Porous clamping device capable of automatically centering and drilling long-thin steel-sheet type parts

A technology of automatic centering and clamping device, which is applied in positioning devices, drilling dies for workpieces, metal processing machinery parts, etc. , low punching accuracy, etc., to achieve the effect of short cycle, simple clamping and high punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

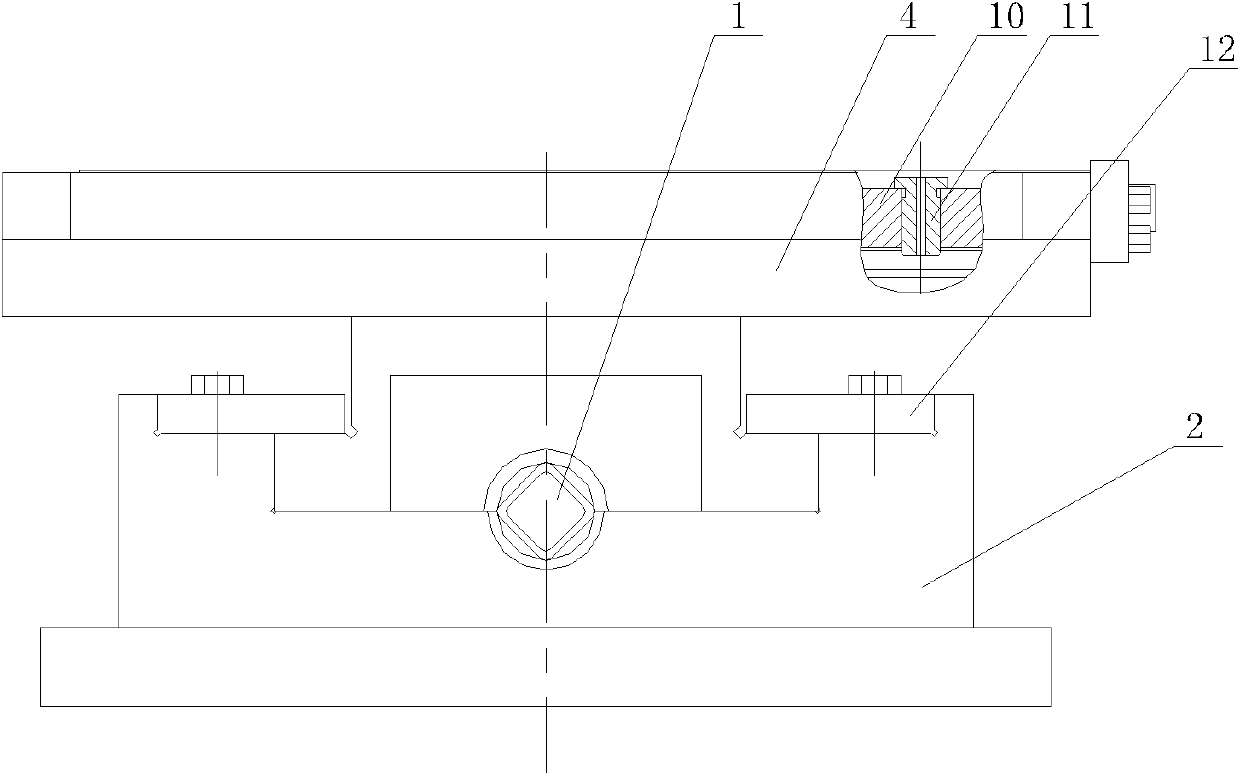

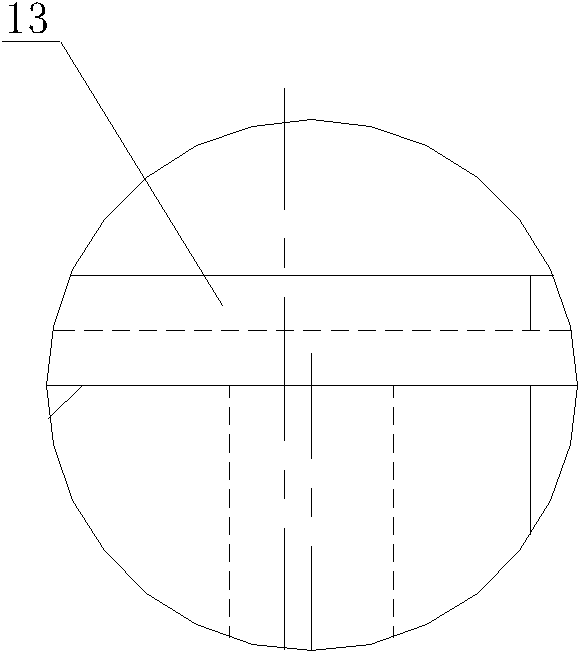

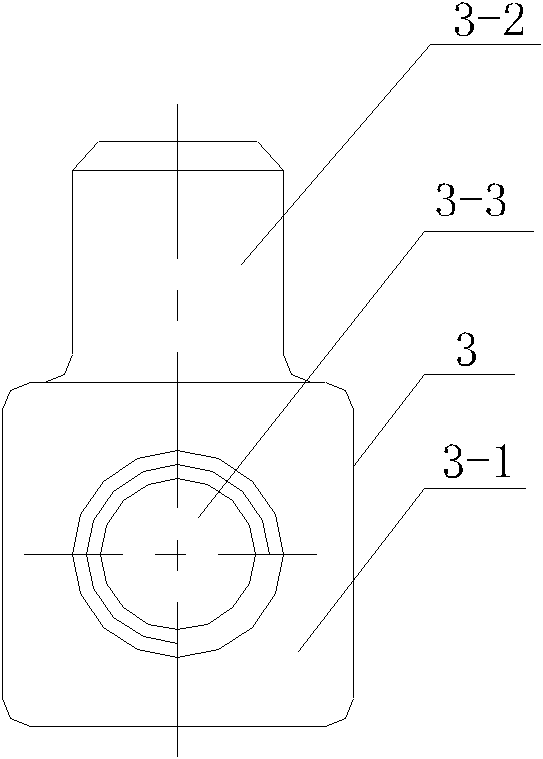

[0009] Specific implementation mode one: combine Figure 1-Figure 16 Illustrate, the multi-hole clamping device for automatic centering drilling of long and thin steel plates in this embodiment, the device includes a base 2, the base 2 is in the shape of a cuboid; the device also includes a screw rod 1, claws 4, side plates 6, top Wire 7, sliding top block 8, mold body 10, a plurality of drill sleeves 11, two nuts 3 and two pressing plates 12; the nut 3 is made up of an integrated square body end 3-1 and a cylindrical rod 3-2 , the side wall of the square body end 3-1 is provided with a through threaded through hole 3-3; the claw 4 includes a first sliding table 4-1, a first limiting table 4-2 and a baffle plate 4-3; The first sliding platform 4-1 is located at the bottom of the first limiting platform 4-2 and is integrated with the first limiting platform 4-2; the sliding top block 8 includes the second sliding platform 8-1 and the second limiting platform 8-2; the second sl...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and Figure 5 Note that both ends of the screw rod 1 in this embodiment are flat ends 1-2. Designed in this way, use the jaws to fix it. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 , figure 2 , Figure 14 and Figure 15 To illustrate, the base 2 of this embodiment is a cast steel base. Such design, good wear resistance. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com