Patents

Literature

191results about How to "Not easy to deflect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

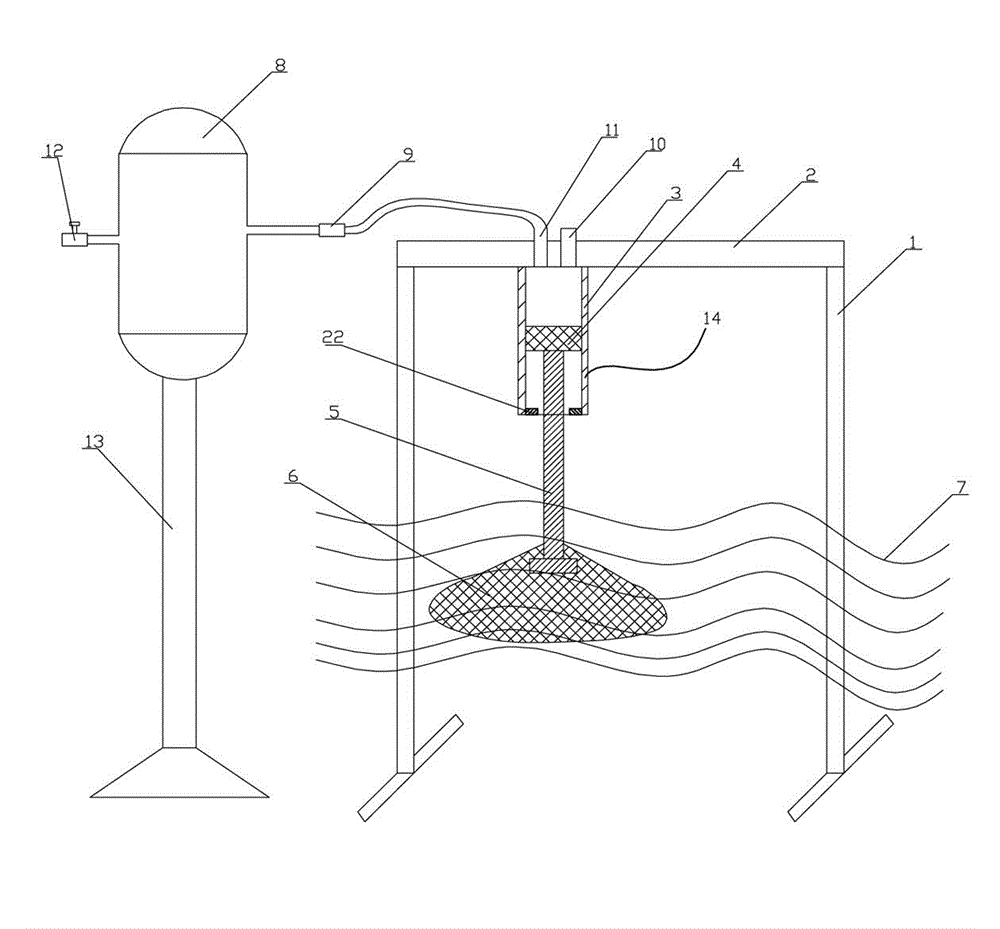

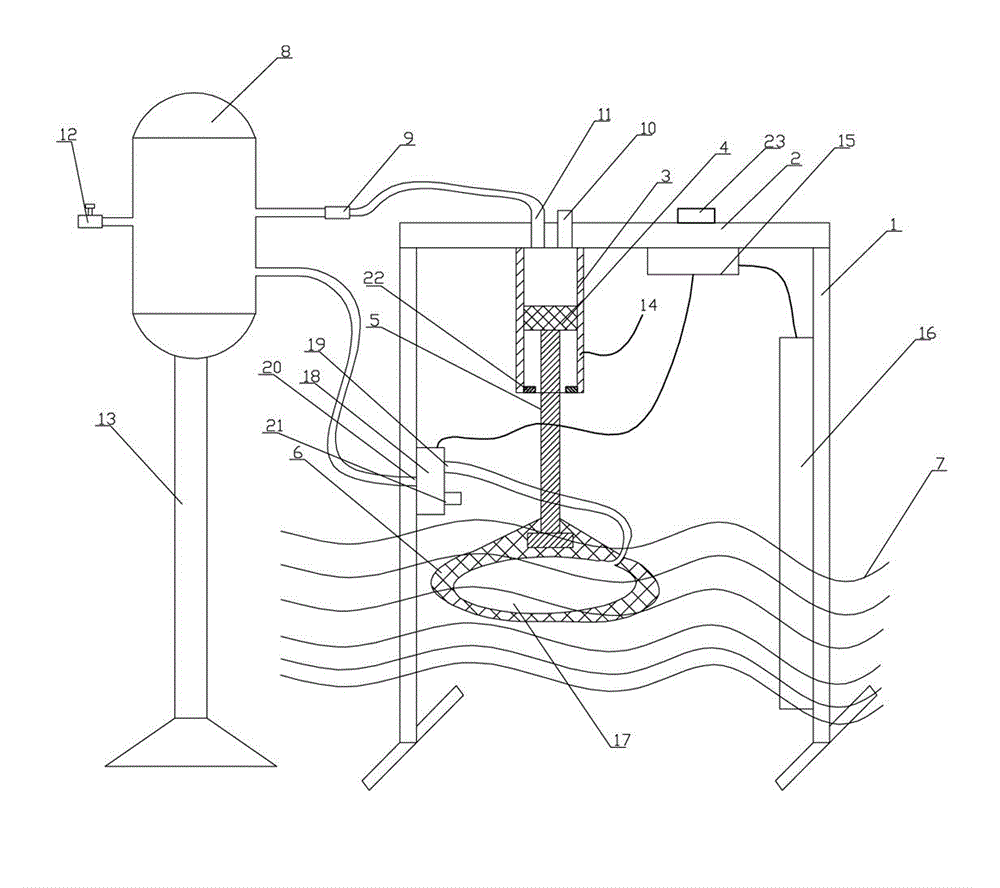

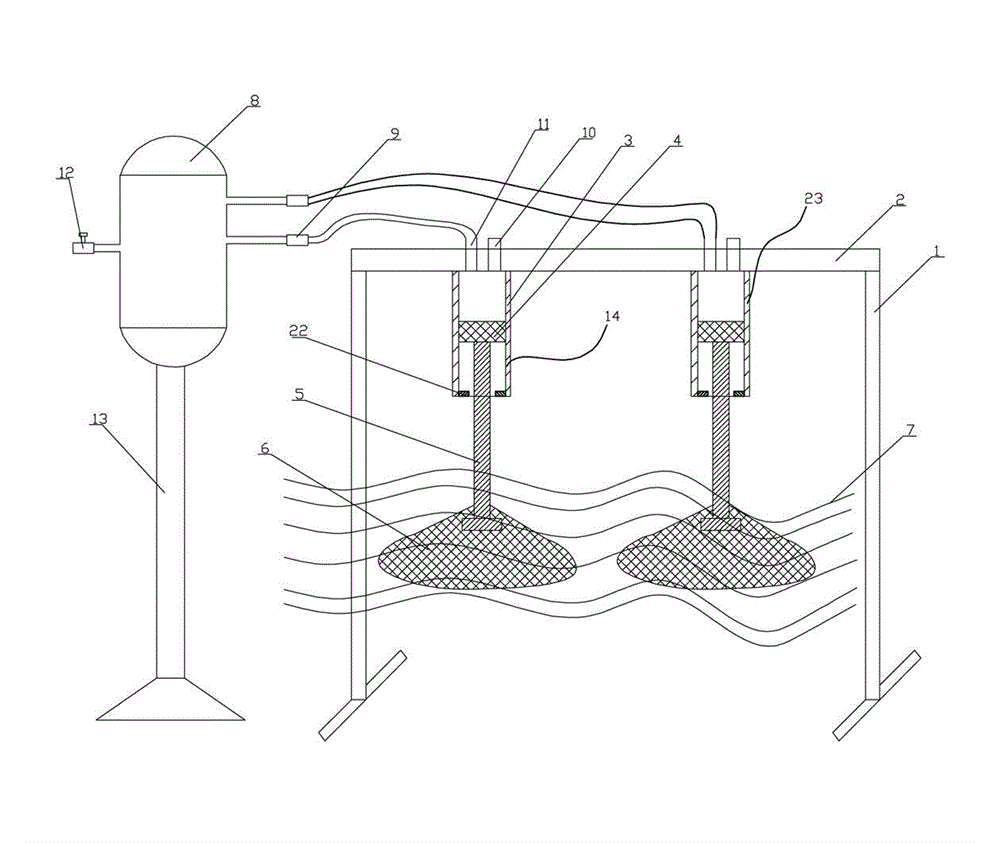

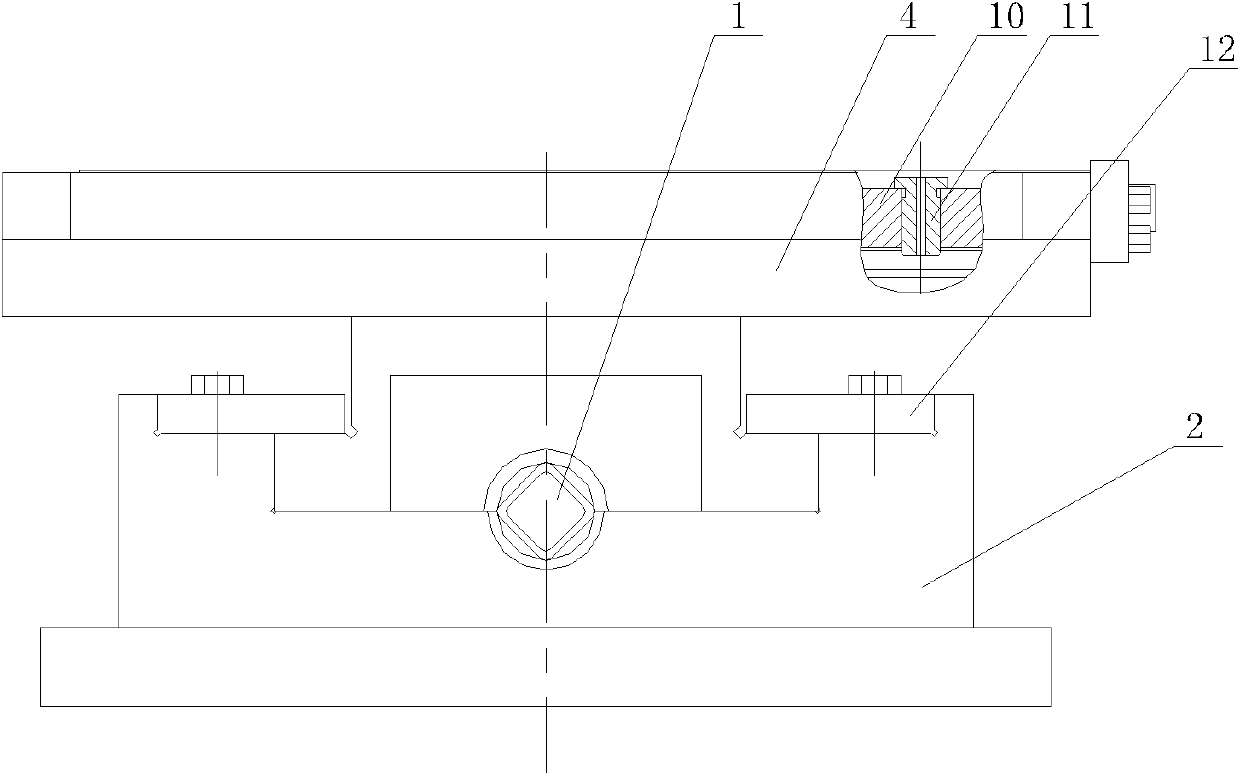

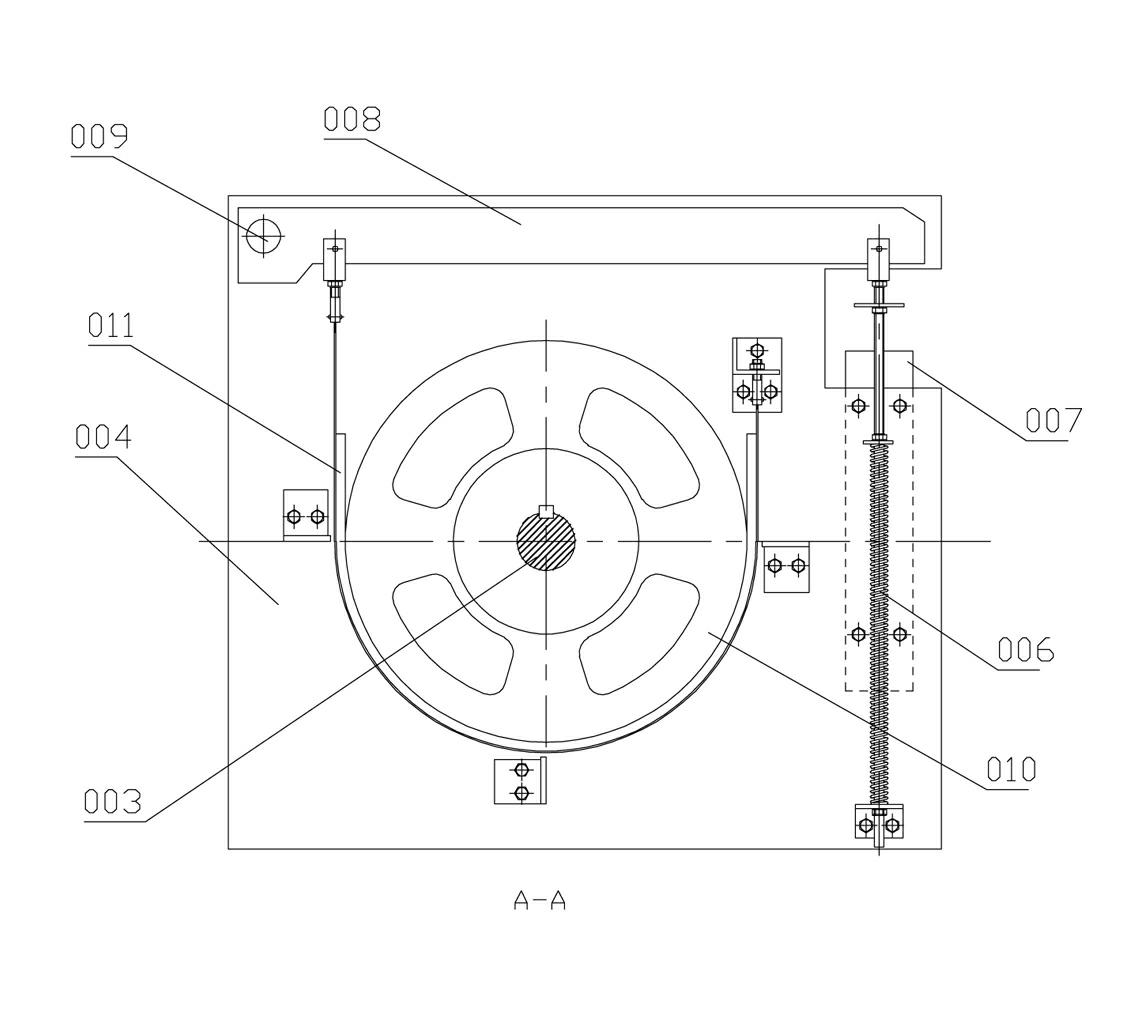

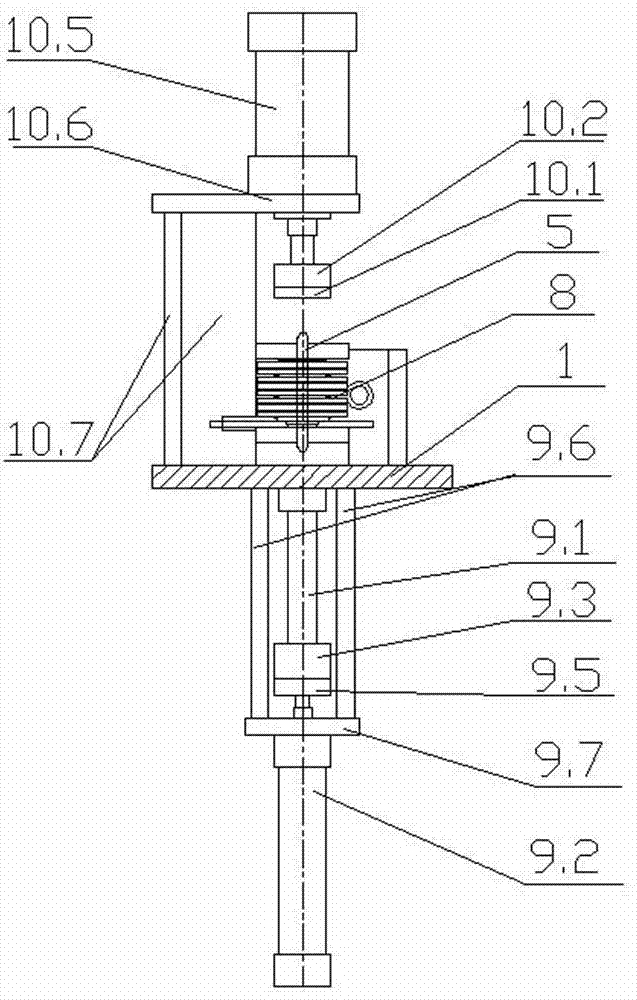

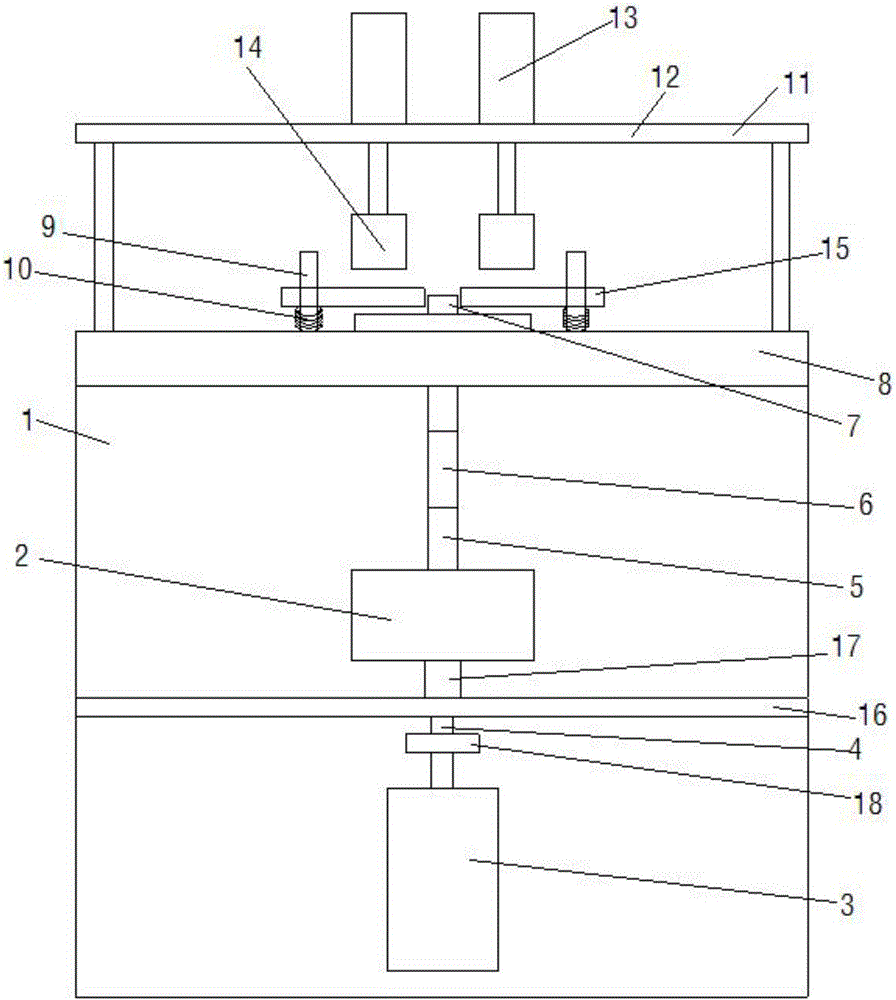

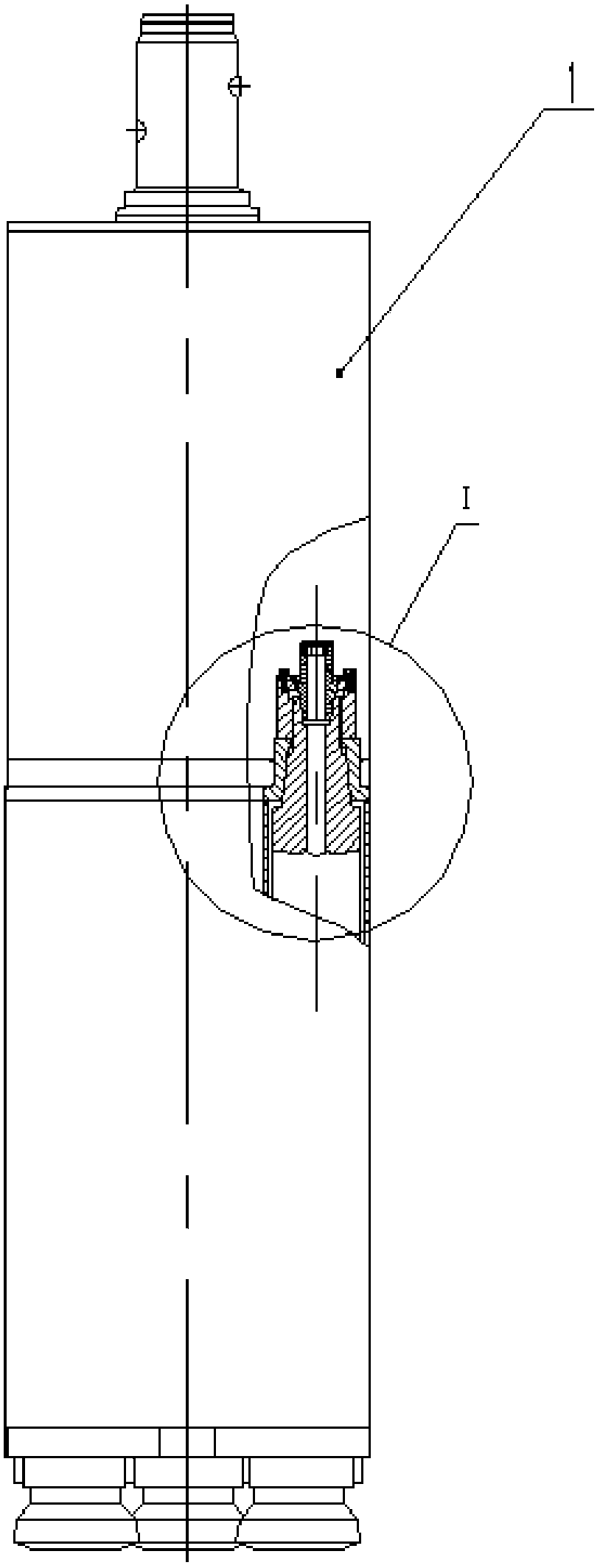

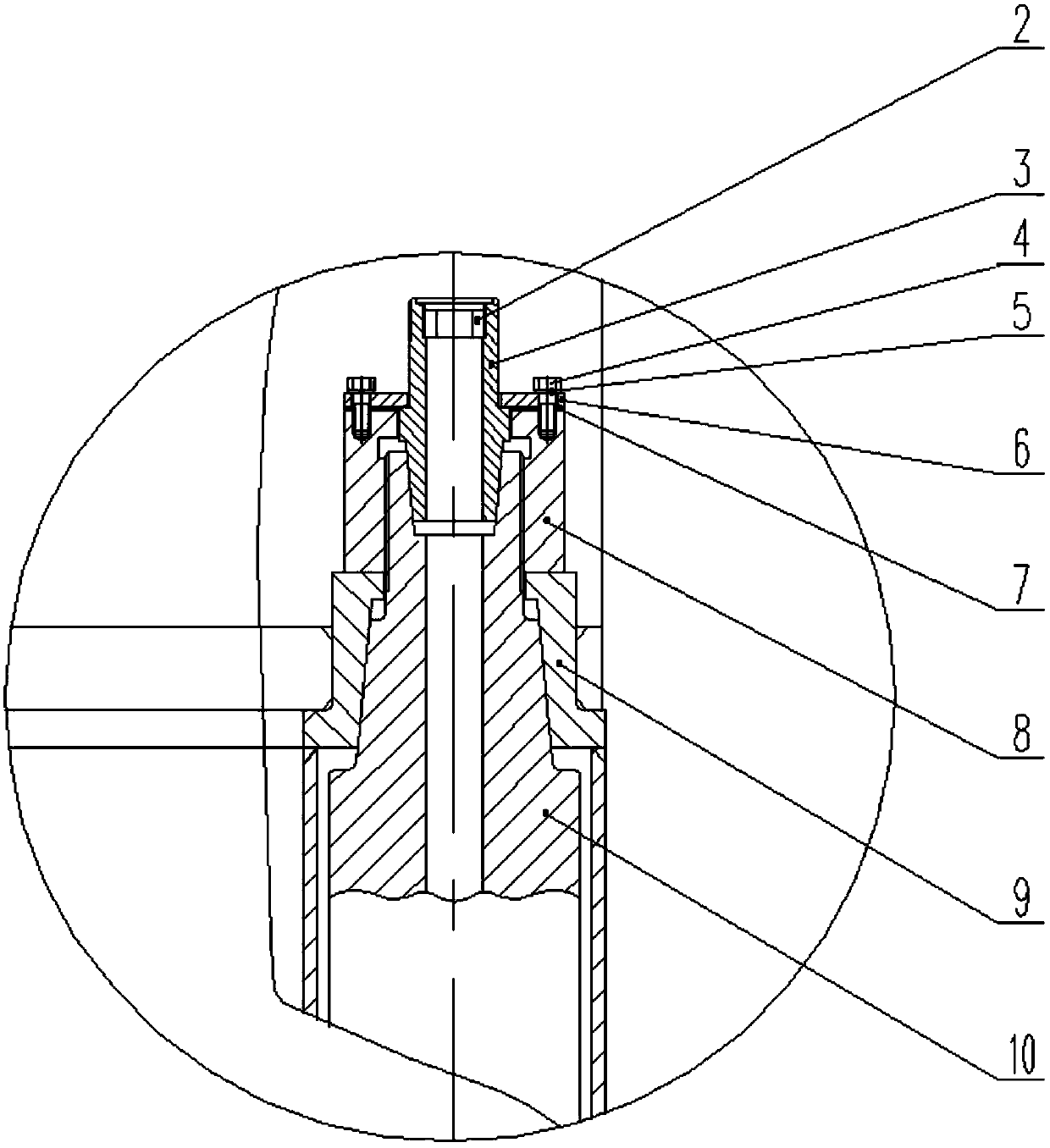

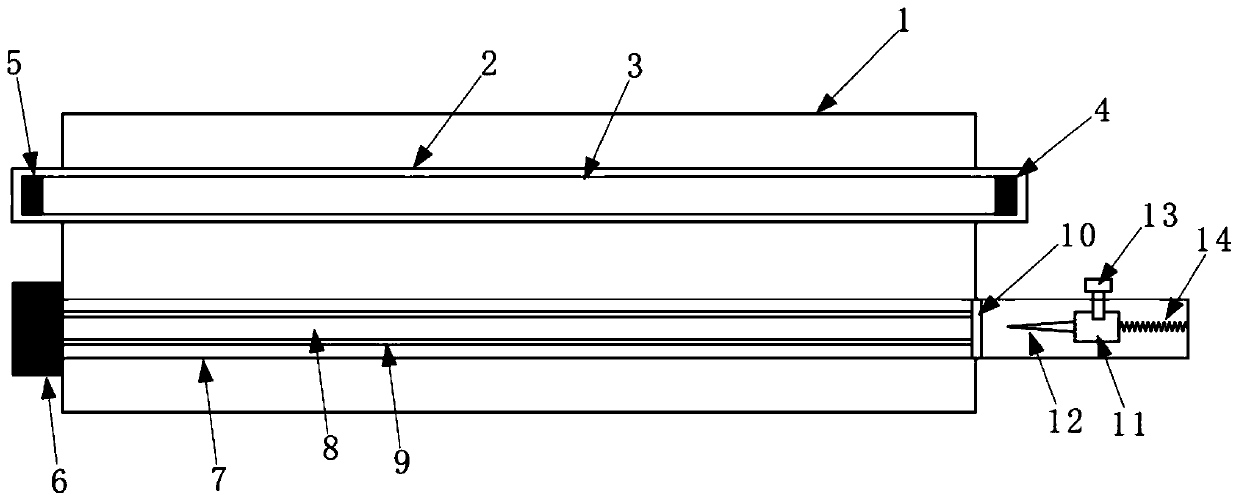

Tidal energy gas supply apparatus

InactiveCN102943957AEfficient use ofLess transfer processMachines/enginesEngine componentsProcess engineeringCheck valve

