Operating table discharging mechanism of carton packaging product splitting machine

A discharge mechanism and slitting machine technology, applied in packaging, transportation and packaging, box making operations, etc., can solve the problems of unsmooth discharge, cardboard collection that cannot be cut, and disordered cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

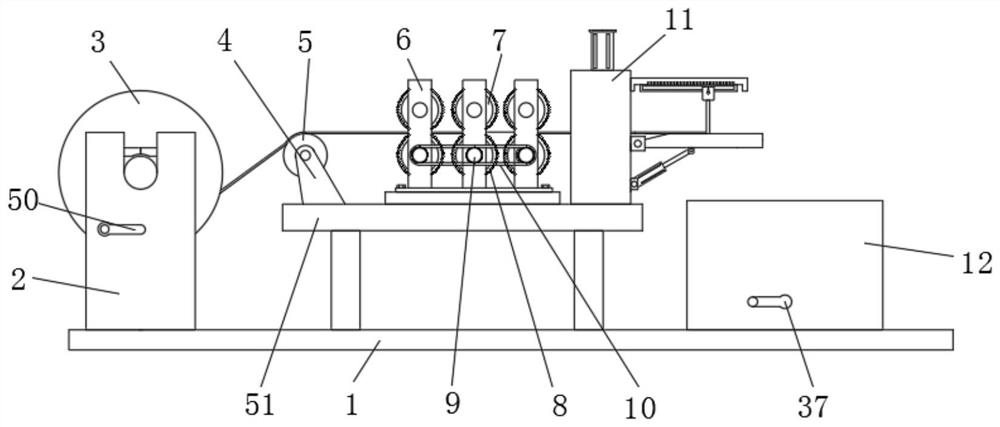

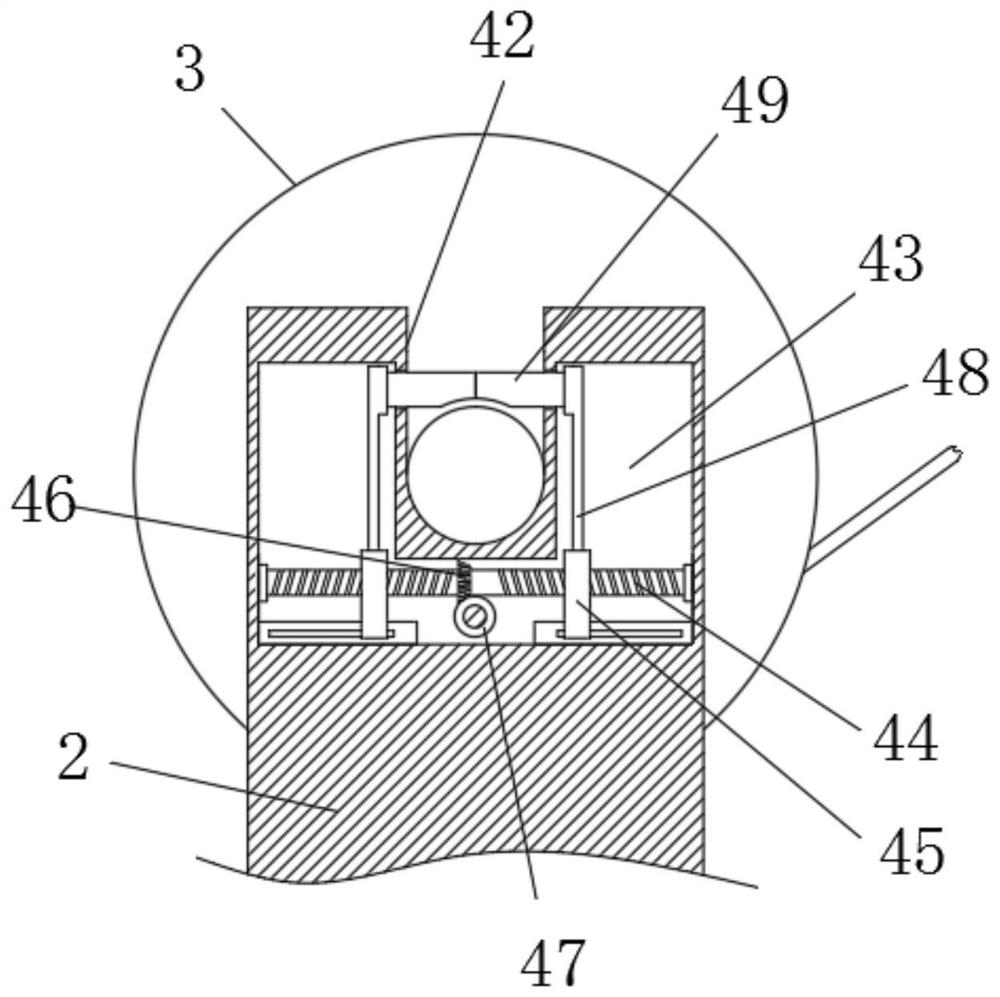

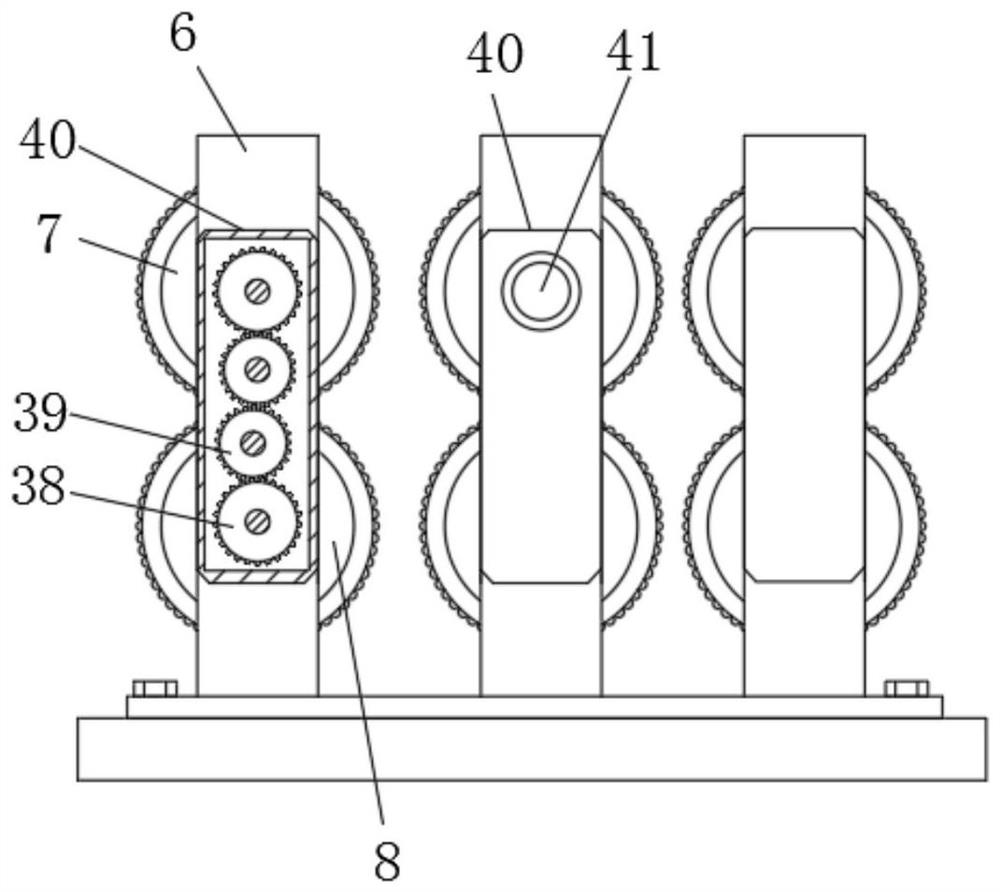

[0030] Refer Figure 1-6 , The operation table discharge mechanism of a carton package slot cutter includes a support base 1, and the tip end of the support base 1 is fixed to the disc 2 and the collecting box 12, respectively, the top end of the support base 1 is located in the disc 2 and The collected box 12 is fixed to the support frame 51, the top end of the disc 2 can be detachable and mounted, and three mounting frames 6 are fixedly connected to the top end of the support frame 51, and the mounting frame 6 is rotated separately. The upper feed roller 7 and the second upper material roller 8 are rotated on one side of the mounting frame 6, and the synchronous wheel 9 is fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com