Power-off braking mechanism for main brake of escalator

A technology of escalator and power failure braking, applied in escalators, hoisting devices, transportation and packaging, etc., can solve the problems of increased maintenance procedures, inconvenient maintenance, high manufacturing costs, etc., and achieve cost control of installation and maintenance. , The effect of easy installation and maintenance, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

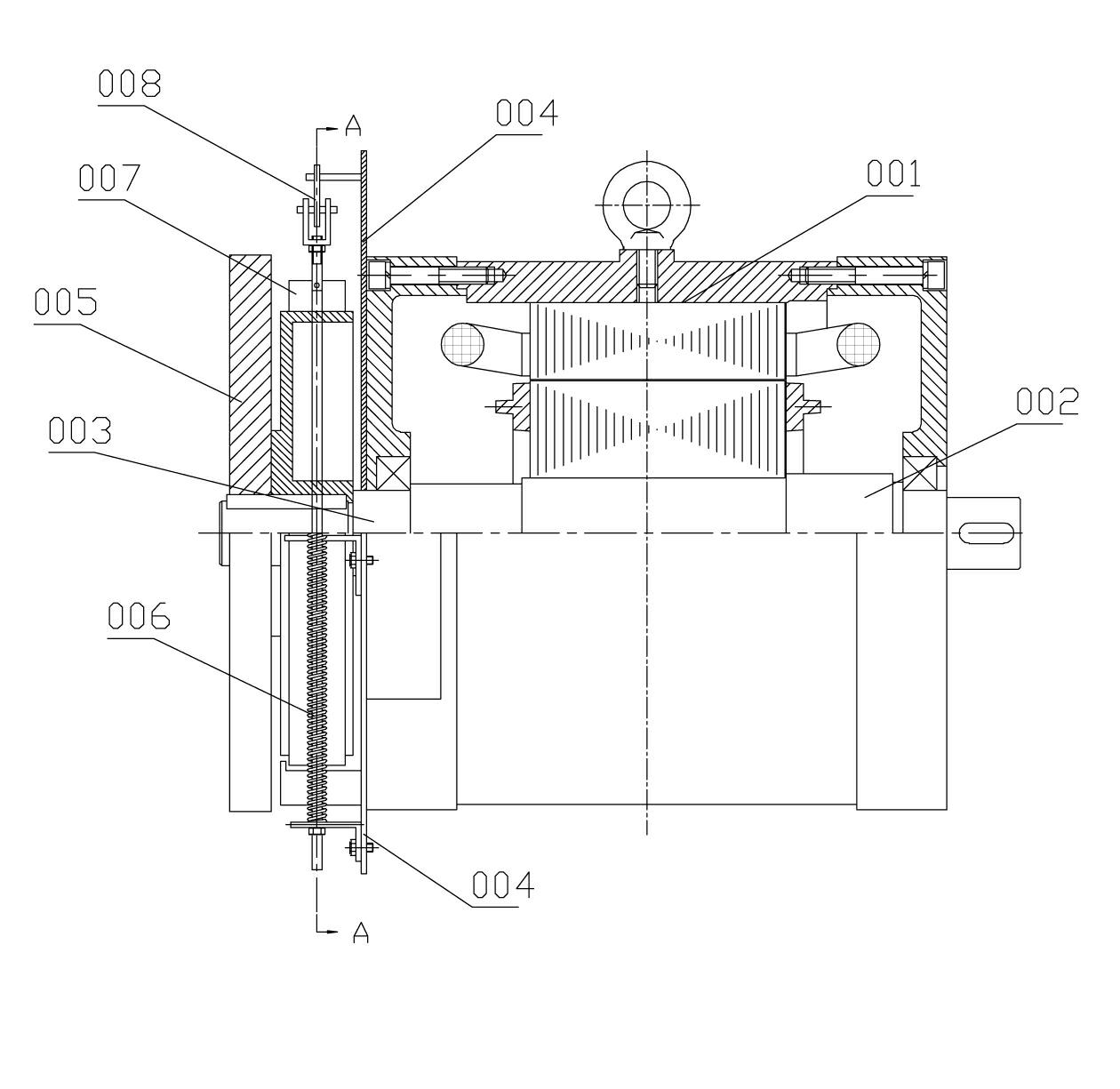

