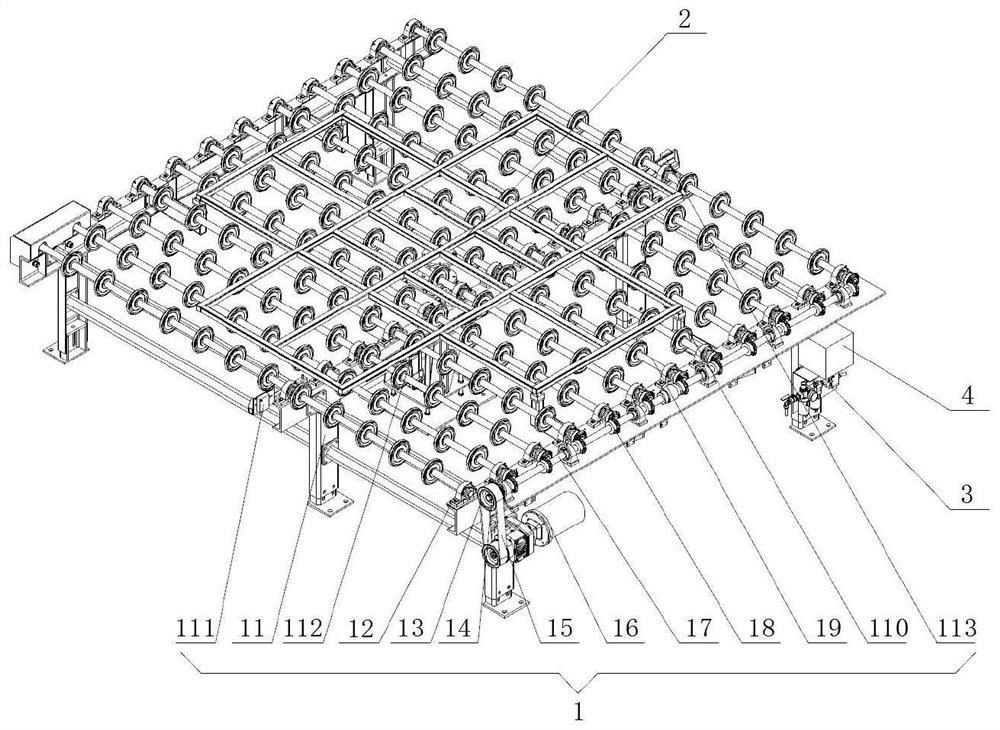

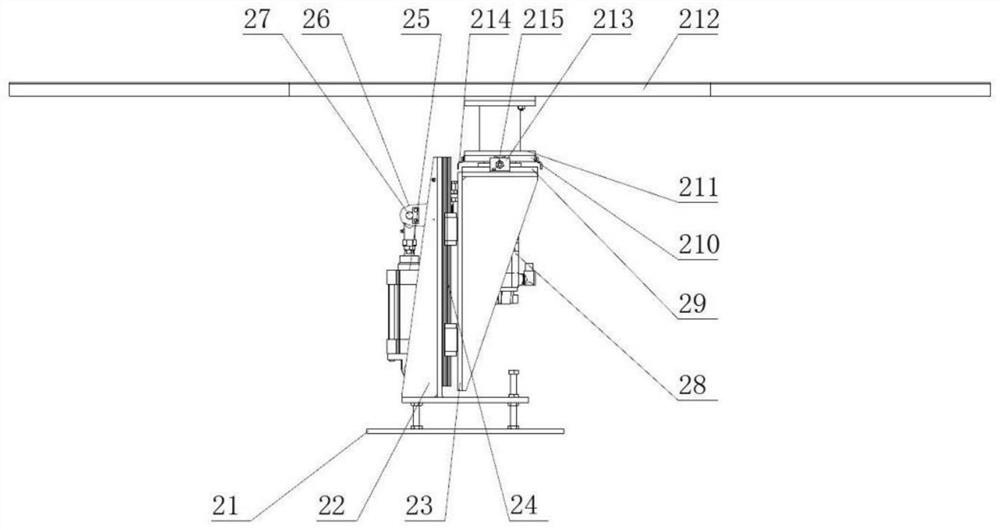

Glass rotary sheet conveying device and conveying method thereof

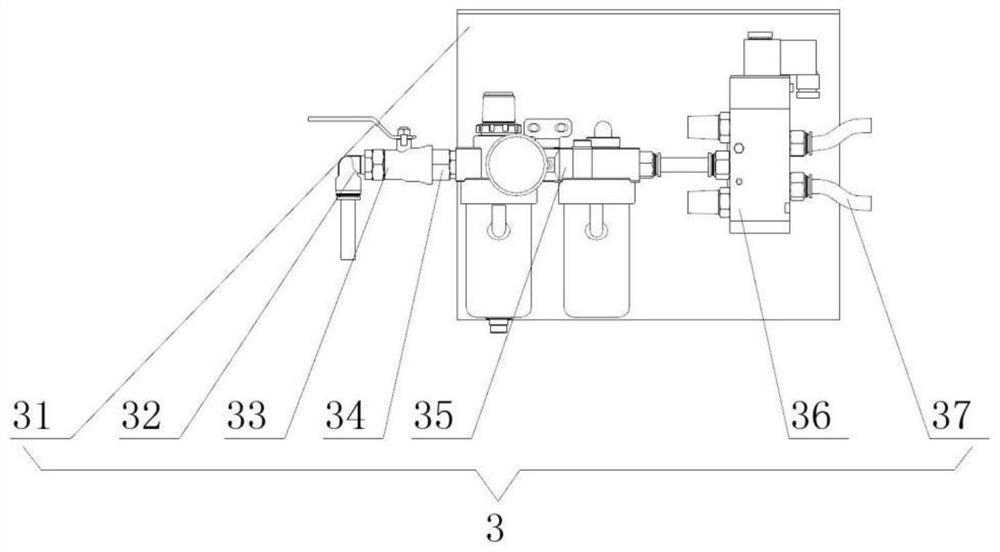

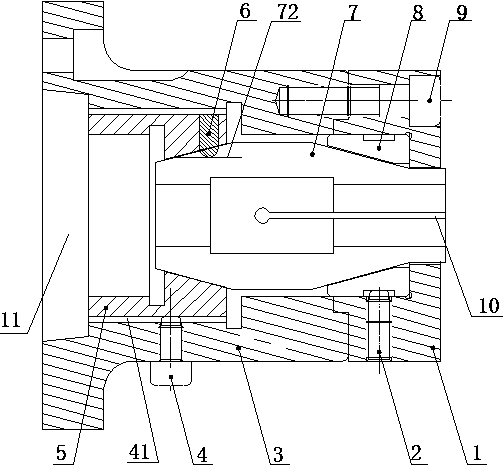

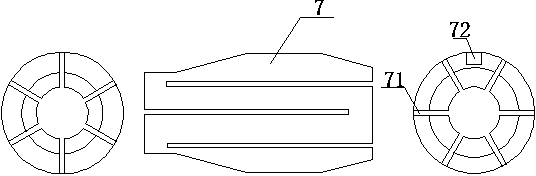

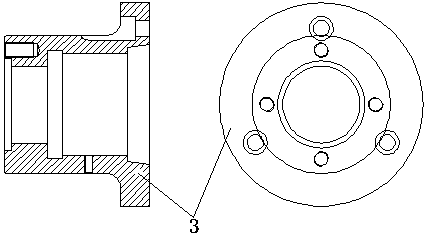

ActiveCN114516541AMeet process requirementsHeight adjustableConveyorsControl devices for conveyorsDrive shaftEngineering

