Spherical pipe connector

A spherical pipe and pipe connection technology, applied in the direction of pipes/pipe joints/fittings, pipes, pipe components, etc., can solve problems such as unsatisfactory burial depth, unsafe hidden dangers, etc., to save operating costs and working time, and have high safety , the effect of shortening the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

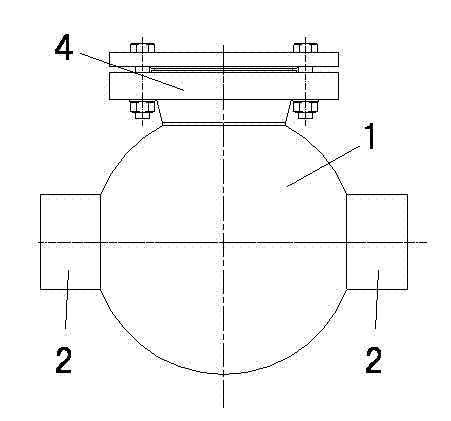

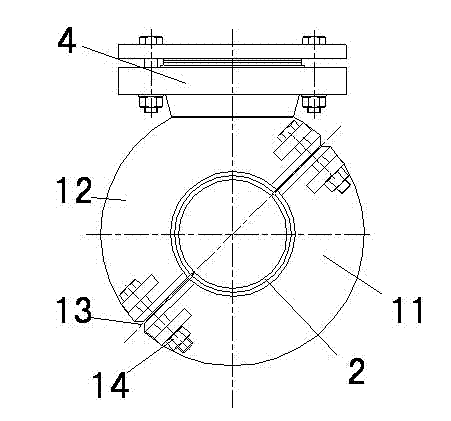

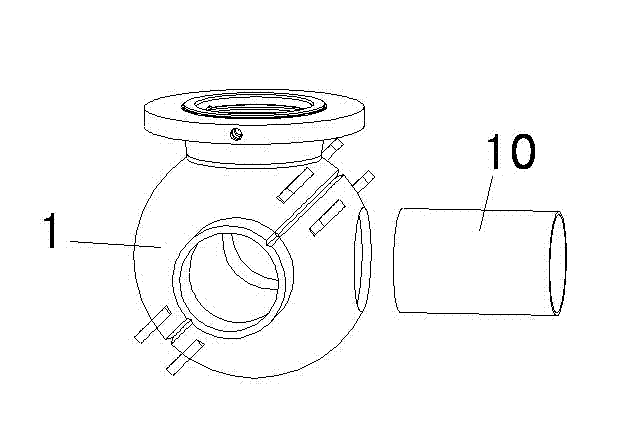

[0021] attached Figure 1-5 It is the first embodiment of the spherical pipe joint according to the present invention, which is suitable for opening holes, and includes a pipe joint body 3, a pipe plug 8, an O-ring seal 9, a pipe plug fixing device (not shown), an upper cover 6 and Flange connection bolts (not marked); the pipe joint body 3 includes a sphere 1; the sphere 1 is provided with a hoop tube 2 and a necked flange 4; the necked flange 4 is used to connect with the opening The hole sealing equipment is connected; the hoop pipe 2 is installed on the pipeline for the non-stop opening and sealing operation; the pipe plug 8 is lowered from the lower blocker to the necking method after the non-stop opening and sealing operation. In the through hole of the flange 4, it is used to cut off the medium in the pipeline after the hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com