Patents

Literature

71results about How to "Guaranteed blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

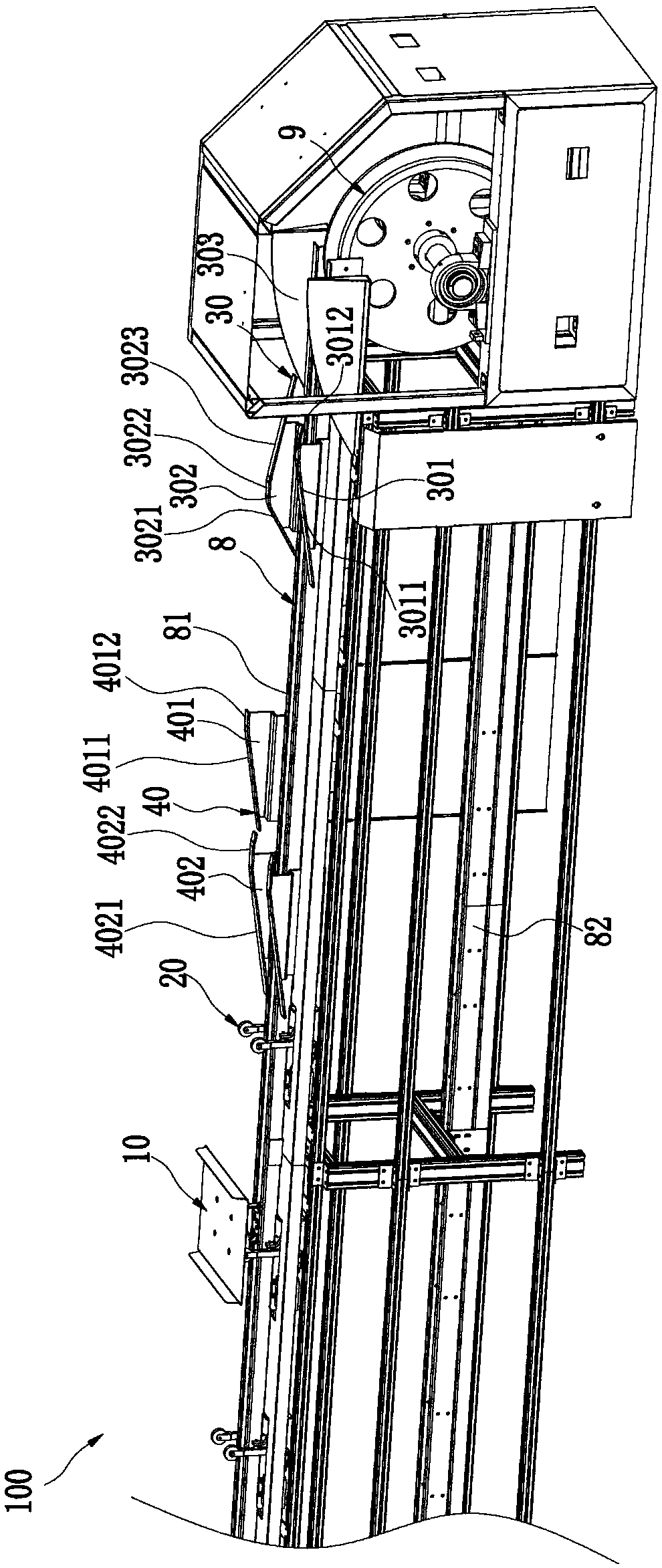

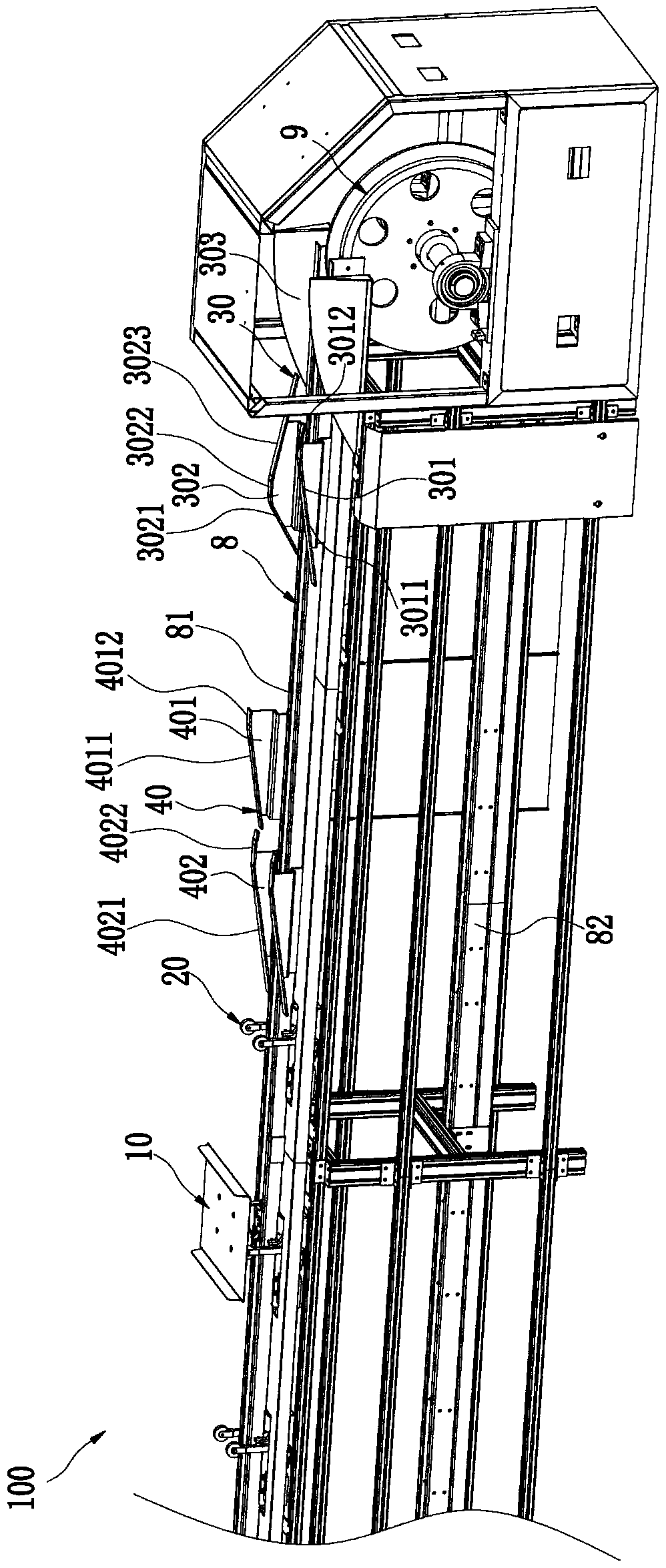

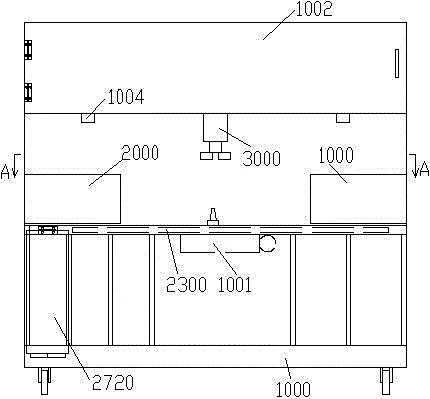

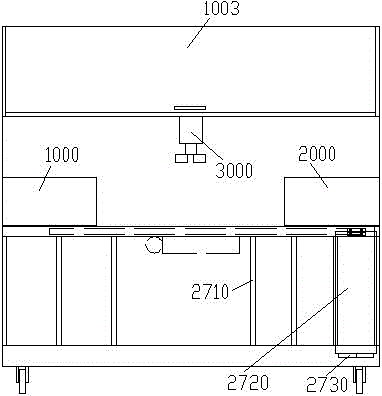

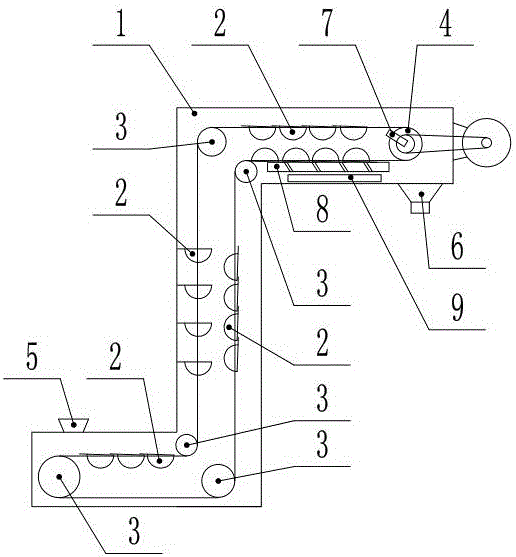

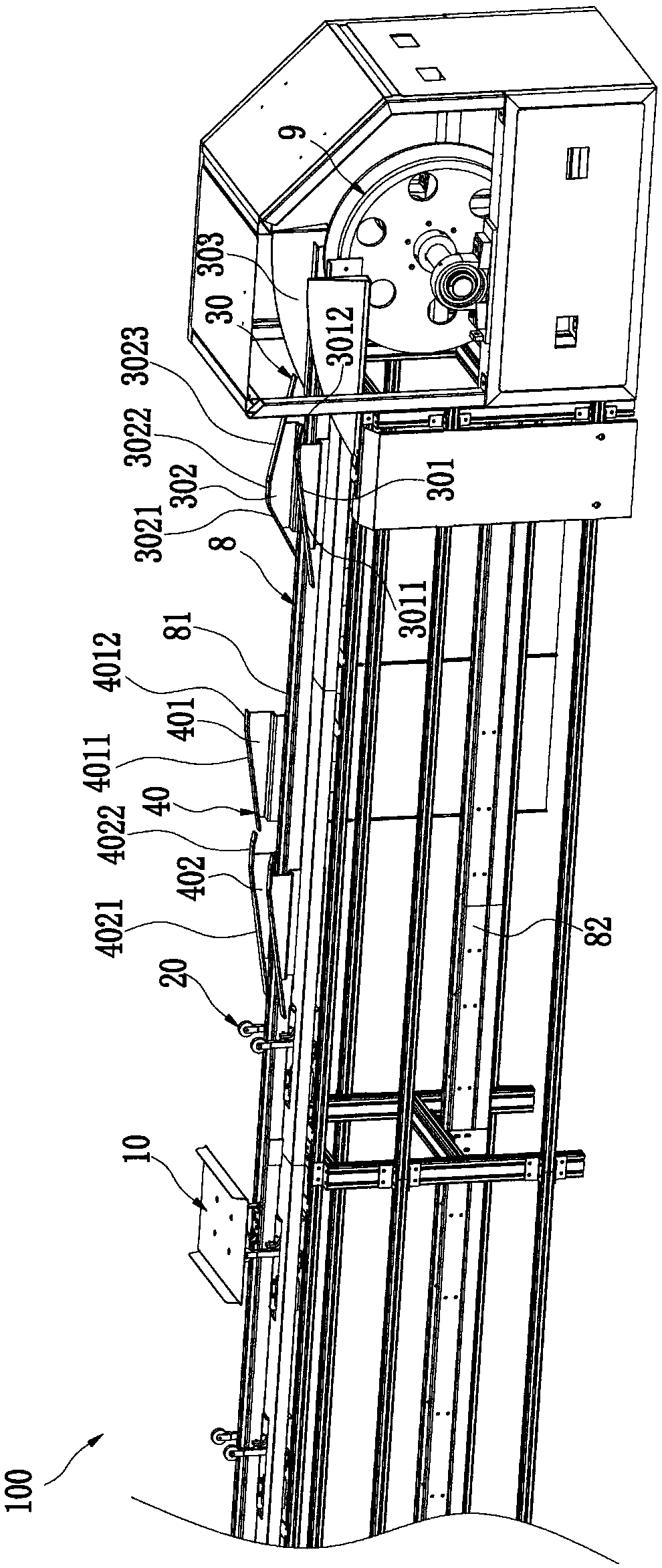

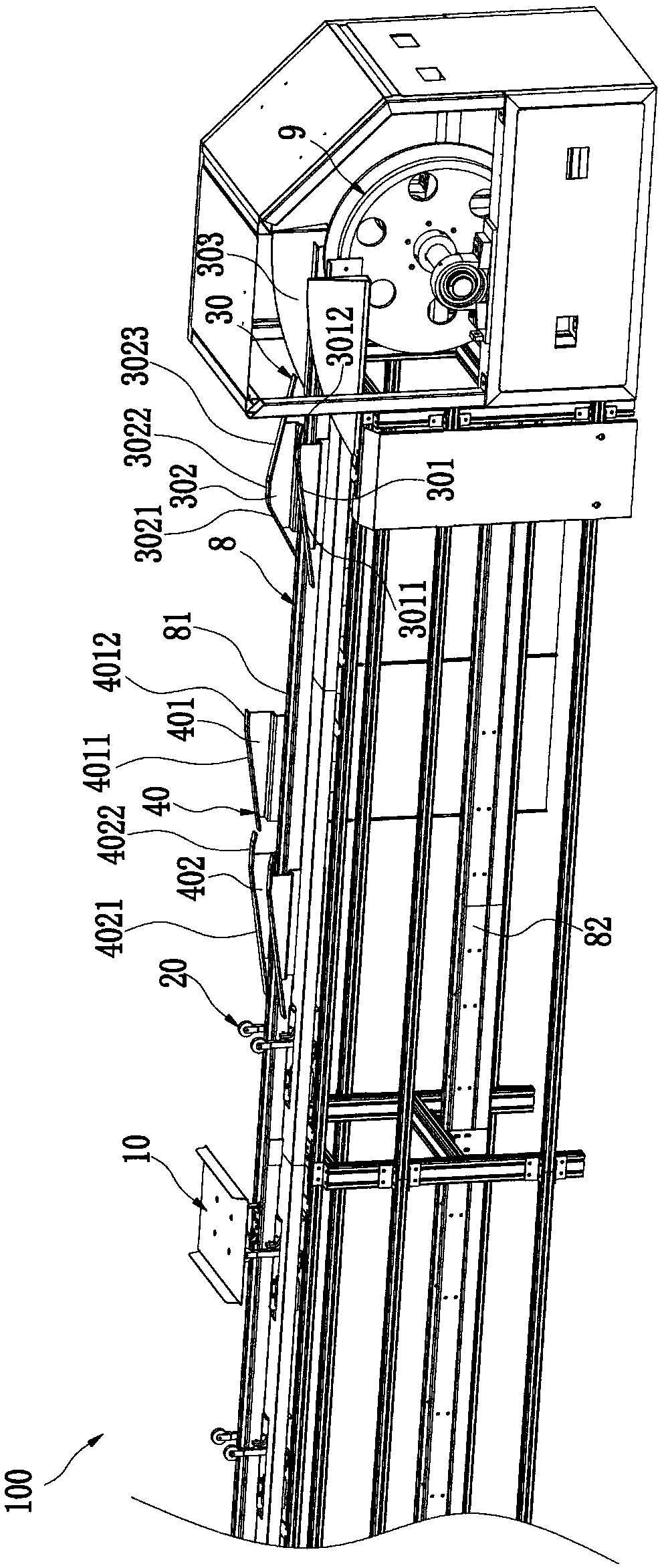

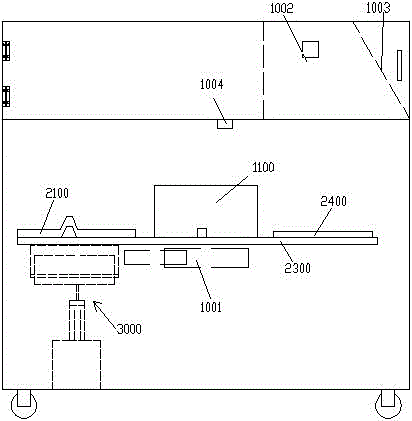

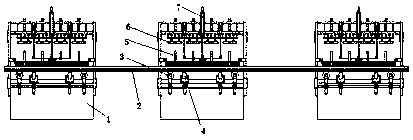

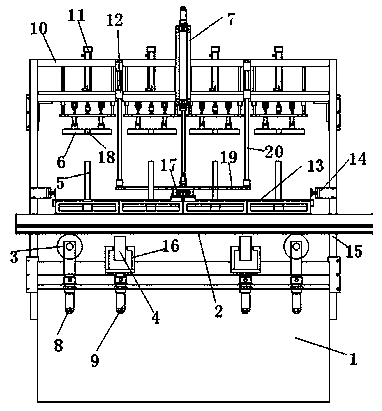

Turning-plate type sorting system

PendingCN108408314AResolve interferenceEffective combinationSortingStorage devicesEngineeringMulti path

The invention discloses a turning-plate type sorting system comprising a track and further comprising a feeding area located beside the track, detecting equipment located on the track and a grid opening area located beside the track. The track is slidably provided with at least one bidirectional turning-plate trolley with a turning plate capable of turning over towards two directions for unloading; and the bidirectional turning-plate trolleys are connected with driving devices driving the bidirectional turning-plate trolleys to slide along the track. In the turning-plate type sorting system, the bidirectional turning-plate trolleys can sort bidirectionally and can be combined with the track to realize synchronous work of multiple trolleys; by controlling the discharging position and discharging direction of each bidirectional sorting trolley, multi-path sorting can be effectively realized under the limited site condition, the problem of disturbance caused by travelling paths of a conventional trolley is avoided, and the requirement on the site is low; meanwhile, the multiple trolleys synchronously sort in multiple paths, and thus the sorting efficiency is greatly improved; and by combining feeding, detecting and sorting openings, automatic operation of the whole sorting process can further be achieved, and the turning-plate type sorting system is advantageously matched with other sorting equipment for being used through the design of discharging grid openings.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