The invention discloses a glass rotary sheet conveying device and a conveying method thereof.The glass rotary sheet conveying device comprises a conveying roller way, a rotary sheet lifting component, a pneumatic component and a controller, and the conveying roller way comprises a transmission shaft, a plurality of transmission rollers, a first sensor, a second sensor and a third sensor; the conveying lifting rotary vane component comprises a first support, a second support, a linear guide rail, a servo motor, a fourth sensor, an air cylinder, a fisheye connector support and a rotating frame. The pneumatic component comprises a first air pipe, a second air pipe, a third air pipe and a five-port two-position electromagnetic valve; and the controller is respectively in telecommunication connection with the first sensor, the second sensor, the third sensor, the fourth sensor and the five-port two-position electromagnetic valve. Linkage control is achieved, glass conveying 90-degree rotation can be accurately achieved, and the process requirement of long edge and short edge exchange conveying of a deep processing production line is met.

Owner:CHINA TRIUMPH INT ENG

Lathe chuck

InactiveCN104191295AEasy to operateLess prone to deflectionWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:WUHU YONGWEI REFRIGERATION ACCESSORIES MFG CO LTD

Wallboard cutting device not prone to deflection

InactiveCN112077898ALess prone to deflectionSkew won'tMetal working apparatusPlate pressureDrive shaft

The invention discloses a wallboard cutting device not prone to deflection. The wallboard cutting device comprises a cutting table, guide plates, first lifting devices, a mounting frame, a feeding belt, a limiting plate, a pressure sensing device, a cutting machine, a second lifting device and a control device. The two long-strip-shaped guide plates are arranged on the cutting table and are parallel to each other. The length direction of the guide plates is parallel to the moving direction of a wallboard. The opposite sides of the two guide plates are provided with a groove and a protruding strip correspondingly. The groove is matched with a male head of the wallboard. The protruding strip is matched with a female groove of the wallboard. The mounting frame is arranged above the cutting table and connected with one first lifting device. A driving shaft and a driven shaft are mounted on the mounting frame. The driving shaft is connected with a power mechanism. According to the wallboardcutting device not prone to deflection, the groove and the protruding strip are arranged on the guide plates correspondingly, so that the wallboard is not prone to deflection in the moving process, the cutting position is not prone to deflection, and the product quality is guaranteed.

Owner:ZHEJIANG XINHAOJI ELECTRIC

Anti-deflection winding device for release film

InactiveCN112830294ANot easy to deflectLess prone to deflectionWebs handlingDust controlStructural engineering

Owner:东莞市金恒晟新材料科技有限公司

Clamping device with overturning function

InactiveCN107972052AAchieve clampingImplement the flip operationGripping headsEngineeringIdler-wheel

The invention discloses a clamping device with the overturning function. The clamping device comprises a clamping air cylinder, wherein two gripper devices are symmetrically arranged below the two sides of the clamping air cylinder in the length direction of the clamping air cylinder; each of the gripper devices comprises a square base; a circular rotary table board is arranged in the center of the square base; two trapezoid idler wheel groups are arranged on opposite end faces of the rotary table board; a vertical rotary device is arranged on the outer side of the square base and is connectedwith the center of the rotary table board; and a clamping rack is arranged above the square base and is connected with the clamping air cylinder. According to the clamping device, the clamping air cylinder drives the gripper devices to be tightened inwards so as to clamp an article; and the rotary table board is matched with the vertical rotary device to turn over the article, so that the clamping device is more convenient to use and saves time and labor.