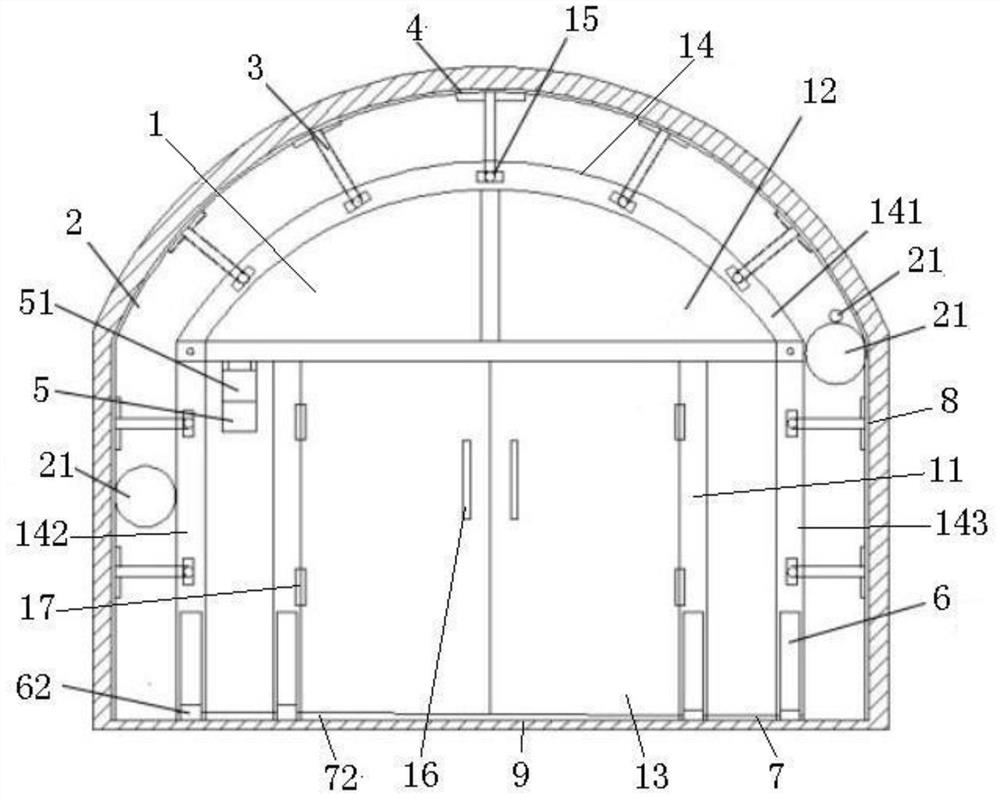

The present invention relates to a tidal energy gas supply apparatus, which is characterized by comprising a support (1), an inflation unit (14) and a gas storage tank (8), wherein the inflation unit (14) comprises a cylinder (3), a piston (4), a piston rod (5) and a floating body (6), the cylinder (3) is arranged on a beam (2) of the support (1), the piston (4) is slidably matched inside the cylinder (3), the upper end of the piston rod (5) is fixedly connected with the piston (4), the lower end of the piston rod (5) is fixedly connected with the floating body (6), the upper end of the cylinder (3) is provided with a first check valve (10) and a gas outlet (11), the gas outlet (11) passes through a second check valve (9) and is communicated with the gas storage tank (8), the lower end of the cylinder (3) is provided with an opening, the opening position is provided with a closing ring (22), and the gas storage tank (8) is provided with an inflation interface (12). The present invention provides a tidal energy gas supply apparatus for providing a gas source for coastal gas using equipment by using tidal energy.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

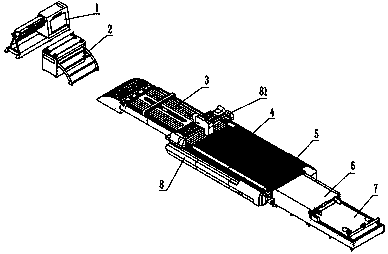

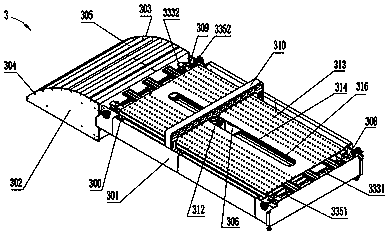

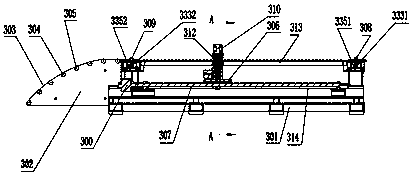

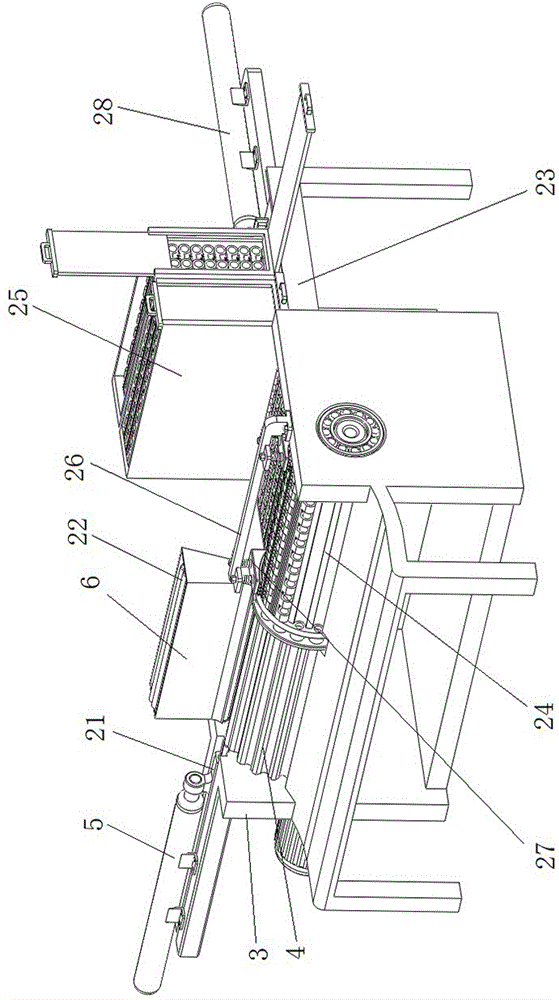

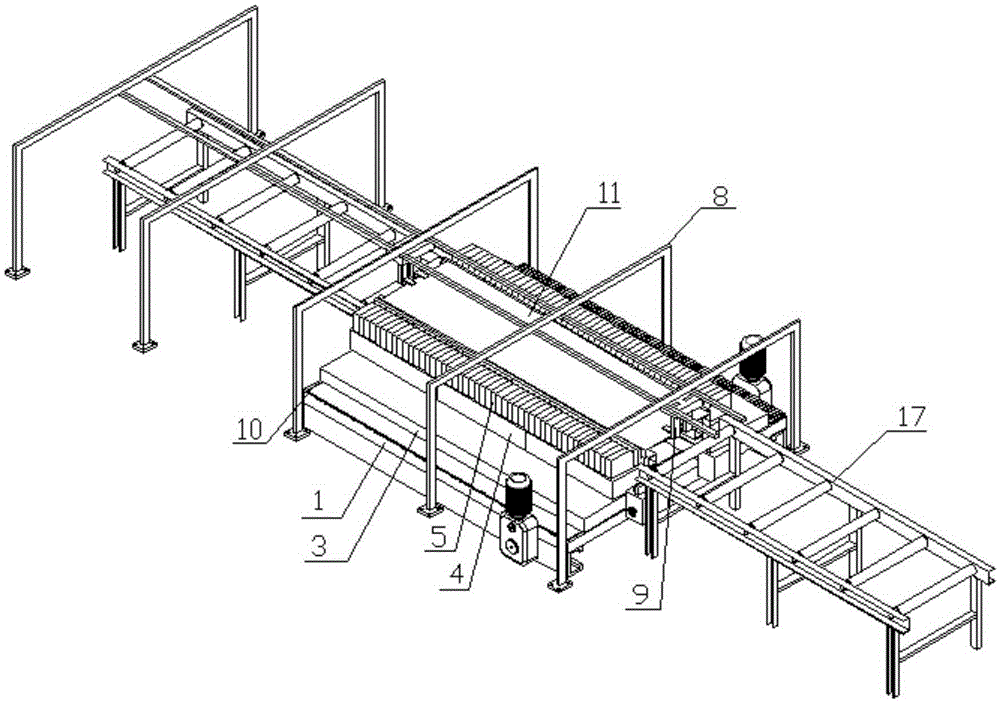

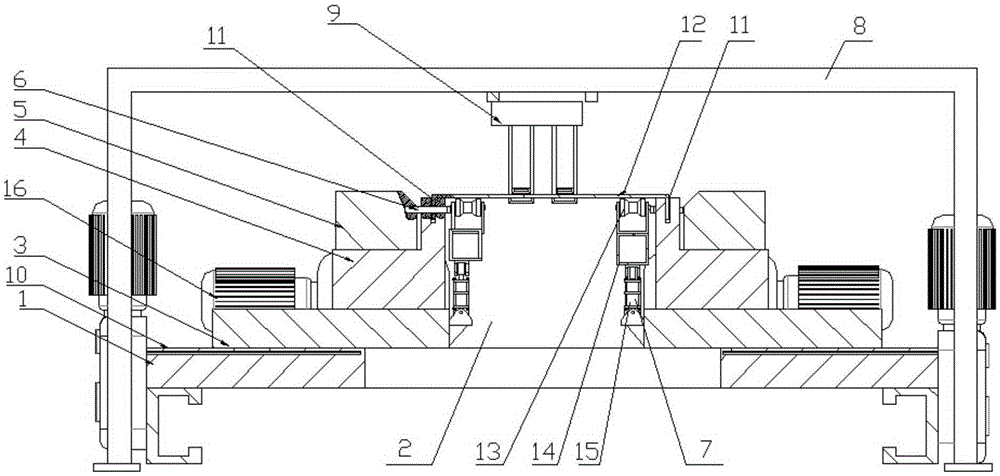

Laser cutting device

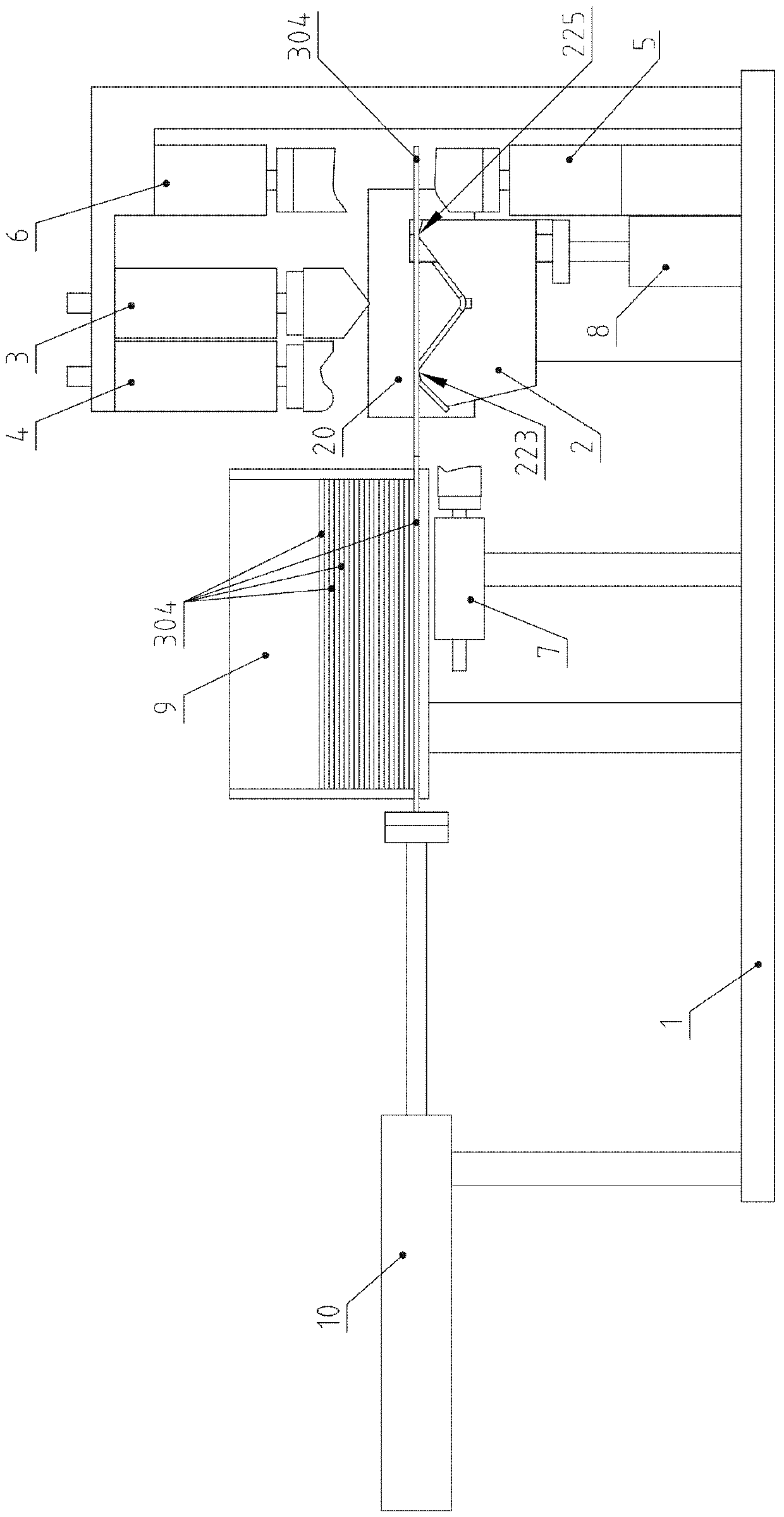

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

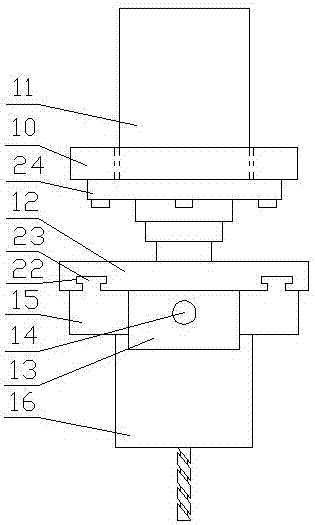

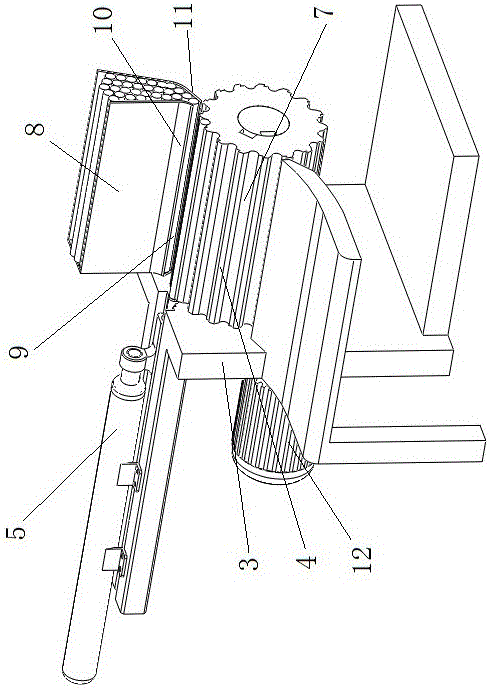

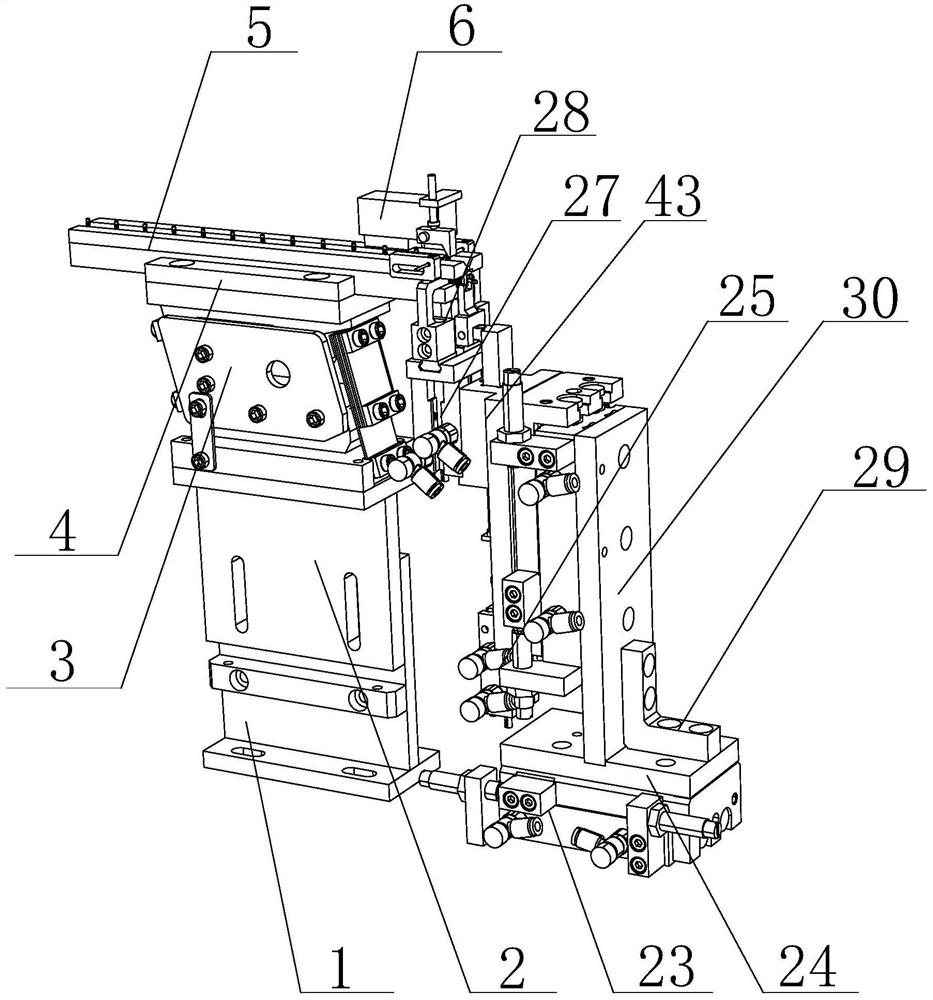

Hole group machining device for machining

ActiveCN107414129AStable and reliable translationNot easy to deflectFeeding apparatusBoring/drilling componentsEngineeringDrill

The invention discloses a hole group machining device for machining. The hole group machining device for machining comprises end portion platforms; supporting legs are welded to the bottoms of the end portion platforms; a side vertical plate is welded to one side of each end portion platform; an adjusting screw rod is connected to each side vertical plate in a threaded manner; the end portion of each adjusting screw rod is rotationally matched with a chuck through a bearing; clamping bolts are connected to the upper portions of the chucks in a threaded manner; the lower portion of each chuck is in sliding fit with a guiding base installed on the corresponding end portion platform; rolling columns are arranged at the bottoms of the inner sides of the chucks; the tops of the side vertical plates are welded to a top plate frame; lifting oil cylinders are detachably connected to the top plate frame, and are connected with lifting frames; lead screw bases are welded to the lifting frames, and are matched with lead screws; sliders are installed on the lead screws in a penetrating manner; and the lower portions of the sliders are connected with electric drills. The hole group machining device for machining can perform machining of group holes, the hole machining efficiency is doubled, operation is convenient and easy, and the hole group machining device for machining is suitable for machining work of holes of boards.