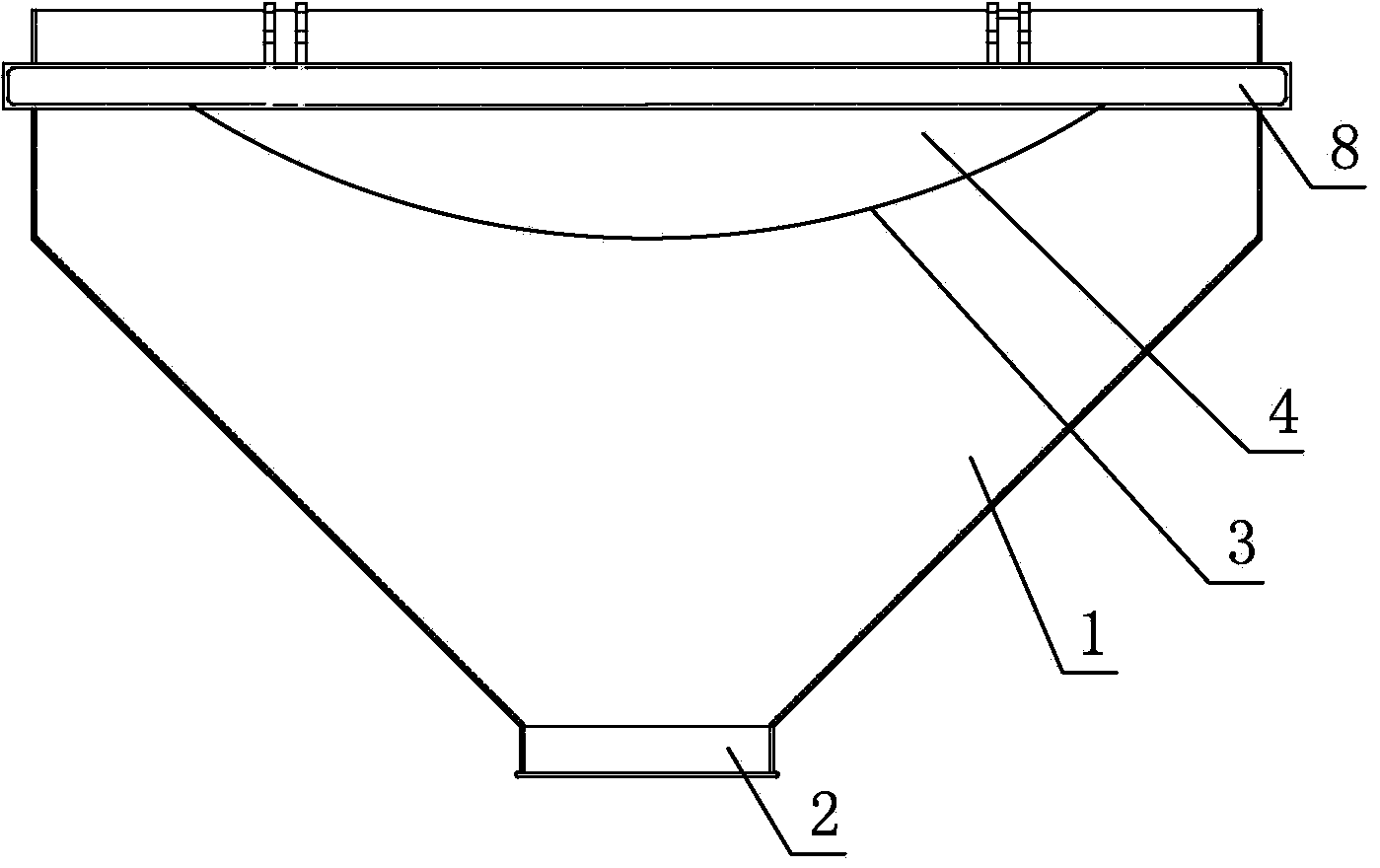

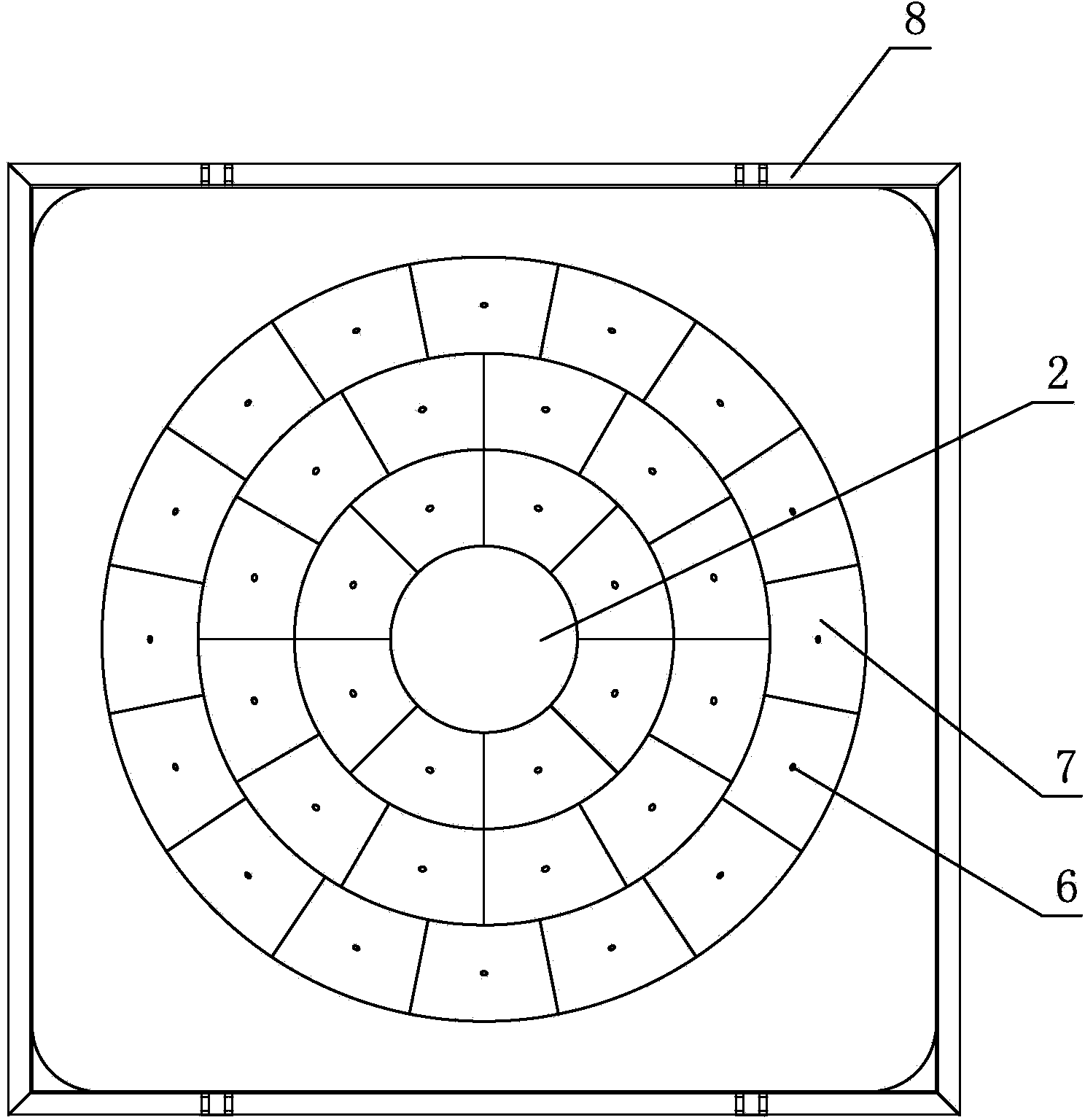

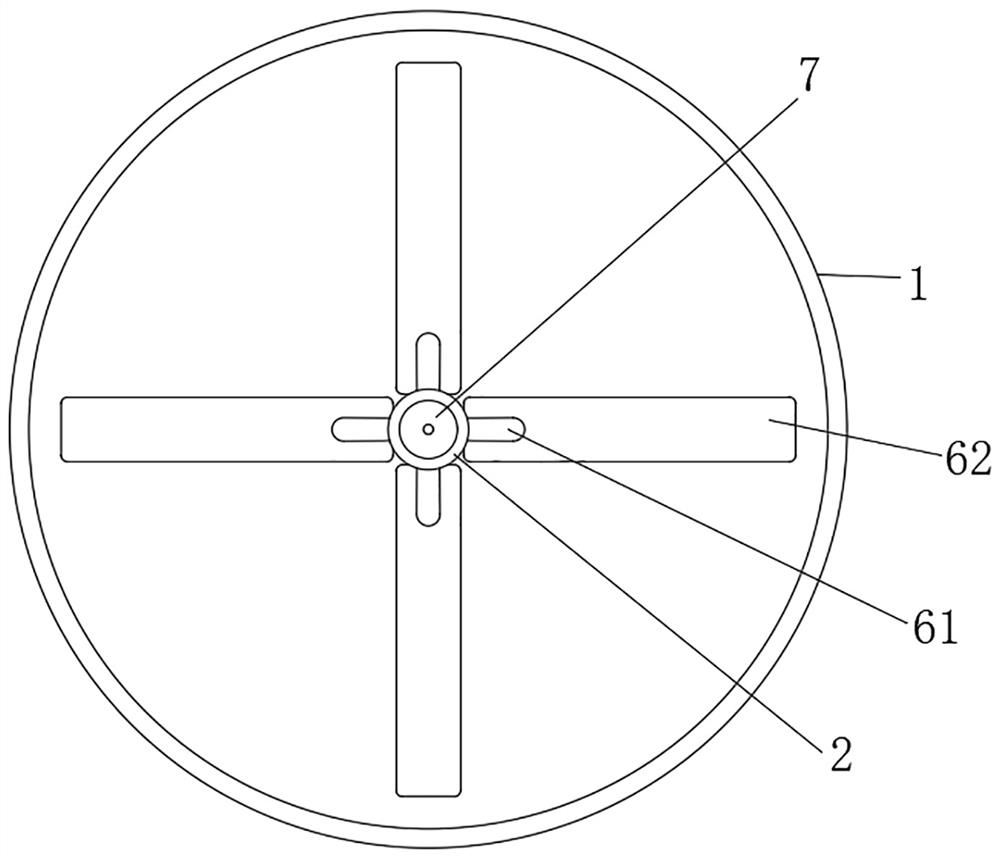

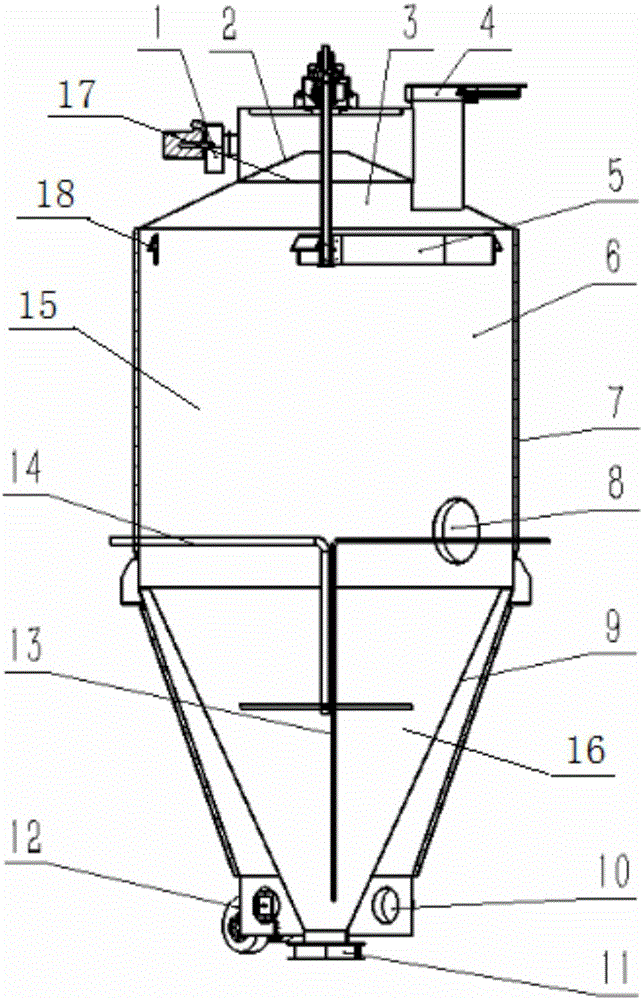

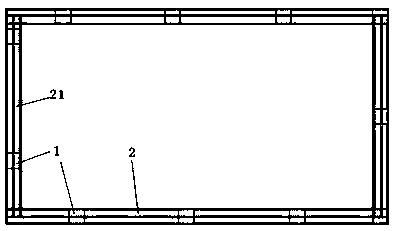

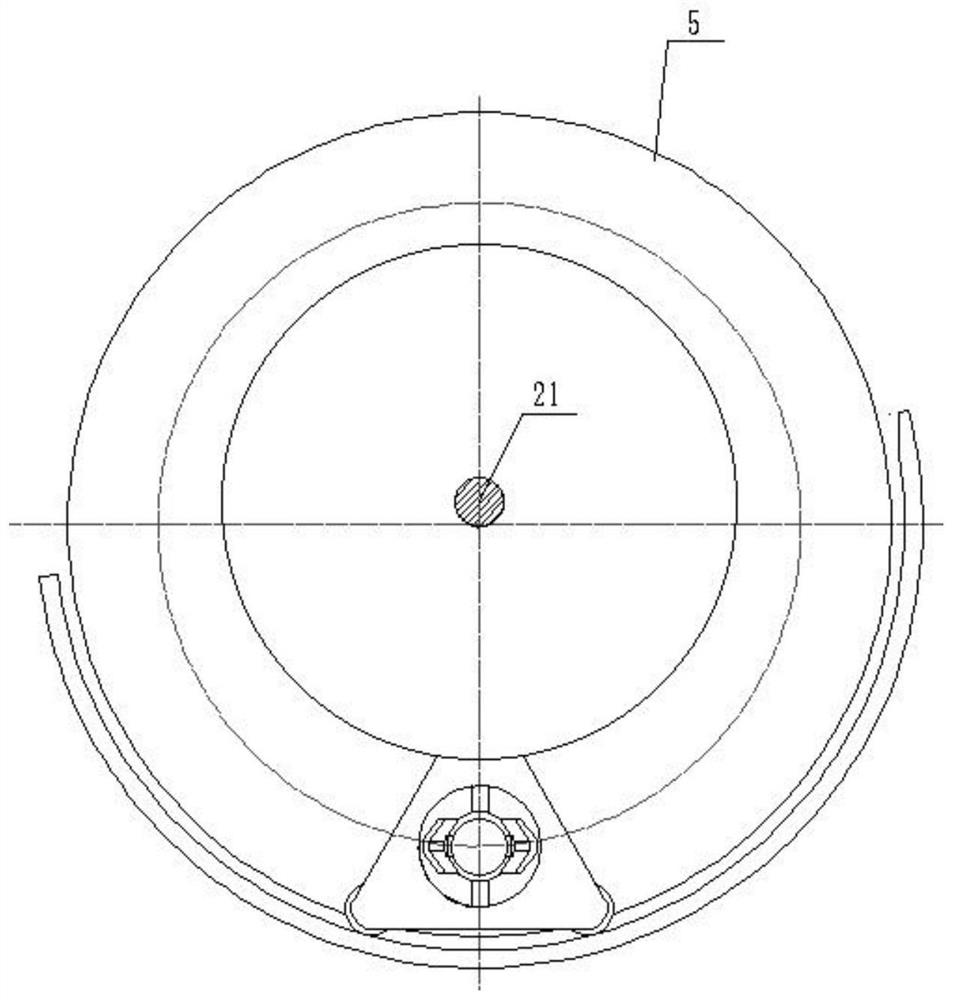

Gathering hopper of stirring station

The invention discloses a gathering hopper of a stirring station. The gathering hopper comprises a conical material barrel, wherein a material blanking port is formed in the bottom of the conical material barrel; four arc-shaped notches with the same size are uniformly formed in the circumference of the top end of the conical material barrel; a material blocking plate is vertically arranged at each arc-shaped notch; the ends of each two adjacent material blocking plates are vertically welded; the four material blocking plates define a square feed port which is matched with the square installation port on the platform of the stirring station; a seal plate is arranged at the clearance which is between the top end of the conical material barrel between each two arc-shaped notches and the welded materials plates arranged at the two arc-shaped notches. The structure of the gathering hopper is reasonable in design; the conical material barrel is adopted and the inner surface is arc-shaped, so that discharge dead angle does not exist, concrete is avoided from adhering to the material barrel and the normal material blanking of the conical material barrel is guaranteed; besides, a replaceable arc-shaped lining plate is additionally arranged at the lower part of the inner side of the conical material barrel, so that the service life of the gathering hopper is greatly prolonged.