Owner:朱旭

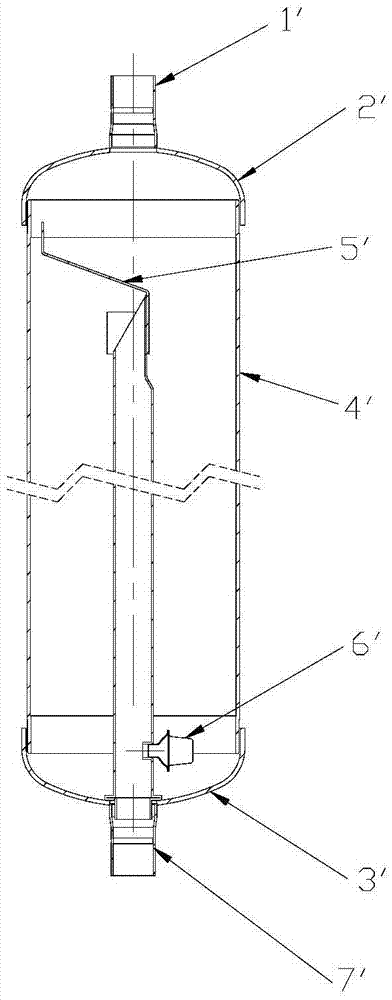

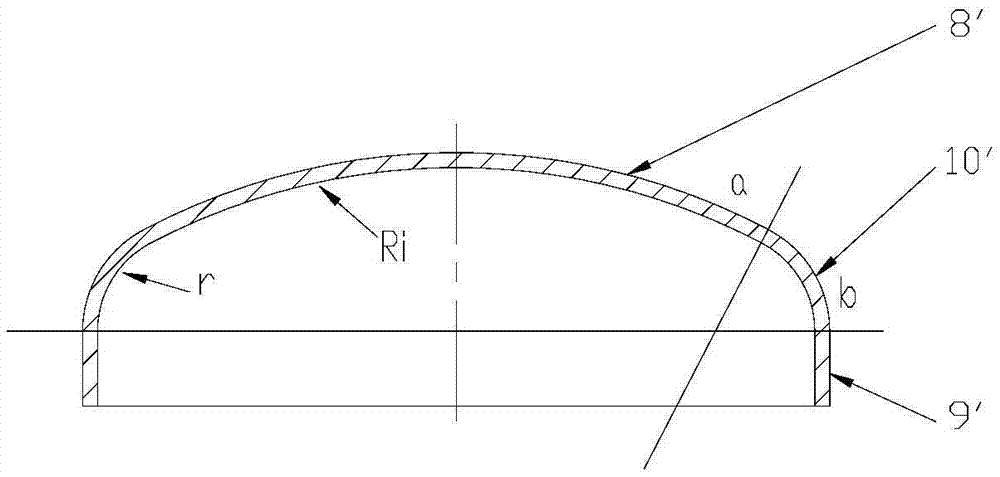

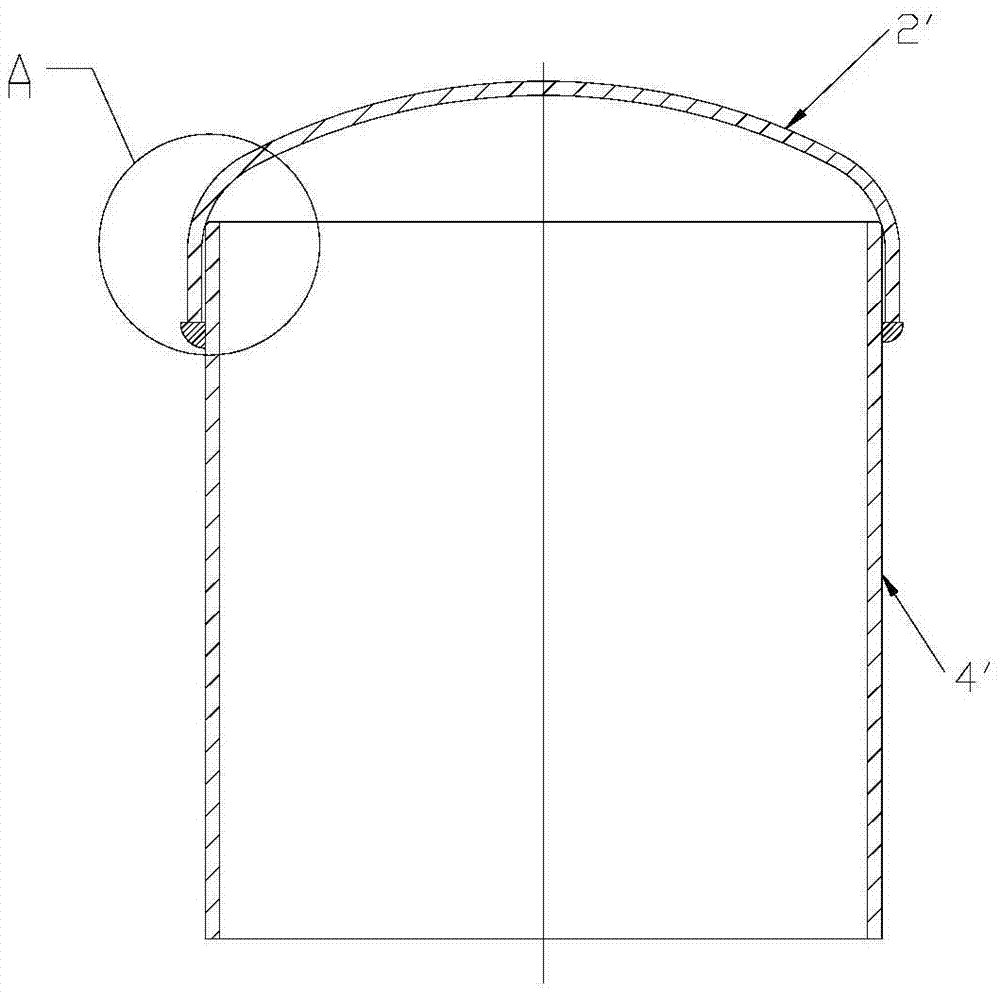

End socket and gas-liquid separator having same

InactiveCN107024043ANot easy to deflectLess prone to deflectionRefrigeration componentsVapor–liquid separatorEngineering

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Piston type pneumatic control valve

InactiveCN108397570ALess prone to deflectionAssembly deviation is smallOperating means/releasing devices for valvesMultiple way valvesControl valvesPiston

The invention relates to a piston type pneumatic control valve which comprises a valve body, a valve cover, a valve rod, a guiding valve seat, a spring, a lower valve port, an upper valve port and a seal ring type valve element. A stepped blind hole is formed in the upper end of the valve body; an air inlet, an air outlet, an air discharge hole and a control port communicating with the stepped blind hole are sequentially formed in the side surface of the valve body from top to bottom; the lower part of the valve rod is inserted into the lower part of the stepped blind hole and can axially movealong the blind hole; the lower end of the valve rod is higher than the control port; the upper part of the valve rod is inserted into an axial through hole of the guiding valve seat and can axiallymove along the through hole; the guiding valve seat is inserted and clamped to the upper part of the stepped blind hole; the upper valve port is formed in the lower end of the guiding valve seat; thelower valve port is formed in the stepped blind hole under the upper valve port; the seal ring type valve element is sleeved in the middle of the valve rod and is located between the lower valve portand the upper valve port; the valve cover is detachably fastened onto the stepped blind hole; and the spring is clamped between the valve cover and the valve rod.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Battery sealing device

ActiveCN104779411AThe binding position is accurateReduce distanceFinal product manufactureSecondary cells manufactureMechanical engineeringBattery cell

The invention relates to a battery sealing device. The device comprises a binding mechanism, a feeding mechanism and a battery conveying mechanism, wherein the binding mechanism is used for pressing sealing nails into battery holes; the feeding mechanism is used for conveying the sealing nails into the binding mechanism; the battery conveying mechanism is used for conveying and determining a position of a battery; the binding mechanism comprises a nail pressing needle for pressing the sealing nails into the battery holes, a first driving part for controlling the nail pressing needle to move up and down and a clamping part for clamping the sealing nails; the first driving part is connected with the nail pressing needle; one end, far away from the first driving part, of the nail pressing needle penetrates through a through hole formed in the middle of the clamping part and extends out of one end, far away from the first driving part, of the clamping part. The battery sealing device has a simple structure, and is convenient to bind, high in binding efficiency and accurate in binding positioning.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com