Owner:南京宝讯精密机械制造有限公司

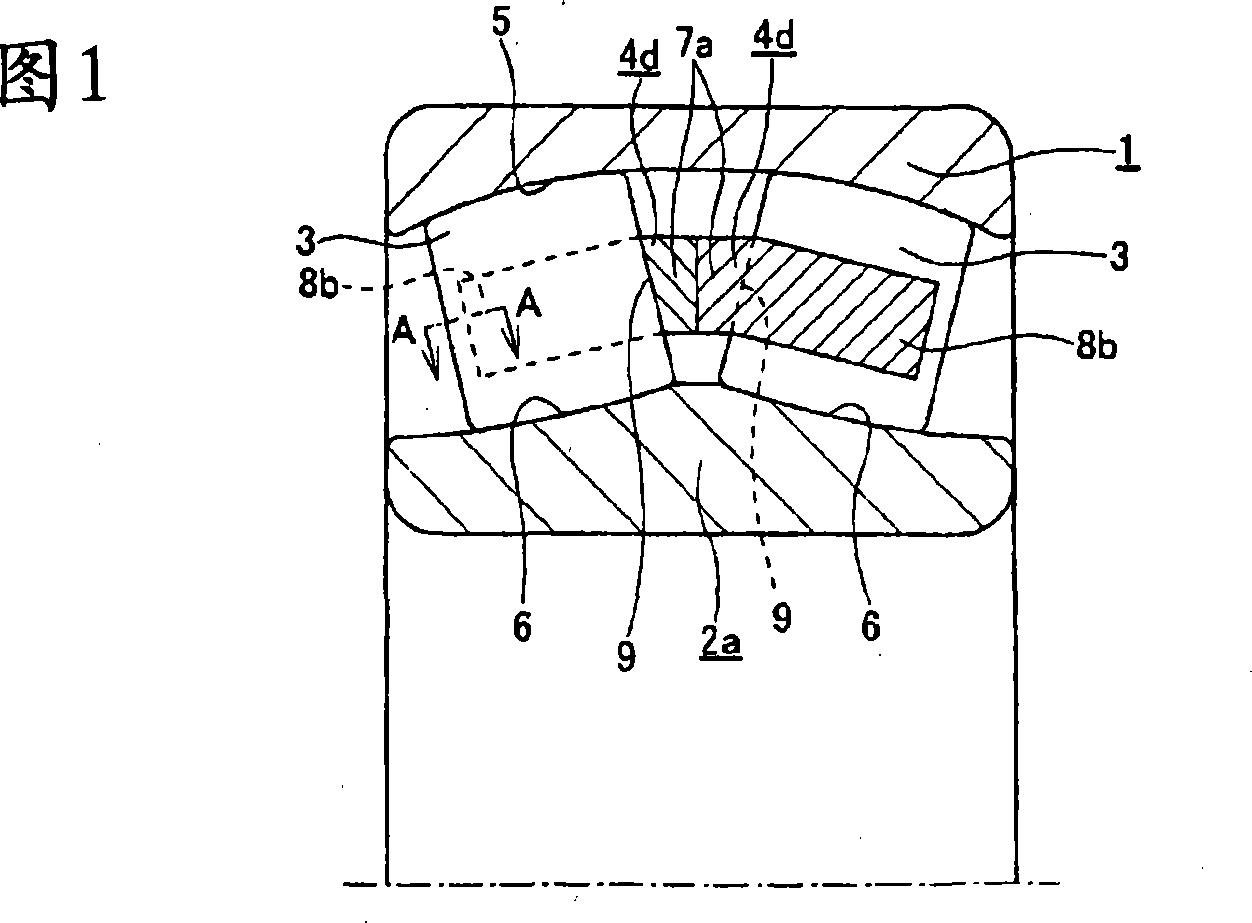

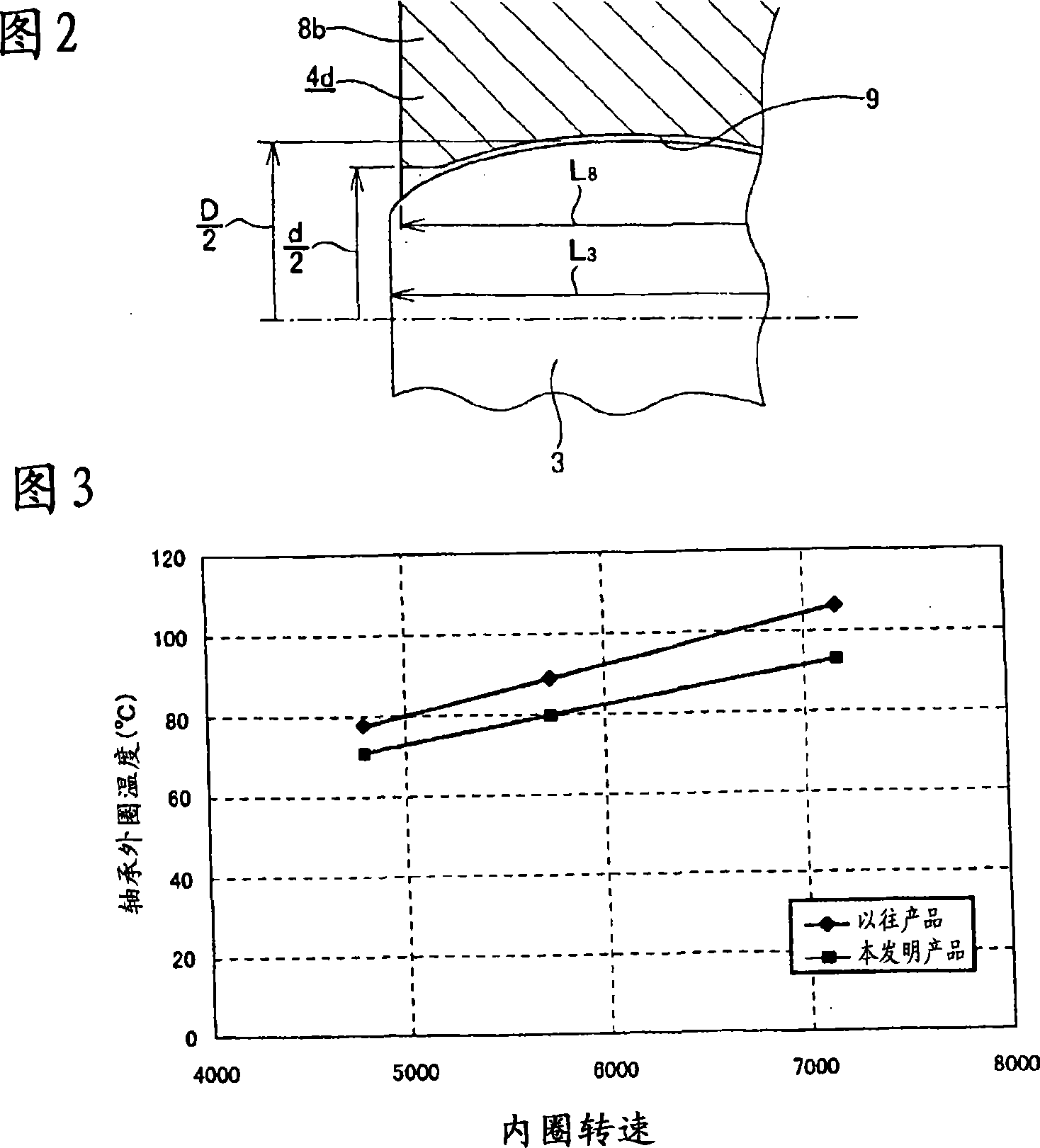

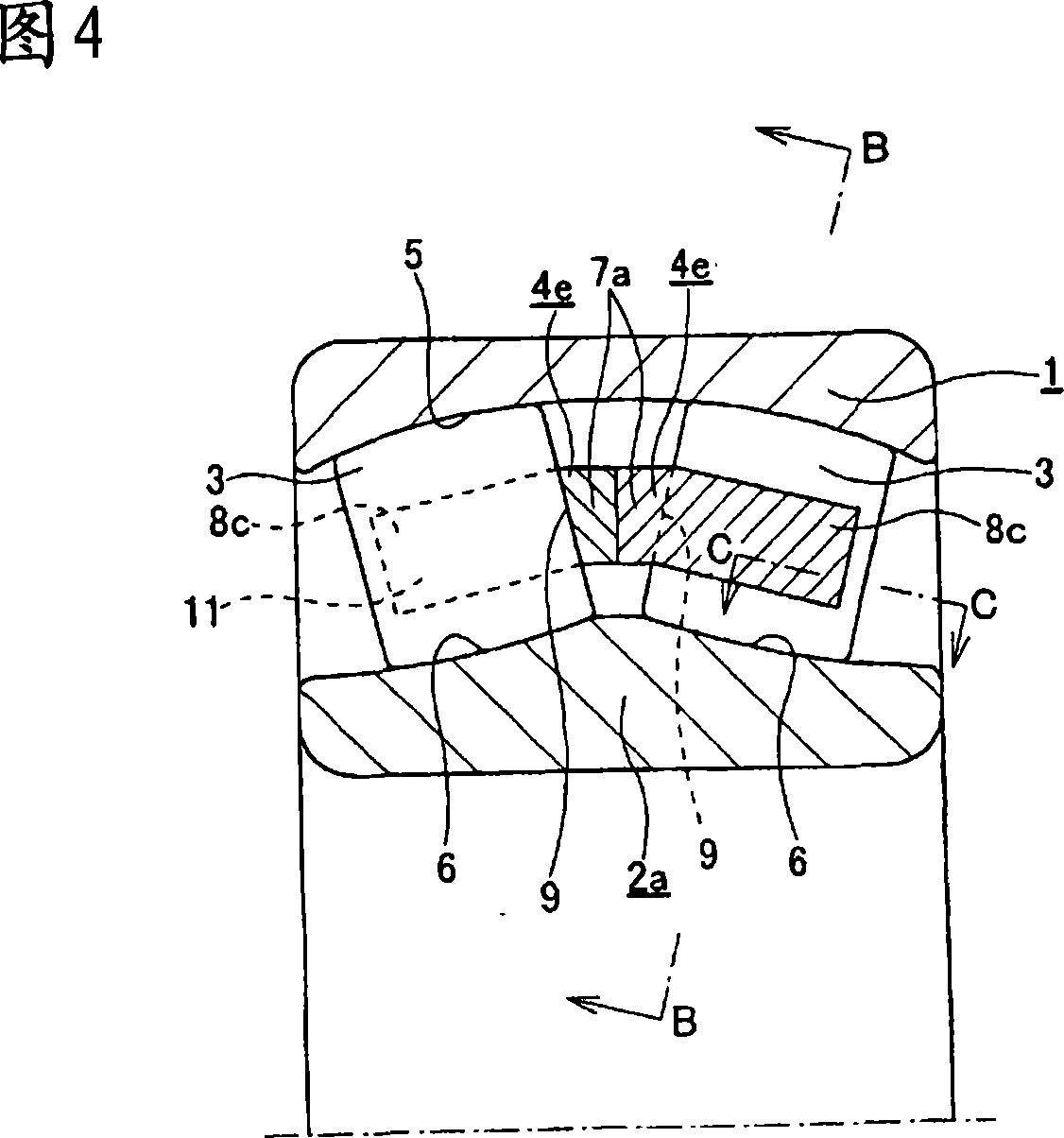

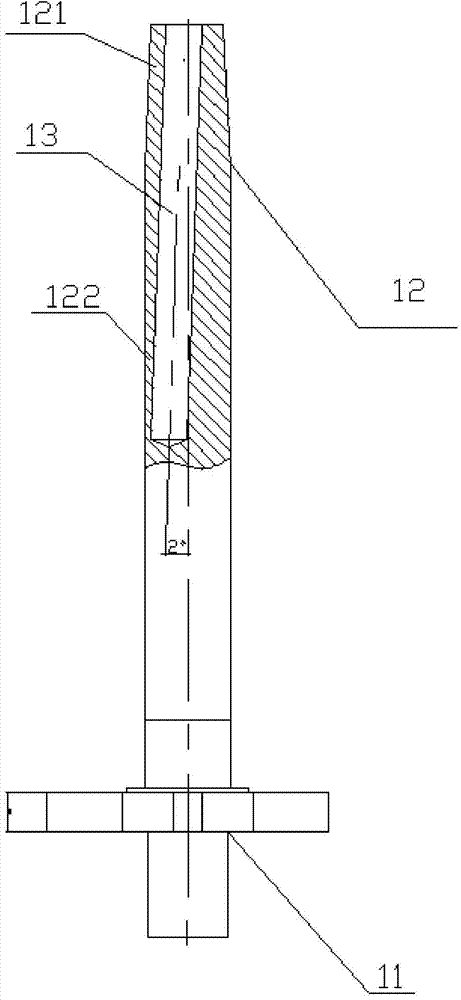

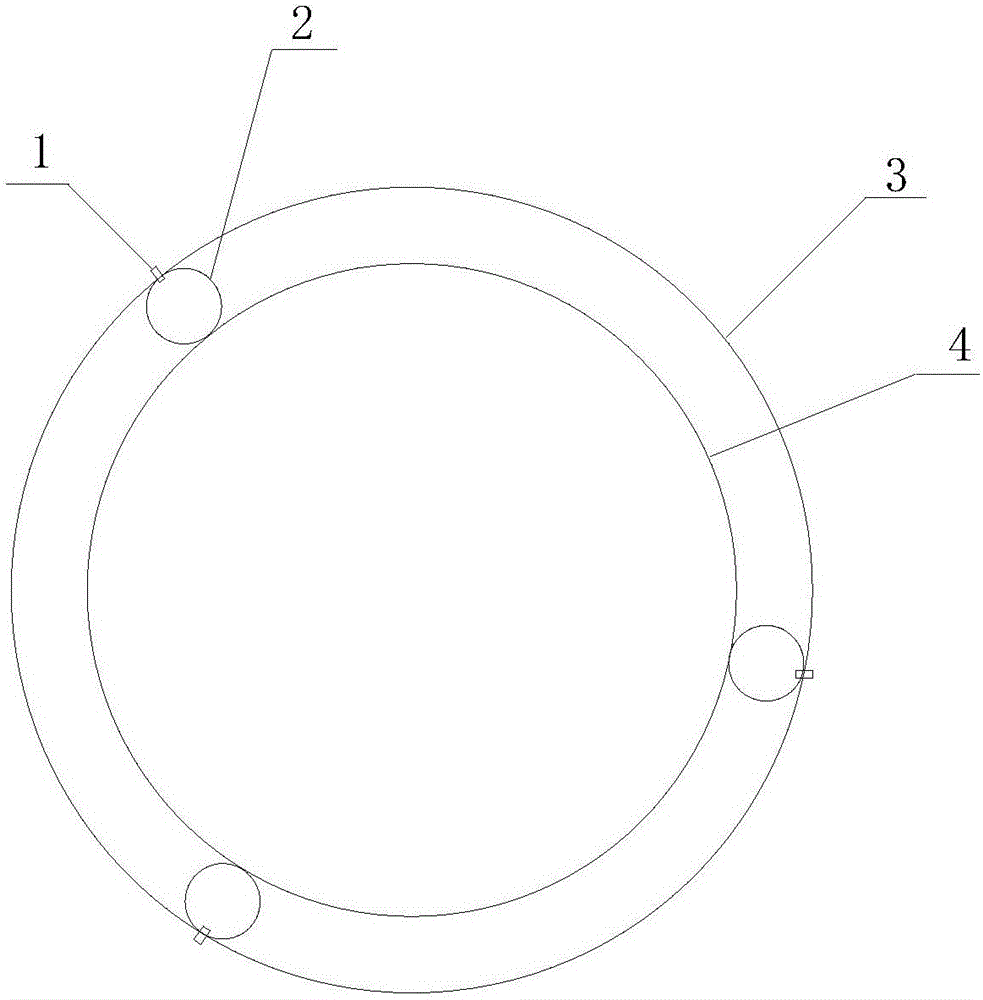

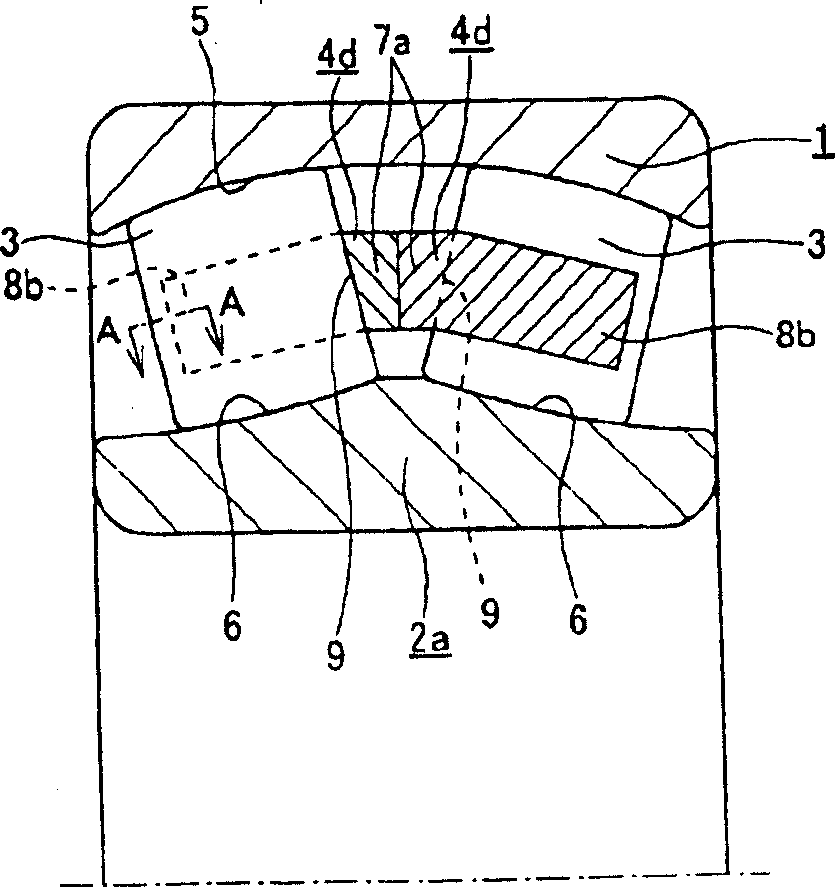

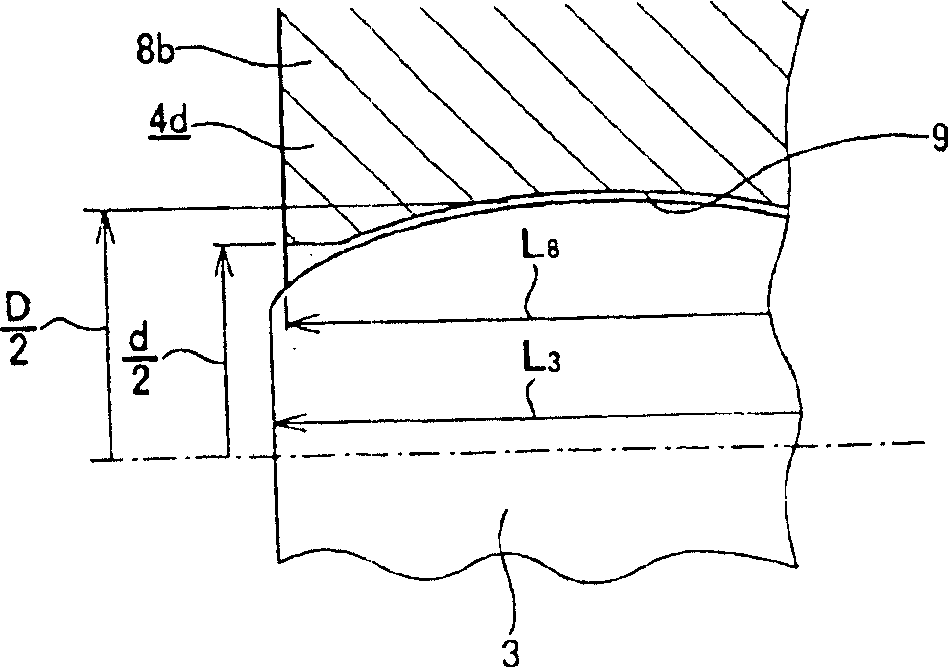

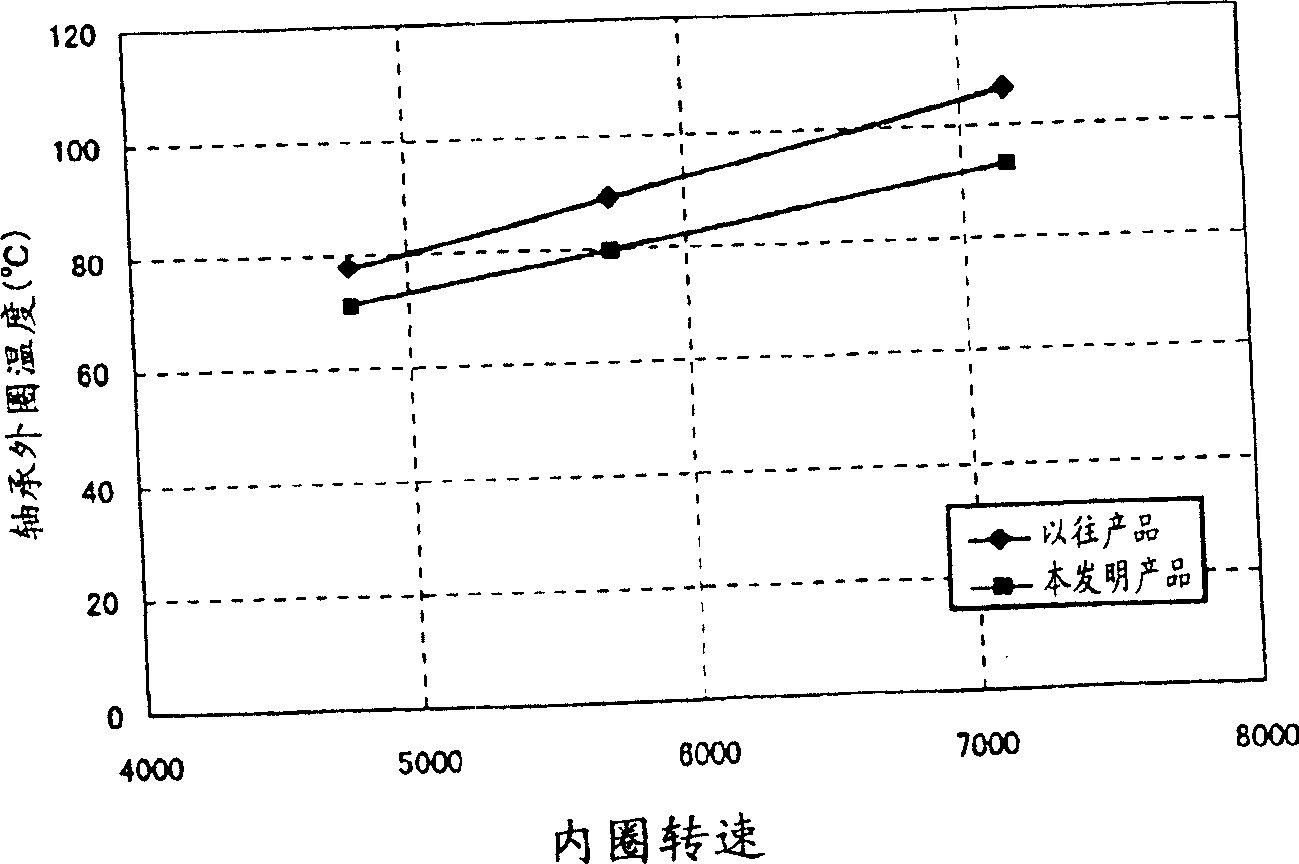

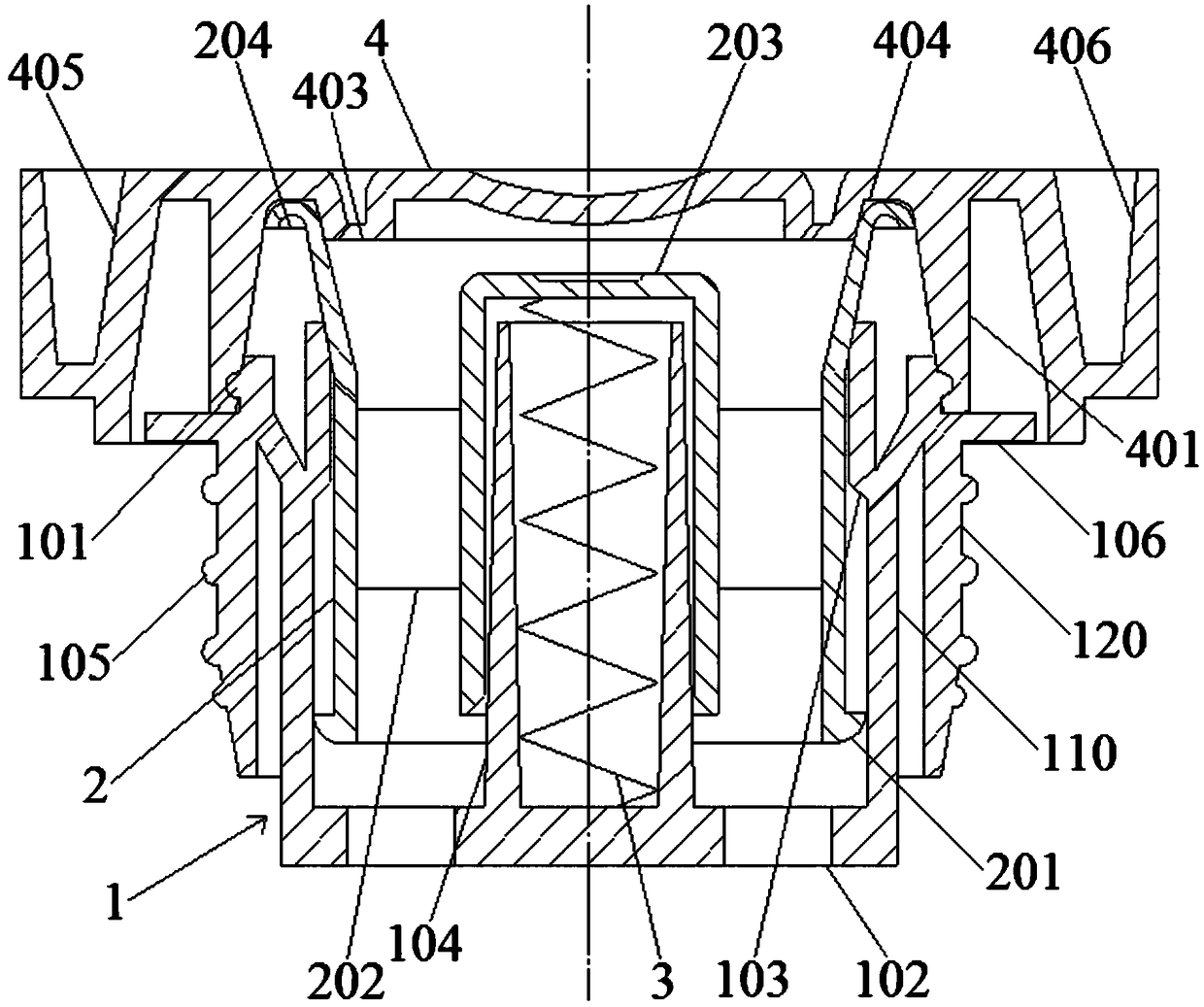

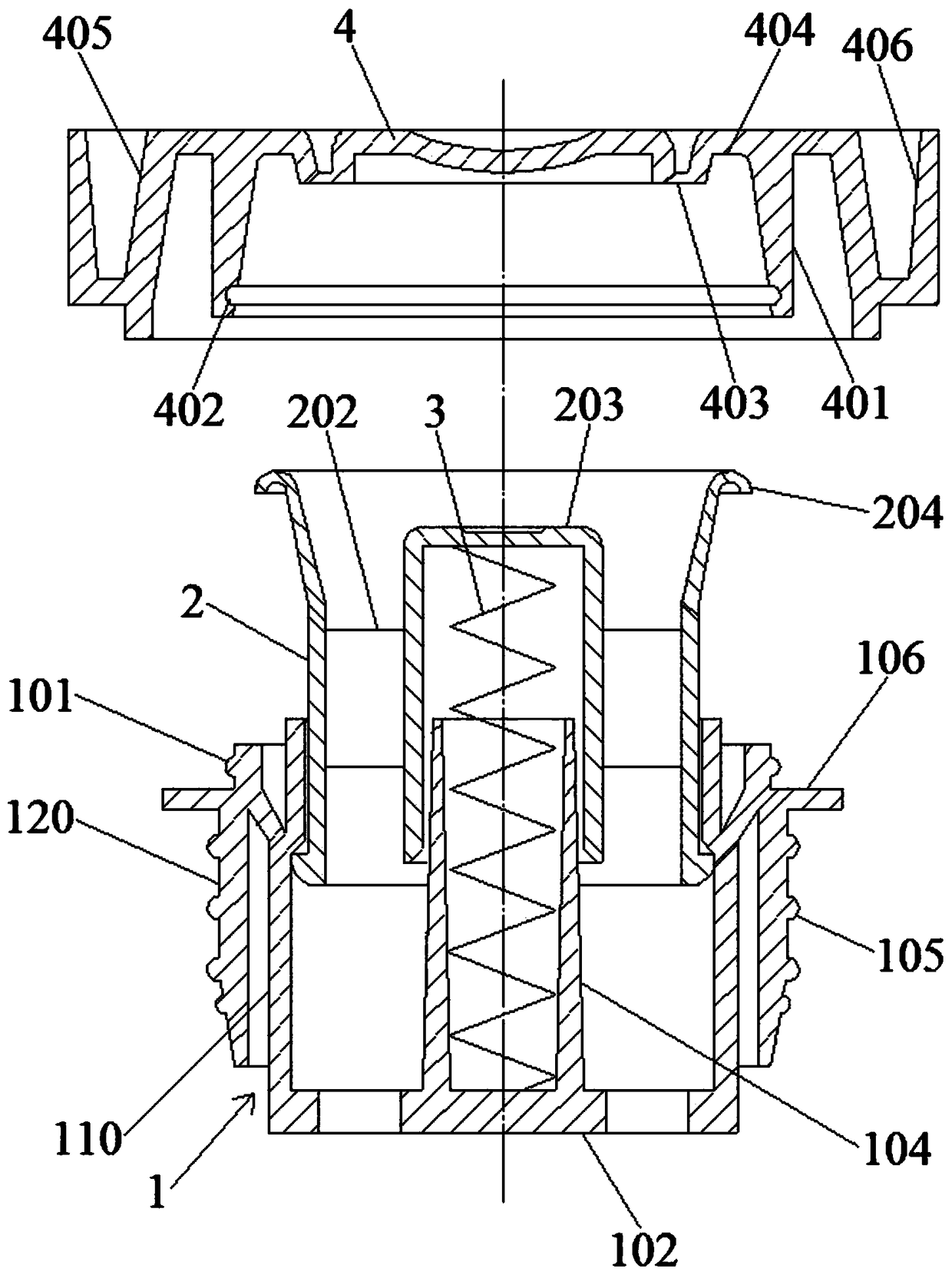

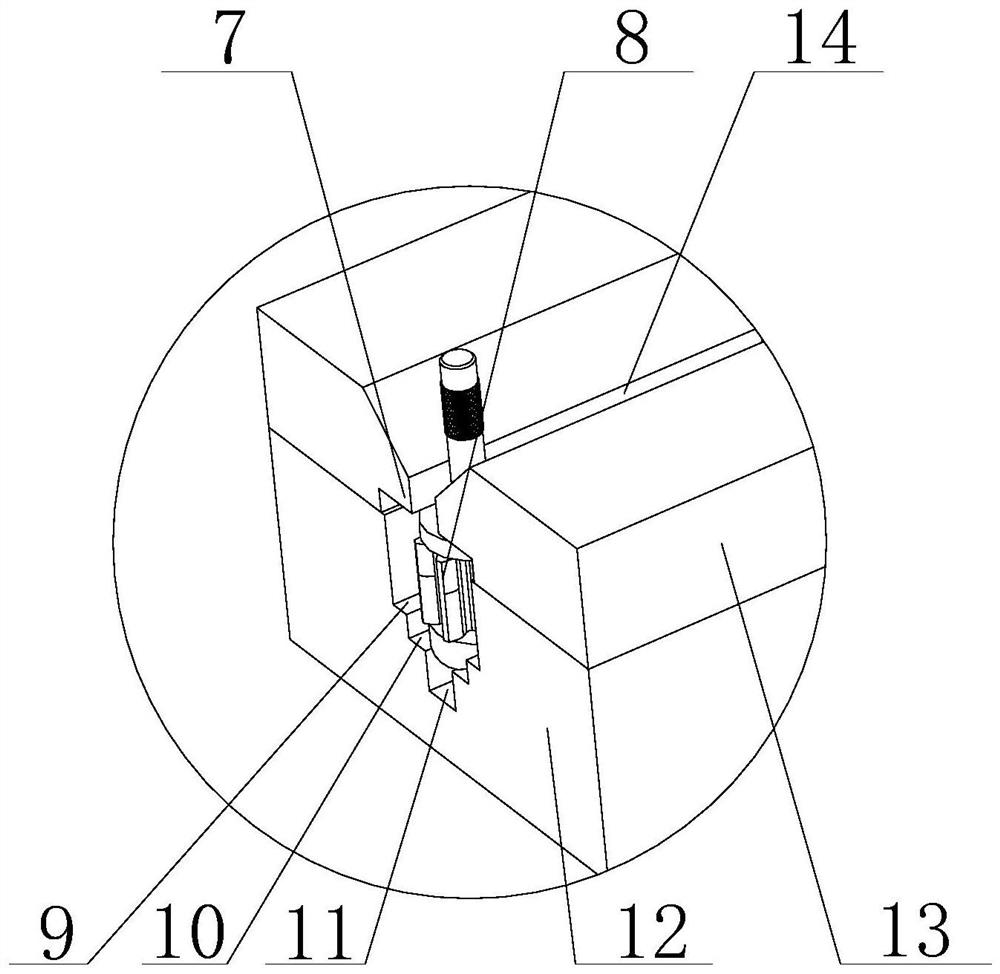

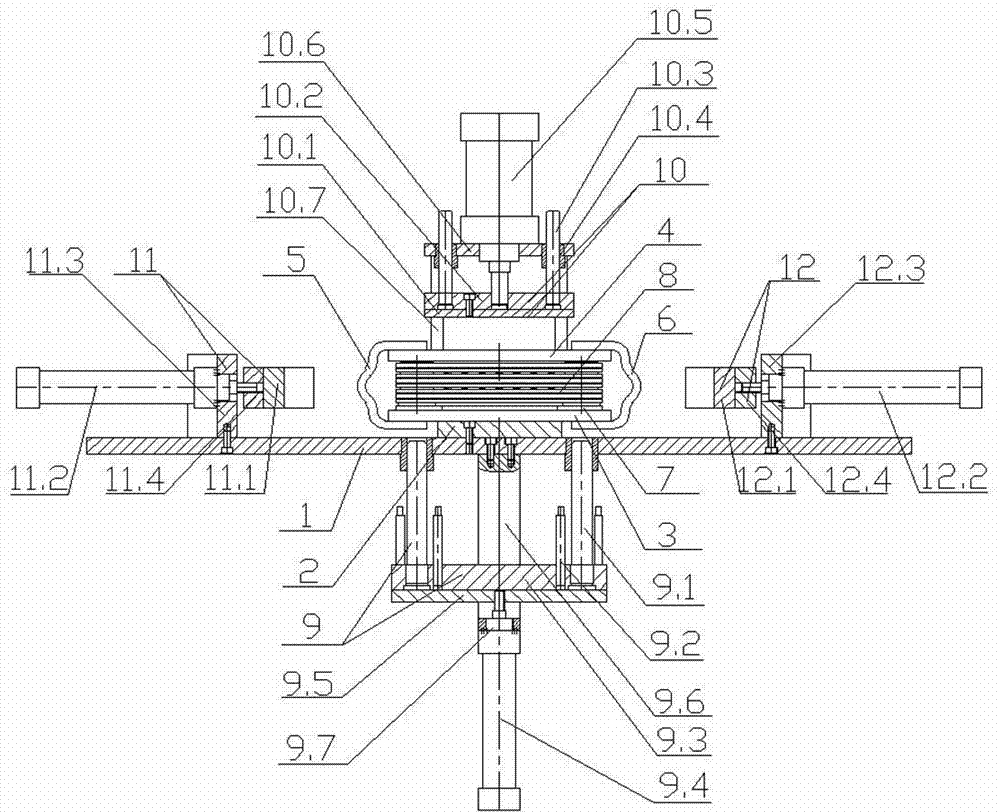

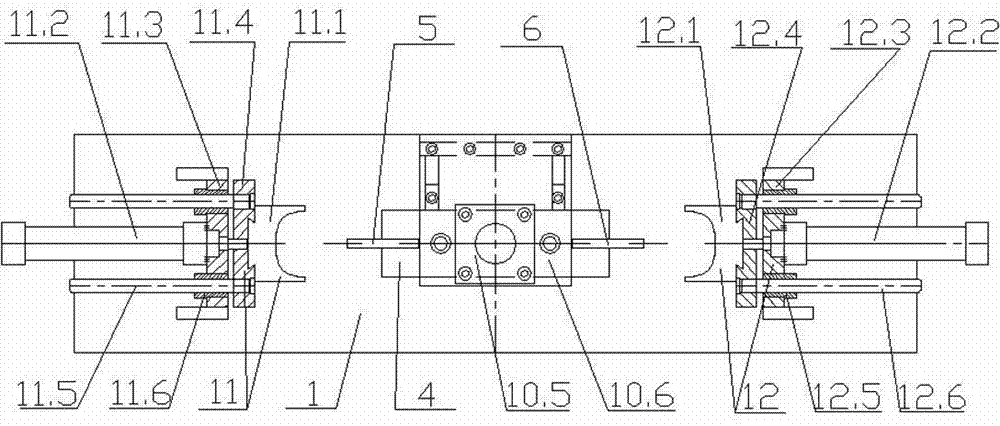

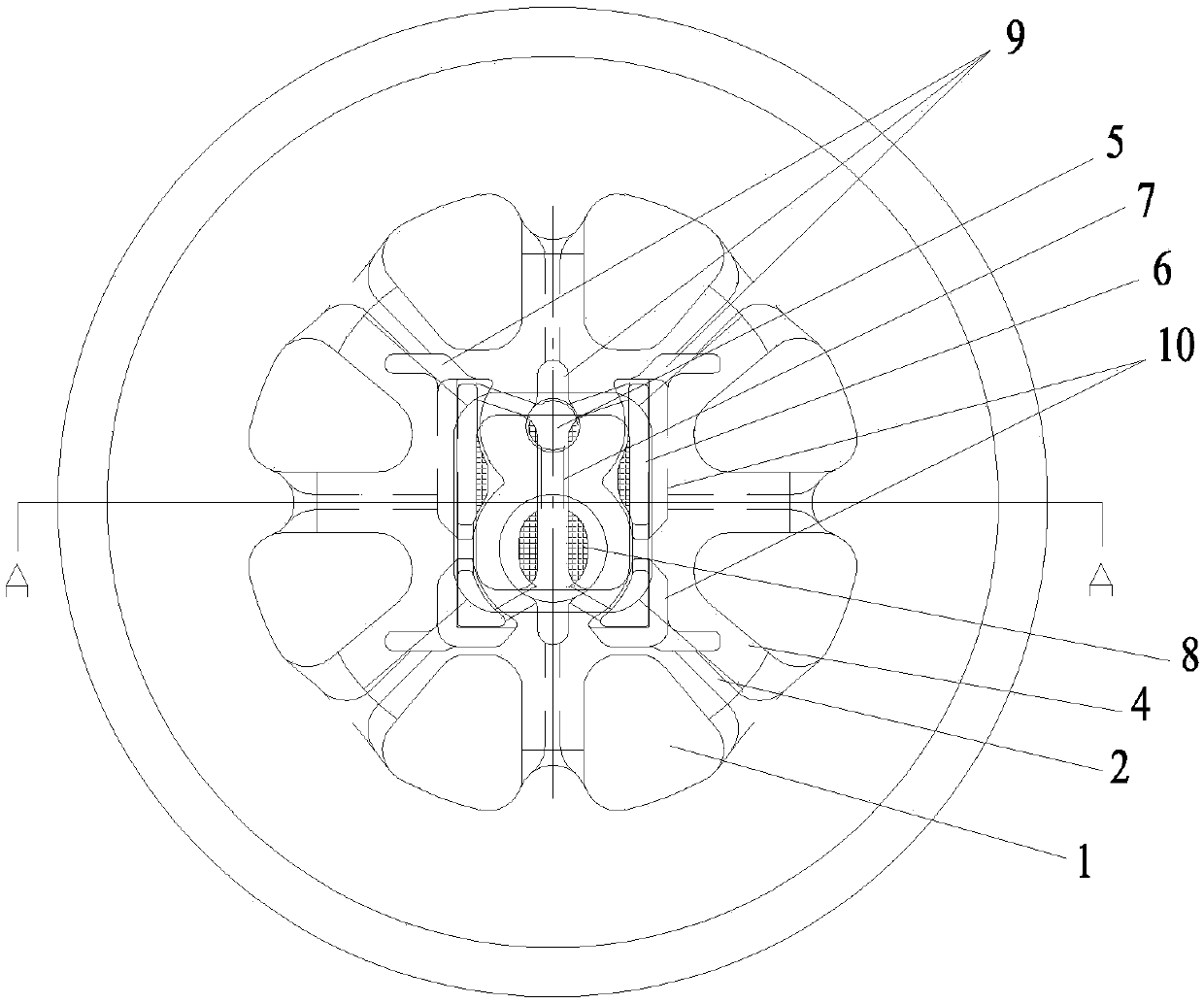

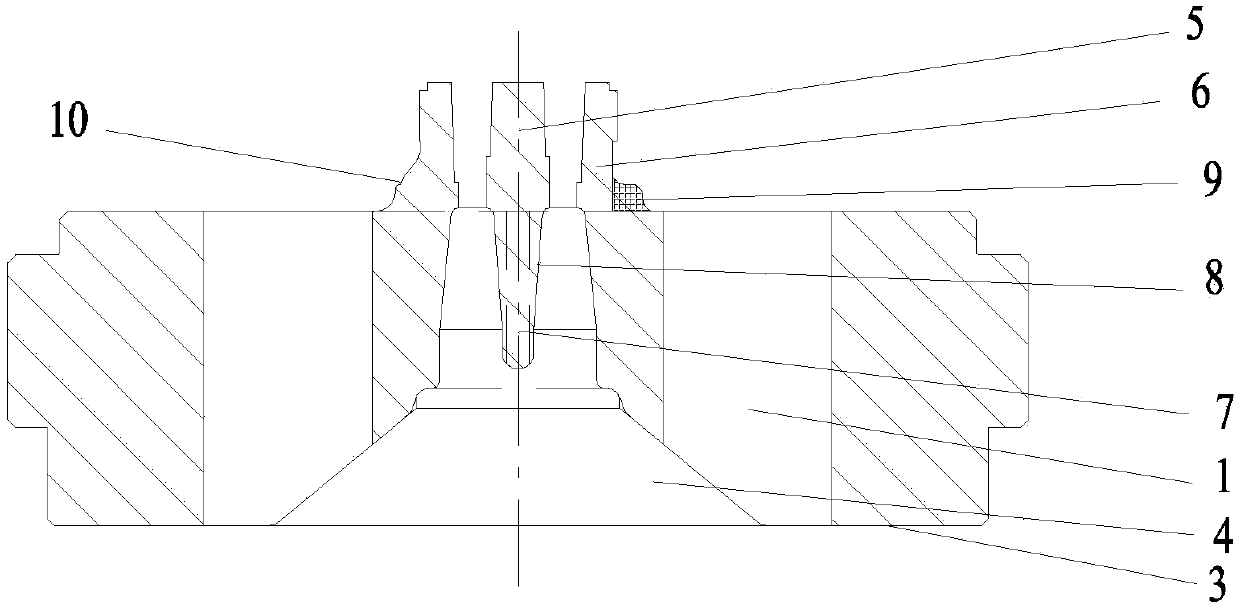

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN101035995AEasy to processLow costRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

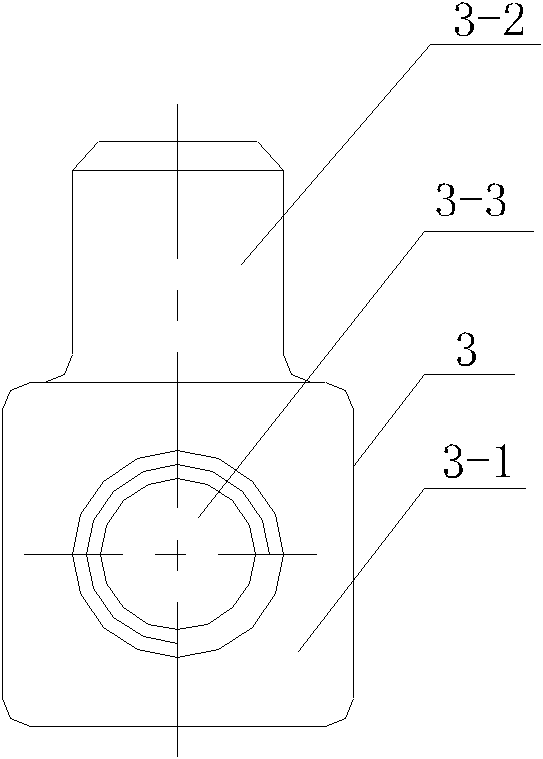

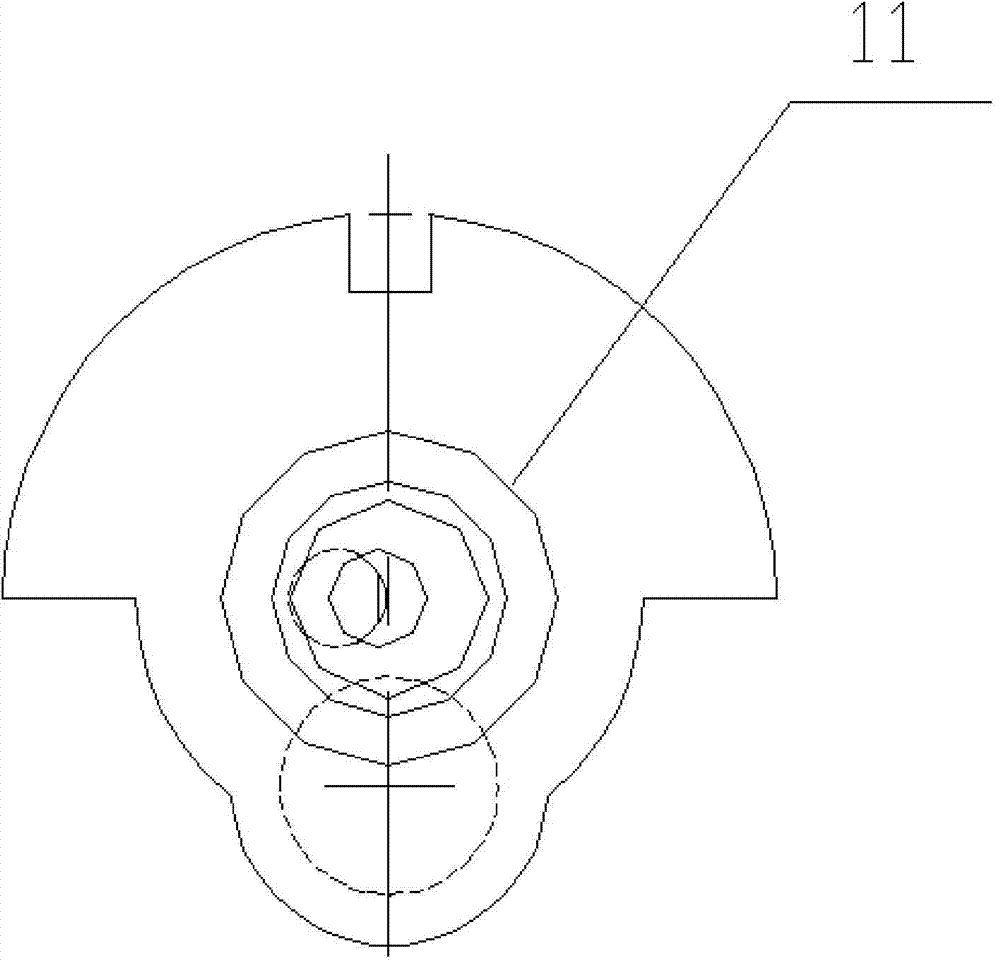

Porous clamping device capable of automatically centering and drilling long-thin steel-sheet type parts

ActiveCN102950312ANot easy to deflectLess prone to deflectionPositioning apparatusMetal-working holdersIsosceles trapezoidPunching

A porous clamp device capable of automatically centering and drilling long-thin steel-sheet type parts relates to a porous centering and drilling clamp device for long-thin steel sheets, and solves the problem that a porous processing mold for the long-thin steel sheets is complex in structure, long in processing period, high in cost, low in punching accuracy and the like. A claw and a sliding top block are slidingly matched with two first sliding chutes on a base, two nuts are arranged in two second sliding chutes on the base and slidingly matched with the second sliding chutes and fixed with the claw and the sliding top block, a stop plate is arranged on the claw which is detachably connected with a slide plate, an inverted isosceles trapezoid groove and a long groove for storing drilling parts are formed between the claw and the sliding top block, a mold is inverted in the isosceles trapezoid groove, a fastening screw leans on the mold, a drill bushing is inlaid in a drilling bushing hole of the mold, a positioning block of a screw rod is arranged in a screw rod support seat on the base, and two ends of the screw rod are connected with the two nuts in a threaded manner. The porous clamp device is used for clamping and fixing in drilling of the long-thin steel-sheet type parts.

Owner:HARBIN JIANCHENG GRP

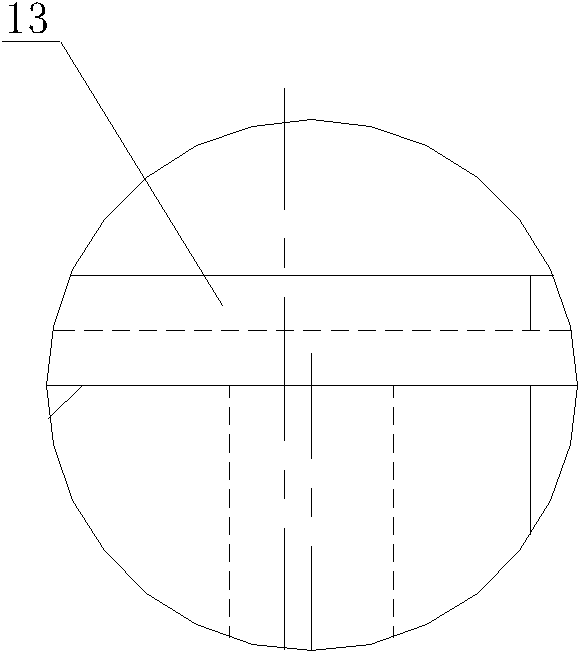

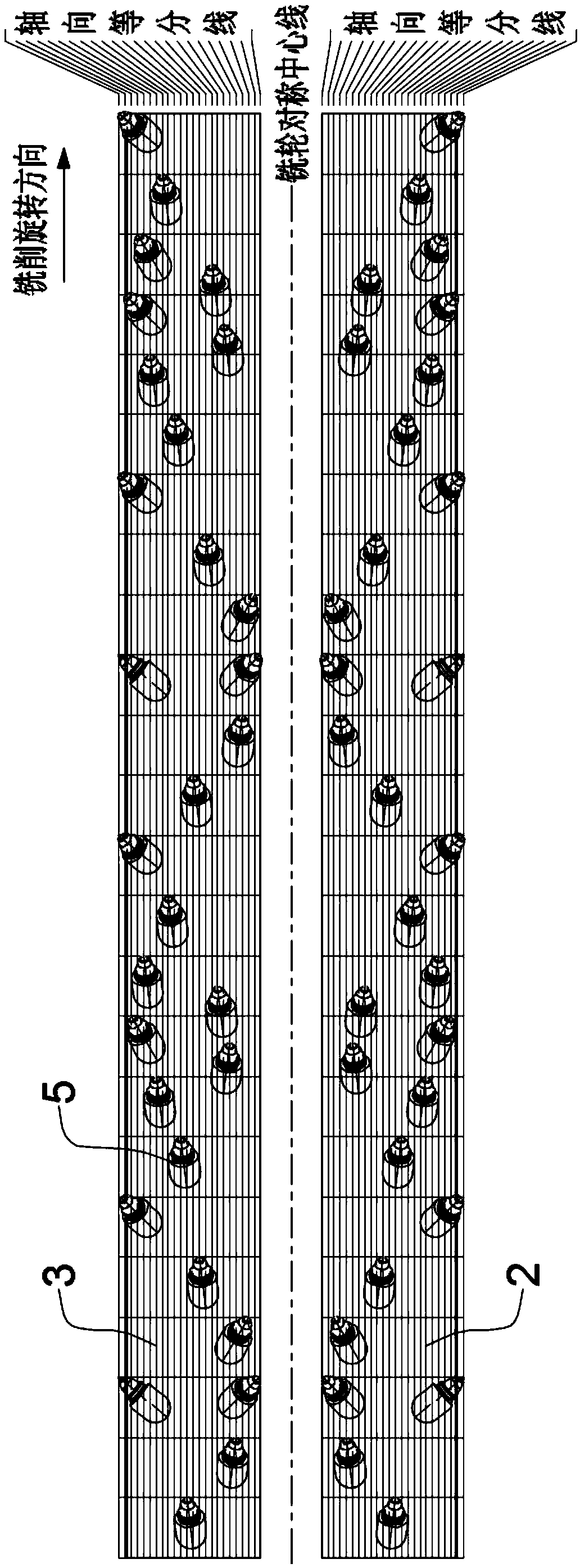

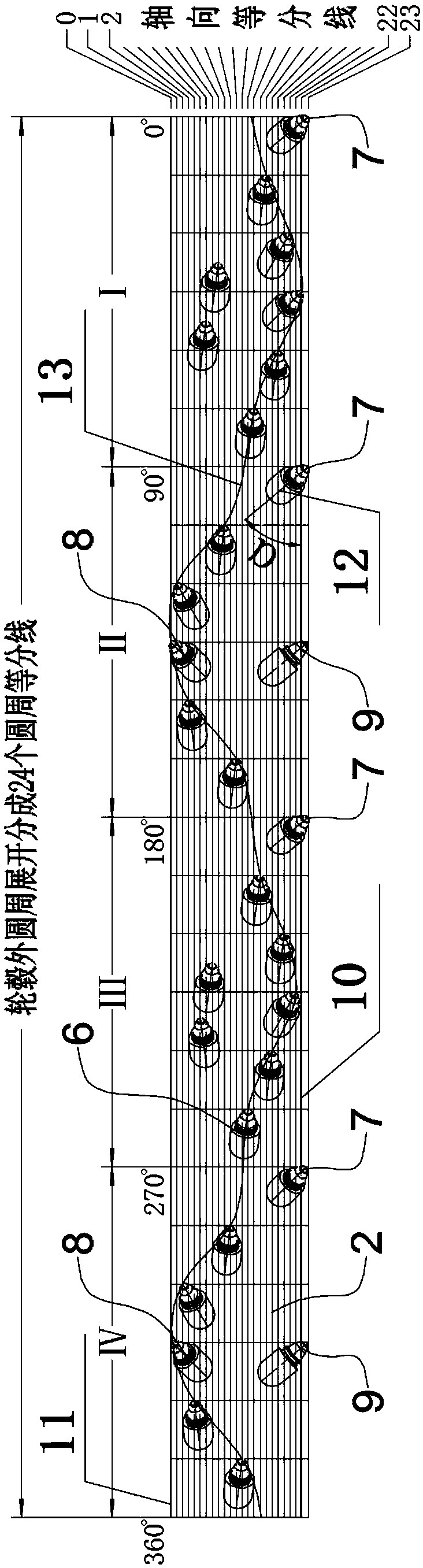

Tooth distribution system for milling wheel of double-wheel slot milling machine

PendingCN108661099AWide range of rock formationsEven rock crushingSoil-shifting machines/dredgersDistribution systemDistribution rule

The invention relates to a tooth distribution system for a milling wheel of a double-wheel slot milling machine. The tooth distribution system comprises a milling wheel main body. Tooth seat plates are positioned and arranged on a left hub and a right hub of the milling wheel main body. Multiple cut teeth are welded and fixed on each tooth seat plate. The cut teeth are symmetrically arranged on the left hub and the right hub according to the tooth distribution rule. The left hub is expanded along the outer circumference of the hub, the expansion plane is divided into multiple equal parts alongmultiple axial bisectrices in the axial direction and meanwhile divided into multiple equal parts along the circumference bisectrix in the circumferential direction. The cut teeth on the left hub aredivided into the middle cut teeth, the outer cut teeth, the inner cut teeth and the groove repairing cut teeth, and meanwhile all the cut teeth are reasonably distributed on the corresponding hubs according to the optimal stress space angle. The tooth distribution system has the beneficial effects that the rock stratum application range is wide, the rock breaking stress is uniform, the wear of milling teeth is small, and the milling efficiency is high.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD +1