Owner:SHANDONG MIX MACHINERY EQUIP

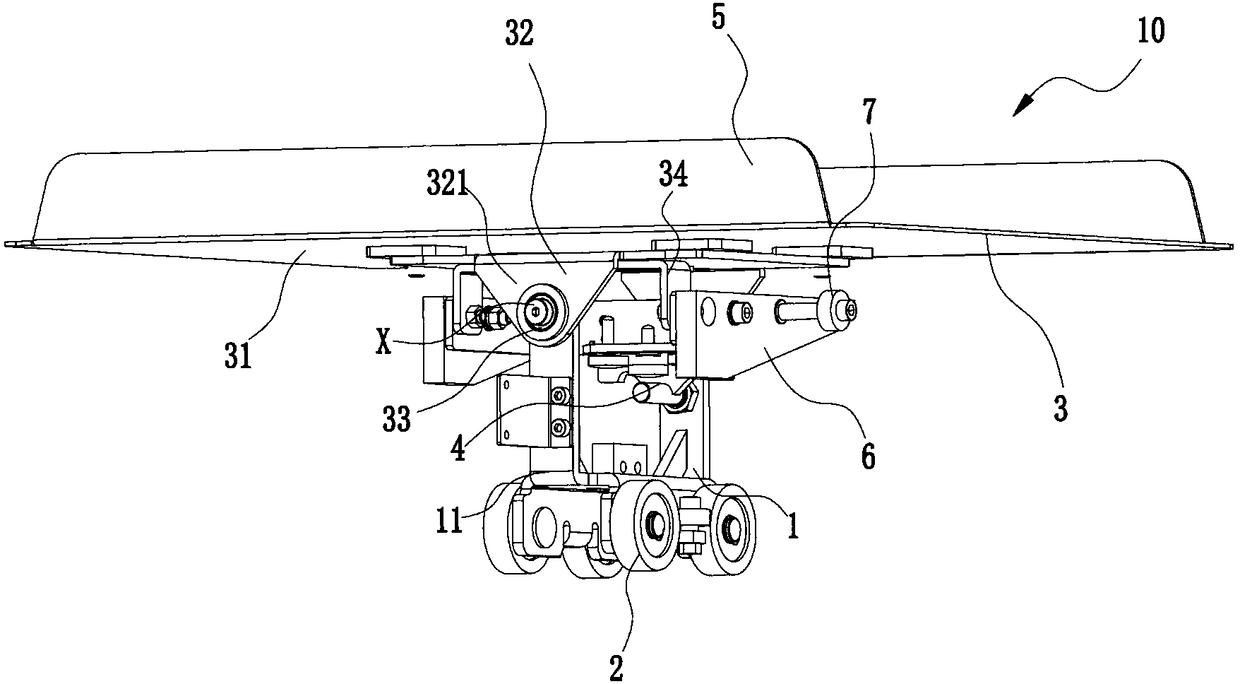

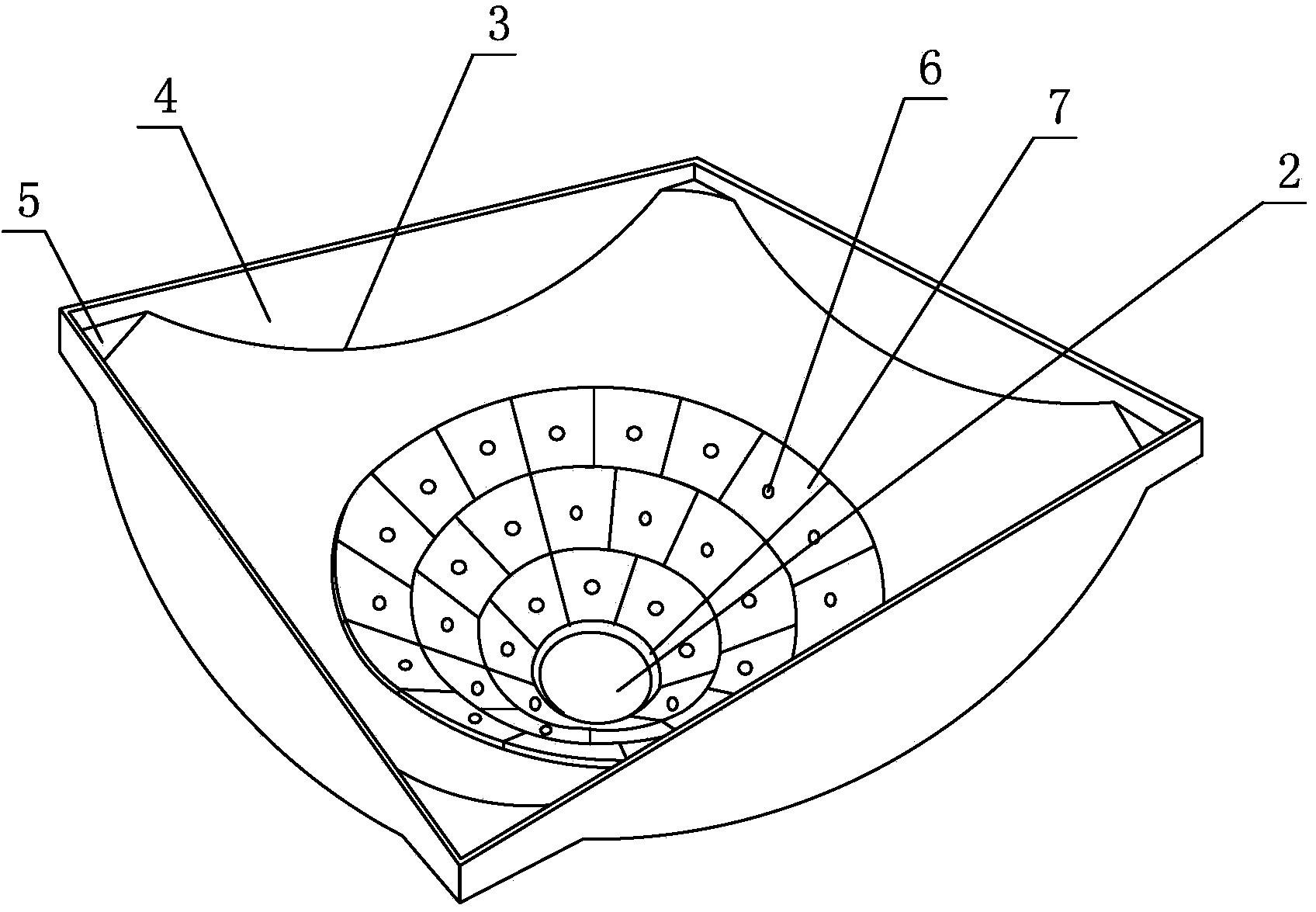

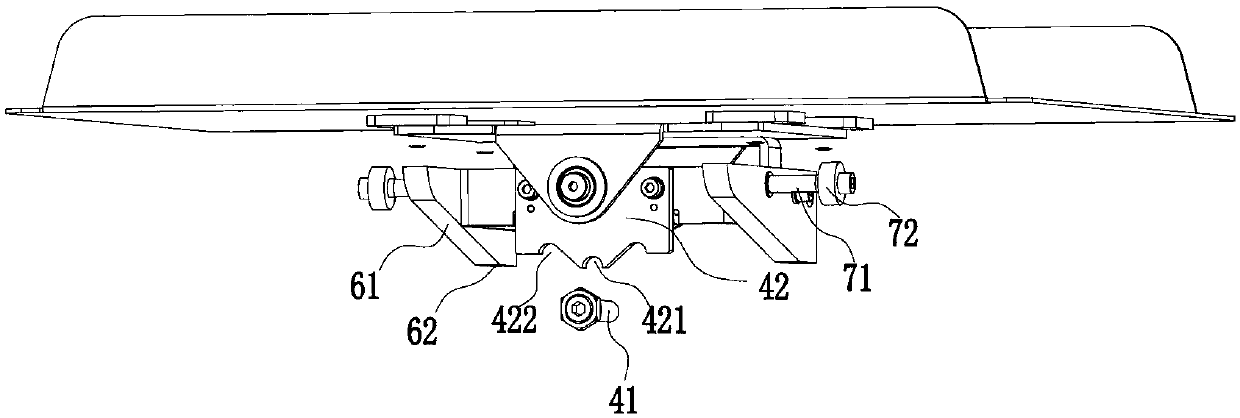

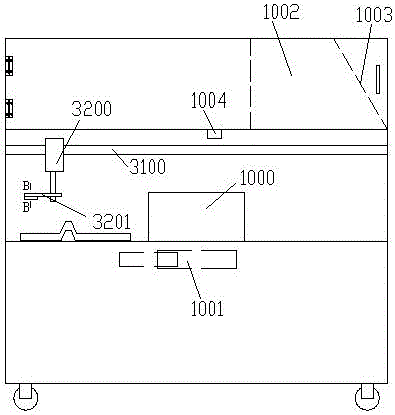

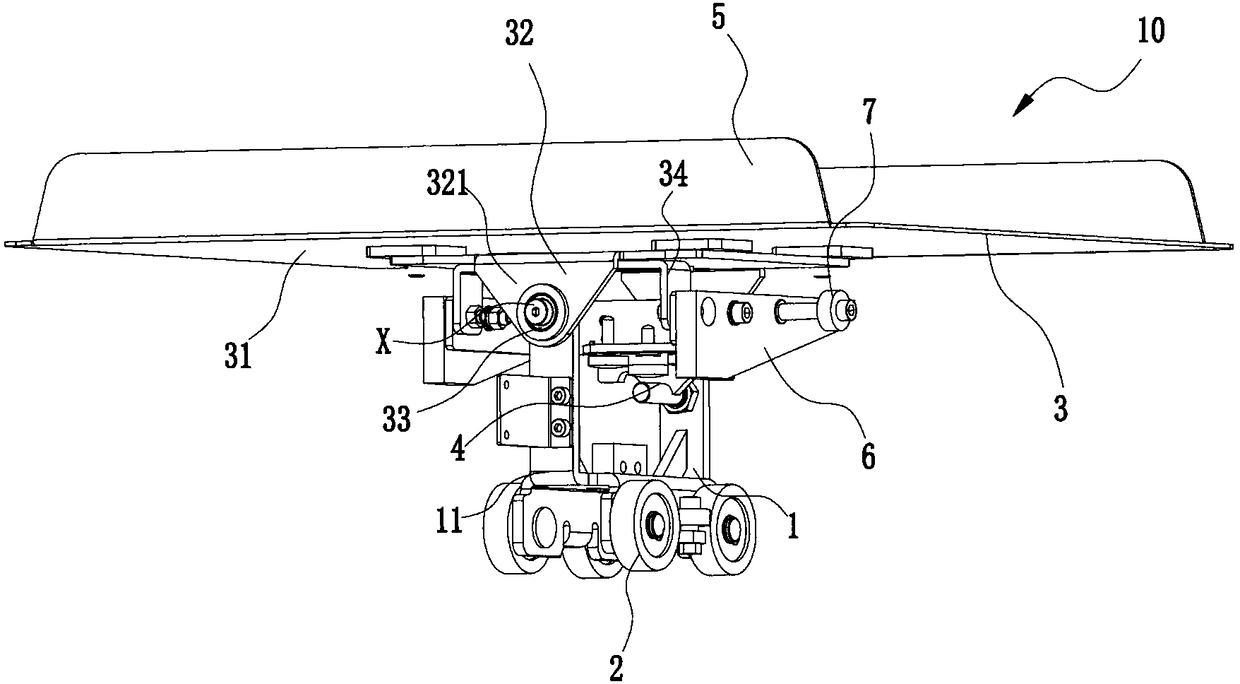

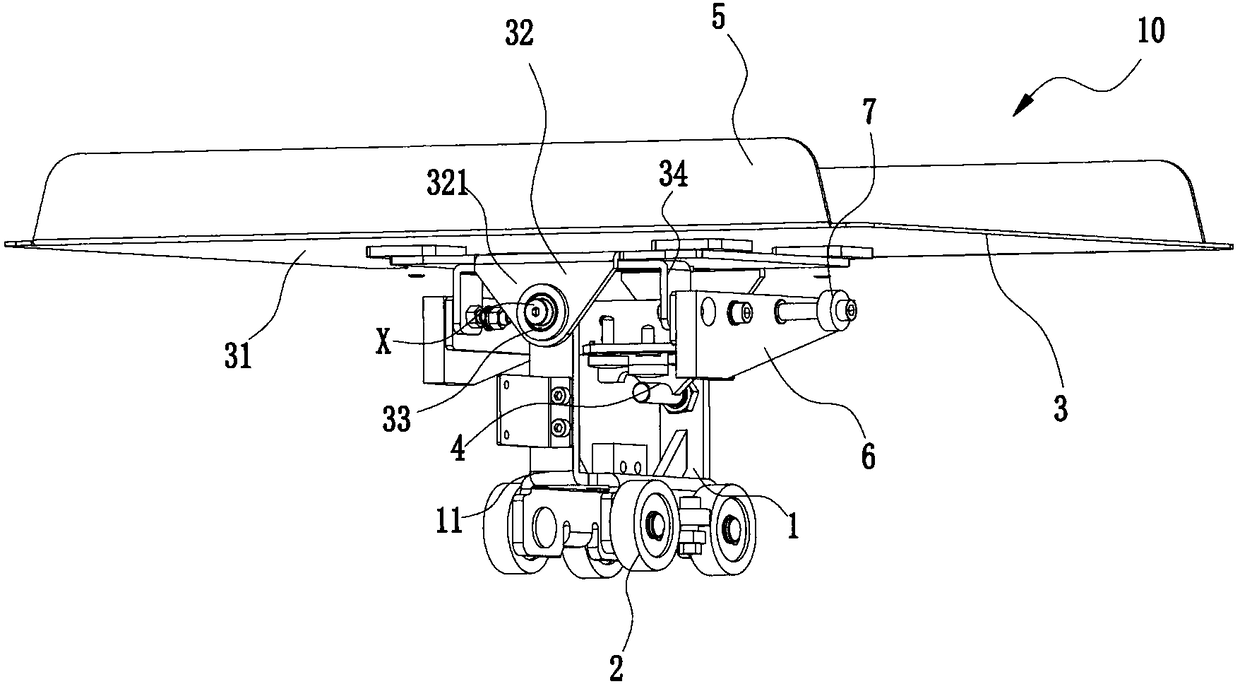

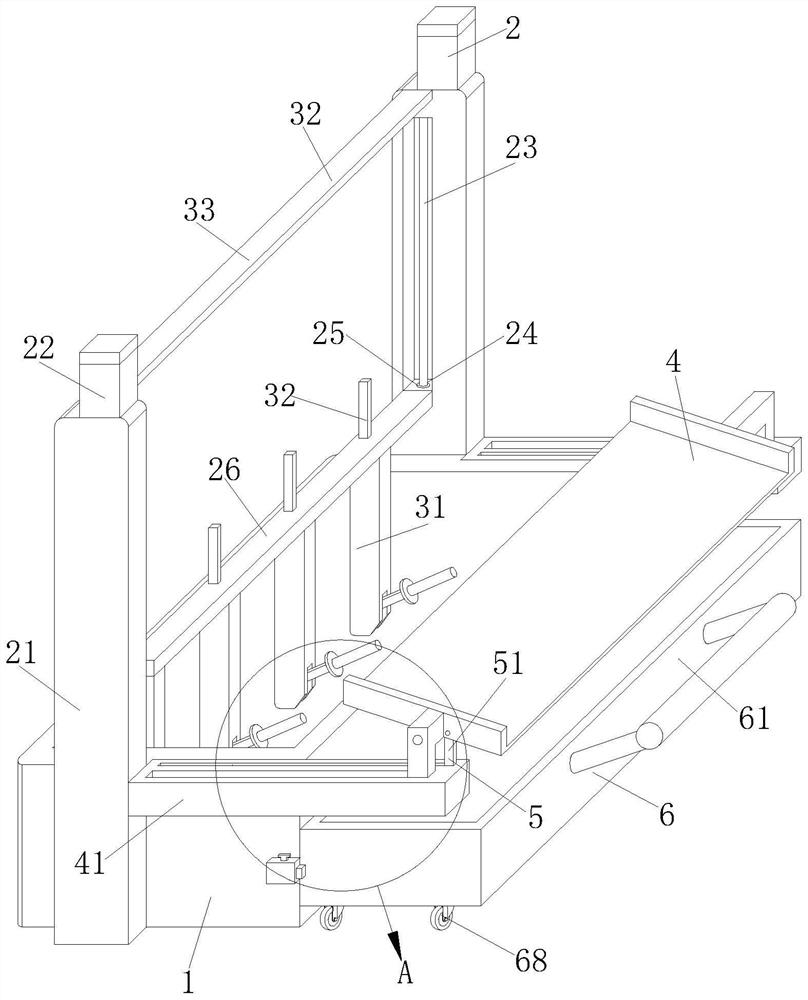

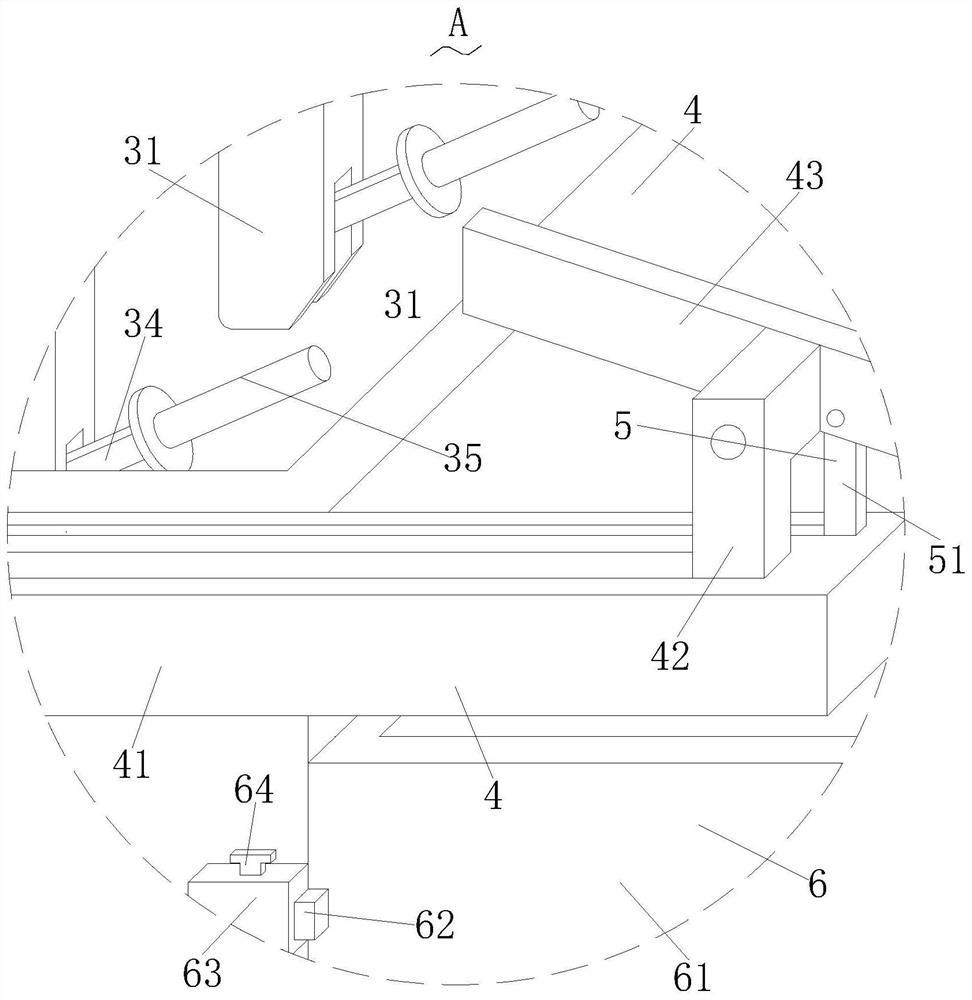

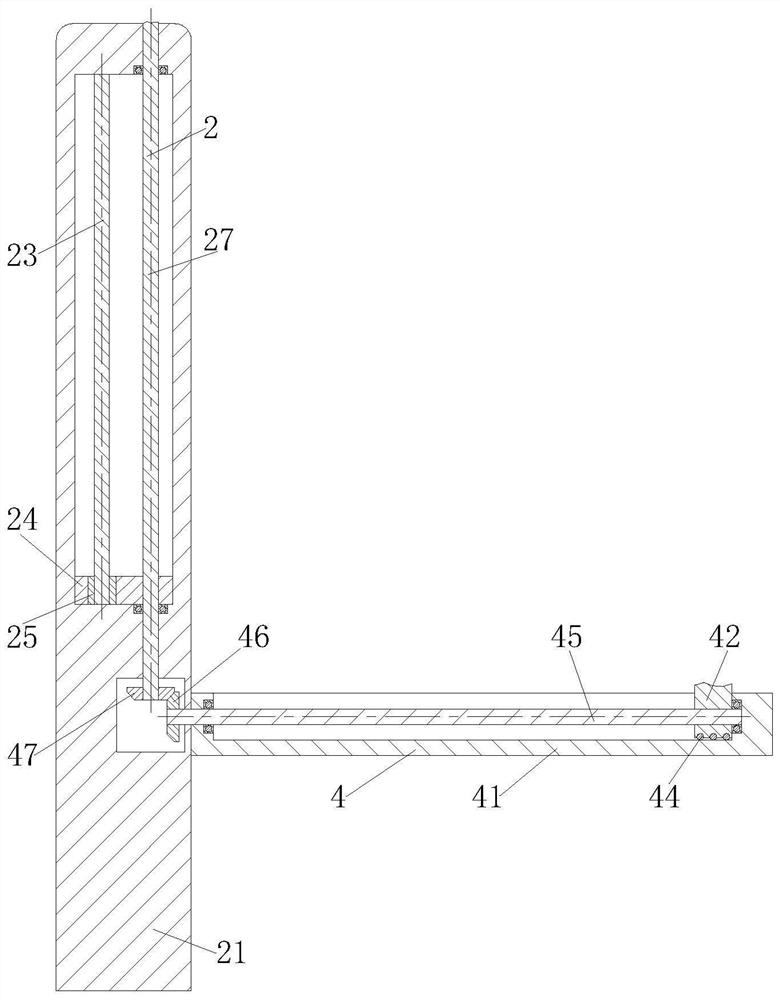

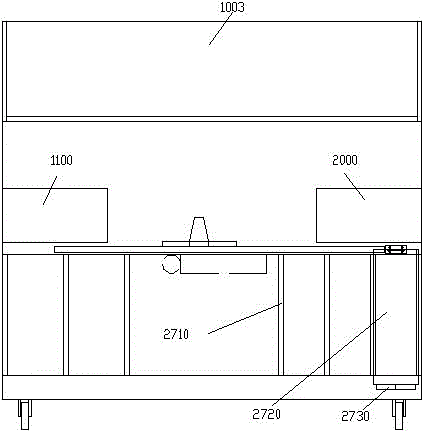

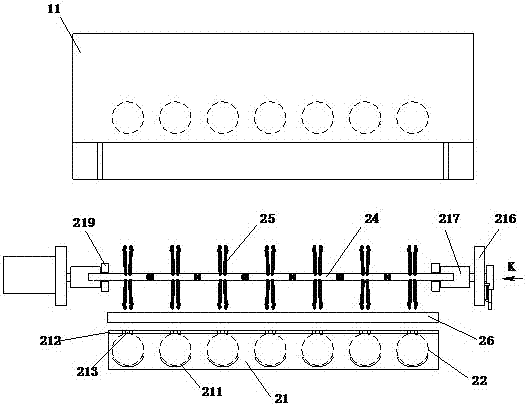

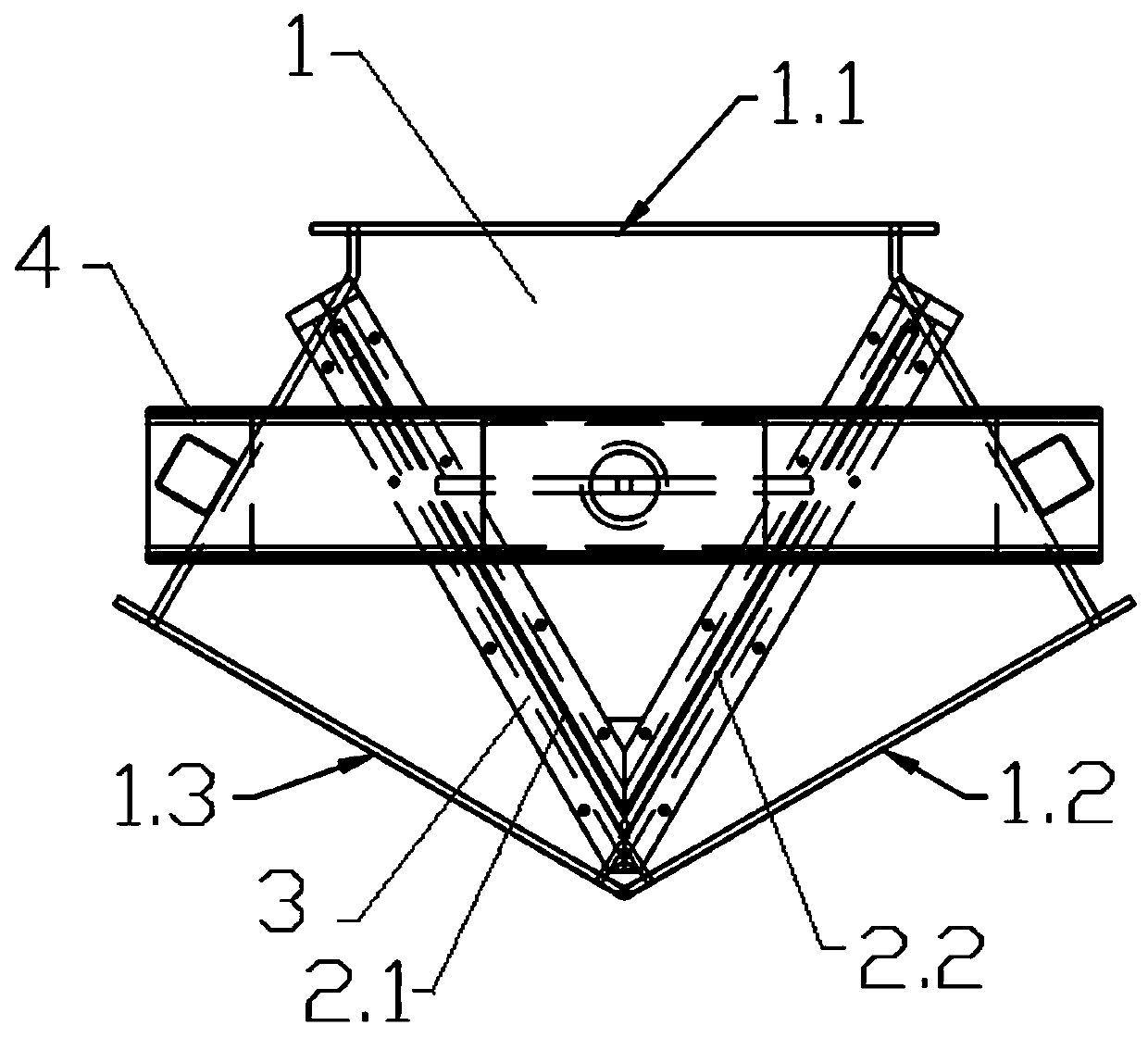

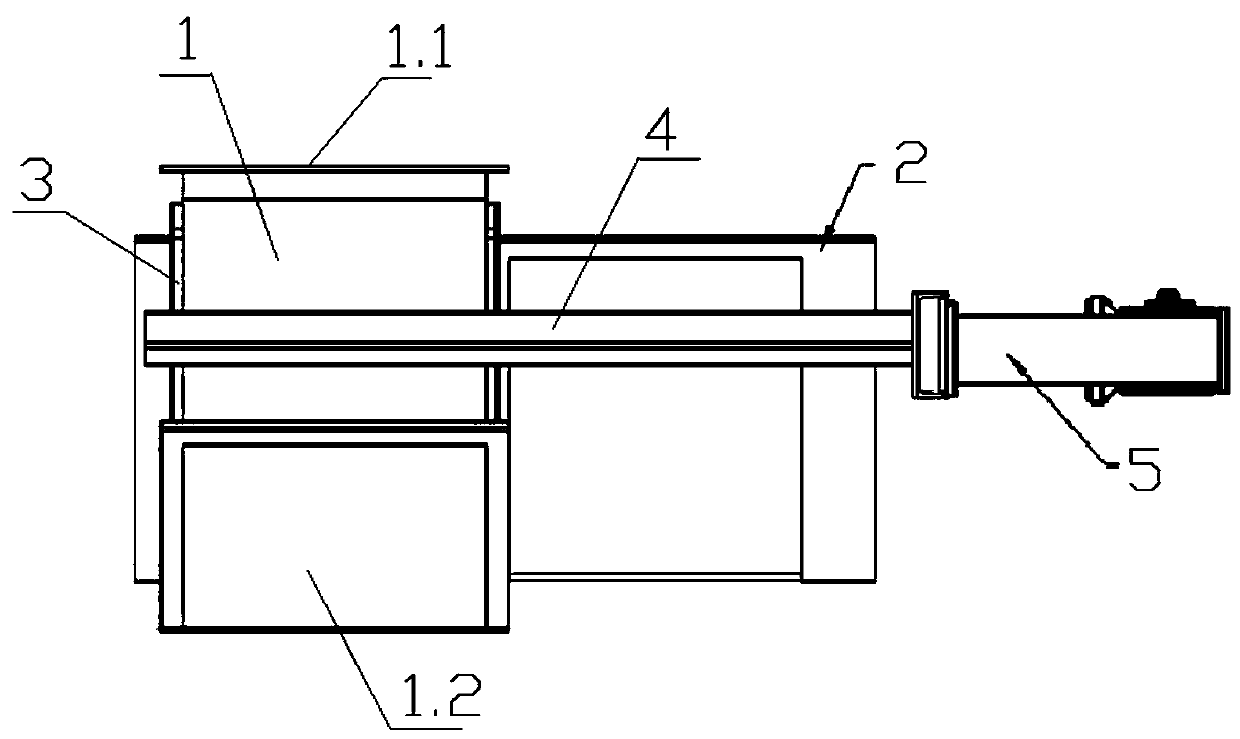

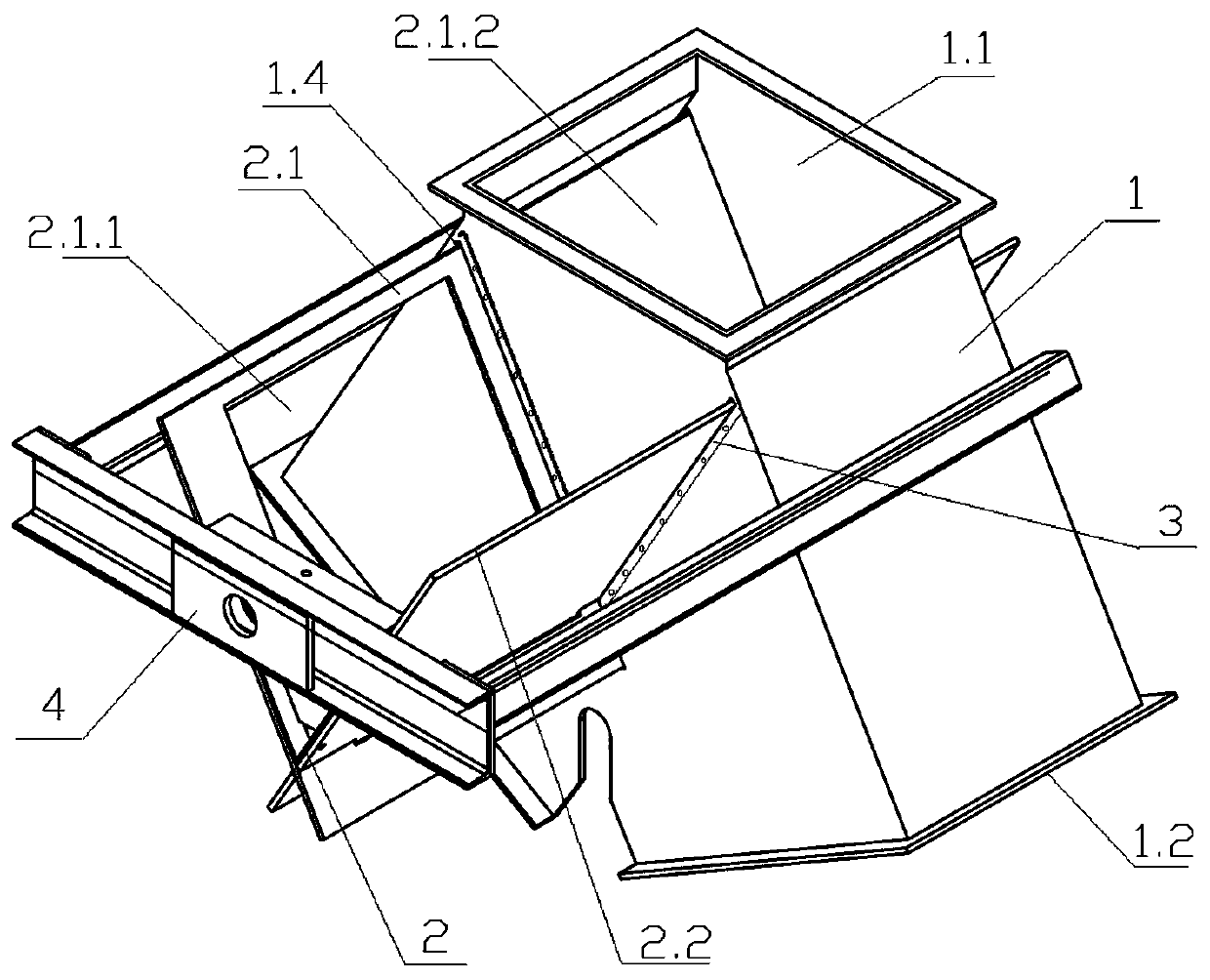

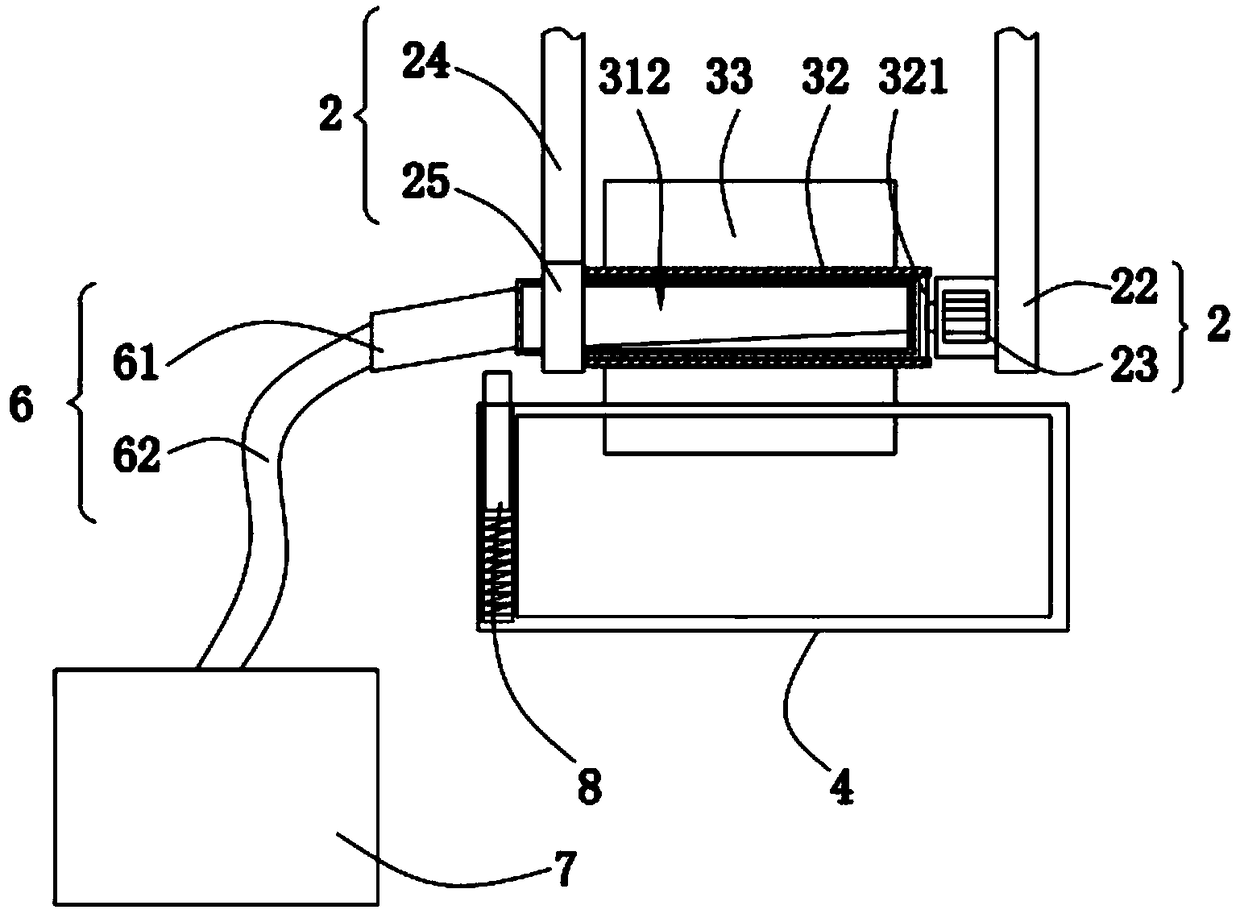

Two-way flipping plate trolley, flipping plate type sorting line and flipping plate type sorting system

The invention discloses a two-way flipping plate trolley, a flipping plate type sorting line and a flipping plate type sorting system. The two-way flipping plate trolley comprises a trolley frame, wherein the bottom portion of the trolley frame is provided with rollers, a flipping plate is pivotally connected above the trolley frame, the connection shaft of the flipping plate and the trolley frameis the symmetry axis of the flipping plate, the flipping plate is maintained horizontally by a position limiting mechanism in a material feeding state, and the flipping plate inclines a certain anglethrough the position limiting mechanism in a material discharge state. According to the present invention, the technical scheme has characteristics of sophisticated design and simple structure; the flipping plate can flip in two directions around the symmetry axis; by arranging the position limiting structure, the flipping plate can be stably maintained at the horizontal state and the inclined state, such that the two-way selective sorting can be effectively achieved; the two-way flipping plate trolley does not require the independent power structure for driving the flipping plate to rotate and the wheel driving structure, such that the whole structure is simplified, and the cost of the equipment is low; and by using the pure mechanical structure, the complicated electrical control structure is not required, such that the production and the maintenance are conveniently performed.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

