Z-shaped elevator

A hoist, 1.Z technology, used in conveyors, transportation and packaging, etc., can solve problems such as deflection, inability to completely unload, and uncertainty in the direction of the hopper, so as to improve the utilization rate, improve the utilization rate, avoid the random flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

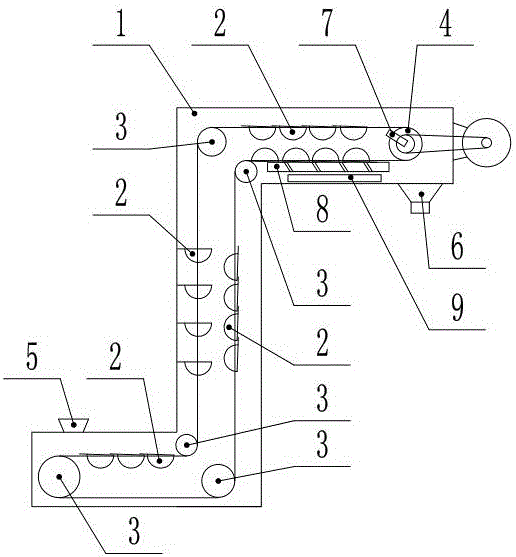

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0018] Such as figure 1 , a Z-shaped hoist, including a Z-shaped body 1 composed of a horizontally arranged base part, a vertically arranged rising part and a horizontally arranged output part, the lower end of the rising part is connected to the front end of the base part, The upper end is connected to the rear end of the output part, the base part, the rising part and the output part all have inner cavities and the three inner cavities communicate in turn to form the Z-shaped inner cavity of the body 1, and the Z-shaped inner cavity is provided with a transmission chain, There are two transmission chains and they are respectively arranged on the left and right sides of the Z-shaped inner cavity;

[0019] A number of hoppers 2 arranged in sequence are installed between the two transmission chains, and the left and right ends of the hopper 2 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com