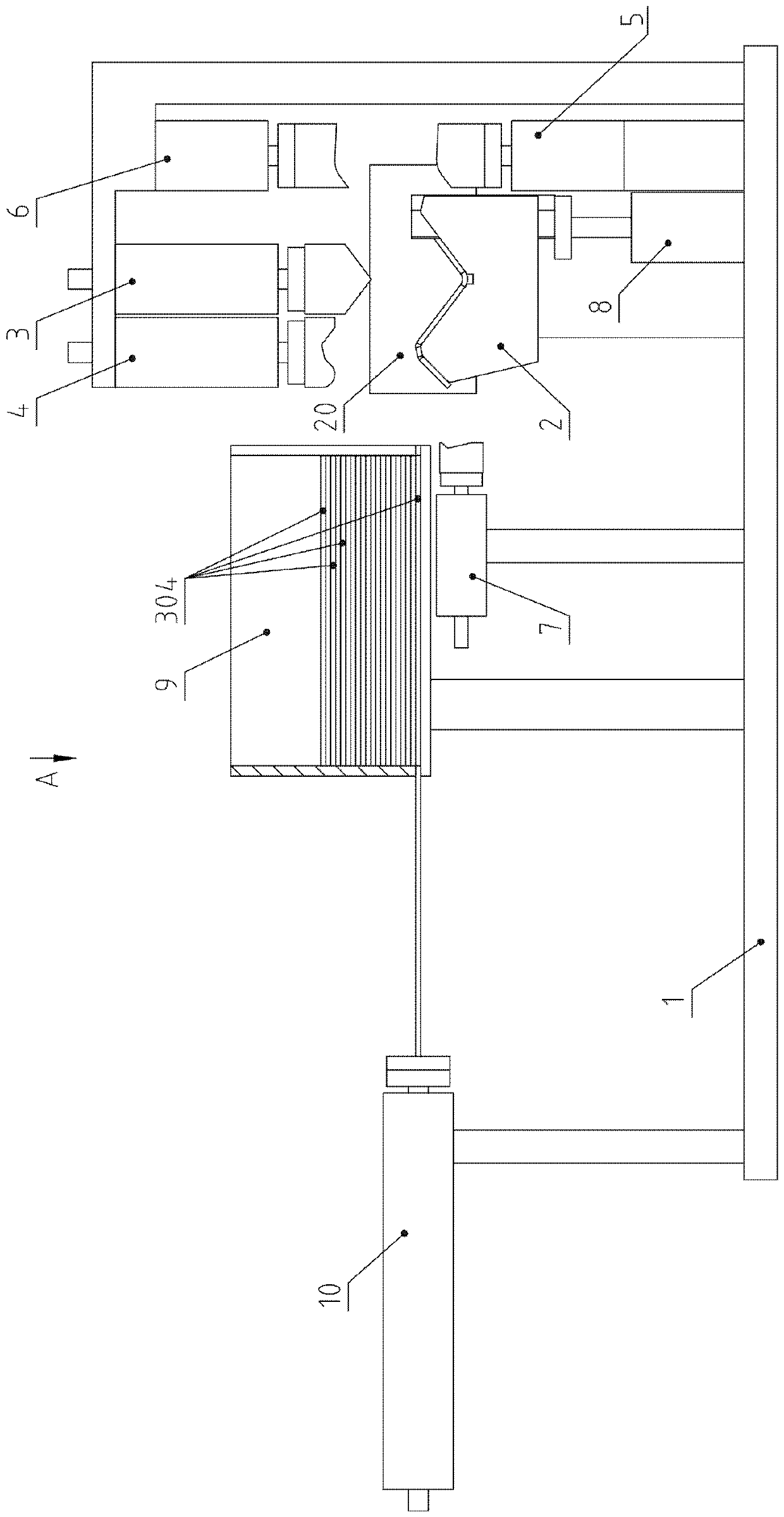

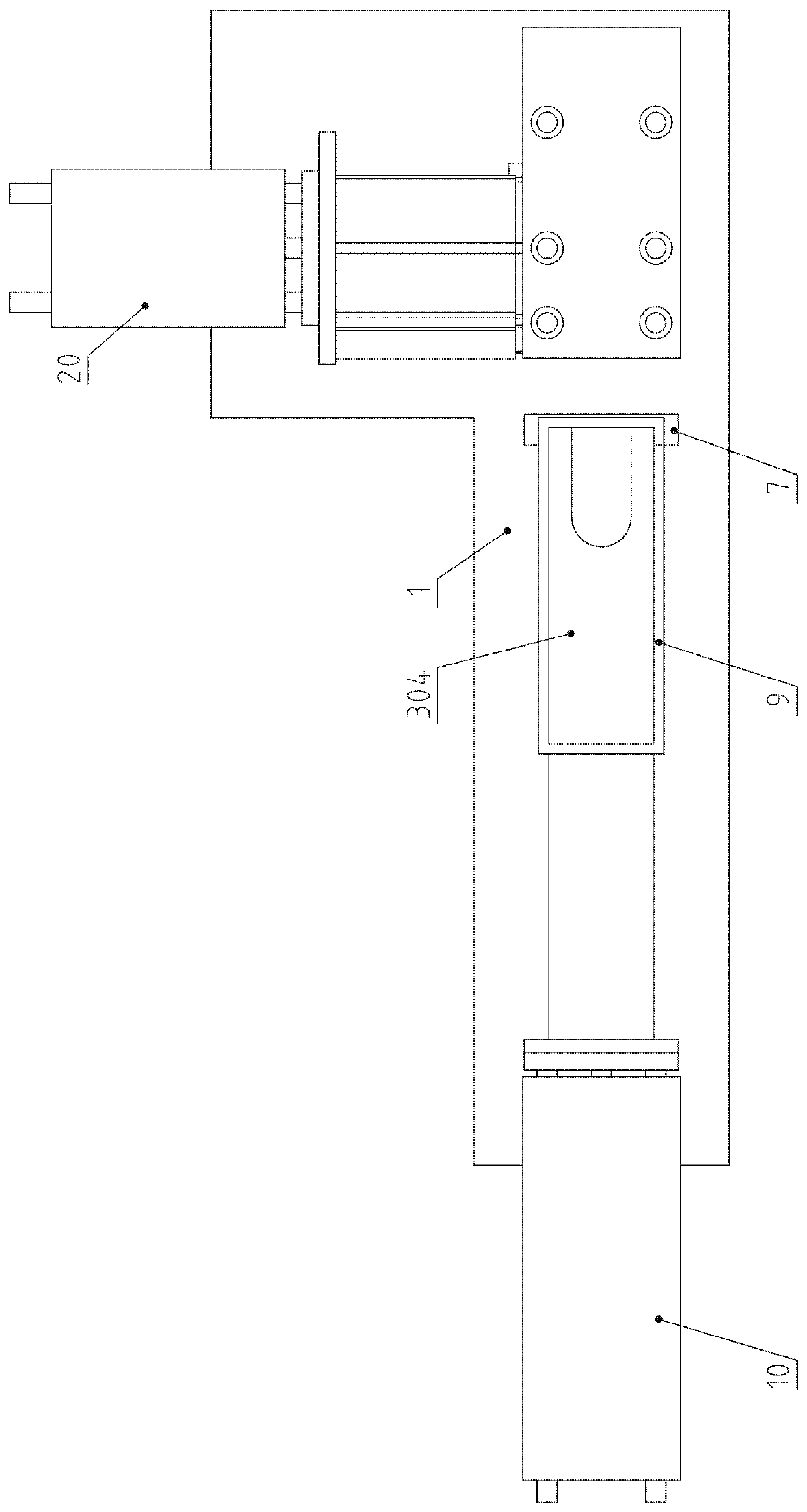

Automatic production device of turnover sliding shifting board used on medical gauze textile machine

ActiveCN110548783ANot easy to deflectReduce error accumulationShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention belongs to the technical field of medical gauze production equipment, and particularly relates to an automatic production device of a turnover sliding shifting board used on a medical gauze textile machine. The device is characterized in that a bending fourth upper die horizontally moves downwards to bend a blank board into a V shape; a bending second and third upper die horizontallymove downwards, and a sliding shifting board third bending and a sliding shifting board second bending are formed by extrusion; a bending fifth lower die horizontally move upwards, a bending fifth lower die fifth plane is abutted against the lower surface of the blank board, a bending fifth upper die horizontally moves downwards, and a sliding shifting board fifth bending is formed by extrusion;and a sliding shifting board first back die horizontally moves forwards, and a sliding shifting board first bending is formed; and a sliding shifting groove positioning column horizontally moves downwards, other dies return, and a material returning pushing board horizontally moves from left to right to push a turnover sliding shifting board away from a bottom die. According to the automatic production device of the turnover sliding shifting board used on the medical gauze textile machine, the precision of the key size is improved, the yield is improved, the workpiece manufacturing cost is reduced, the production automation degree is improved, and the working efficiency is improved.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

Pulverized coal boiler capable of subcritically combusting lean coal

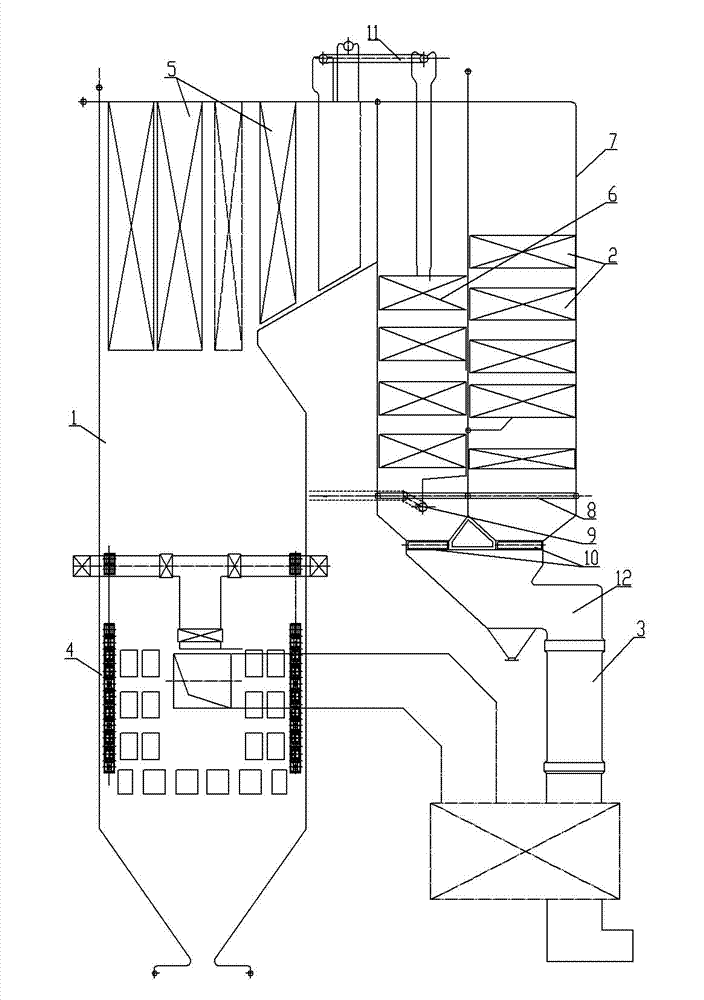

ActiveCN103206699AImprove fullnessNot easy to deflectIndirect carbon-dioxide mitigationSteam boilersAir preheaterCombustor

The invention provides a pulverized coal boiler capable of subcritically combusting lean coal. The pulverized coal boiler comprises a hearth, superheaters, coal economizers and an air preheater. Combustors are arranged in the hearth. The pulverized coal boiler is characterized in that the superheaters include high-temperature superheaters and low-temperature superheaters, the high-temperature superheaters are arranged on the upper side of the hearth, a flue with a vertical shaft is communicated with the upper side of the hearth, two sides of the flue with the vertical shaft are separated from each other, the low-temperature superheaters and the coal economizers are respectively arranged on the two sides of the flue with the vertical shaft, a superheated steam inlet pipeline is arranged below the low-temperature superheaters, an emergency spray attemperator is mounted on the overheated steam inlet pipeline, the flue with the vertical shaft is provided with flue gas temperature regulating barriers which are respectively arranged below the low-temperature superheaters and the coal economizers, and the high-temperature superheaters and the low-temperature superheaters are respectively connected with trim spray attemperators. The pulverized coal boiler has the advantages that the lean coal with the Vdaf (volatile) equal to 14% can be sufficiently combusted in the boiler, so that energy is sufficiently utilized, and the pulverized coal boiler is energy-saving.