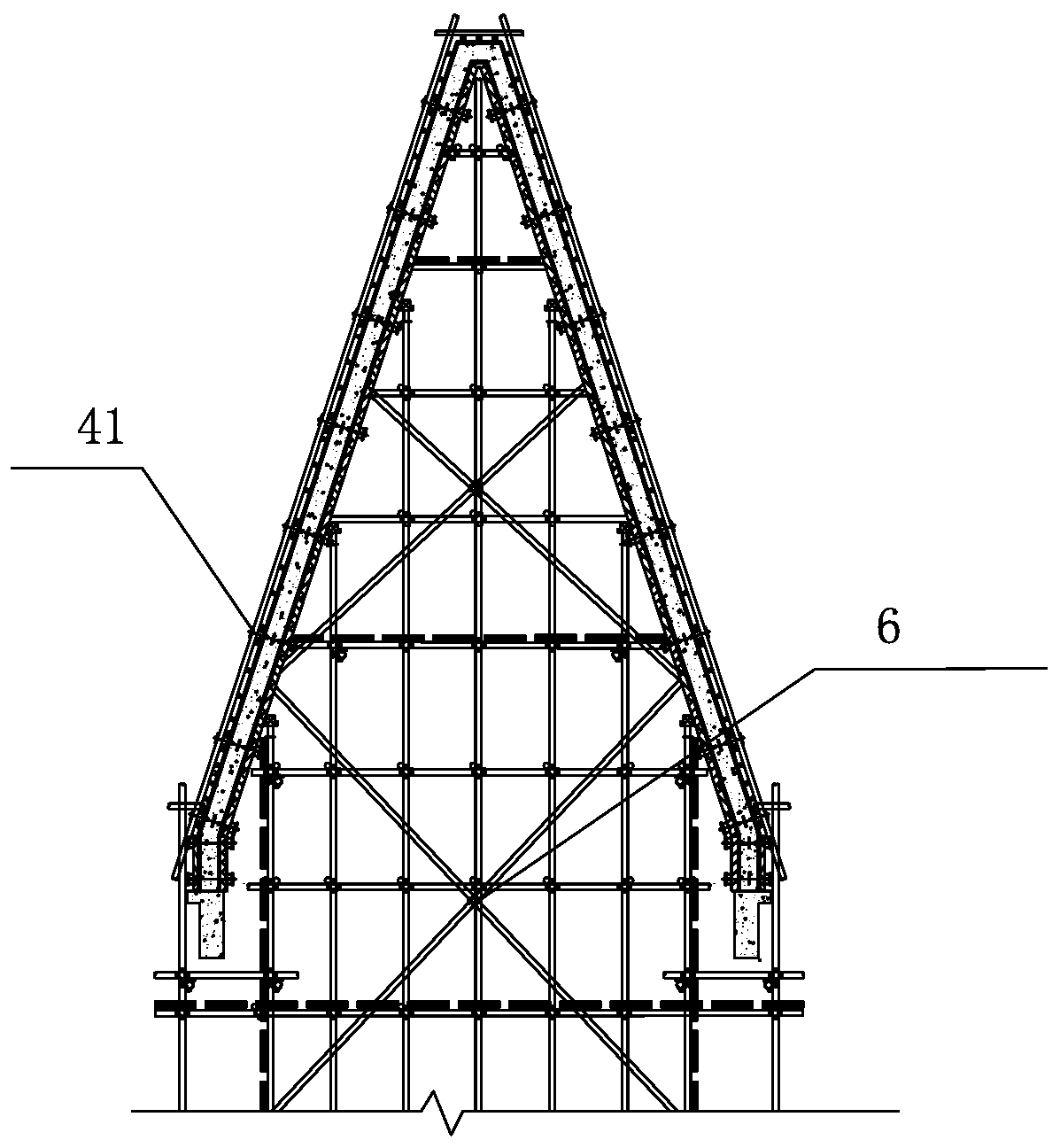

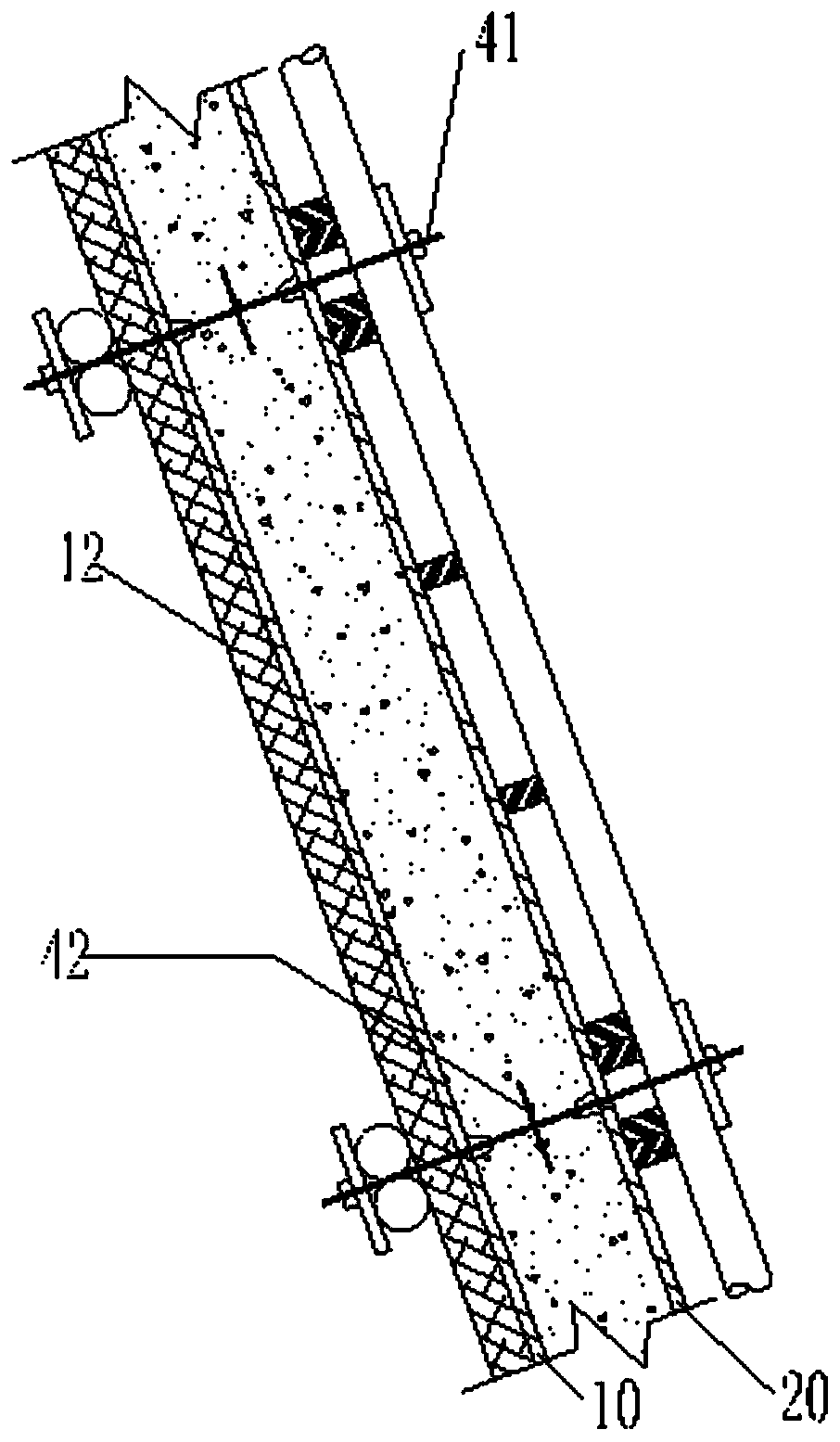

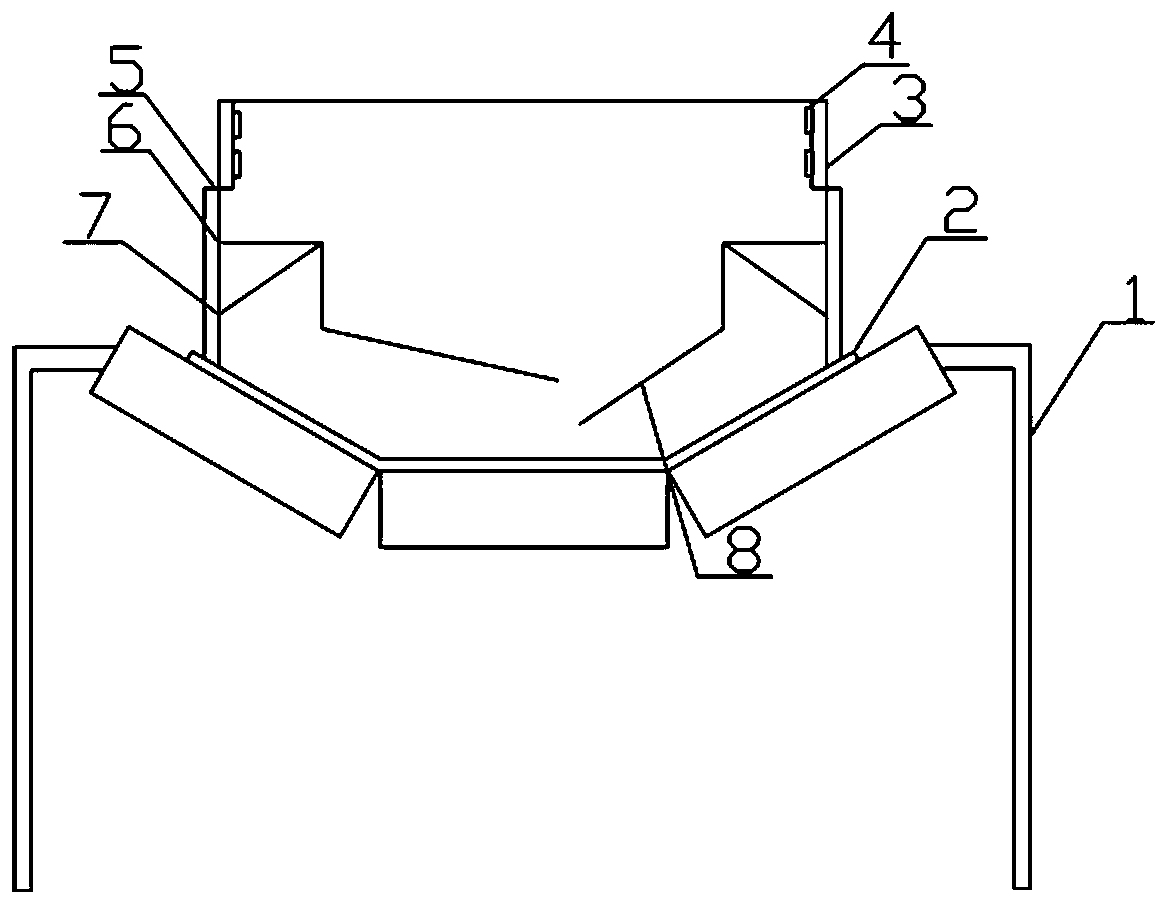

Tower concrete structure pointed roof formwork system and construction method

PendingCN110017020AEfficient vibrating workThe vibrating work is orderlyForms/shuttering/falseworksBuilding material handlingSurface layerTower

The invention discloses a tower concrete structure pointed roof formwork system and a construction method, relates to the technical field of formwork systems, and is used for solving the problem thatthe compactness of concrete is difficult to control when concrete is poured on a pointed roof large-gradient sloping roof. The formwork system comprises a bottom-layer formwork and a surface-layer formwork. the bottom-layer formwork is fixed through a full framing bent frame and has the same gradient as the large-gradient sloping roof of a pointed roof to be poured; and the surface-layer formworkis arranged above the bottom-layer formwork in parallel, the surface-layer formwork and the bottom-layer formwork are connected through a fastening assembly to form a cavity, and pouring grooves are formed in the surface-layer formwork at certain intervals from bottom to top. Two layers of formworks, namely, the bottom-layer formwork and the surface-layer formwork, are arranged, and the pouring grooves are reserved in the surface-layer formwork, the pouring grooves are formed in a segmented mode to achieve layered pouring, and therefore it is well guaranteed that on-site sharp-topped sloping roof concrete discharging is achieved, and concrete vibrating work is efficiently and orderly conducted.

