Automobile damping fixing piece sectional material die

A technology for automobile shock absorption and fixing parts, applied in the direction of metal extrusion dies, etc., can solve the problems of easy deflection of cavity wall thickness, insufficient filling of intermediate ribs, complex design structure, etc. Effect of surface roughness and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

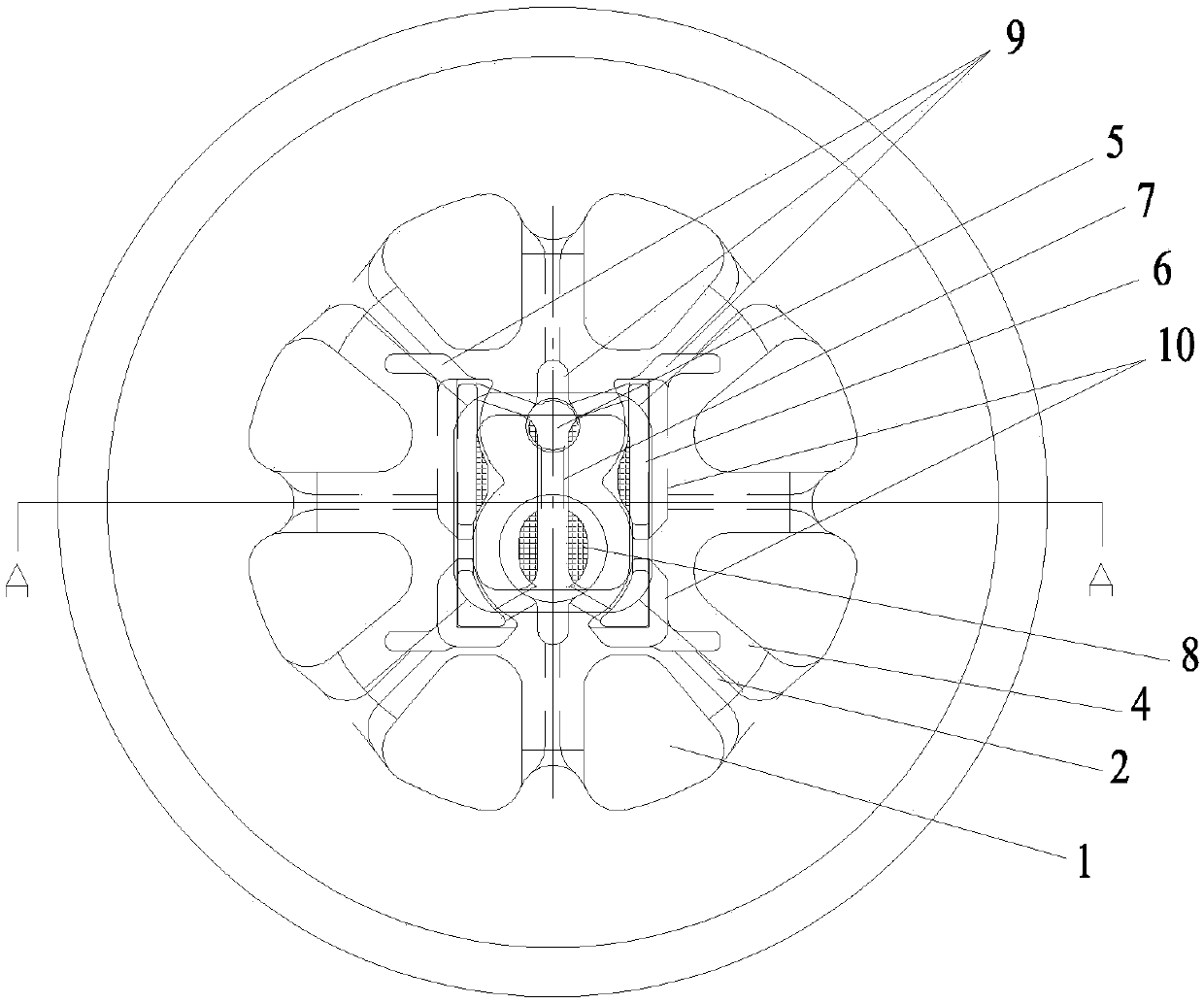

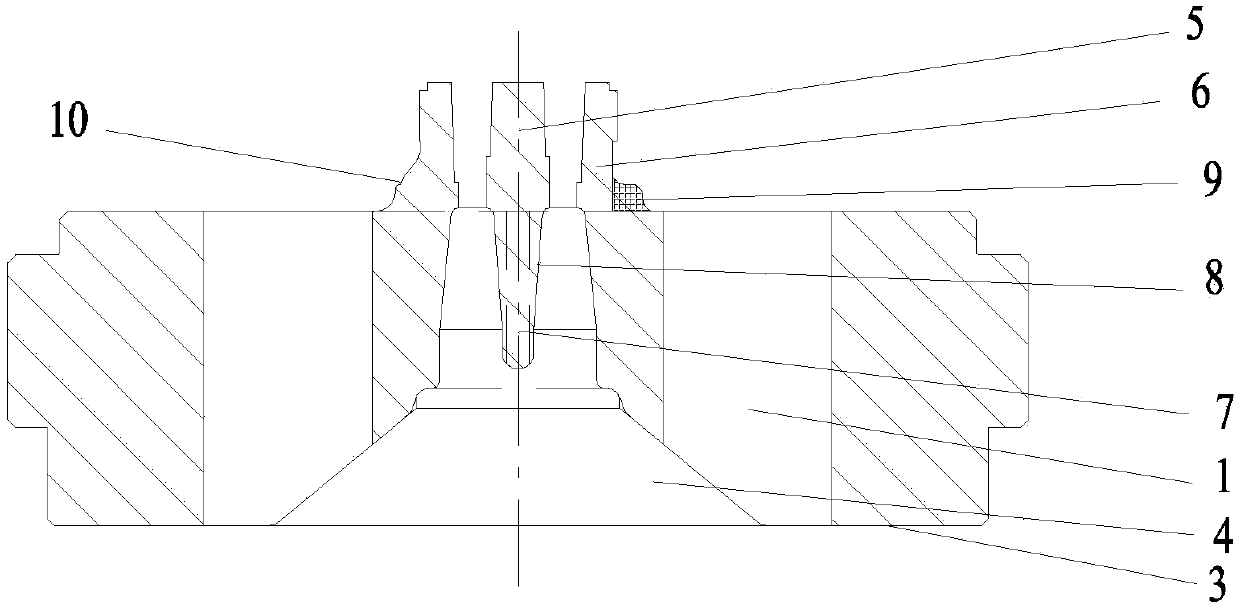

[0021] Such as Figure 2-7 Shown: the automobile shock absorbing fixture profile mold, which includes an upper mold and a lower mold superimposed on each other, and the upper mold and the lower mold are assembled with two screws and two pins. Eight peripheral distribution holes 1 and eight distribution bridges 2 are arranged on the feed surface 3 of the upper die. The peripheral distribution holes 1 and the distribution bridges 2 are evenly arranged along the circumference, and the center is provided with a middle distribution hole 4. The middle distribution hole 4 is funnel-shaped. The discharge surface of the upper mold is provided with two inner mold cores 5 , large and small, corresponding to the holes of the profile, and symmetrical outer mold cores 6 are arranged on both sides thereof. A core bridge 7 is provided between the inner mold core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com