Owner:WUXI HUAGUANG BOILER

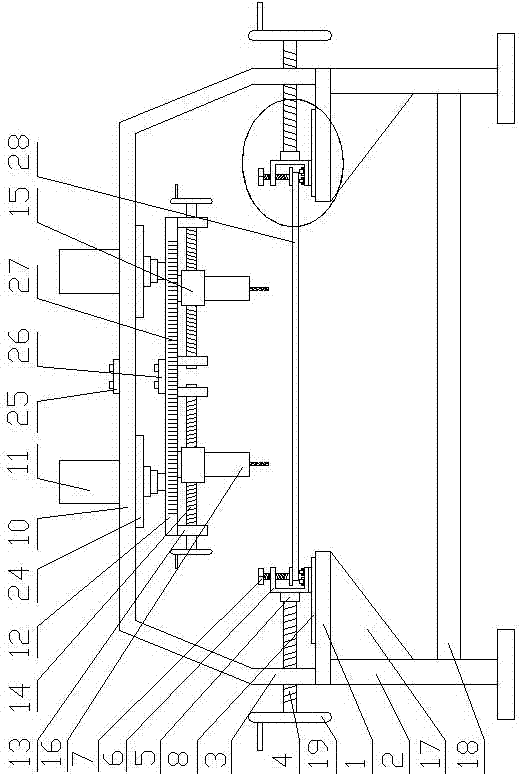

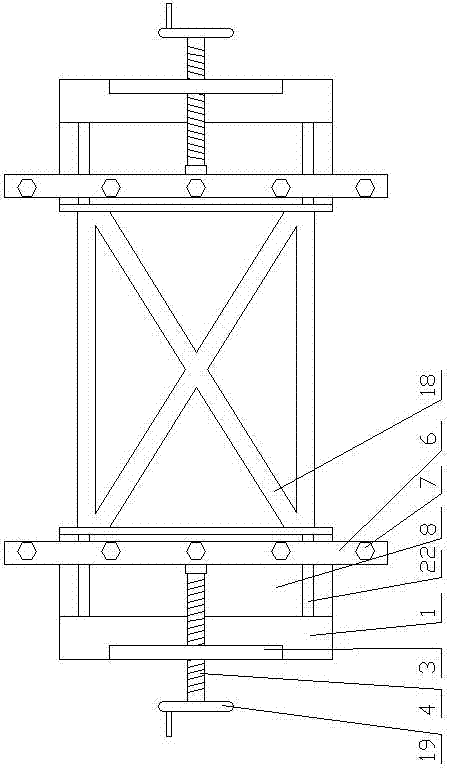

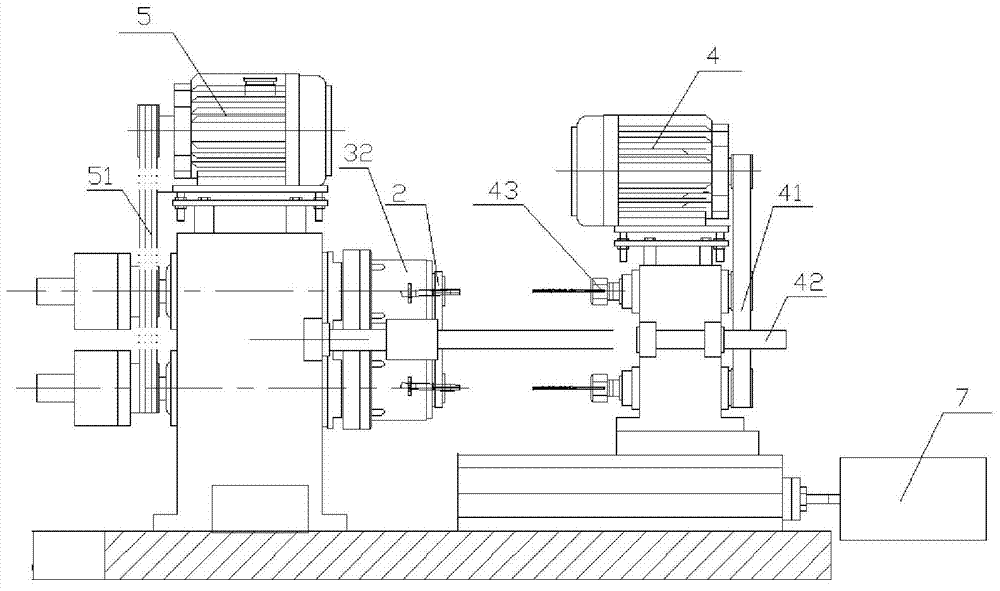

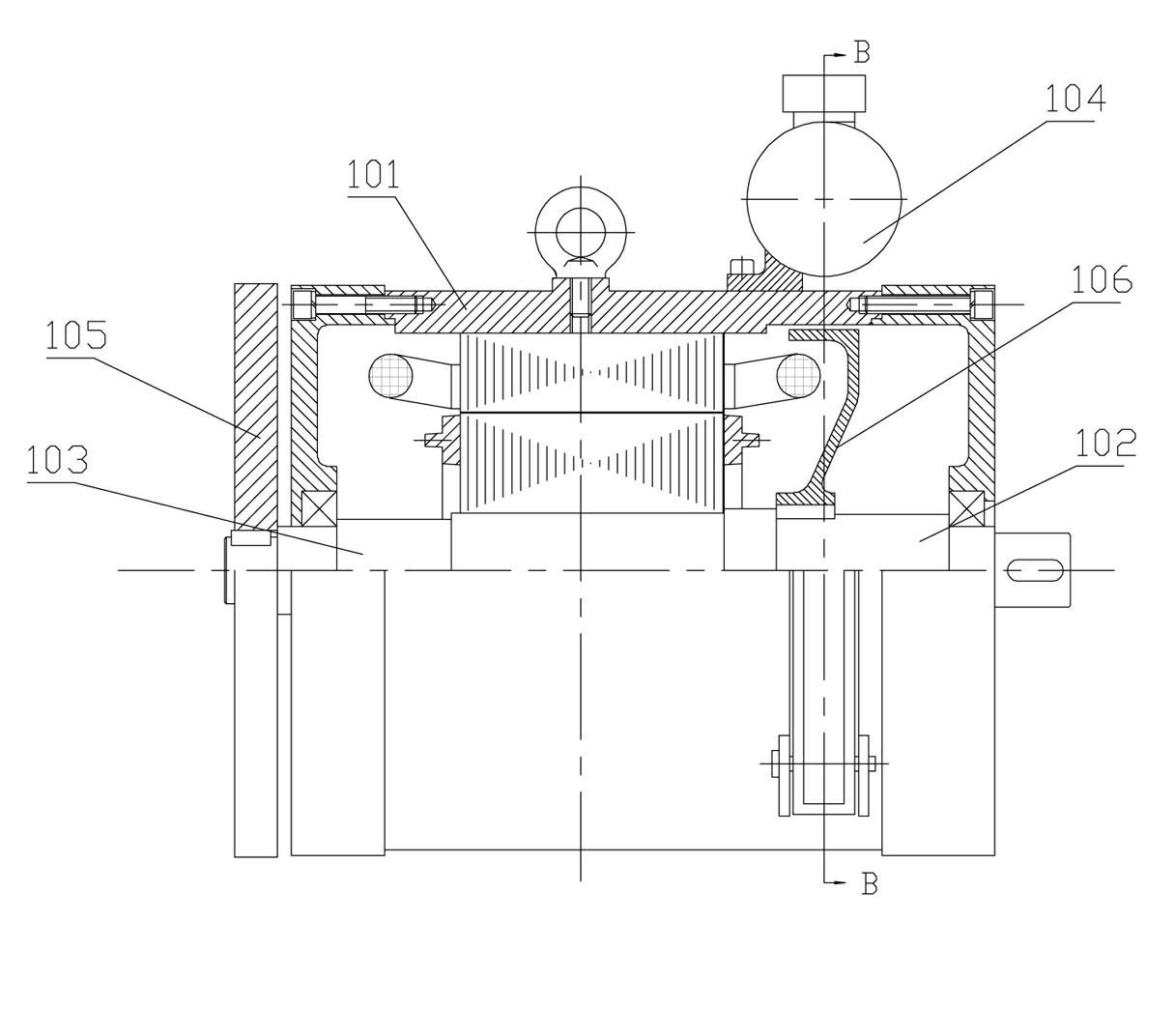

Dual power rotation deep inclined hole drill machine and processing method thereof

InactiveCN104759660AReduce forceNot easy to collapseBoring/drilling machinesReciprocating motionEngineering

The invention relates to the technical field of deep inclined hole drilling, in particular to a dual power rotation deep inclined hole drill machine. The dual power rotation deep inclined hole drill machine comprises a drilling device connected with a drill bit, a first drive device which drives the drilling device to perform reciprocating motion and drill a deep inclined hole for a work piece, a clamp used to fix the work piece, at least one group of clamping devices capable of clamping the clamp and a second drive device which drives the clamping devices to rotate, wherein the central line of the drill bit, the central line of the clamp and the central line of the deep inclined hole are located on the same straight line, and the rotation direction of the drill bit is opposite to the rotation direction of the clamp. The dual power rotation deep inclined hole drill machine is simple in structure and strong in practicability.

Owner:玉环制冷设备配件有限公司

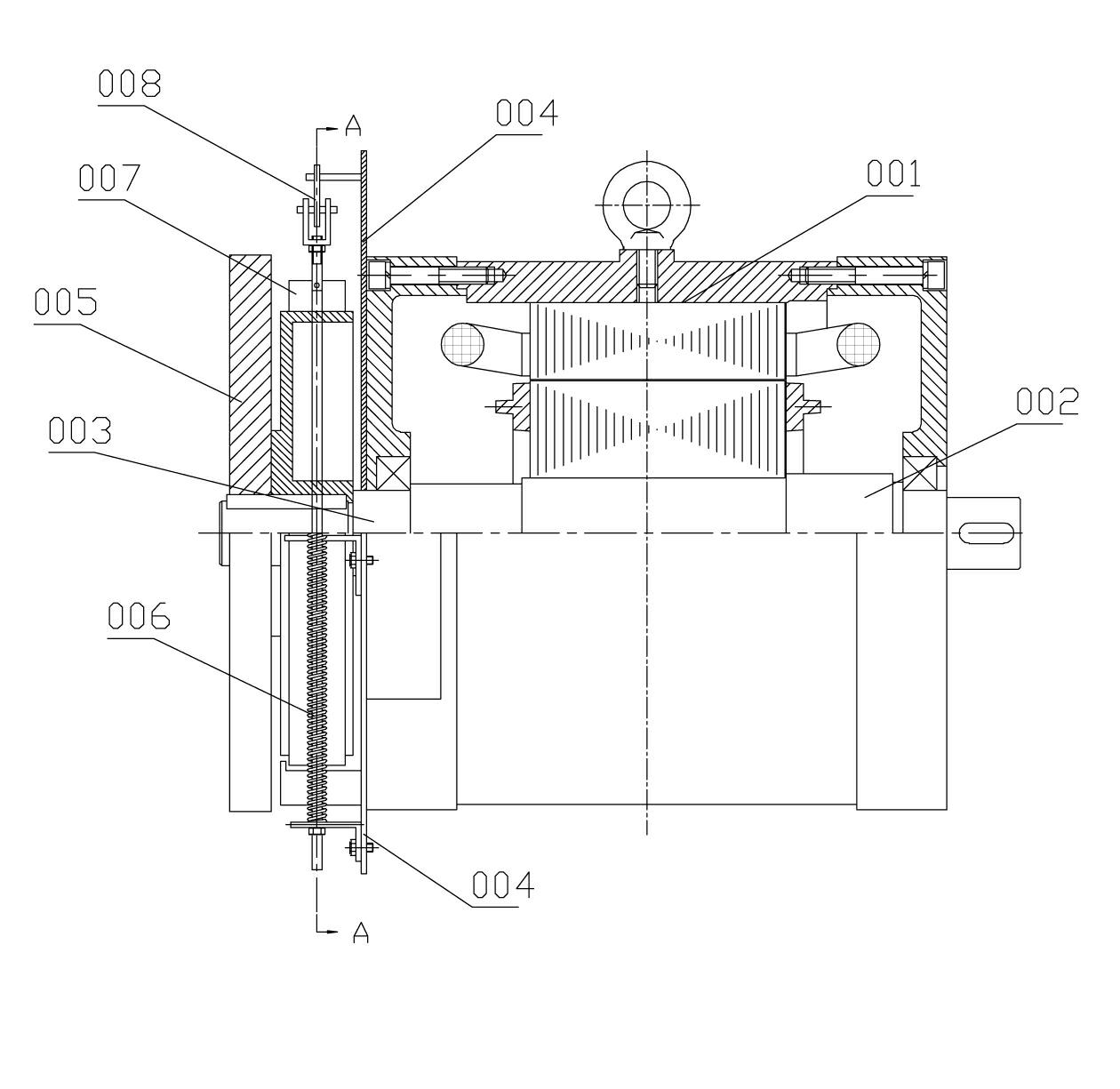

Power-off braking mechanism for main brake of escalator

ActiveCN102674130AAvoid influenceReduce weightEscalatorsHoisting equipmentsBand brakeAutomotive engineering

Owner:NINGBO XINDA ELEVATOR FITTINGS FACTORY

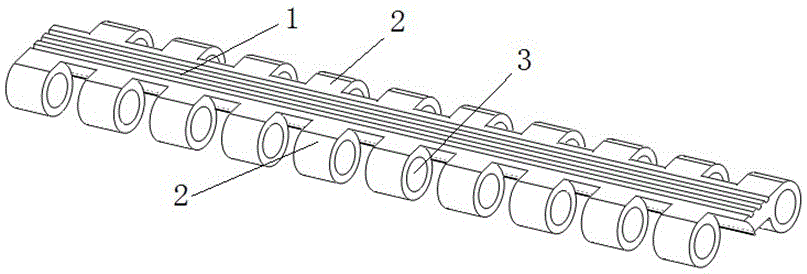

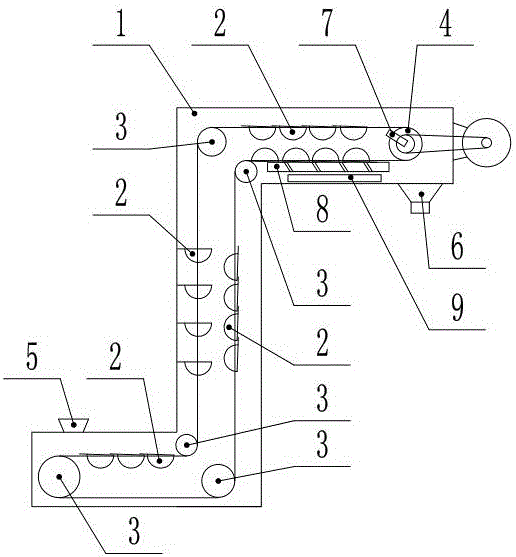

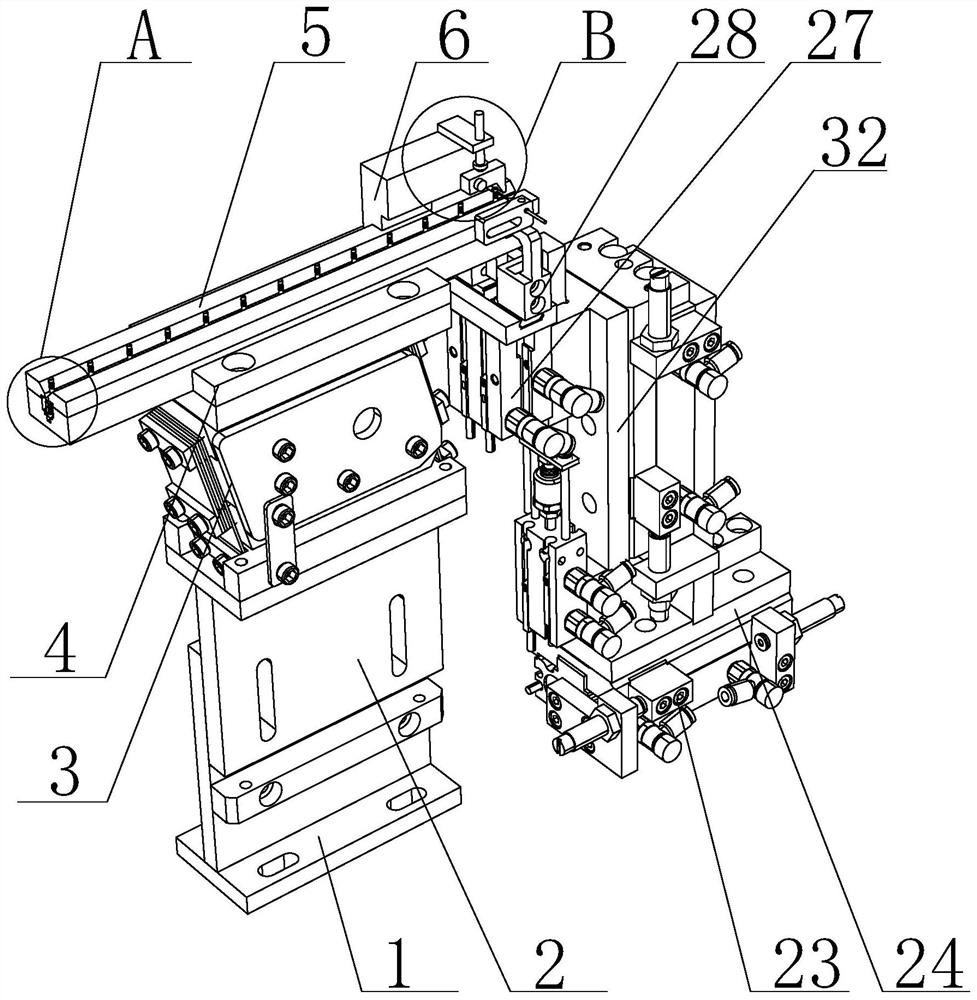

Pin shaft supply device and row chain link pin installing equipment using pin shaft supply device

PendingCN107432491ANot easy to deflectReduce labor intensityTobacco treatmentMetal working apparatusChain linkEngineering

The invention relates to a pin shaft supply device and row chain link pin installing equipment using the pin shaft supply device. The pin shaft supply device comprises an installing frame and a pin shaft conveying roller rotationally assembled on the installing frame, wherein a pin shaft falling box is also arranged on the installing frame; a plurality of pin shaft positioning grooves which are used for realizing the positioning matching with pin shafts and can be used for discharging the pin shafts in the axial direction of the pin shaft conveying roller are formed in the outer periphery of the pin shaft conveying roller in the circumferential direction; and the pin shaft falling box is provided with a pin shaft falling opening through which a single pin shaft can pass and fall into the corresponding pin shaft positioning groove. The pin shaft falling box only allows the single pin shaft to pass and to fall into the corresponding pin shaft positioning groove in each time; then, the pin shaft is installed into a row chain link; the installation in a manual pin taking manner one by one in the prior art is avoided; the work intensity is low; the work efficiency is high; the pin shaft is positioned; deviation cannot easily occur in the pin shaft installing process; and the pin shaft and the row chain link are protected.

Owner:CHINA TOBACCO HENAN IND

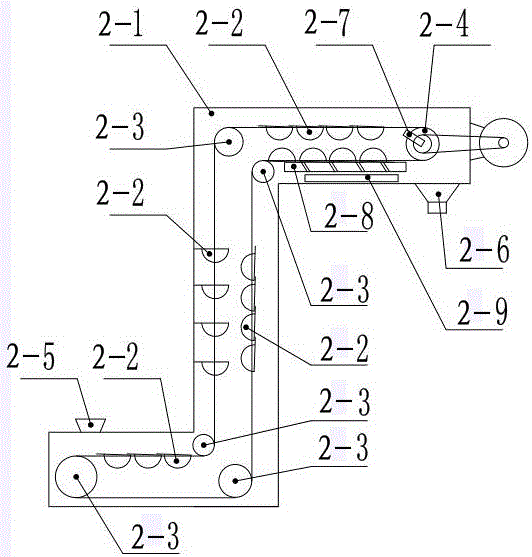

Z-shaped elevator

The invention discloses a Z-shaped elevator. The Z-shaped elevator comprises a Z-shaped body (1) provided with a Z-shaped inner cavity. Transmission chains are arranged in the inner cavity. The two transmission chains are arranged on the left side and the right side of the inner cavity correspondingly. Hoppers (2) are arranged between the two transmission chains and provided with upward openings. The left end and the right end of each hopper (2) are rotationally connected with the transmission chains on the left side and the right side correspondingly, and the rotation connecting positions are located above the no-load gravity centers and the load gravity centers of the hoppers (2). The positions of the rear edges of the opening ends of the hoppers (2) are connected with retaining sides located on the outer sides of the opening ends and used for making contact with the front edges of the opening ends of the adjacent back hoppers (2). Overturning of the hoppers (2) due to disturbance can be avoided, and meanwhile the utilization rate of the Z-shaped elevator is increased.

Owner:WUZHOUFENG AGRI SCI & TECH

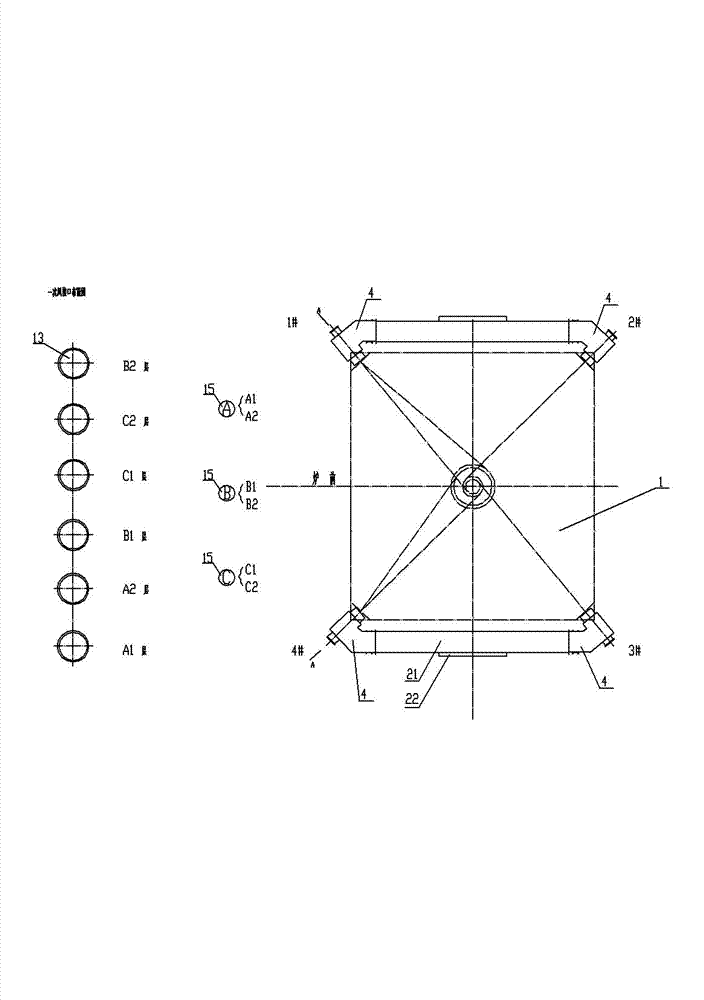

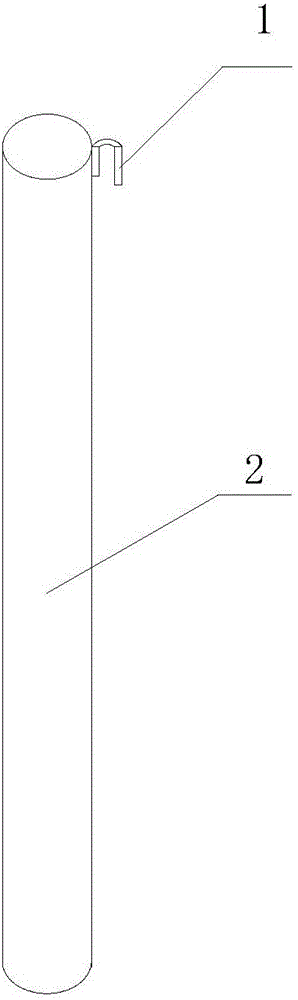

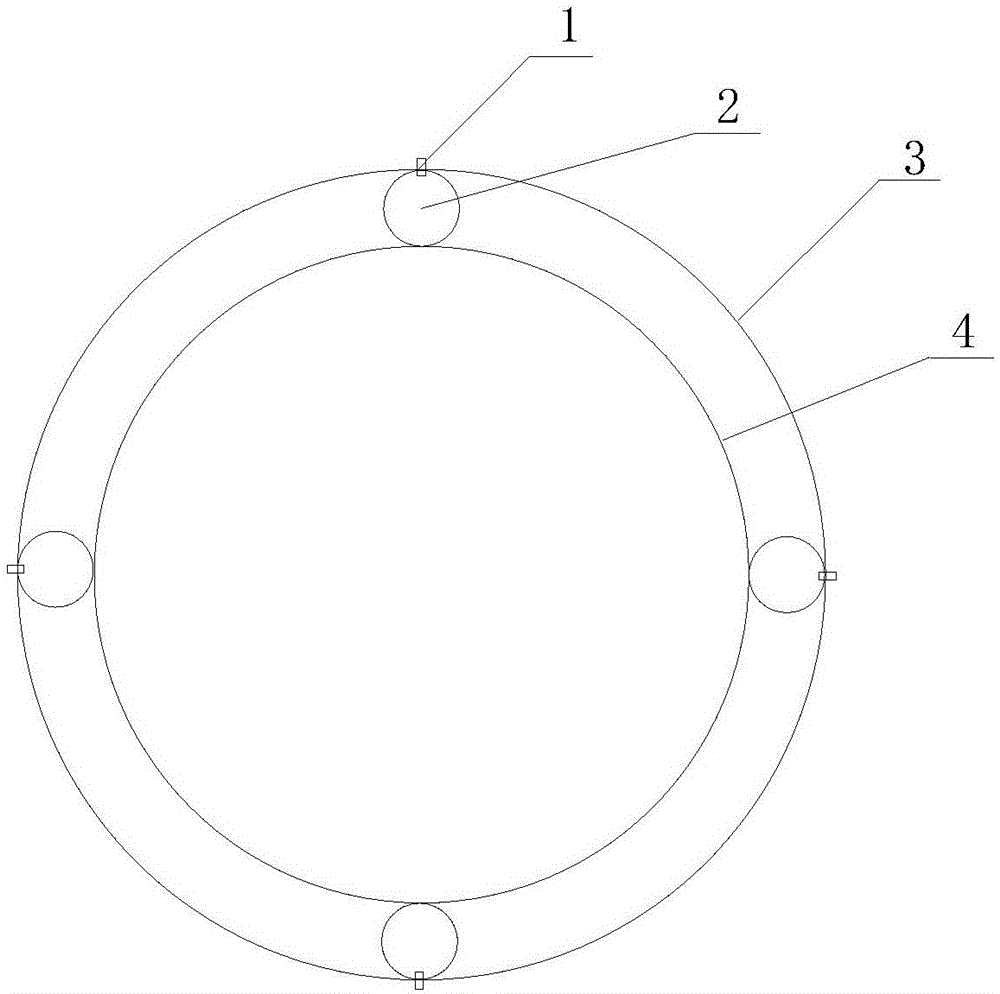

Isolation protection device and construction method for preventing pile foundation reinforcement cage deflection