Owner:SHANGHAI CONSTR NO 1 GRP

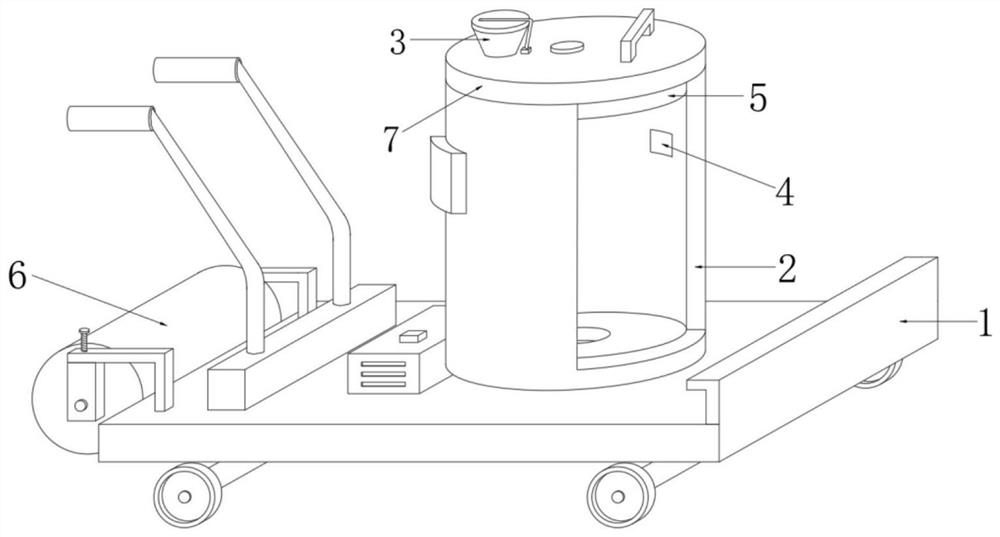

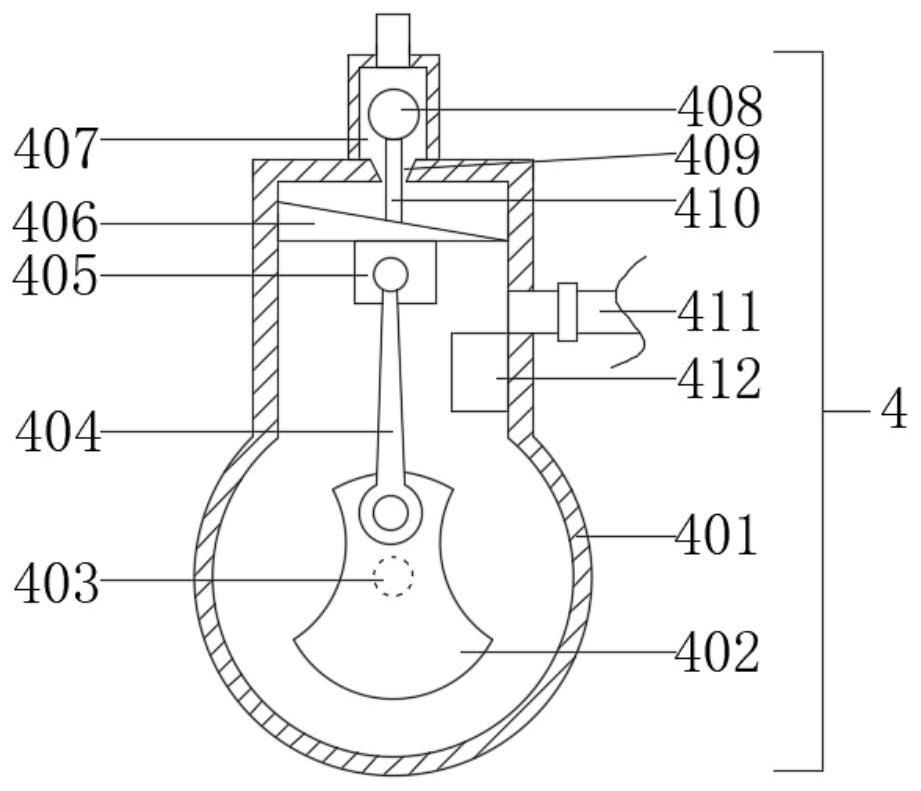

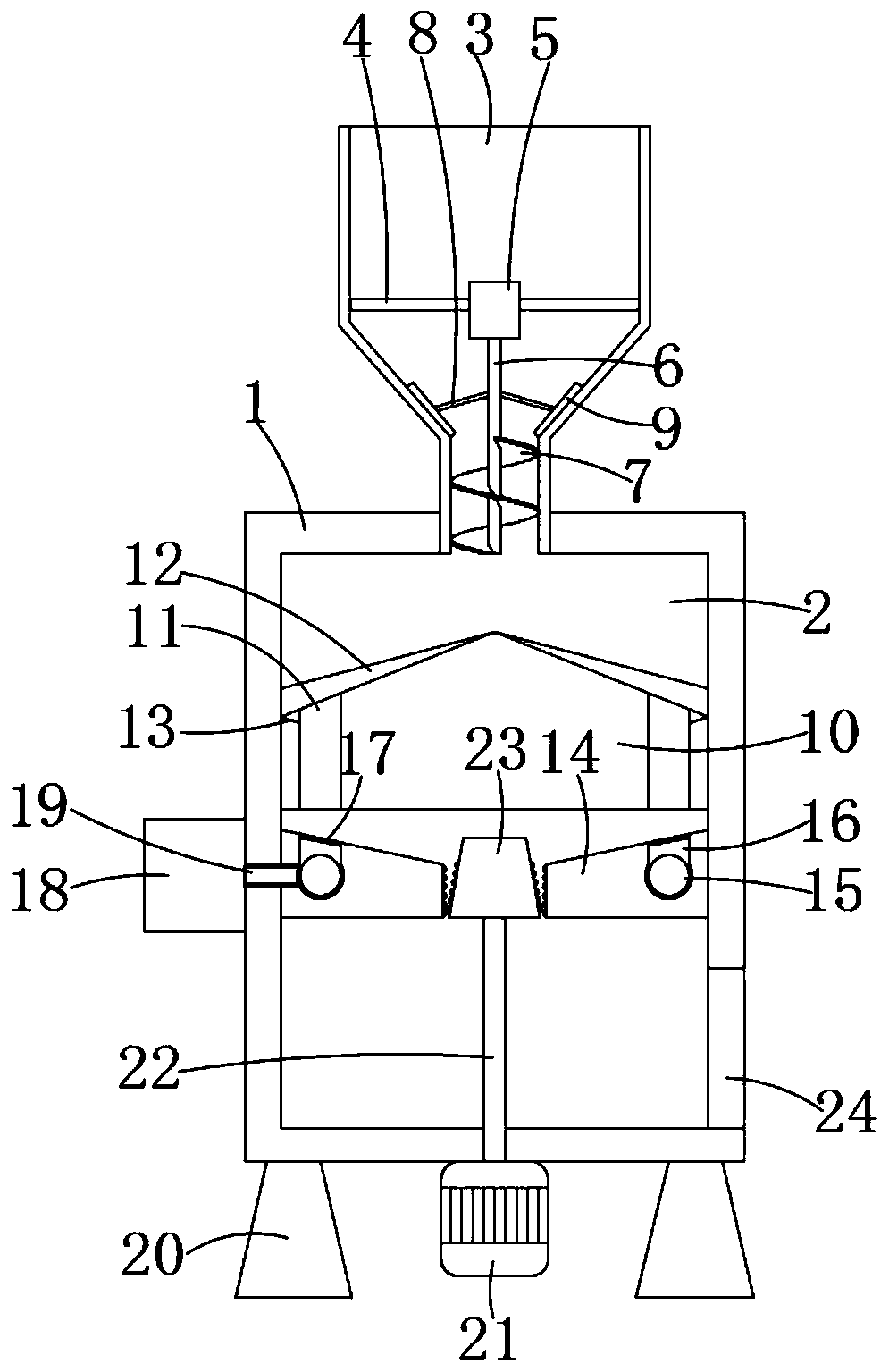

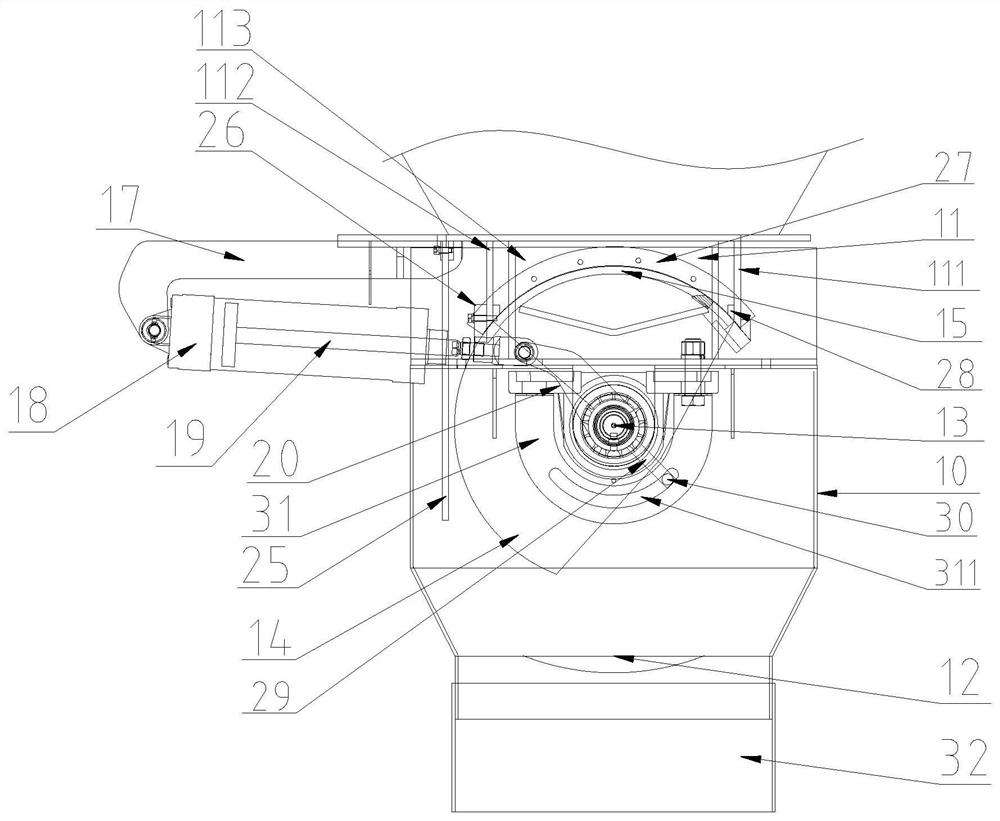

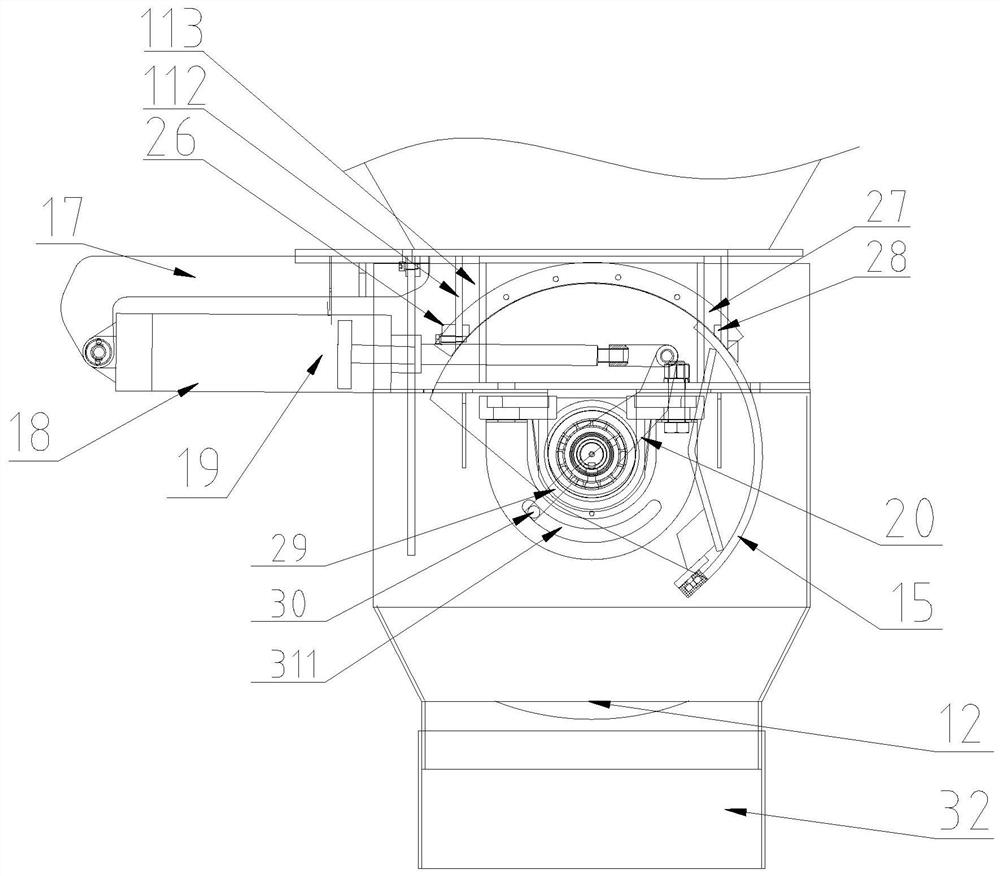

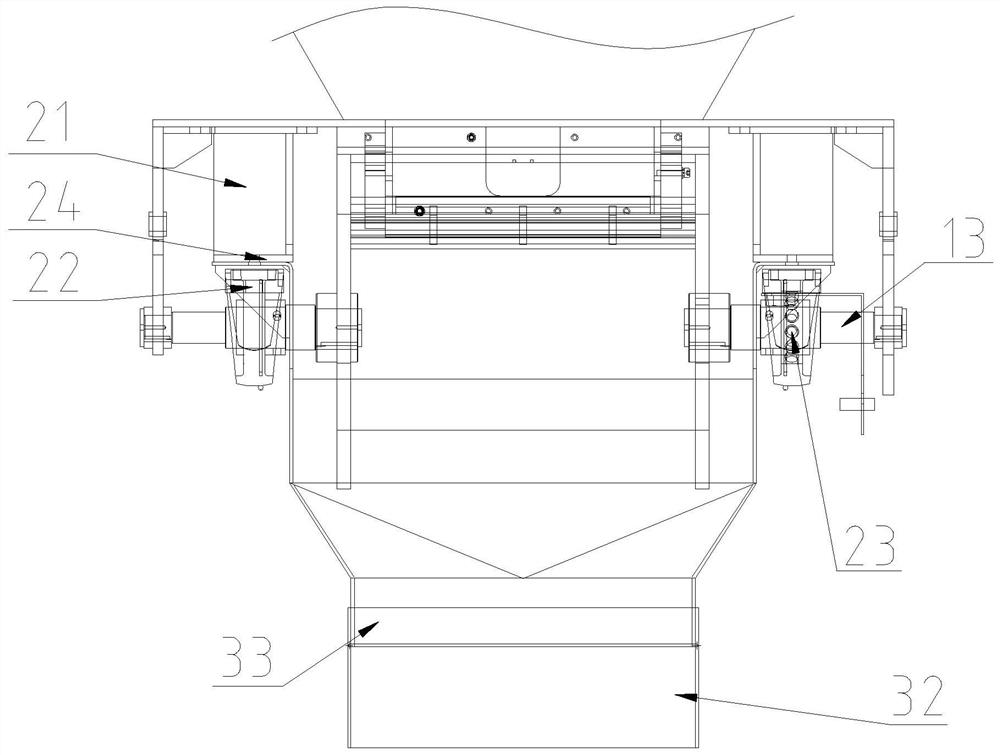

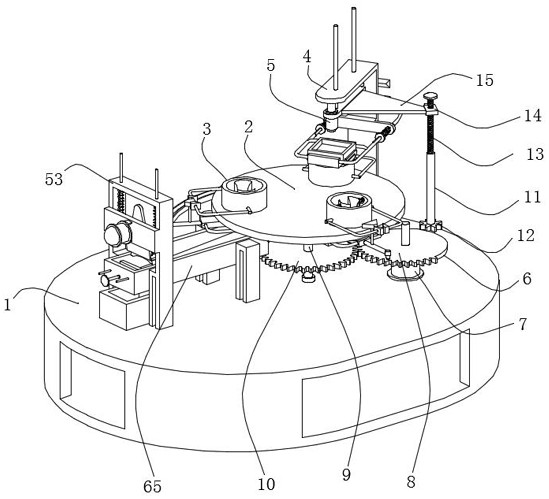

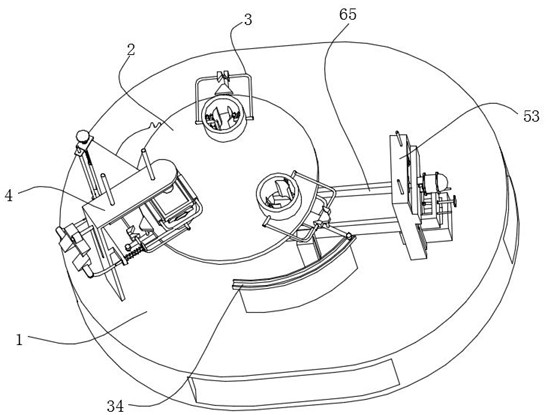

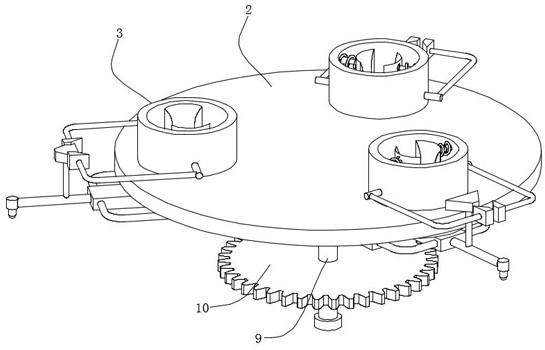

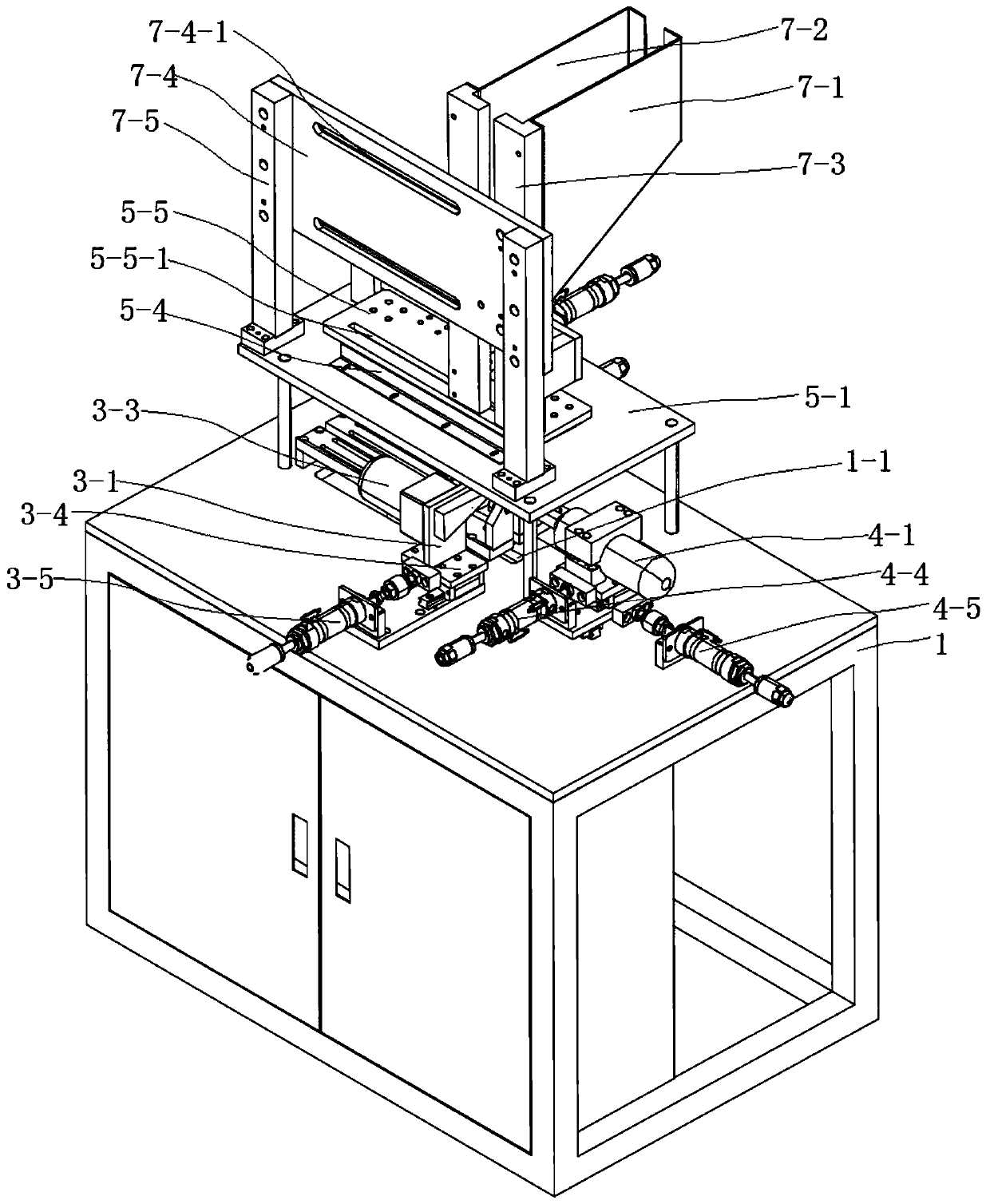

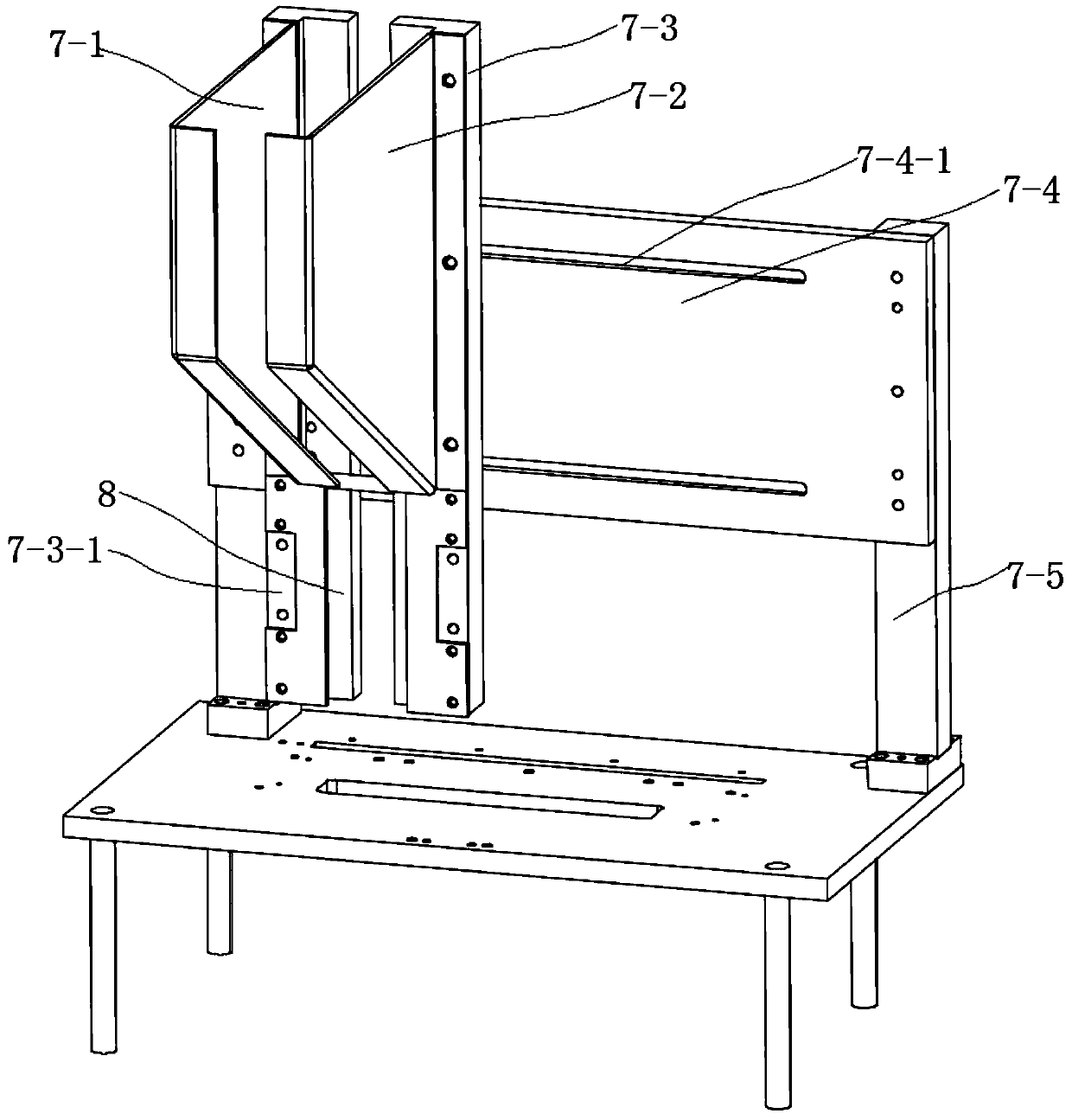

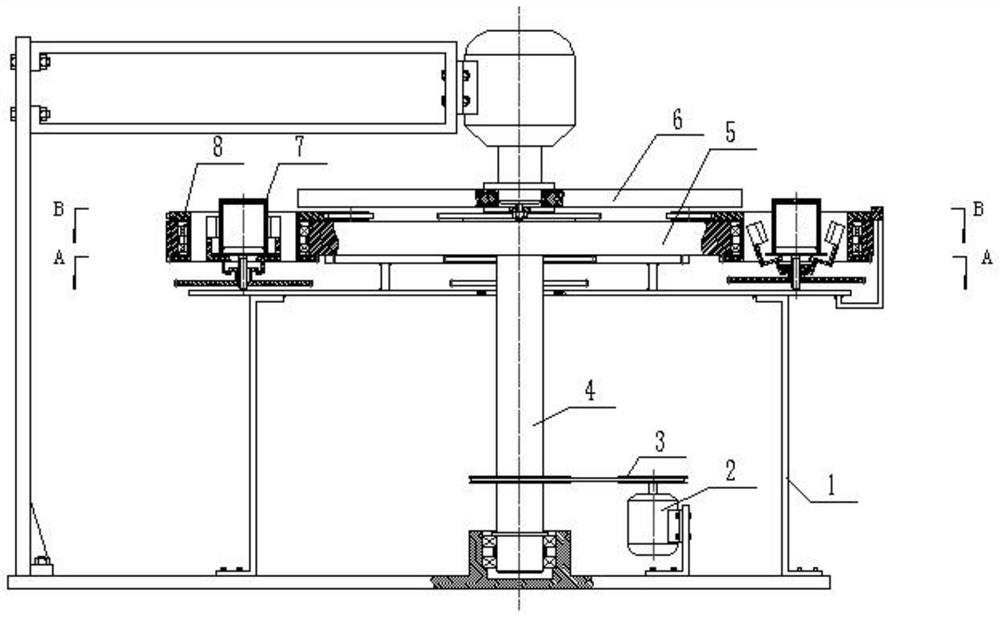

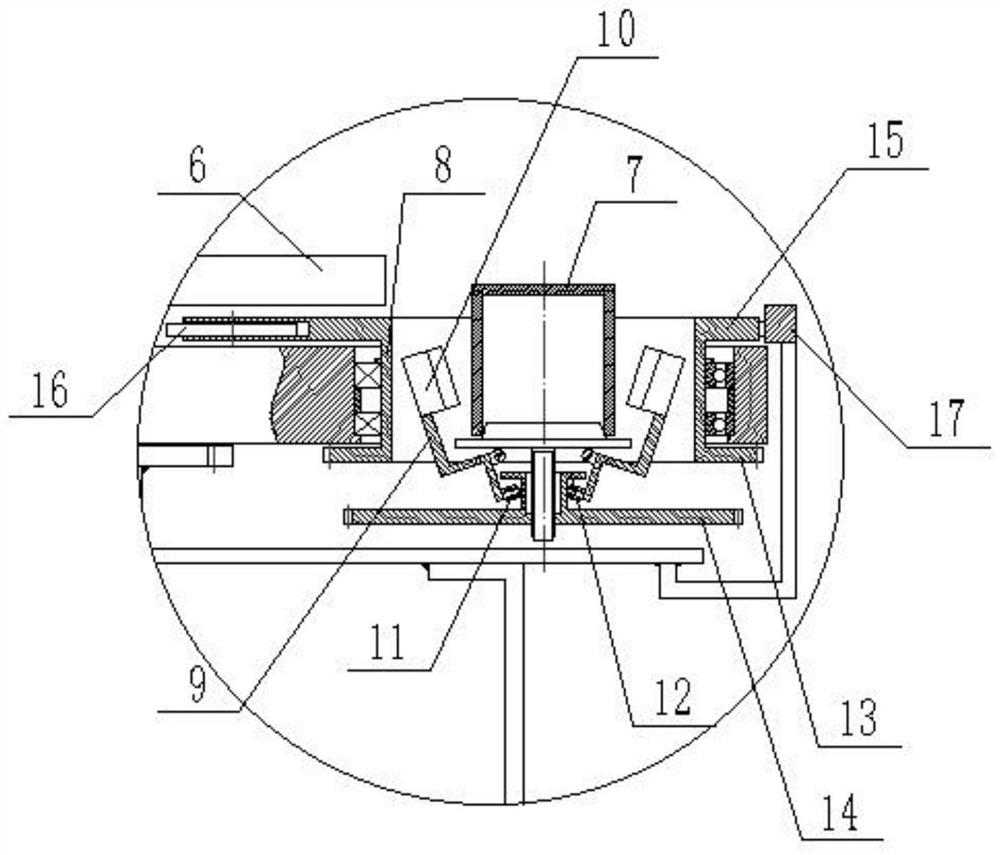

Intelligent rotary disc metal casting and nozzle separation integrated machine and operating method thereof