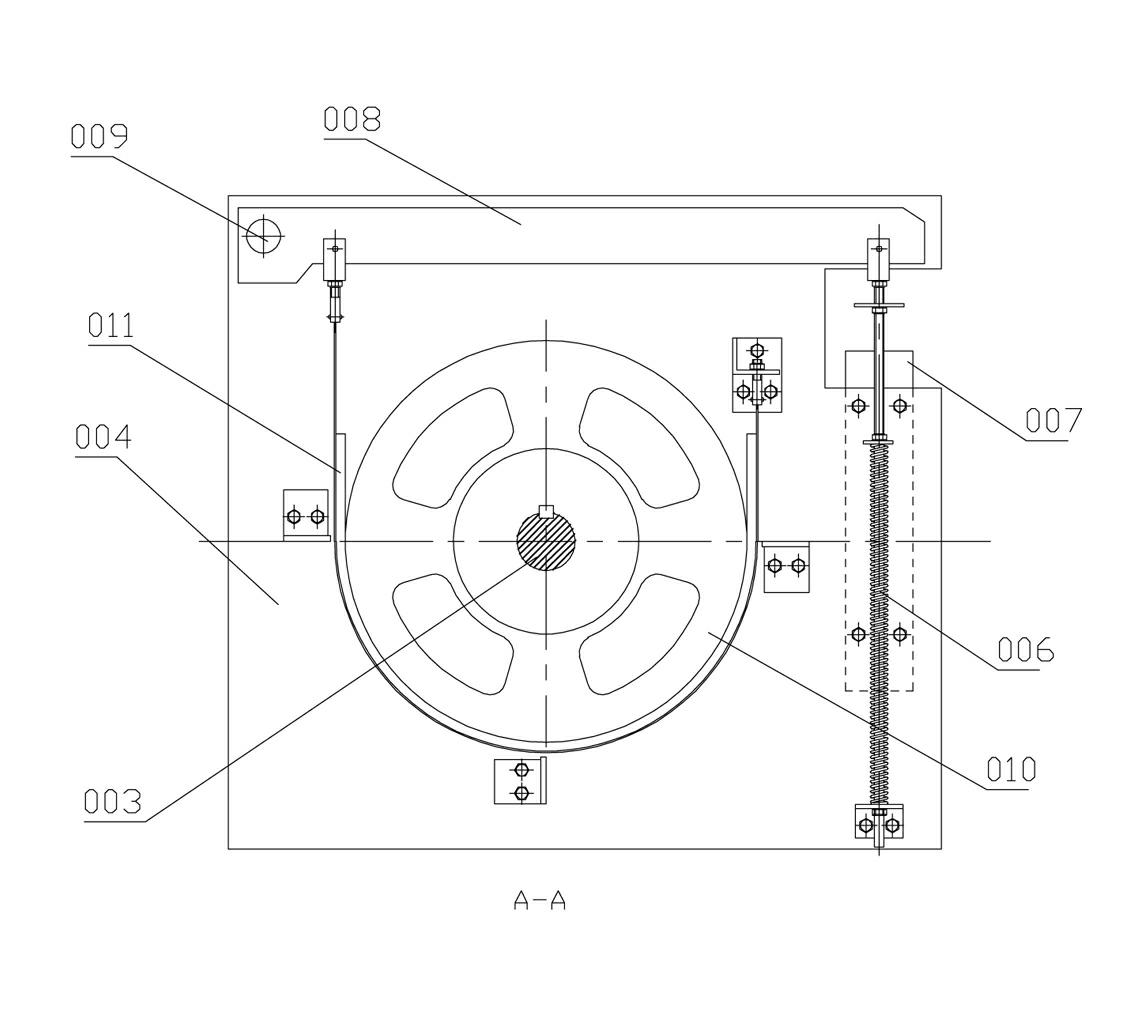

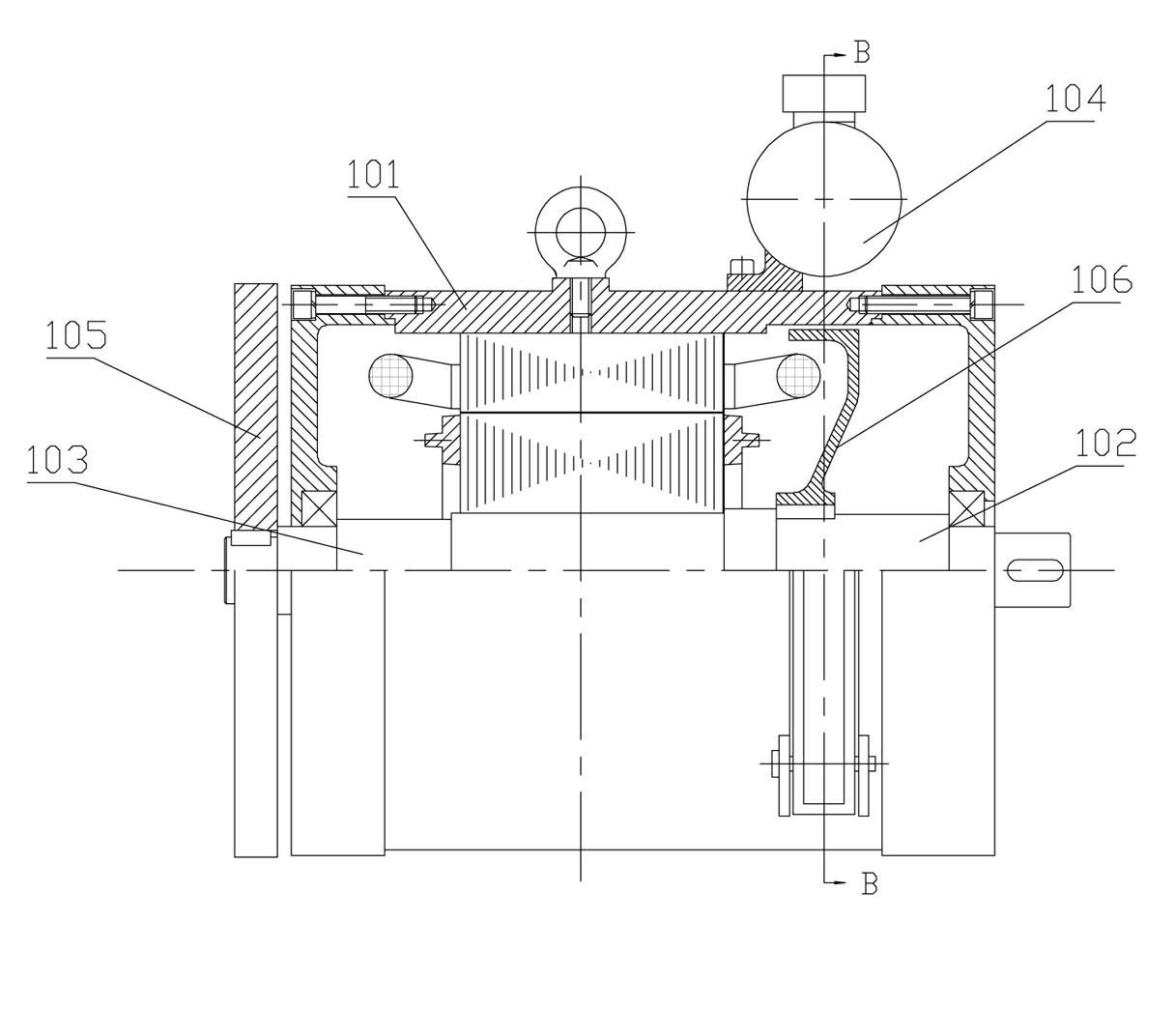

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] combined with Figure 5 to attach Figure 6, a power-off braking mechanism for the main brake of an escalator, which includes a brake wheel 12, a brake band 11, a first brake band traction member for keeping the brake band 11 away from the brake wheel 12 and a To make the brake band 11 close to the second brake band traction part of the brake wheel 12, the braking action surface on the brake band 11 is in clearance fit with the outer peripheral surface of the brake wheel 12, and the brake wheel 12 and the brake wheel The rotating shaft of the main motor of the escalator is limited in the circumferential direction, and the brake wheel 12 and the braking band 11 are installed in the motor base 10 of the main motor of the escalator. The brake wheel 12 and the brake band 11 are located in the cavity between the outside of the motor winding 15 of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com