PendingCN106836197ANot easy to deflectPrevent left and right rotationBulkheads/pilesRebarBending moment

The invention provides an isolation protection device and construction method for preventing pile foundation reinforcement cage deflection, and belongs to a bridge construction auxiliary device in construction engineering and a construction method of the bridge construction auxiliary device. The isolation protection device comprises a guiding column, and a hook is arranged at the top end of the guiding column. The hook is shaped like an n. The construction method for preventing pile foundation reinforcement cage deflection comprises the steps that the guiding column stretches into a pile hole; the n-shaped hook is hanged on a steel casing; a reinforcement cage is installed in place; concrete is poured. The isolation protection device and construction method for preventing pile foundation reinforcement cage deflection have the advantages that the guiding column has the effects of guiding and isolation with the hole wall on the reinforcement cage, and in the pouring process, the reinforcement cage is not likely to deflect. Along with increasing of the poured concrete quantity, the torque becomes larger, the guiding column always exists to conduct isolation and guiding in the middle, it is guaranteed that on the condition that the torque becomes larger, deflection does not occur, the bending moment in the reinforcement cage is not accumulated to be too large, the phenomena that in the concrete pouring process, the reinforcement cage rotates left and right, swings to collide the hole wall, deflects and deforms can be effectively prevented, deflection control is stable and reliable, and the construction quality is guaranteed.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

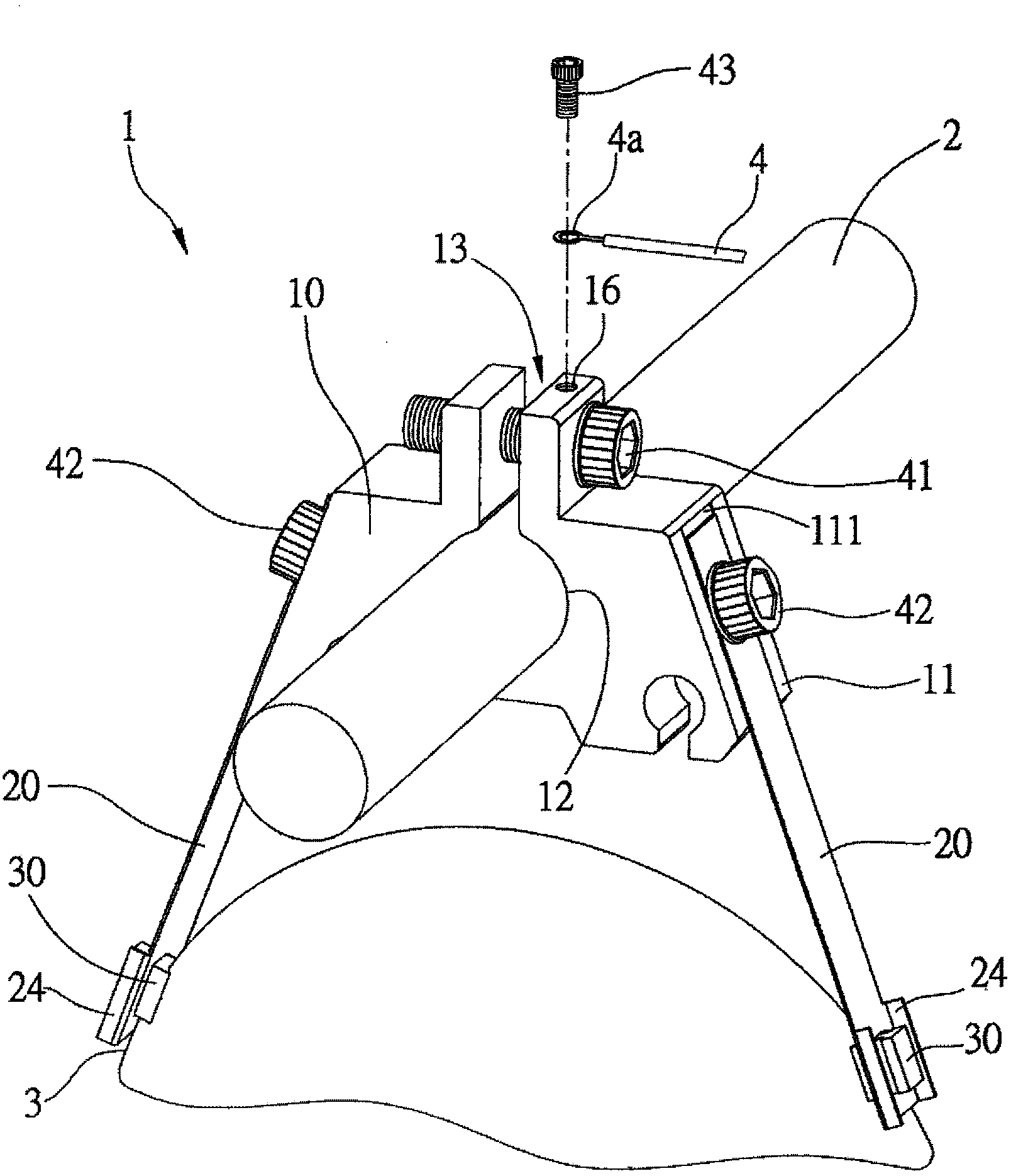

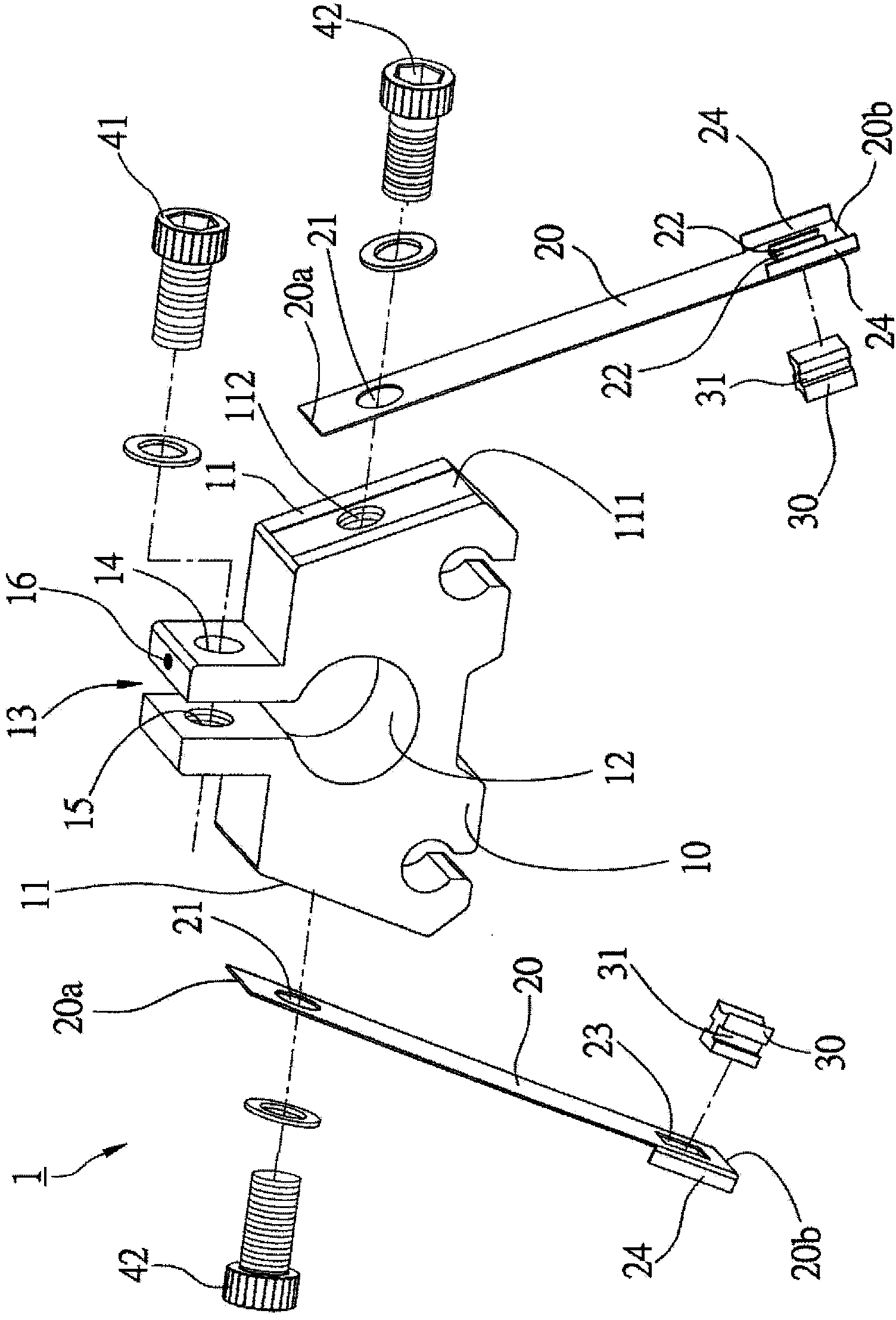

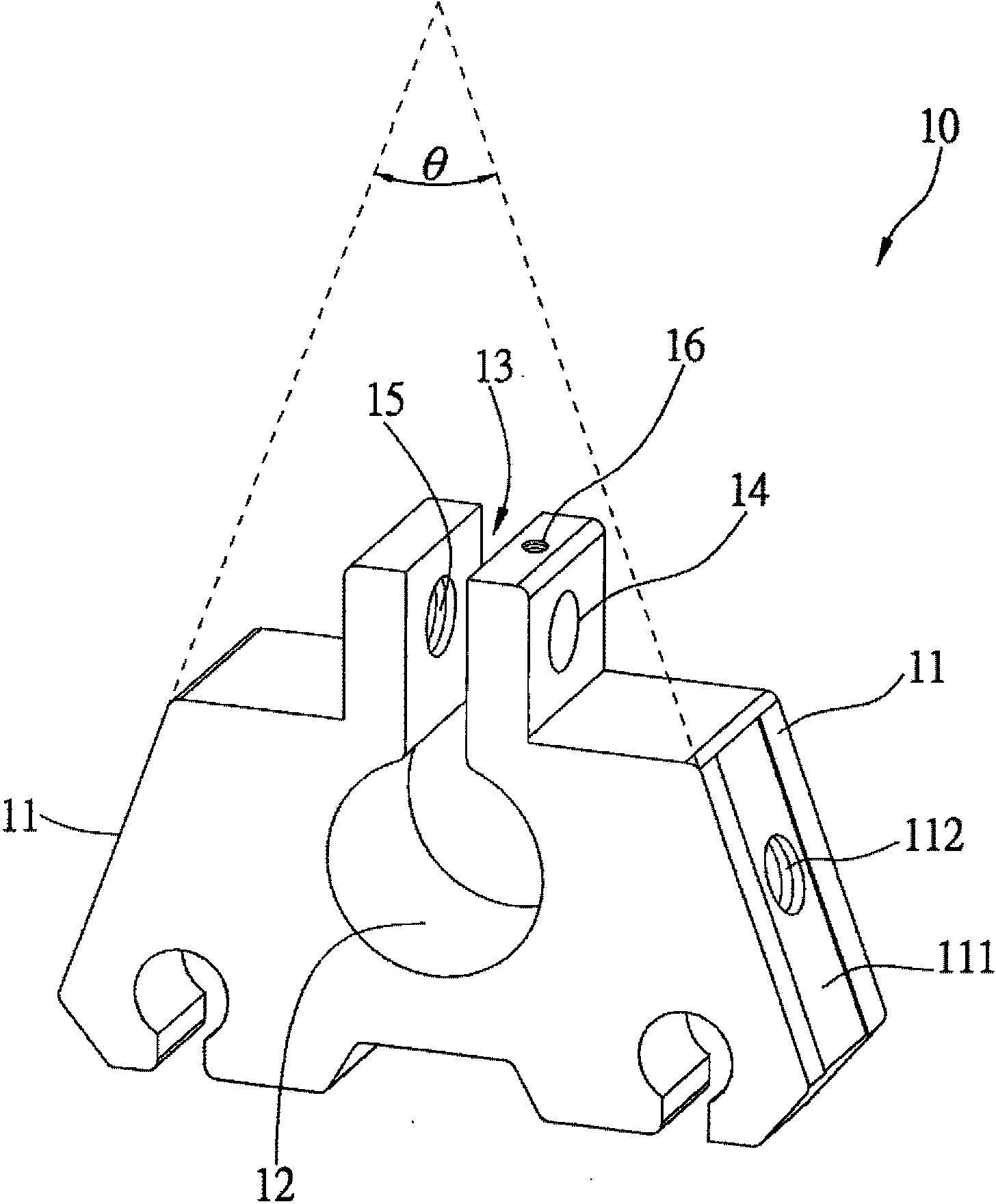

Collection ring carbon brush holder

InactiveCN104112964ANot easy to deflectGood electrical conduction performanceRotary current collectorEngineeringMechanical engineering

The invention relates to a collection ring carbon brush holder arranged between a fixing shaft and a collection ring. The collection ring carbon brush holder comprises a combination seat, two guide point supports and two carbon brushes, wherein the combination seat has two combination faces and a shaft hole, the two combination faces are arranged at front and back sides of the combination seat, the combination faces respectively dent to form a groove, the shaft hole is arranged between the two combination faces for penetration of a fixing shaft, each support has a first end and a second end, each first end is combined with one corresponding groove of the combination seat, the two carbon brushes are respectively combined with each second end and are used for contacting with the collection ring.

Owner:TAIWAN LONG HAWN ENTERPRISES

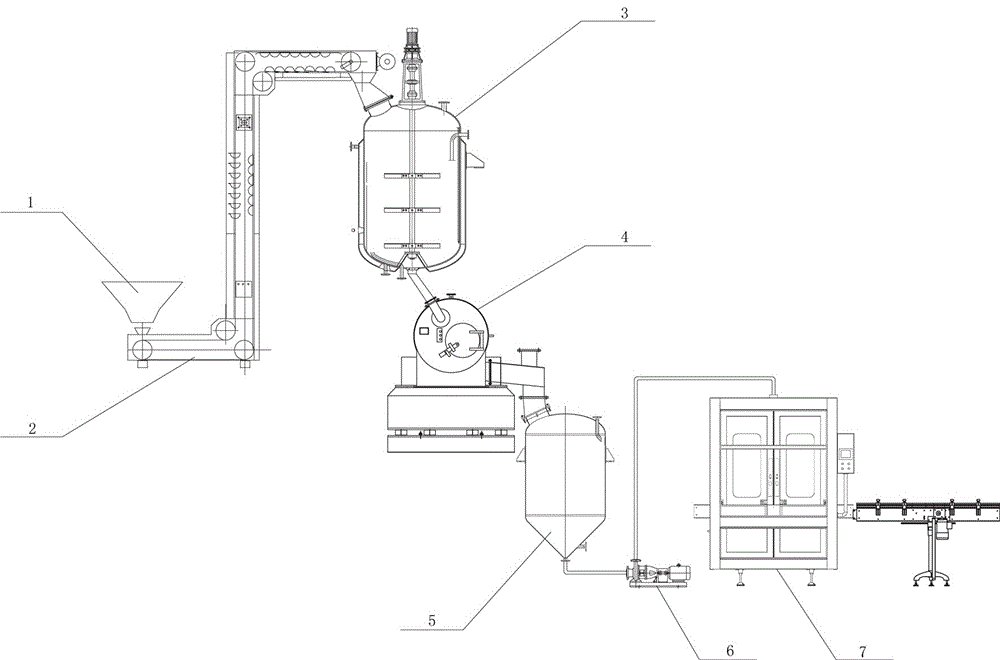

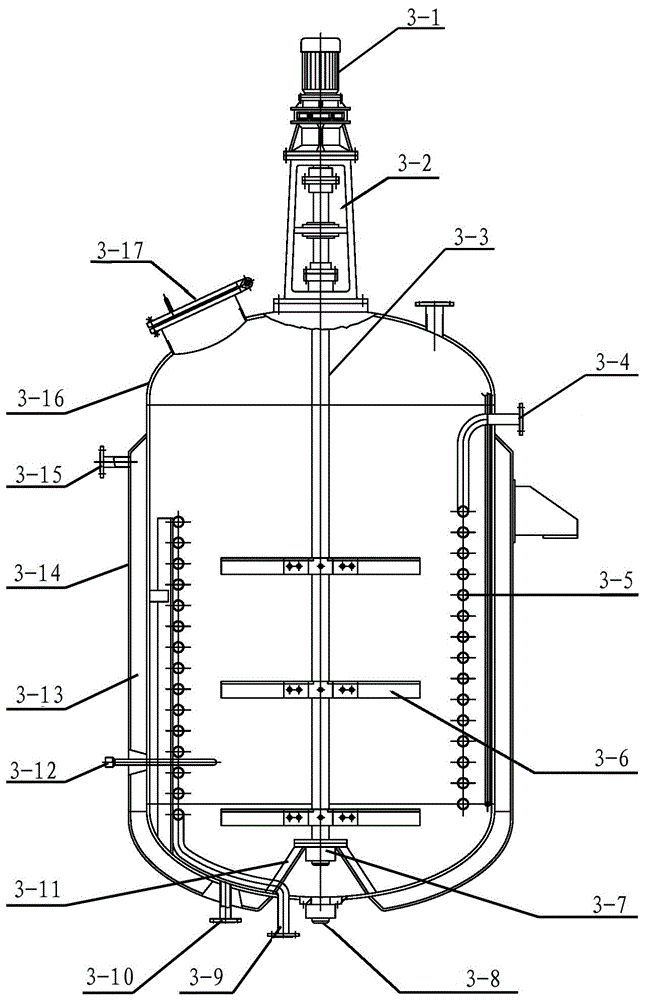

Microbial fermentation fertilizer production system

InactiveCN106316487ANot easy to deflectGuaranteed blankingChemical industryOrganic fertiliser preparationTemperature controlSolenoid valve

The invention provides a microbial fermentation fertilizer production system. A discharging opening of a mixture charging hopper (1) is located over a feeding opening (2-5) of a Z-shaped elevator (2), a discharging opening (2-6) of the Z-shaped elevator (2) is connected with a feeding opening (3-17) of a fermentation tank (3), a discharge solenoid valve (3-8) of the fermentation tank (3) is connected with the feeding end of a centrifuge (4), the liquid phase discharging end of the centrifuge (4) is connected with the feeding end of a finished product tank (5), and the discharging end of the finished product tank (5) is connected with a filling machine (7) through a centrifugal delivery pump (6). The microbial fermentation fertilizer production system has the advantages that overturning, caused by disturbance, of the Z-shaped elevator hopper is avoided, and the utilization rate of the Z-shaped elevator is increased; fermentation tank temperature control is more convenient, and a better energy-saving effect is achieved.

Owner:WUZHOUFENG AGRI SCI & TECH

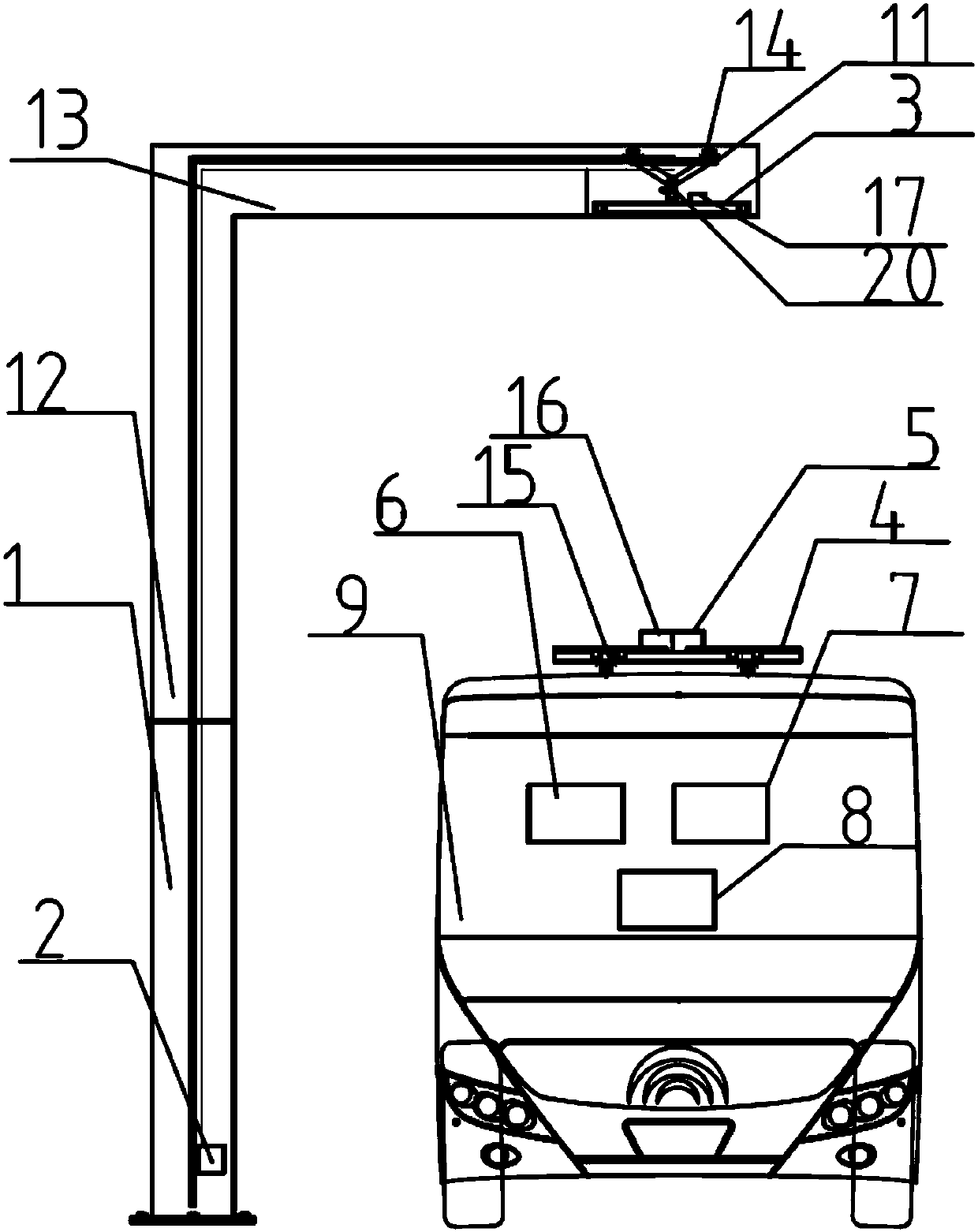

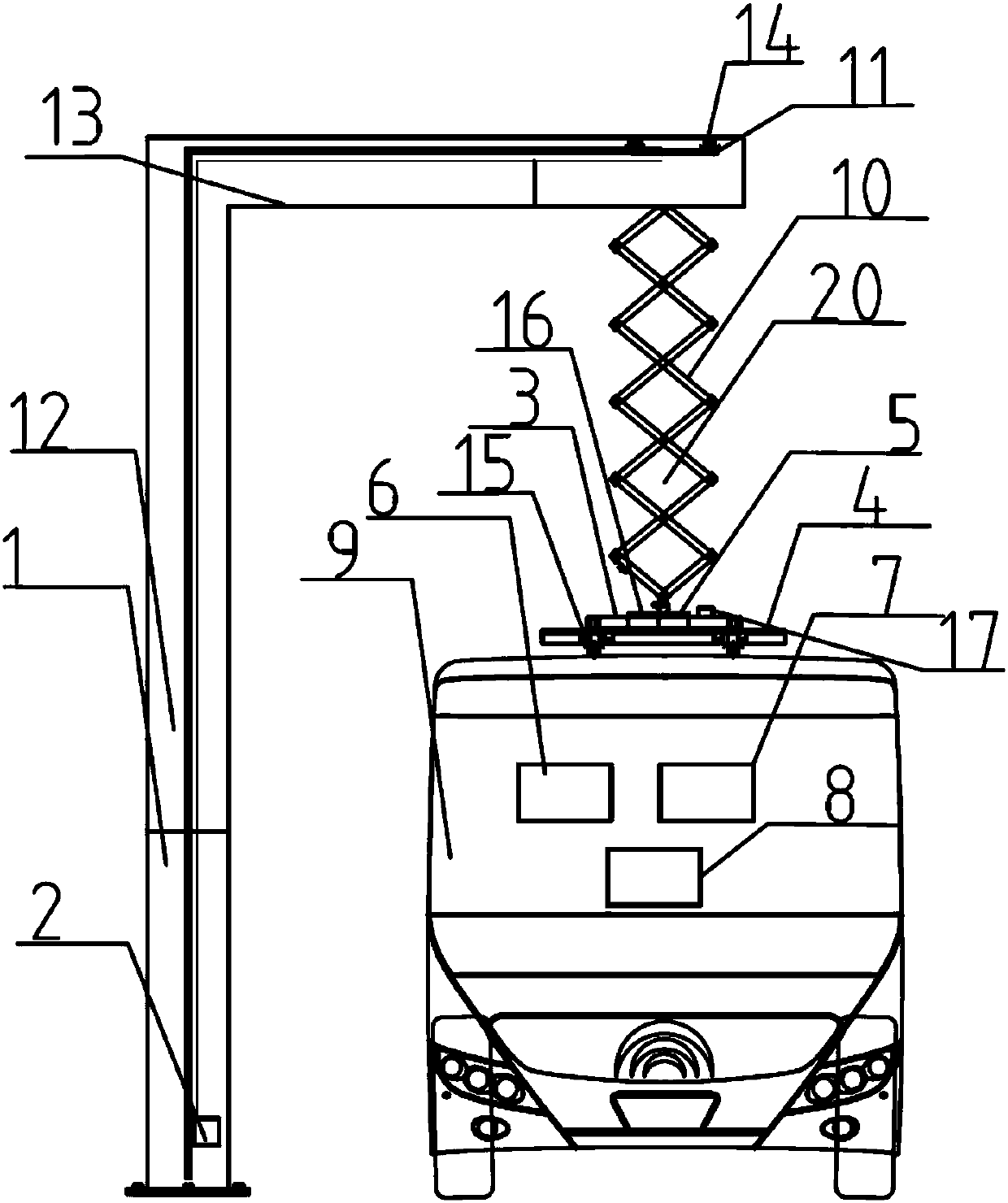

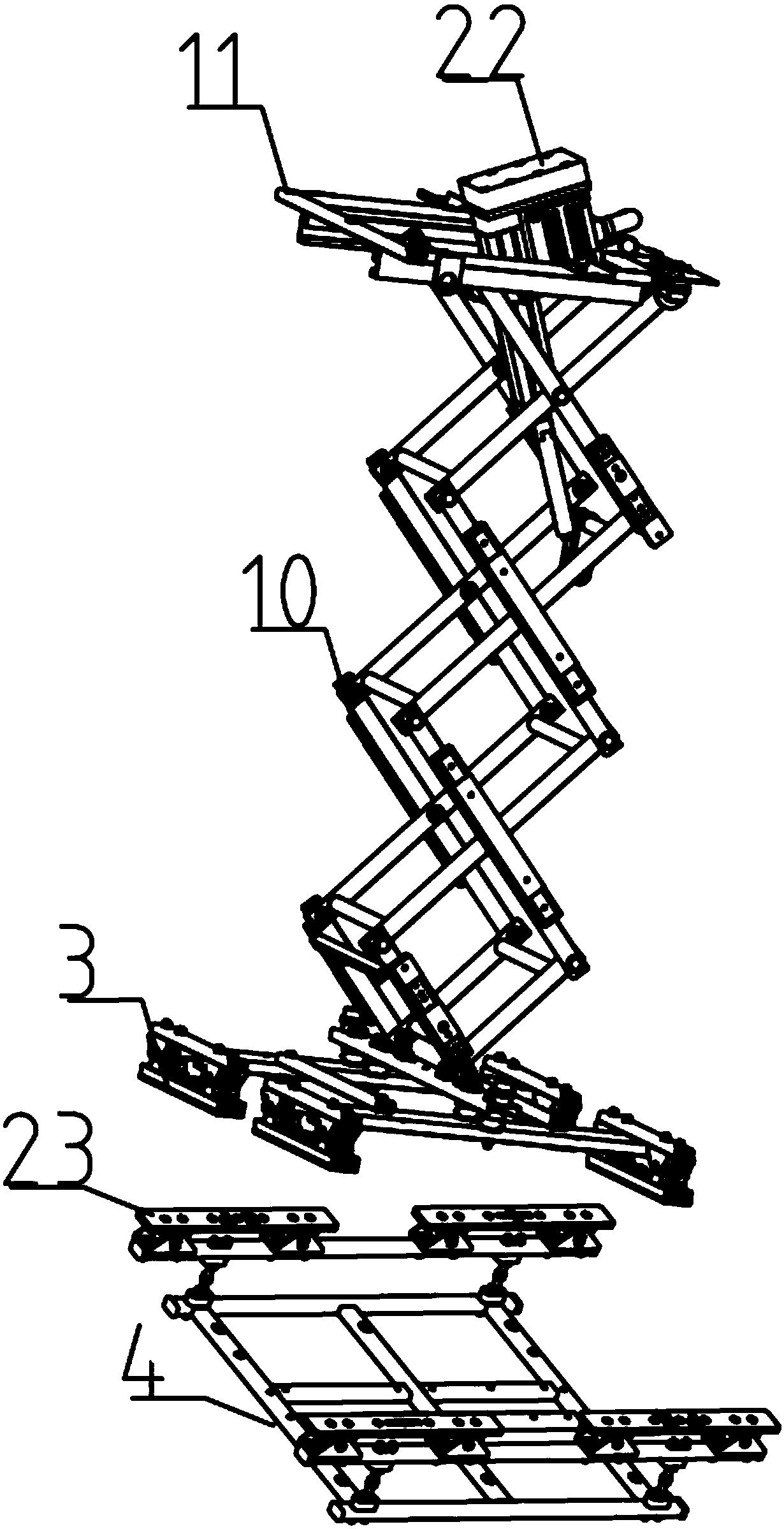

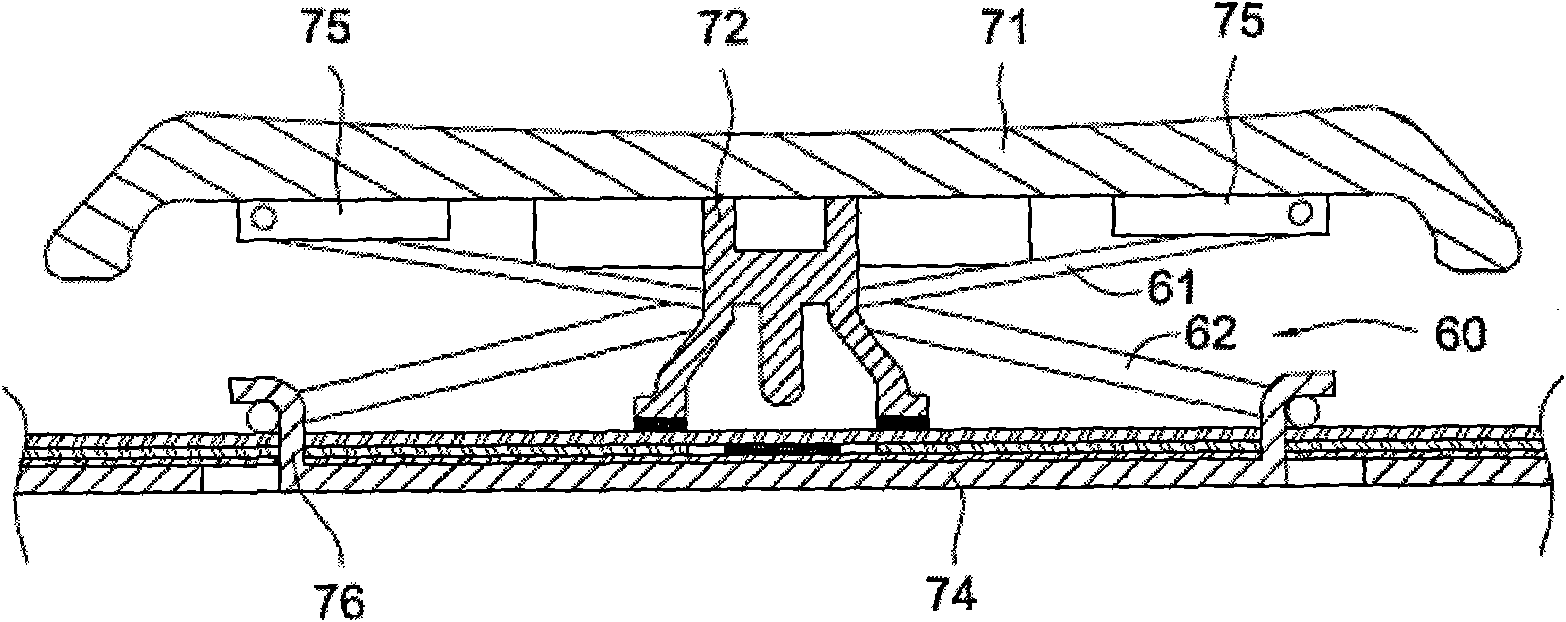

Reverse pantograph, charging system and car

PendingCN110014915AImplement automatic connectionLow accuracy requirementsCharging stationsElectric vehicle charging technologyElectricityPower flow