The invention relates to an intelligent rotary disc metal casting and nozzle separation integrated machine and an operating method thereof. The integrated machine comprises a cabinet. An annular rotary disc driven by an electric dividing plate is arranged in the middle of the cabinet. A positioning rod for containing a metal casting is arranged at the front portion of the annular rotary disc. A metal casting and nozzle separation device for allowing the metal casting to rotate to the position to achieve water gas separation is arranged on one side of the annular rotary disc. A metal casting separation device for allowing the metal casting to rotate to the position to achieve product separation of the metal casting is arranged on the other side of the annular rotary disc. A clamping mechanism for clamping waste of the metal casting to the rear portion of an annular disc body to be discharged after rotating to the front portion is further arranged at the portion, located above the annular rotary disc, of the cabinet. Blanking grooves are further formed in the front portion and the rear portion below the annular disc body respectively. The separation integrated machine is compact in structure and high in automation degree, and is conveniently used for nozzle separation of the metal casting and separation of the metal casting, and the operating method is easy and convenient.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

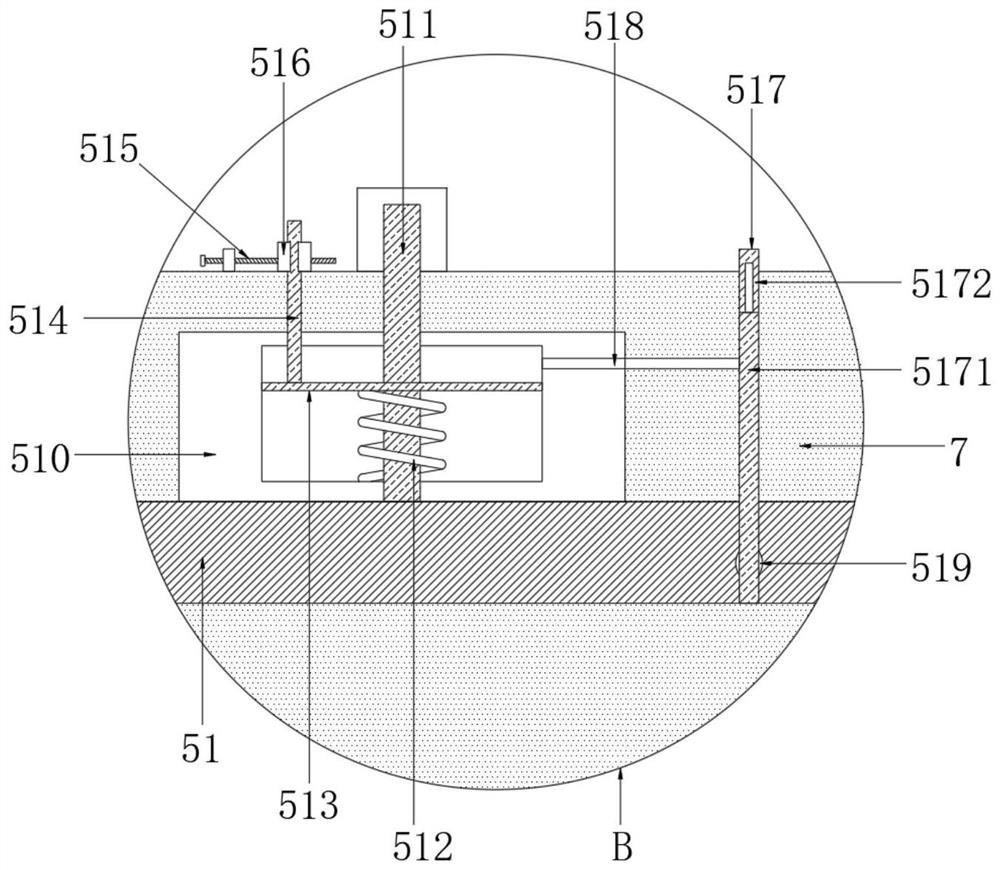

Asphalt paving device with air pressure adjusting mechanism for building construction

InactiveCN113279309AReduce spacingGuaranteed blankingRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses an asphalt paving device with an air pressure adjusting mechanism for building construction in the technical field of asphalt paving equipment. The asphalt paving device comprises a vehicle body and a material storage tank, a pressing roller is installed on the outer wall of the left side of the vehicle body, a cover plate is fixedly installed on the outer wall of the top of the material storage tank, and a baffle is hinged to the outer wall of the top of a feeding hopper; an adjusting device is arranged at the top of an inner cavity of the material storage tank, a heating plate is arranged in the center of the inner cavity of the material storage tank, mercury in the device expands after being heated, a check block can be pushed leftwards, the check block is inserted into an opening, the opening is sealed, a movable plate becomes a closed plate body, a spring is pushed to expand, and a movable rod drives the movable plate to move downwards. The distance between the asphalt raw material and the movable plate is reduced, so that the air pressure between the asphalt raw material and the movable plate is not greatly reduced, normal blanking of asphalt is ensured, and the asphalt raw material is uniformly scattered in a construction area.

Owner:孙团伟

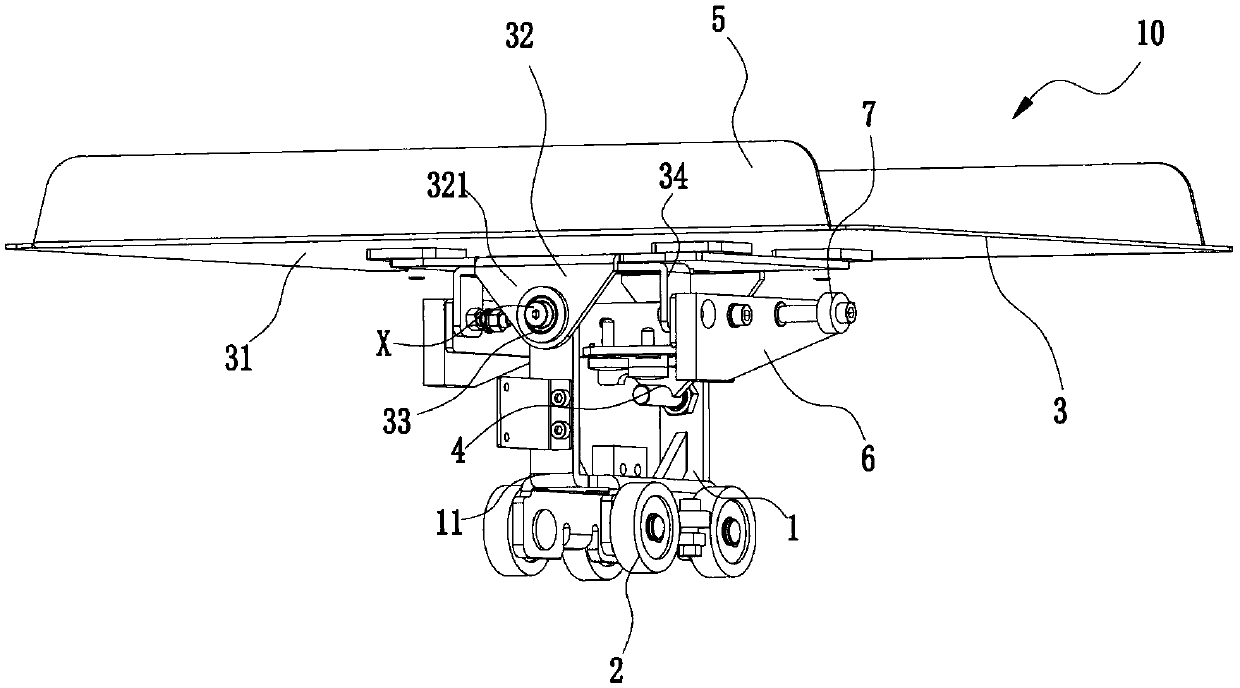

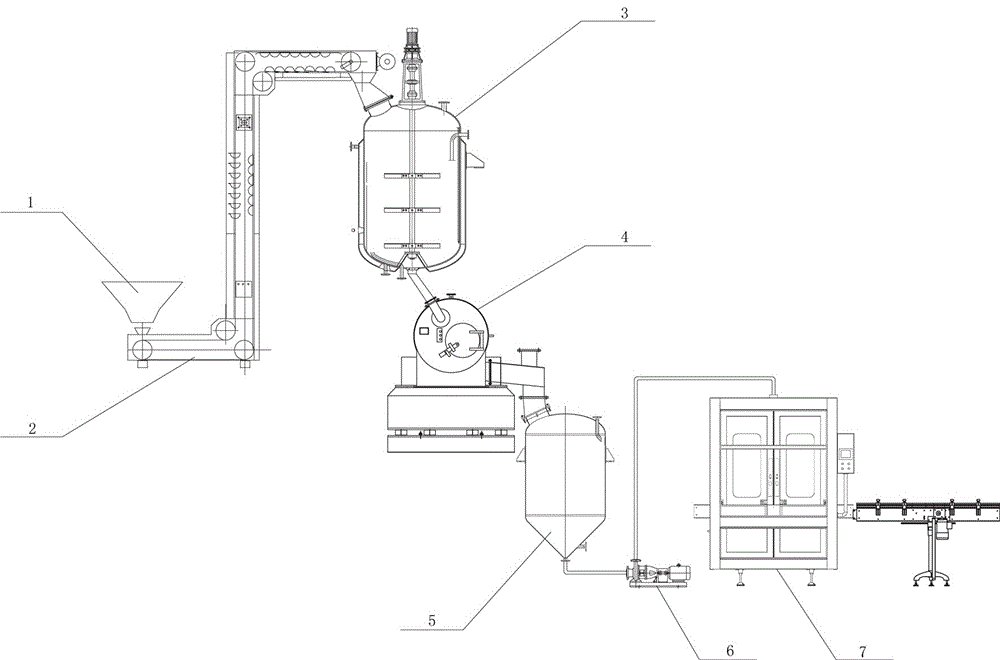

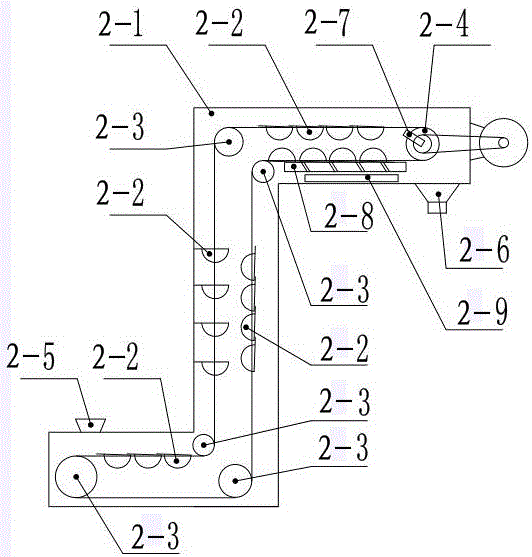

Z-shaped elevator

The invention discloses a Z-shaped elevator. The Z-shaped elevator comprises a Z-shaped body (1) provided with a Z-shaped inner cavity. Transmission chains are arranged in the inner cavity. The two transmission chains are arranged on the left side and the right side of the inner cavity correspondingly. Hoppers (2) are arranged between the two transmission chains and provided with upward openings. The left end and the right end of each hopper (2) are rotationally connected with the transmission chains on the left side and the right side correspondingly, and the rotation connecting positions are located above the no-load gravity centers and the load gravity centers of the hoppers (2). The positions of the rear edges of the opening ends of the hoppers (2) are connected with retaining sides located on the outer sides of the opening ends and used for making contact with the front edges of the opening ends of the adjacent back hoppers (2). Overturning of the hoppers (2) due to disturbance can be avoided, and meanwhile the utilization rate of the Z-shaped elevator is increased.

Owner:WUZHOUFENG AGRI SCI & TECH

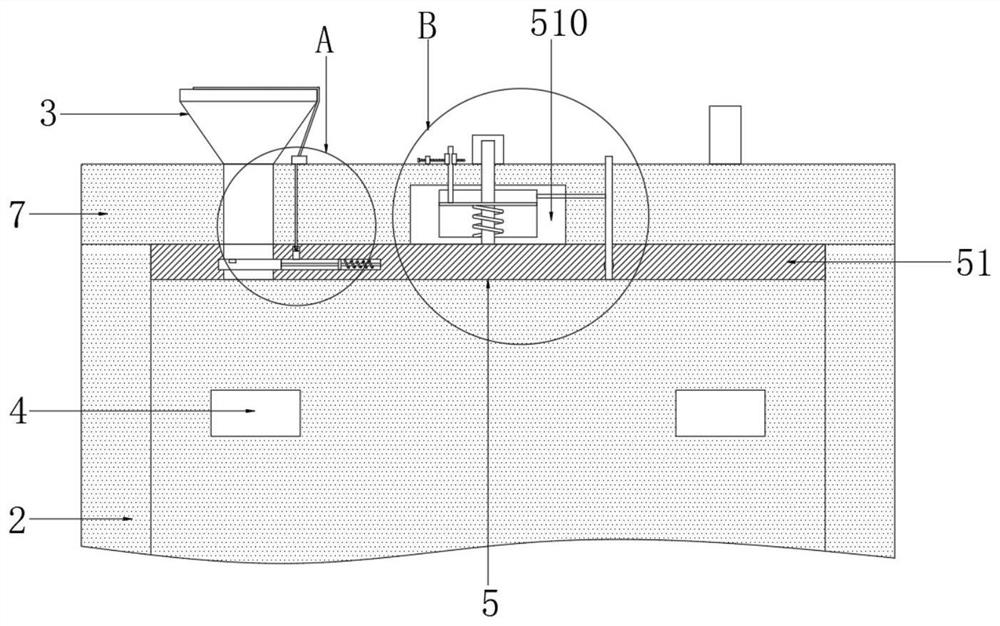

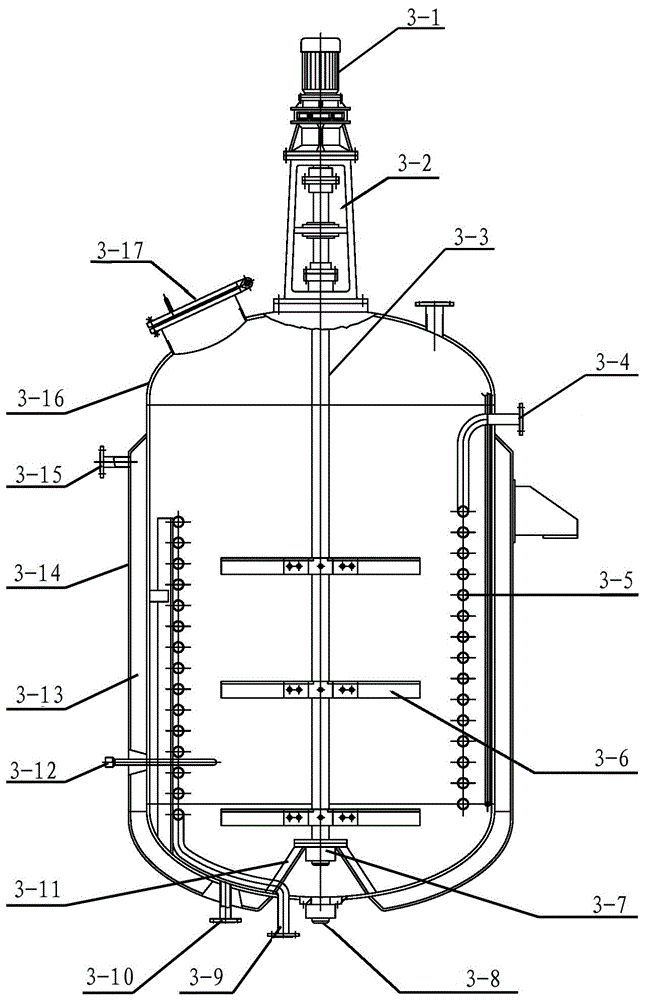

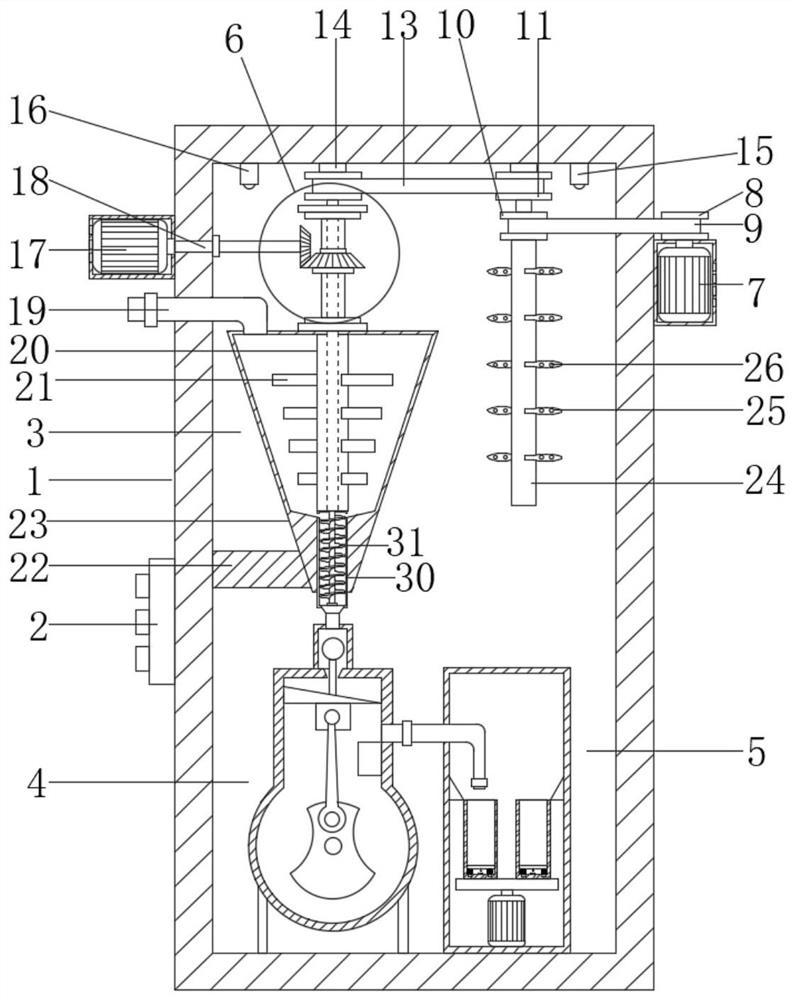

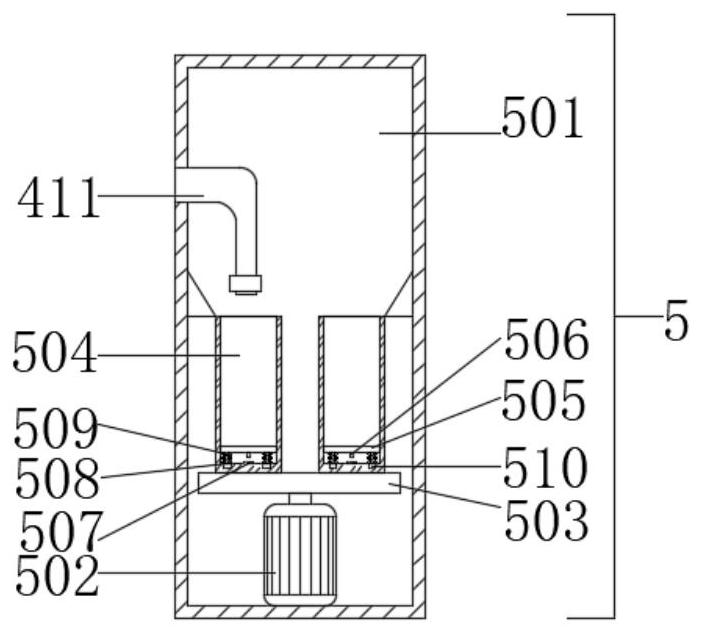

Microbial fermentation fertilizer production system

InactiveCN106316487ANot easy to deflectGuaranteed blankingChemical industryOrganic fertiliser preparationTemperature controlSolenoid valve

The invention provides a microbial fermentation fertilizer production system. A discharging opening of a mixture charging hopper (1) is located over a feeding opening (2-5) of a Z-shaped elevator (2), a discharging opening (2-6) of the Z-shaped elevator (2) is connected with a feeding opening (3-17) of a fermentation tank (3), a discharge solenoid valve (3-8) of the fermentation tank (3) is connected with the feeding end of a centrifuge (4), the liquid phase discharging end of the centrifuge (4) is connected with the feeding end of a finished product tank (5), and the discharging end of the finished product tank (5) is connected with a filling machine (7) through a centrifugal delivery pump (6). The microbial fermentation fertilizer production system has the advantages that overturning, caused by disturbance, of the Z-shaped elevator hopper is avoided, and the utilization rate of the Z-shaped elevator is increased; fermentation tank temperature control is more convenient, and a better energy-saving effect is achieved.

