Novel professional light guide plate CCD film laminating machine

A light guide plate and film laminating machine technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of unstable production of light guide plate film, unstable cutting effect of light guide plate, surface Instable film cutting and other problems, to achieve the effect of reducing floating around, stable adhesion removal effect, and stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

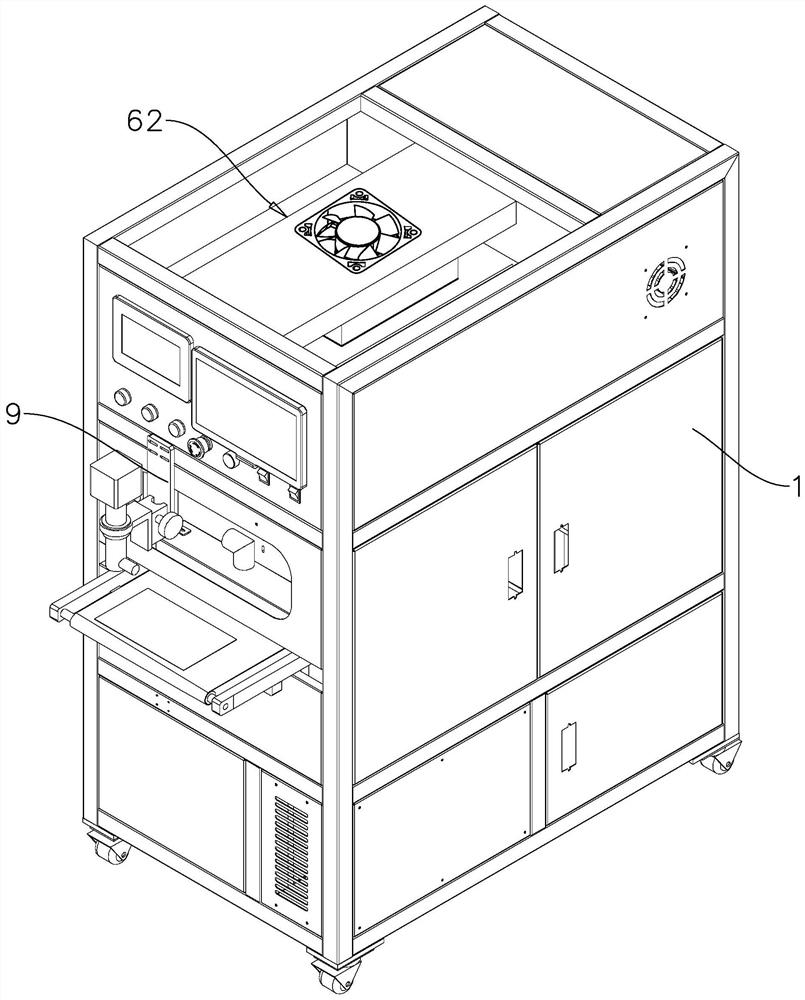

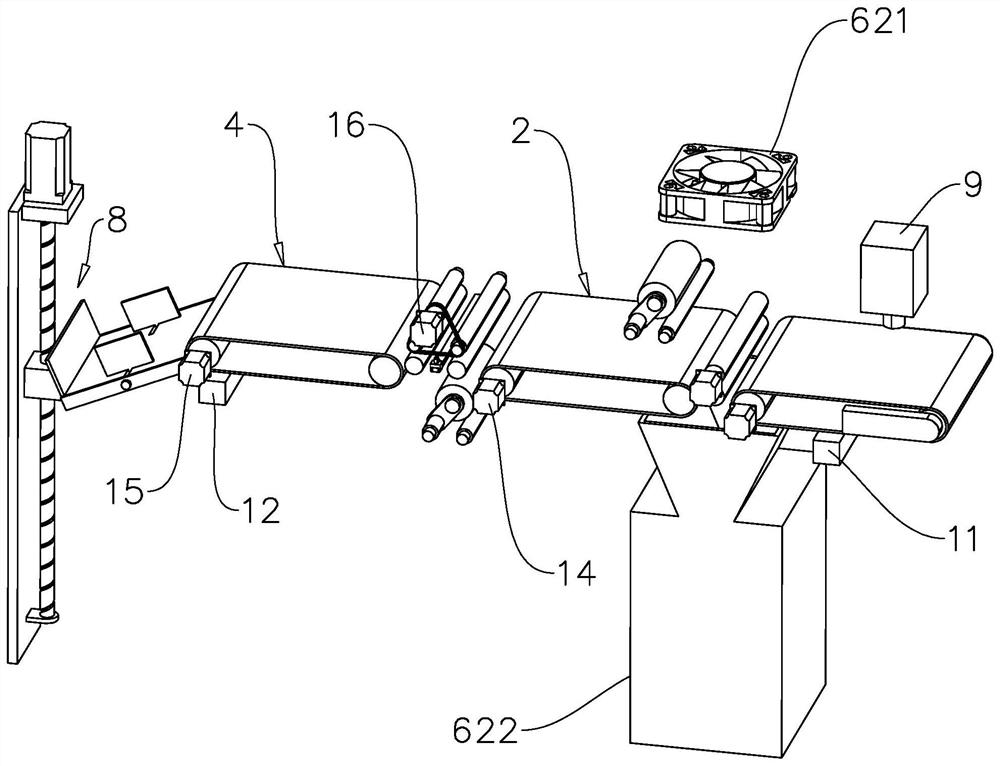

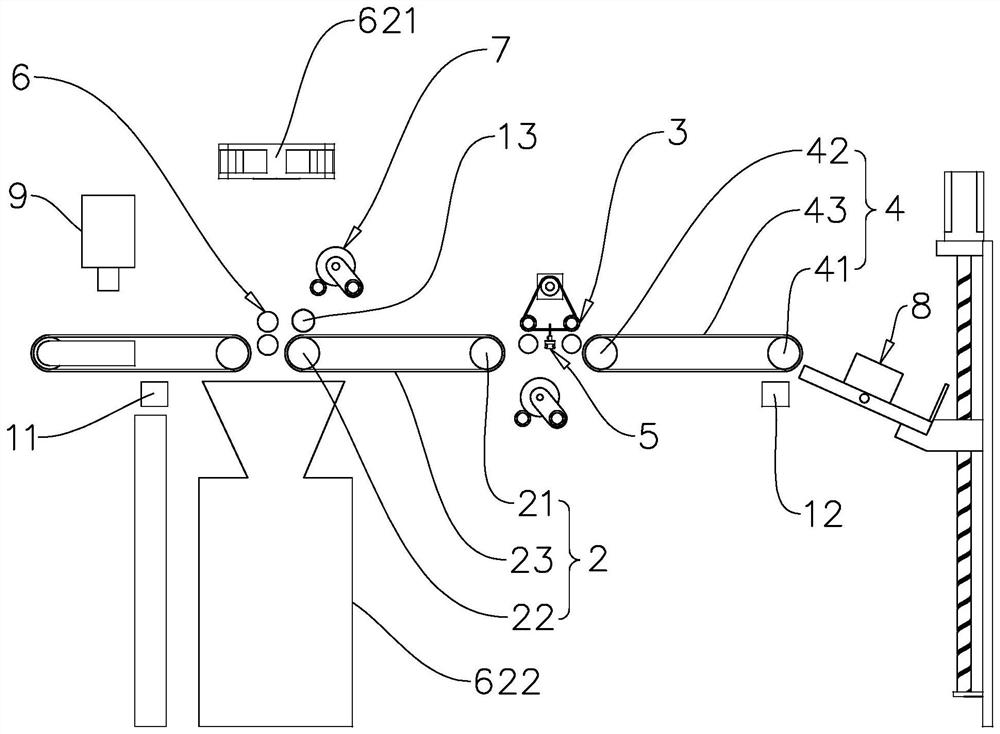

[0044] A new type of professional light guide plate CCD laminating machine, refer to figure 1 and figure 2 , comprising a frame 1, one end of the frame 1 along its own length direction is the feed end and the other end is the discharge end, the feed end of the frame 1 is provided with a first transmission mechanism 2, and the discharge end of the frame 1 is provided with There is a second conveying mechanism 4, and the first conveying mechanism 2 and the second conveying mechanism 4 are located on the same level. combine image 3 The first transmission mechanism 2 includes a first driving roller 21, a first driving roller 22, and a first conveyor belt 23 covering the first driving roller 21 and the first driving roller 22, and the two ends of the first driving roller 21 are rotatably connected to Frame 1, the first drive roller 22 is also rotatably connected to the frame 1, and the frame 1 is provided with a first motor 14 at one end position of the first drive roller 21, a...

Embodiment 2

[0055] The difference between the embodiment and the embodiment is that, with reference to Figure 9 and Figure 10 One groove wall of the slot 521 is provided with a mounting groove 523 and the opposite groove wall is provided with a locking groove 524. The notches are set relative to each other. A locking component 54 is installed in the installation groove 523 . The locking component 54 includes a compression spring 541 and a locking block 542 . The knife handle is provided with a lock hole 531, and the lock hole 531 is connected to the installation groove 523 and the lock groove 524 at the same time. The cutting blade 53 is locked and fixed in the slot 521 . In this embodiment, preferably, the lock block 542 is spherical, and the aperture of the lock hole 531 is slightly smaller than the diameter of the lock block 542. When taking out the cutting blade 53, only a large pulling force is required, and the lock block 542 can be locked in the lock hole 531. The pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com