The invention relates to a reverse pantograph, a charging system and a car. The reverse pantograph comprises a pantograph head, the pantograph head comprises one or more pantograph positive pole plates used for being crossed with positive pole plates of a collector-shoe gear of the car during charging contact, and one or more pantograph negative pole plates used for being crossed with negative pole plates of the collector-shoe gear of the car during charging contact. A positive pole and a negative pole on the pantograph head of the pantograph are correspondingly crossed with and are in buttingcontact with a positive pole and a negative pole of the collector-shoe gear of the car; and in the charging process, the errors in the front, rear, left and right directions of the actual parking position of the car are within the allowable range, the positive pole plates and the negative pole plates of the pantograph can reliably make contact with the positive pole plates and the negative pole plates of the collector-shoe gear correspondingly, thus the precision requirements for the positioning and parking position of the car are lowered, it is ensured that charging is conducted normally, the contact form that the pole plates are arranged in a crossed mode is utilized, the current carrying area is increased, and high-current and high-power charging is ensured.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Self-aligning roller bearing with retainer and method of manufacturing the retainer for the self-aligning roller bearing

ActiveCN100489328CCost containmentInhibit sheddingRoller bearingsBearing componentsBarrel ShapedSpherical roller bearing

There is realized a self-aligning roller bearing with retainer that stabilizes the orientation of spherical rollers and prevents these spherical rollers from skewing, and which can be rotated at high speed, and furthermore which enables efficient lubricant feed into pockets 9. By rotating a turning tool 14 as it revolves, the surfaces on both sides in the circumferential direction of respective column sections are processed into concave curved surfaces that oppose a rolling surface of the respective spherical rollers across a pocket clearance into which lubricant oil can be fed. The length of the column sections 8c is less than the length in the axial direction of the spherical rollers, and greater than a half of the length, and an end portion of the side surface in the circumferential direction of the respective column sections 8c projects further in the circumferential direction than an intermediate portion thereof, and the spherical rollers are embraced in the pockets 9.A self-aligning roller bearing with a retainer enabling high speed operation by stabilizing the attitude of barrel shaped rollers to prevent the barrel shaped rollers from being skewed and the efficient feeding of a lubricant into pockets (9) and a method of manufacturing the retainer for the self-aligning roller bearing. In the self-aligning roller bearing, the both side faces of each column part (8c) in the circumferential direction are machined to recessed curved faces facing the rolling surface of each barrel shaped roller through pocket clearances allowing the lubricant to feed thereto with a cutting tool (14) revolving while rotating on its axis. Also, the length of each column part (8c) is set equal to or less than the axial length of each barrel shaped roller and more than the half of the axial length thereof, the side face tip portion of each column part (8c) in the circumferential direction are projected from the intermediate portion thereof in the circumferential direction.

Owner:NSK LTD

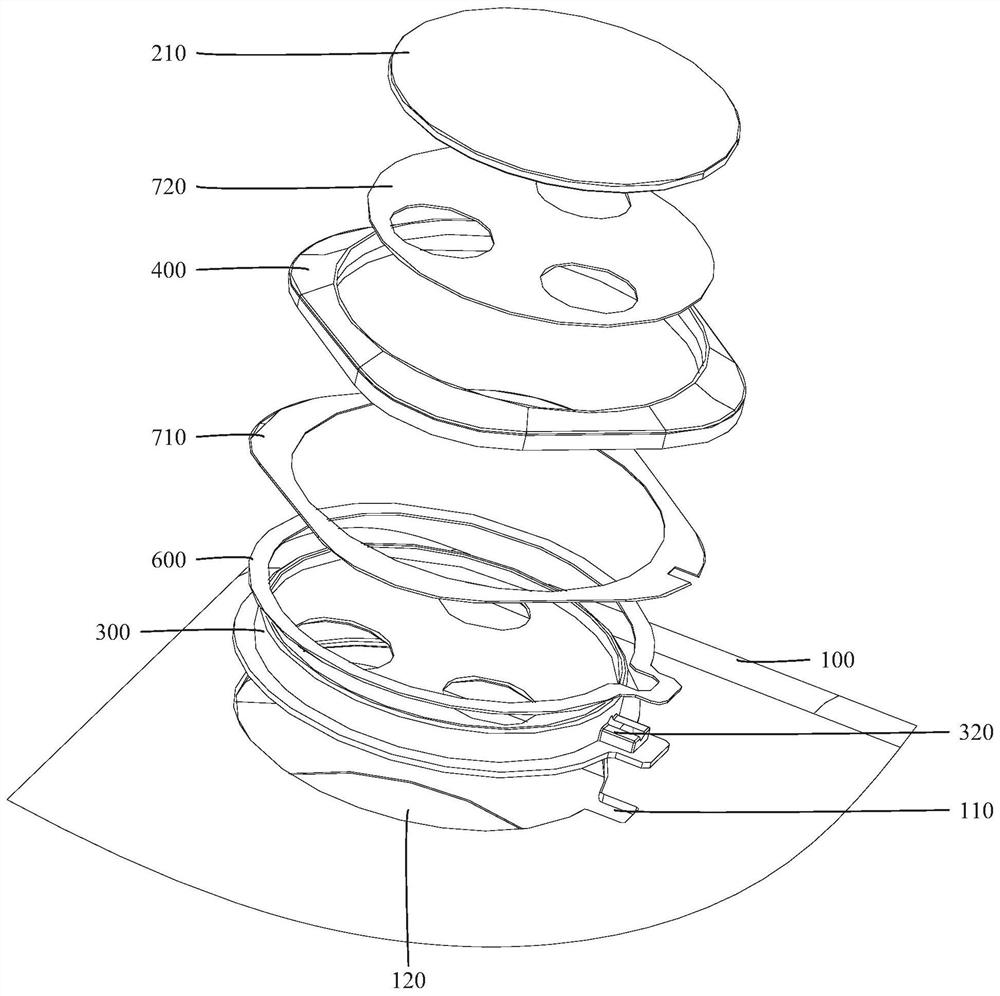

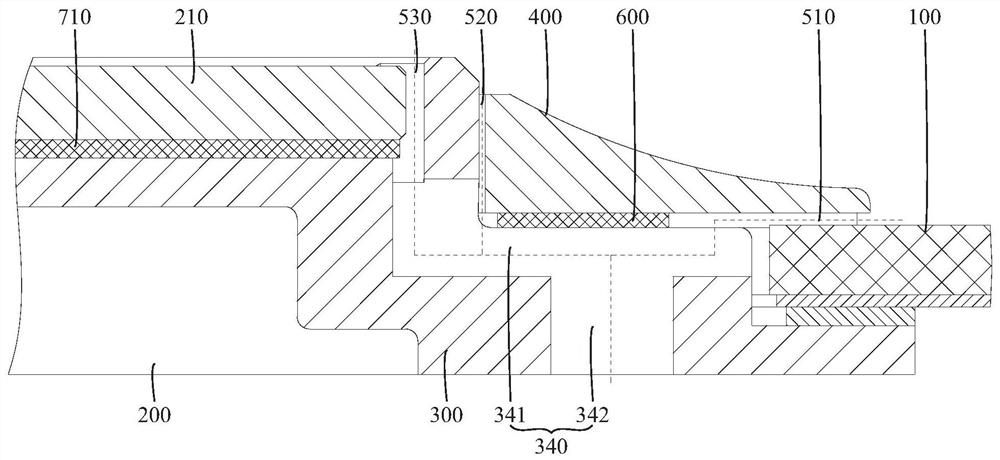

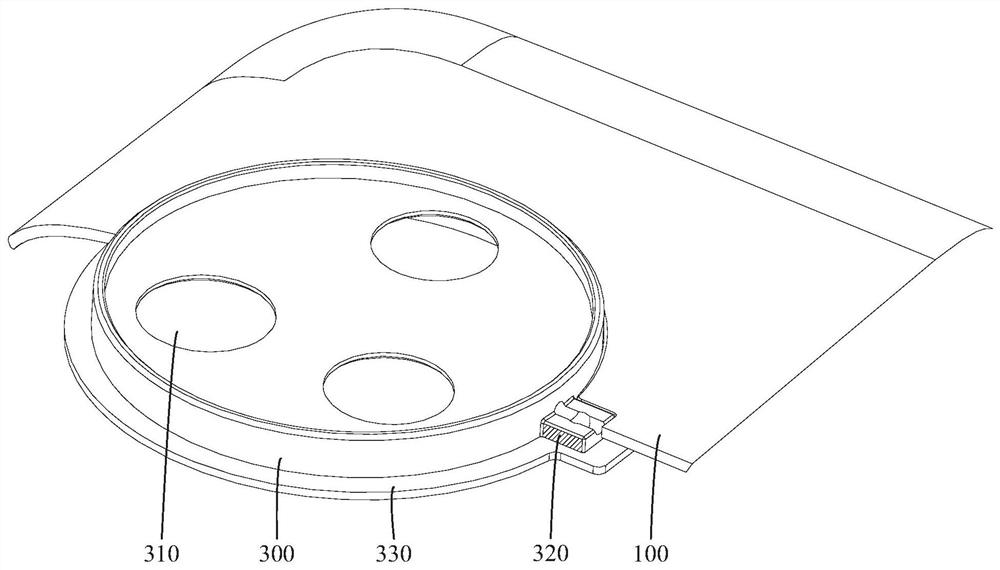

Retractable oil bottle lid

ActiveCN109229840ANot easy to spillConsistent pressureClosure with auxillary devicesBottle capTop cap

The invention discloses a retractable oil bottle lid. The retractable oil bottle lid comprises an inner plug, an oil pouring spout, a spring and a top lid; an upper port of the inner plug is providedwith an annular clamping platform, a porous plate is arranged at a lower port, and a necked step is arranged at the inner side of the inner plug; the lower end of the oil pouring spout stretches intothe inner plug, an annular step is arranged at the lower end of the oil pouring spout and hooked at the lower side of the necked step, and multiple diversion plates are arranged inside the oil pouringspout; the spring is arranged in the inner plug and the oil pouring spout, and located between the diversion plates and the porous plate; the top lid comprises a buckling wall, and an annular clamping groove is formed in the inner side of the buckling wall and matched with the annular clamping platform. According to the retractable oil bottle lid, an oil pouring opening of an oil bottle can be lengthened, so that oil drops do not easily spill on the oil bottle after oil is poured out of the oil bottle and collected; meanwhile, the retractable oil bottle lid does not occupy much space, oil return is easy, the oil outlet amount is even, and the oil does not easily spill.

Owner:上海傲腾进出口有限公司

Intelligent assembling system and method for swing frame assembly of intelligent gas meter based on Internet of Things

PendingCN113651092AImprove assembly efficiency and assembly qualityIncrease contact areaMetal working apparatusJigging conveyorsTrackwayInternet of Things

The invention discloses an intelligent assembling system for a swing frame assembly of an intelligent gas meter based on the Internet of Things, which comprises a track for conveying the swing frame assembly, a swing stop block for stopping the swing frame assembly is arranged at an output end of the track, and the swing stop block can swing in a vertical plane. By means of the arranged track, the swing frame assembly can be automatically fed, and meanwhile it is guaranteed that the swing frame assembly is not prone to deflection in the conveying process in the track, so that it is guaranteed that a grabbing mechanism on a follow-up assembly line can stably take the swing frame assembly, meanwhile, the swing stop block used for stopping the swing frame assembly is further arranged at the output tail end of the track, the swing frame assembly in the track is prevented from falling off from the track, and when the grabbing mechanism on the assembly line takes the swing frame assembly in the track, the swing stop block can rotate in the vertical plane, and it is guaranteed that the swing frame assembly can be taken smoothly.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

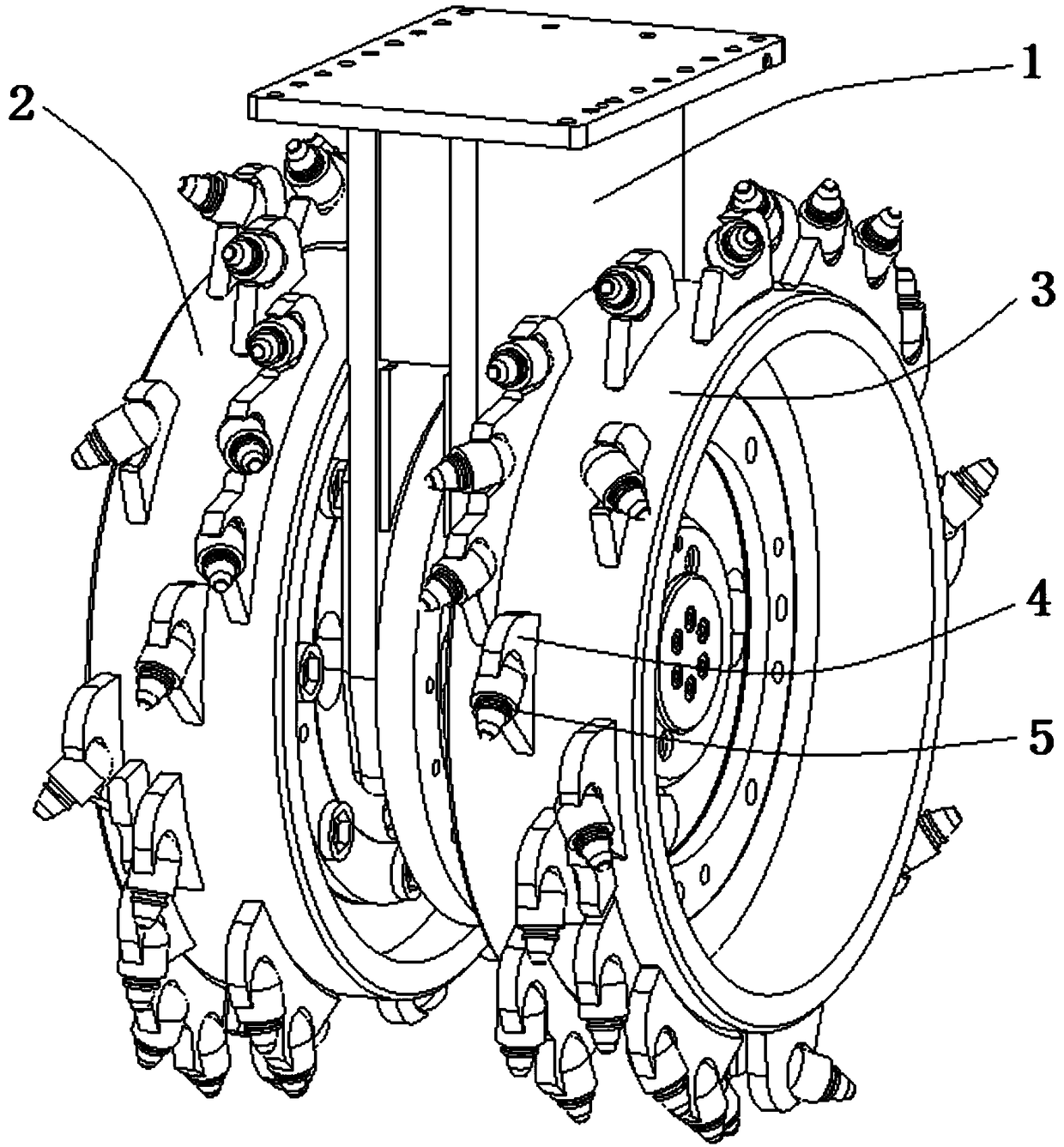

Soldering clamping device for engine oil cooler

ActiveCN102728925AAvoid distortionImprove clamping efficiencySoldering auxillary devicesPhysicsEngineering

The invention discloses a soldering clamping device for an engine oil cooler. The device comprises a fixed plate, a bottom plate, a left clamping mechanism, a right clamping mechanism, a lower soldering plate for holding the engine oil cooler, an upper soldering plate arranged on the engine oil cooler, a positioning mechanism, a compacting mechanism, a left profiling mechanism and a right profiling mechanism, wherein the bottom plate is fixed on the fixed plate; the lower soldering plate is arranged on the bottom plate; the left clamping mechanism and the right clamping mechanism are clamped on the lower soldering plate and the upper soldering plate which clamp the engine oil cooler; the left profiling mechanism and the right profiling mechanism adapt to the ends of the engine oil cooler in shape; the positioning mechanism, the compacting mechanism, the left profiling mechanism and the right profiling mechanism are connected with the fixed plate; the positioning mechanism is positioned below the fixed plate; the compacting mechanism is positioned above the fixed plate; and the left profiling mechanism and the right profiling mechanism are positioned on two sides of the compacting mechanism. The soldering clamping device for the engine oil cooler is high in clamping efficiency and can ensure the clamping precision.

Owner:宁波路润冷却器制造有限公司

Safety type automobile angle adjuster torque testing device

The invention discloses a safety type automobile angle adjuster torque testing device. A torque sensor (2) is arranged in an operation cabinet (1), the input end of the torque sensor (2) is connected with a clutch (18) via a coupling (4), the clutch (18) is connected with a motor (3), the output end of the torque sensor (2) is connected with one end of a rotary shaft (5), the other end of the rotary shaft (5) is connected with one end of a universal joint (6), the other end of the universal joint (6) is connected with one end of a testing head (7), and the other end of the testing head (7) is connected with the splined hole of the angle adjuster after passing through the top surface (8) of the operation cabinet (1). The angle adjuster is easy to fix and clamp and is not easy to displace, and has voice prompt after the clamping; and moreover, the damage of the torque sensor caused by motor overloading can be prevented, the safety coefficient is high, and the service life of the torque sensor is long.

Owner:KUNSHAN HAOSHUO PRECISION MECHANISM CO LTD

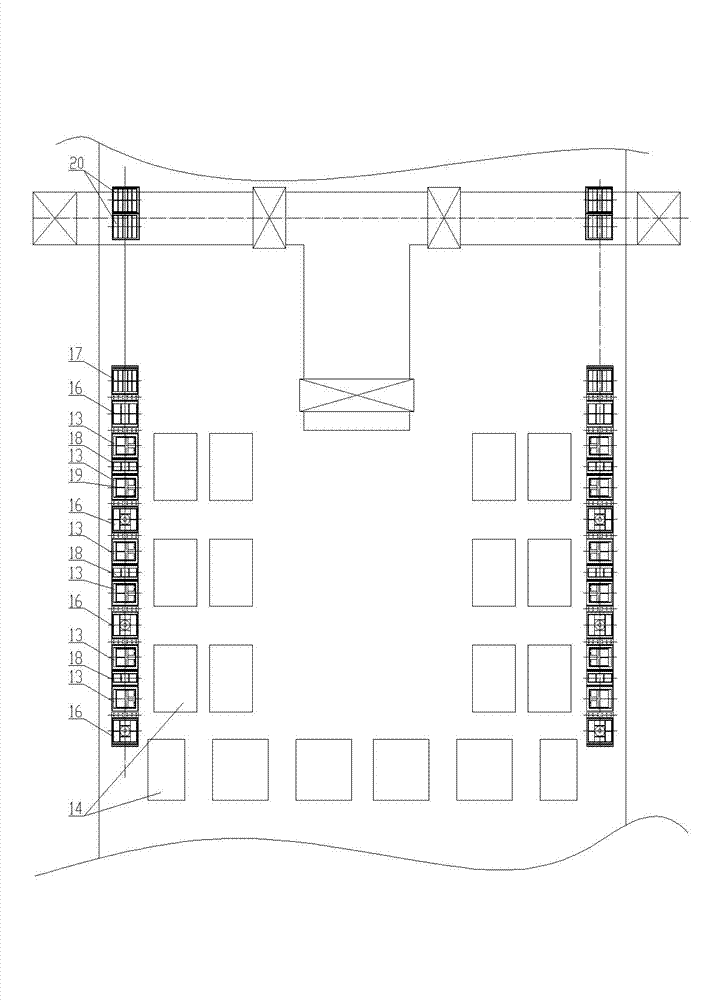

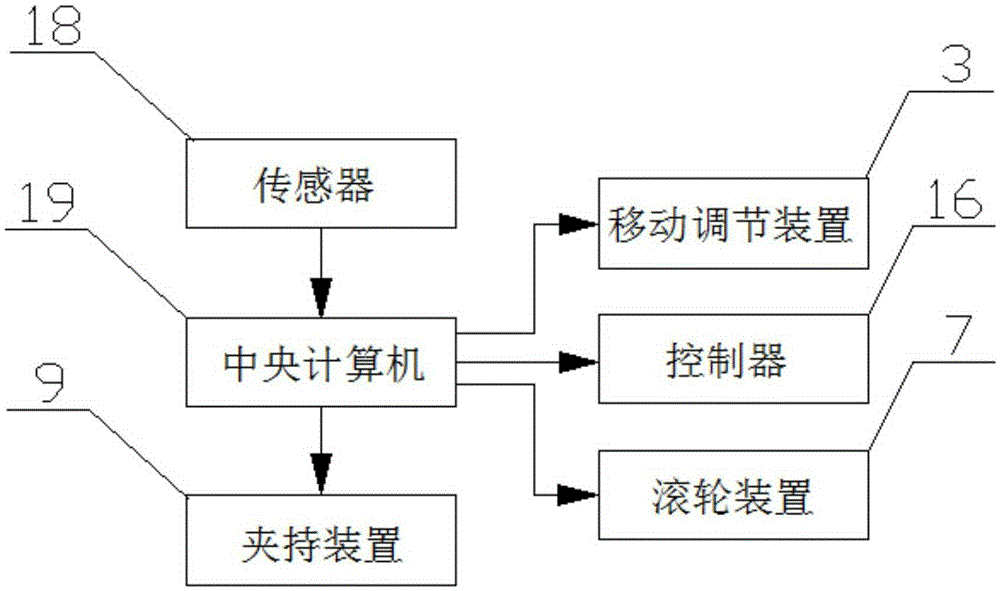

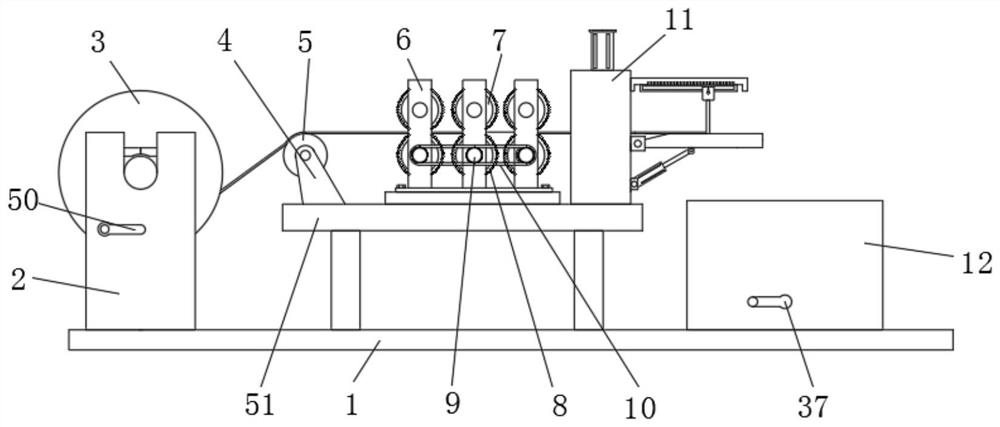

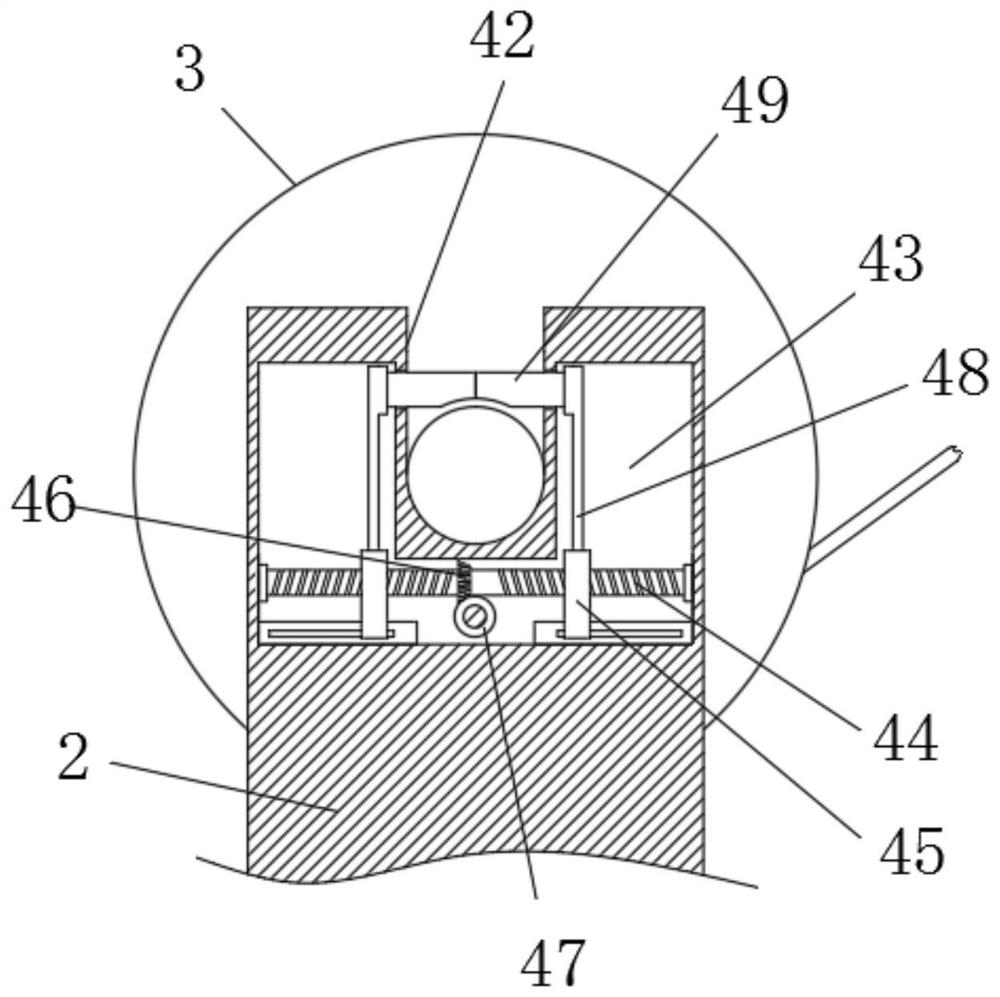

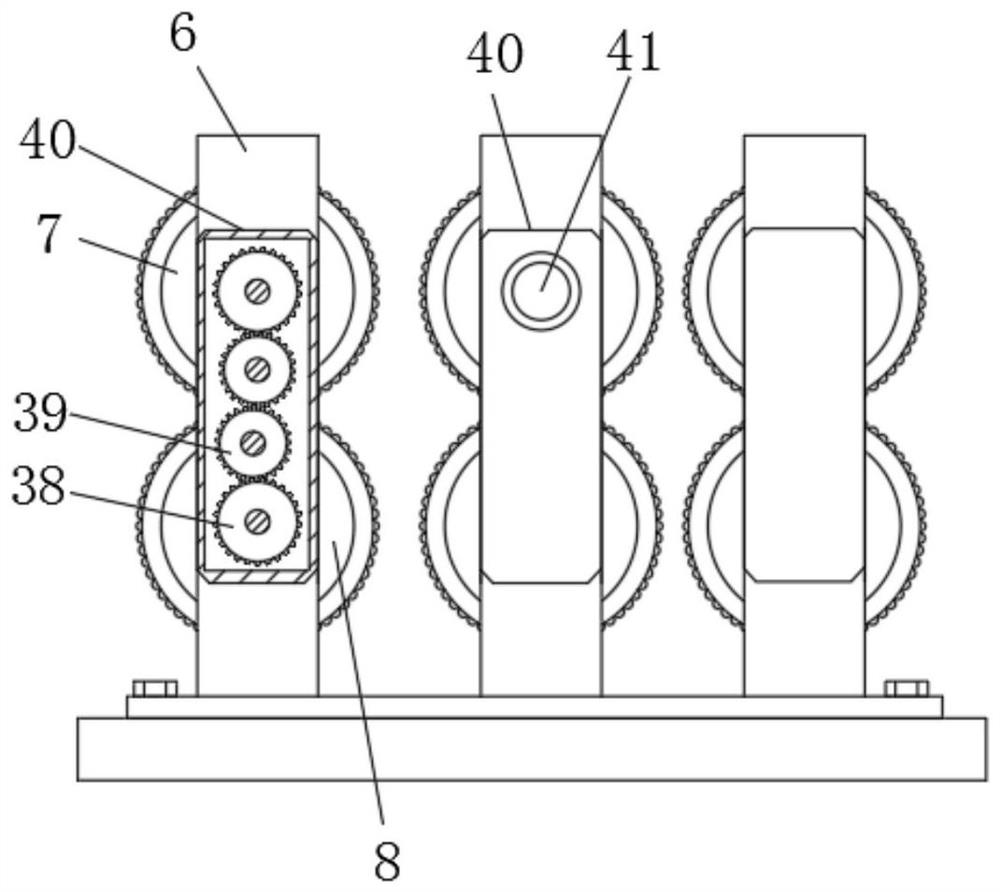

Automatic quick punch press for aluminum alloy building template

ActiveCN105312404AImprove securityImprove machining accuracyMetal-working feeding devicesPositioning devicesEngineeringAluminium alloy

The invention relates to an automatic quick punch press for an aluminum alloy building template. The punch press comprises a working platform, wherein a workpiece punching channel is formed in the working platform, movable adjusting devices capable of moving in the horizontal direction of the workpiece punching channel are arranged on the two sides of the workpiece punching channel respectively, and punching clamp devices are arranged on the two movable adjusting devices respectively; punching devices are arranged on the two punching clamp devices respectively, punch pins of the two punching devices both face the workpiece punching channel, and workpieces are punched by the two punching devices through the punch pins; a roller device capable of stretching and retracting in the vertical direction is also arranged in the workpiece punching channel and used for pushing the workpieces in the workpiece punching channel, a machine frame is arranged above the workpiece punching channel, a clamping device capable of moving along the workpiece punching channel is arranged on the machine frame, and the workpieces can be clamped and moved by the clamping device into the workpiece punching channel. Compared with the prior art, the punch press has the advantages that the workpieces can be punched automatically, the safety factor is high, machining precision is high, and production efficiency is high.

Owner:山东迈拓林铝模板工程技术有限公司

Operating table discharging mechanism of carton packaging product splitting machine

PendingCN113071142AStable outputNot easy to deflectPaper-makingBox making operationsCartonPaperboard

The invention relates to the technical field of carton packaging, and discloses an operating table discharging mechanism of a carton packaging product splitting machine. The operating table discharging mechanism comprises a supporting base, wherein the top end of the supporting base is fixedly connected with a discharging frame and a collecting box respectively, a supporting frame is fixedly connected to the position, between the discharging frame and the collecting box, of the top end of the supporting base, a discharging winding roller is detachably installed at the top end of the discharging frame, three mounting frames are fixedly connected to the top end of the supporting frame, a first feeding roller and a second feeding roller are rotationally installed on the mounting frames respectively, and a synchronous wheel is rotationally installed on one side of each mounting frame. The operating table discharging mechanism is reasonable in structure and convenient to use, a paperboard can be stably driven to move from left to right, discharging is stable, deflection is not prone to occurrence, a portion with a certain length is measured for cutting, a notch is flat, the paperboard after being cut can be automatically poured into the collecting box to be collected, the height of a push plate is adjustable, the paperboard can be pushed upwards, and the paperboard can be more conveniently taken out of the collecting box.

Owner:颍上县新浩纸箱包装有限公司

Electronic device

ActiveCN111901463ANot easy to deflectPrevent rotationTelephone set constructionsOptical ModuleEngineering

The invention discloses electronic equipment, and belongs to the technical field of communication equipment. The electronic equipment comprises a shell, an optical module and a first decorating part,a mounting hole is formed in the shell; the optical module is arranged in the shell; at least part of the first decorating part is positioned in the mounting hole; wherein the surface of the first decorating part is provided with a light transmitting hole, the optical module and the light transmitting hole are oppositely arranged, one of the shell and the first decorating part is provided with a positioning bulge, the other one of the shell and the first decorating part is provided with a positioning groove, and the positioning bulge and the positioning groove are positioned and matched alongthe circumferential direction of the mounting hole. According to the scheme, the problem that the decorating part is prone to deflection in the assembling process of the electronic equipment can be solved.

Owner:VIVO MOBILE COMM CO LTD

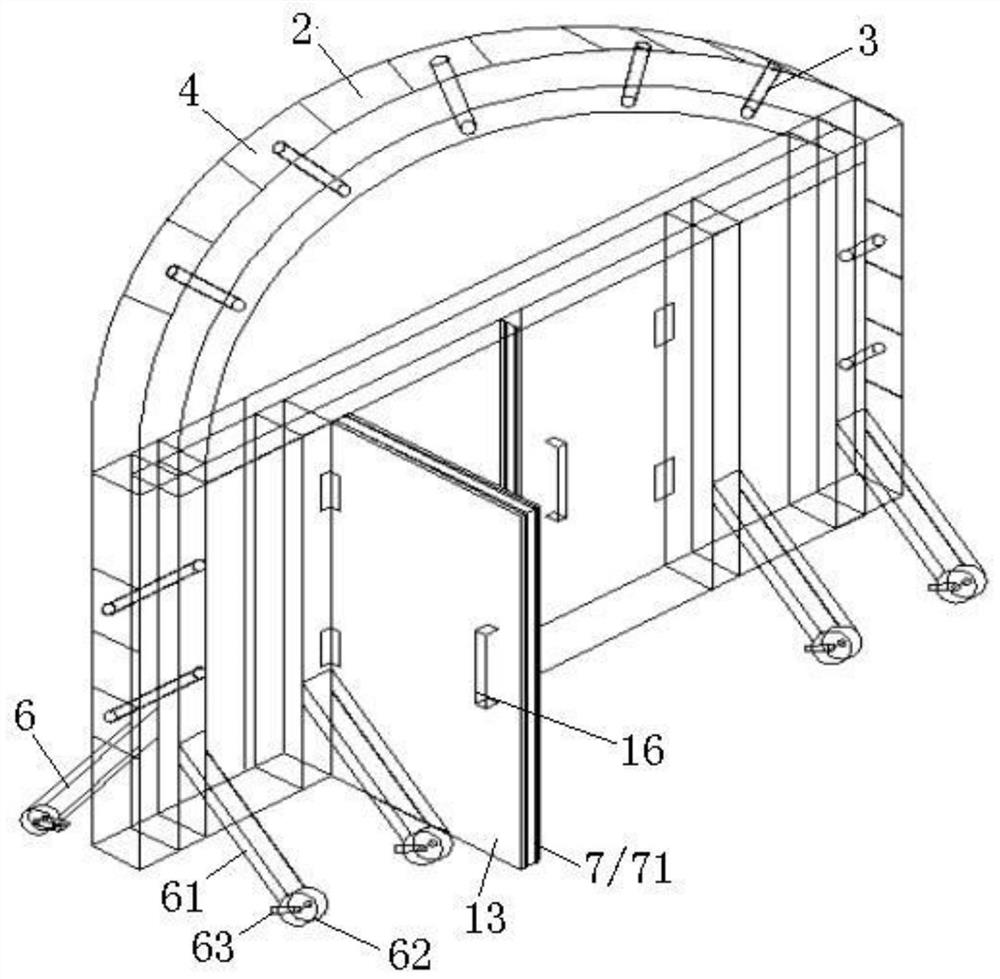

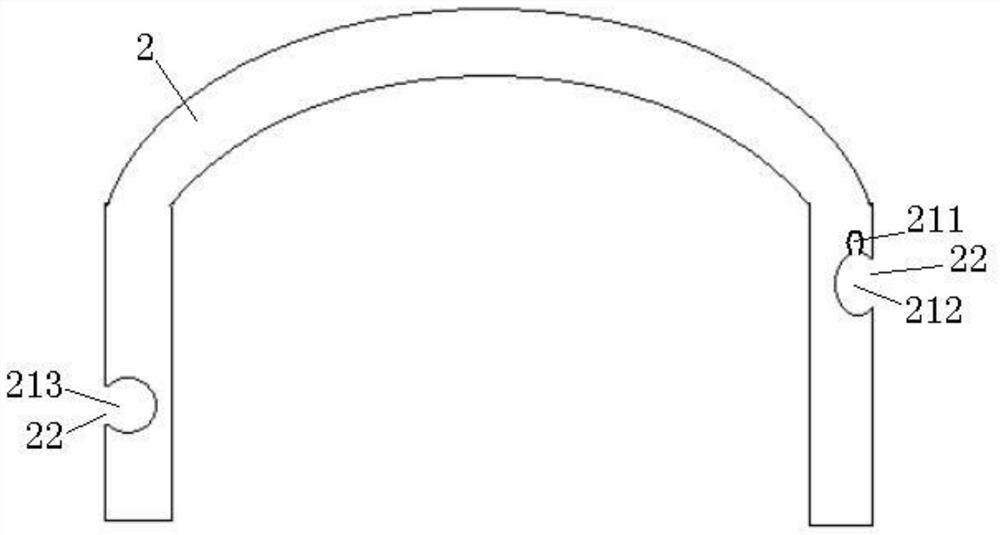

Closed door device suitable for mine tunnels

InactiveCN111608729AIncrease contact surfaceNot easy to shiftMining devicesTunnel/mines ventillationArchitectural engineeringMaterial resources

The invention provides a closed door device suitable for mine tunnels. The device comprises a door main body, an airbag, telescopic rods and a support cushion. The innermost side of the airbag is connected to the frame of the door main body, the telescopic rods are arranged around the door main body, one ends of the telescopic rods are fixedly connected to the frame of the main body, the other ends are connected with the support cushion, and the support cushion is connected to the outermost airbag skin of the airbag into a whole in a bonding mode. According to the device, the door main body inthe middle of a door body is of a hard structure, the edge is an inflatable airbag, so that the door body has certain strength and stability, and good sealing performance; according to the device, oxygen loss can be reduced and the utilization rate of oxygen can be improved without affecting underground ventilation; as the tunnels advance, the position of the closed door can be gradually adjustedto adapt to changes of the environment, so that a closed space is always maintained at an appropriate size, the oxygen concentration in a local space can be maintained, constant oxygen supply effectis ensured, a large amount of underground space resources, material resources and financial resources can be effectively saved, the maintenance is convenient, and the cost is low.

Owner:CENT SOUTH UNIV

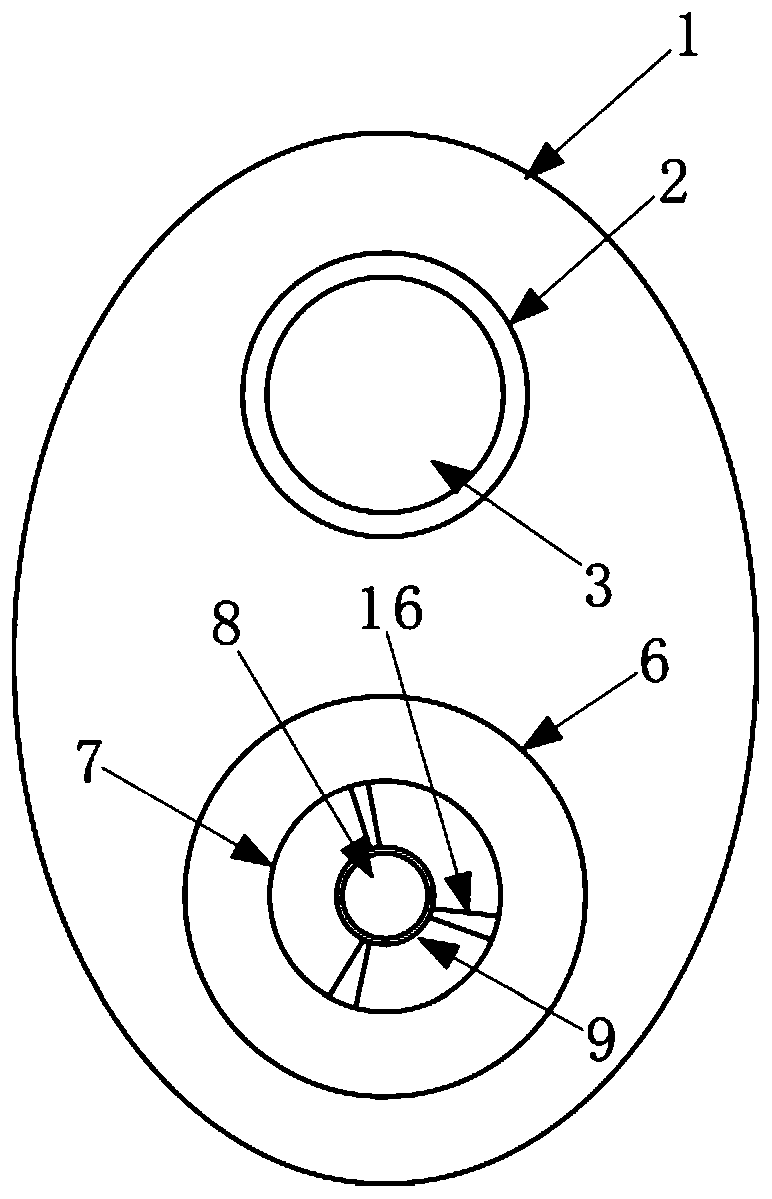

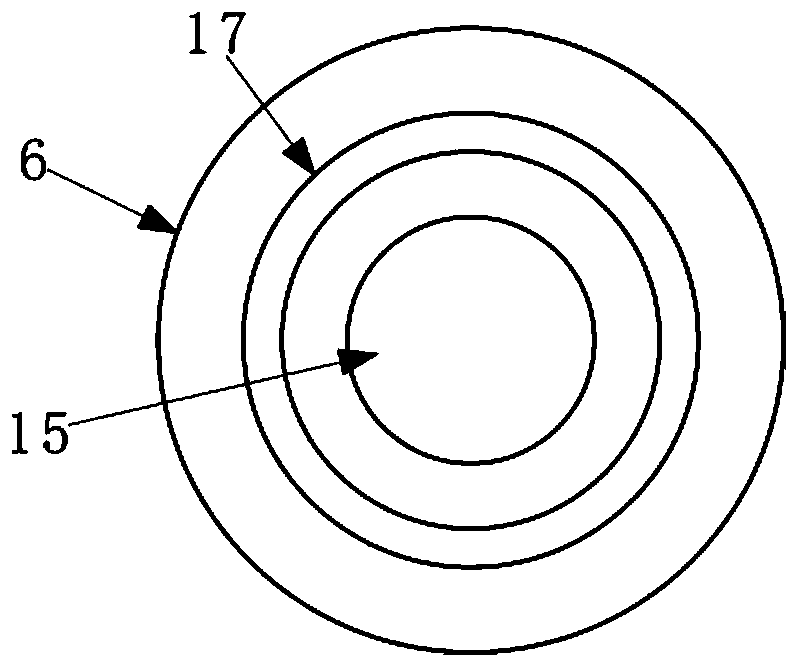

A combined DTH hammer sealing and anti-loosening structure

ActiveCN106050127BFit tightlyNot easy to deflectBorehole drivesBulkheads/pilesUpper jointEngineering

The invention discloses a combined down hole hammer sealing and anti-loosening structure. The structure includes a pore damping adjusting apparatus, a fitting, a pressure plate, a sealing gasket, a bolt, a spring gasket, a circular nut, an impactor upper joint, and a positioning taper sleeve. The impactor upper joint is locked to the positioning taper sleeve through the circular nut. The fitting is pressed against the impactor upper joint through the pressure plate, the sealing gasket, the bolt and the spring gasket. The fitting is also provided with the pore damping adjusting apparatus and can adjust the amount of air inflow. The impactor upper joint is in conical surface contact with the fitting and the positioning taper sleeve. Due to the pressing action of a pressure cover and the locking action of the circular nut, the contact surfaces of two pairs of conical surface undergo elastic deformation and are tightly bonded, which can generate greater friction. Therefore, the structure has sealing and anti-loosening functions.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Automobile damping fixing piece sectional material die

InactiveCN107838215AReduce on-board turnaround timeIncrease productivityExtrusion diesEngineeringVolumetric Mass Density

The invention discloses an automobile damping fixing piece sectional material die. The automobile damping fixing piece sectional material die comprises an upper die body and a lower die body which aremutually stacked. The feeding face of the upper die body is provided with eight peripheral flow dividing holes and eight flow dividing bridges. The peripheral flow dividing holes and the flow dividing bridges are evenly arranged in the circumferential direction, and a middle flow dividing hole is formed in the center. A large inner die core and a small inner die core are arranged on the discharging face of the upper die body, outer die cores are arranged on the two sides of the inner die cores, and a die core bridge is arranged between the two inner die cores. The lower die body is internallyprovided with a first-level welding-on chamber, a second-level welding-on chamber, a cavity and a product outlet in sequence, and the second-level welding-on chamber and a sectional material are consistent in outline. According to the automobile damping fixing piece sectional material die, it is guaranteed that the surface of the sectional material is smooth, the density and mechanical performance are perfect, the size is accurate, and using is excellent and perfect. The cost is reduced, and the machine feeding circulation time of the die is shortened; and the production efficiency of the sectional material is improved, and the production cost is reduced.

Owner:JIANGYIN GIANSUN MOLD

Pyrotechnic composition laser

InactiveCN111211472AIncrease energy densityEasy to processLaser detailsPyrotechnic compositionEngineering

The invention discloses a pyrotechnic composition laser. The pyrotechnic composition laser comprises a light condensation cavity; a vibration exciter and a first protection tube are arranged in the light condensation cavity; a pyrotechnic composition column is arranged in the first protection tube; the pyrotechnic composition column is coated with a uniform energy-containing material layer; one end of the pyrotechnic composition column and one end of the first protection tube are fixed to the light condensation cavity through fixing devices; a trigger device is arranged at the other end of thefirst protection pipe; a firing pin for impacting the pyrotechnic composition column is arranged in the trigger device; the fixed end of the firing pin is connected to the inner wall of the trigger device through a spring; an inserting groove is formed in the fixed end; a trigger piece capable of being pulled out is arranged in the inserting groove; and the trigger piece penetrates through the trigger device. According to the technical schemes of the invention, chemical energy stored in pyrotechnic composition is utilized; the energy-containing material is deflagrated to serve as a pumping source, so that pumping energy density is large; the pumping source is easy to machine and form through a powdery viscous agent. Therefore, the laser of the invention has the advantages of large outputenergy, light weight, small size and convenience in integration.

Owner:SOUTHWEAT UNIV OF SCI & TECH

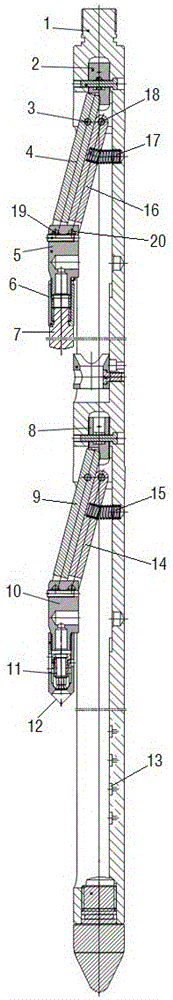

Throwing and refloating device

InactiveCN106223891AEnsure synergyReduced pull resistanceBorehole/well accessoriesEngineeringDistributor

The invention provides a throwing and refloating device which comprises a main body of the throwing and refloating device, a connector and a claw mechanism connected between the main body of the throwing and refloating device and the connector, wherein the claw mechanism comprises an inner claw and an outer claw which are disposed inside and outside respectively; upper ends of the inner claw and the outer claw are in a hinged connection with the main body of the throwing and refloating device; lower ends of the inner claw and the outer claw are in a hinged connection with the connector; and two hinged points of the upper and lower ends of the inner claw and two hinged points of the upper and lower ends of the outer claw are located at four vertexes of a parallelogram. In comparison with a single-claw structure in the prior art, the device is characterized in that the double claws are disposed on the connector; the inner claw and the outer claw work together, and thus the connector is not deflected to the main body of the throwing and refloating device easily, so that a force bearing direction of a blocking device is consistent with a hole shift axis of a water distributor as much as possible, and lifting and pull resistance of the throwing and refloating device is reduced; and the four hinged points are located at the four vertexes of the parallelogram, and thus cooperative effects of the inner claw and the outer claw are ensured, so that joint effects brought by the inner claw and the outer claw to the connector can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

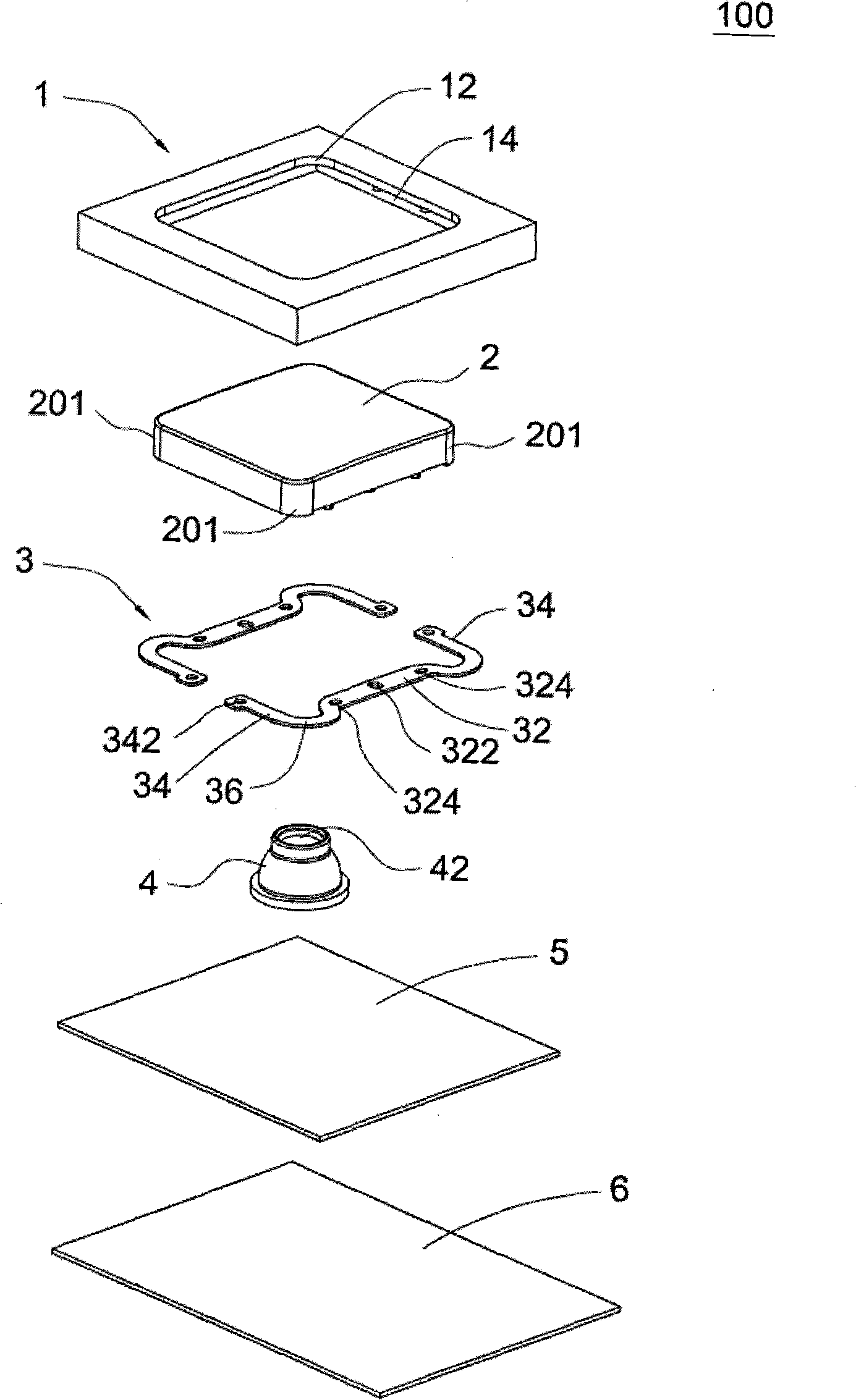

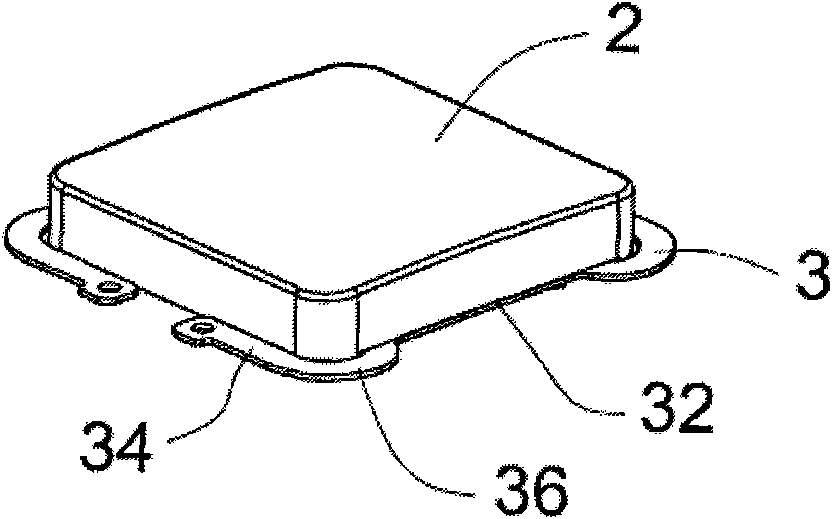

Spring type key

The invention relates to a spring type key. The key comprises a key frame and a key cap with a plurality of outer corners, wherein the key cap is embedded in an accommodating hole of the key frame; the key also comprises a plurality of strip-shaped elastic arms; each elastic arm comprises an inner fixing arm part, at least one outer movable arm part and at least one corner transition part for connecting the inner fixing arm part with the at least one outer movable arm part; each corner transition part corresponds to each outer corner; and each inner fixing arm part is positioned inside an edge on one side of the bottom of the key cap, and the corner transition part corresponding to the inner fixing arm part extends out of the edge and extends to an edge adjacent to the edge along the corresponding outer corner and is fixed on the key frame through the outer movable arm part. The spring type key has the advantages of lower cost and proper pressing force, and the elastic arms of the spring type key contribute to reducing thickness of the key.

Owner:PRIMAX ELECTRONICS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com