Owner:WUZHOUFENG AGRI SCI & TECH

Overturning plate type sorting line

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

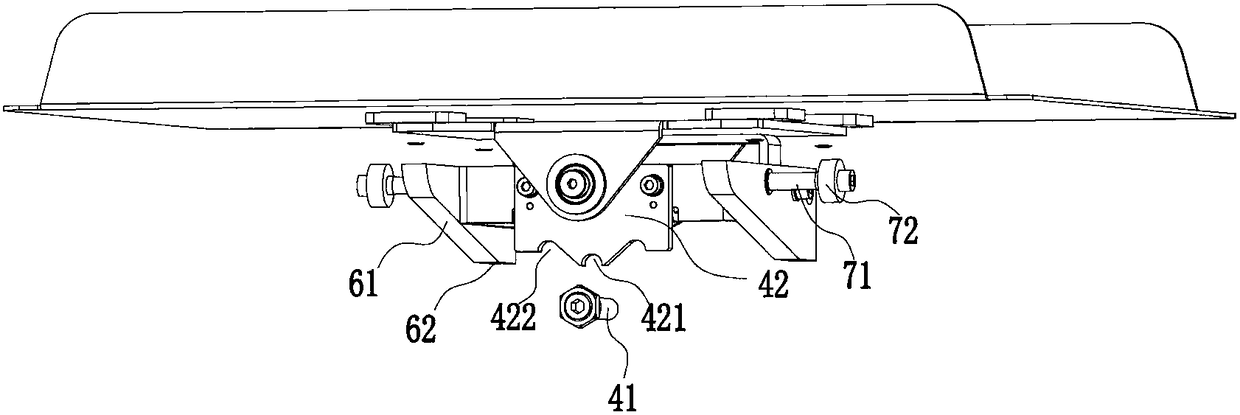

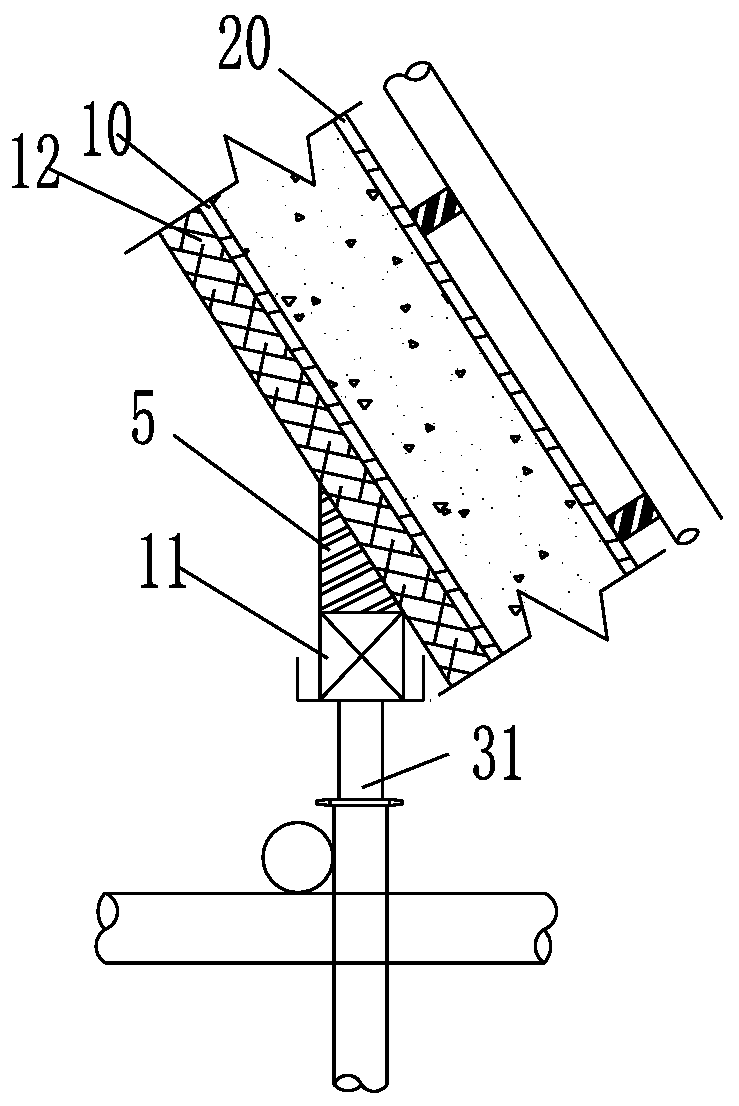

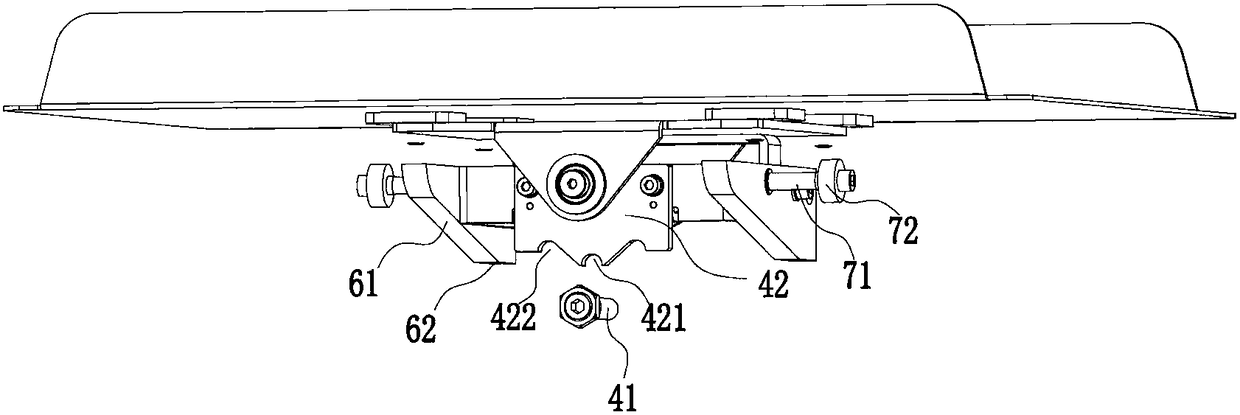

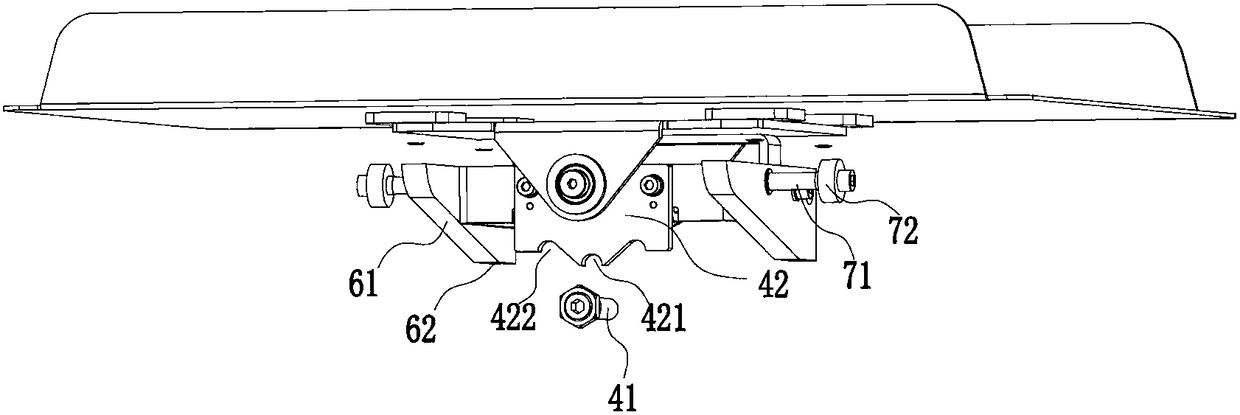

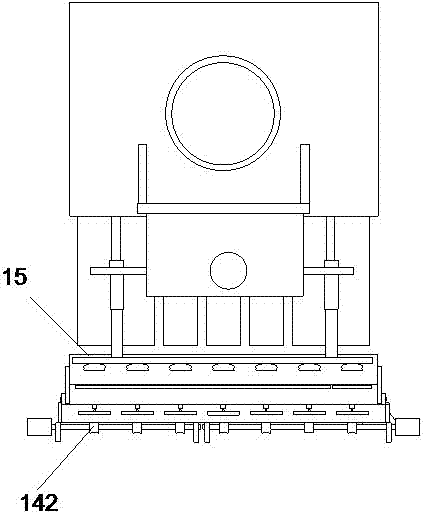

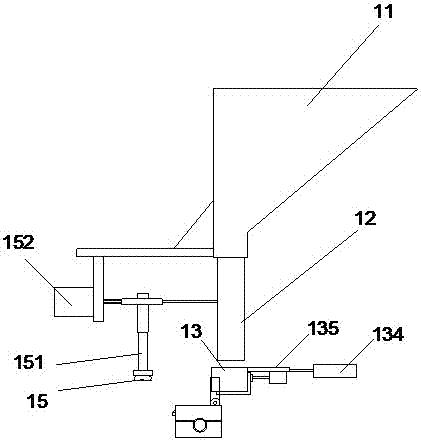

Turning plate jacking device and turning plate type sorting line

PendingCN108516295AExquisite designSimple structureConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses a turning plate jacking device and a turning plate type sorting line. The turning plate jacking device comprises a supporting plate, an ejecting rod is connected to the supporting plate in a pivot mode, a rotating wheel is arranged at the top end of the ejecting rod, and a power device driving rotation of the ejecting rod is connected to the lower end of the ejecting rod. In the first state, the power device keeps the ejecting rod inclined; and in the second state, the power device keeps the ejecting rod vertical. The design of the scheme is exquisite, the turning platejacking device can be rotated by the ejecting rod, and though the power device, the ejecting rod can be effectively switched between the inclined and the vertical state; and a two-way turning plate trolley without the power of the turning plate can pass through under the inclined state, in the vertical state, the two-way turning plate trolley is in contact with the turning plate so that the turning plate can automatically turn to the inclined state to achieve discharging, the requirement of automatic discharging of the trolley without the power of the turning plate is effectively met, the technical support is provided for non-stop discharging, the loss of parts and the time elapse during starting and stopping are saved in the case of non-stop discharging, and the sorting efficiency is improved.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

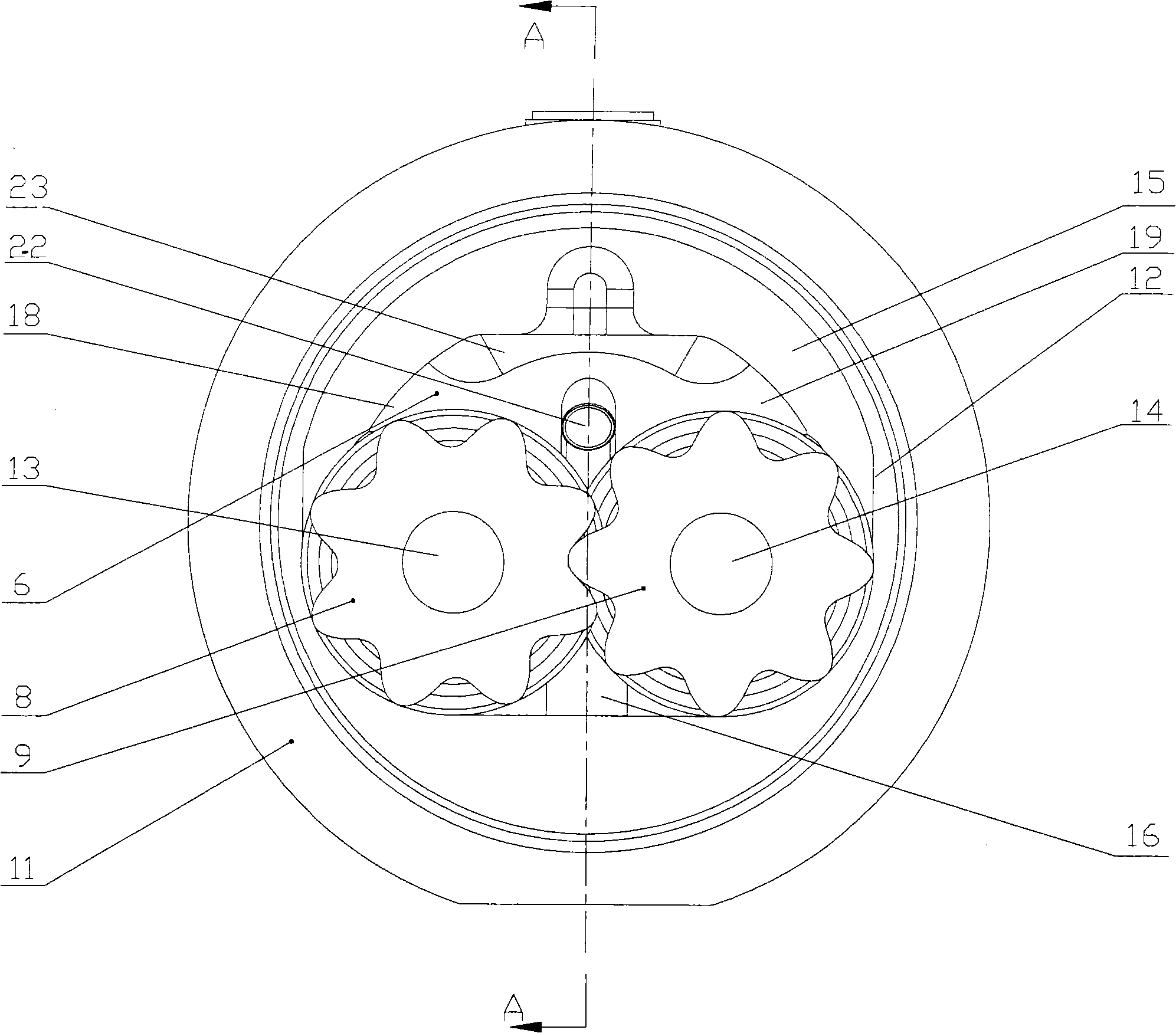

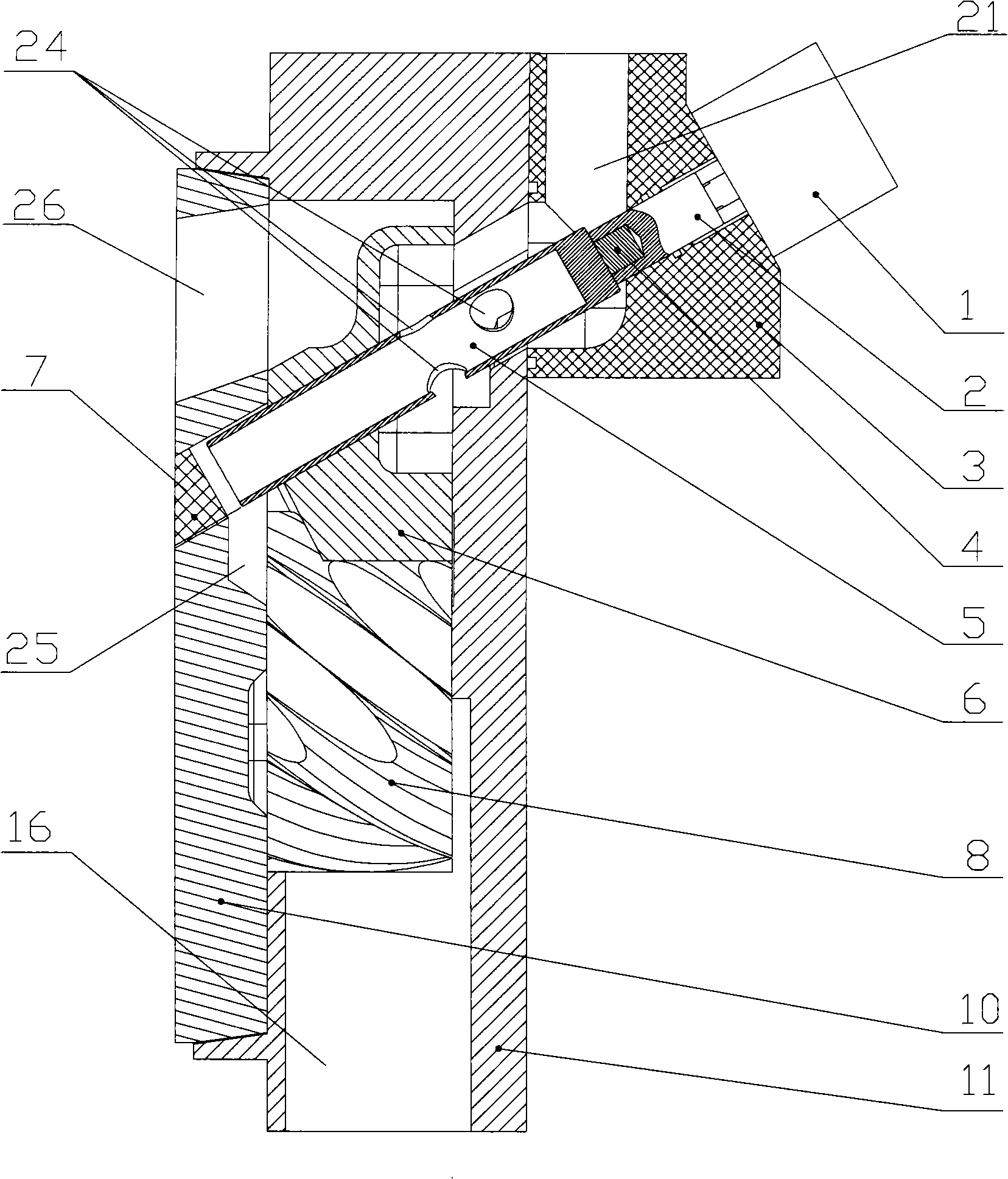

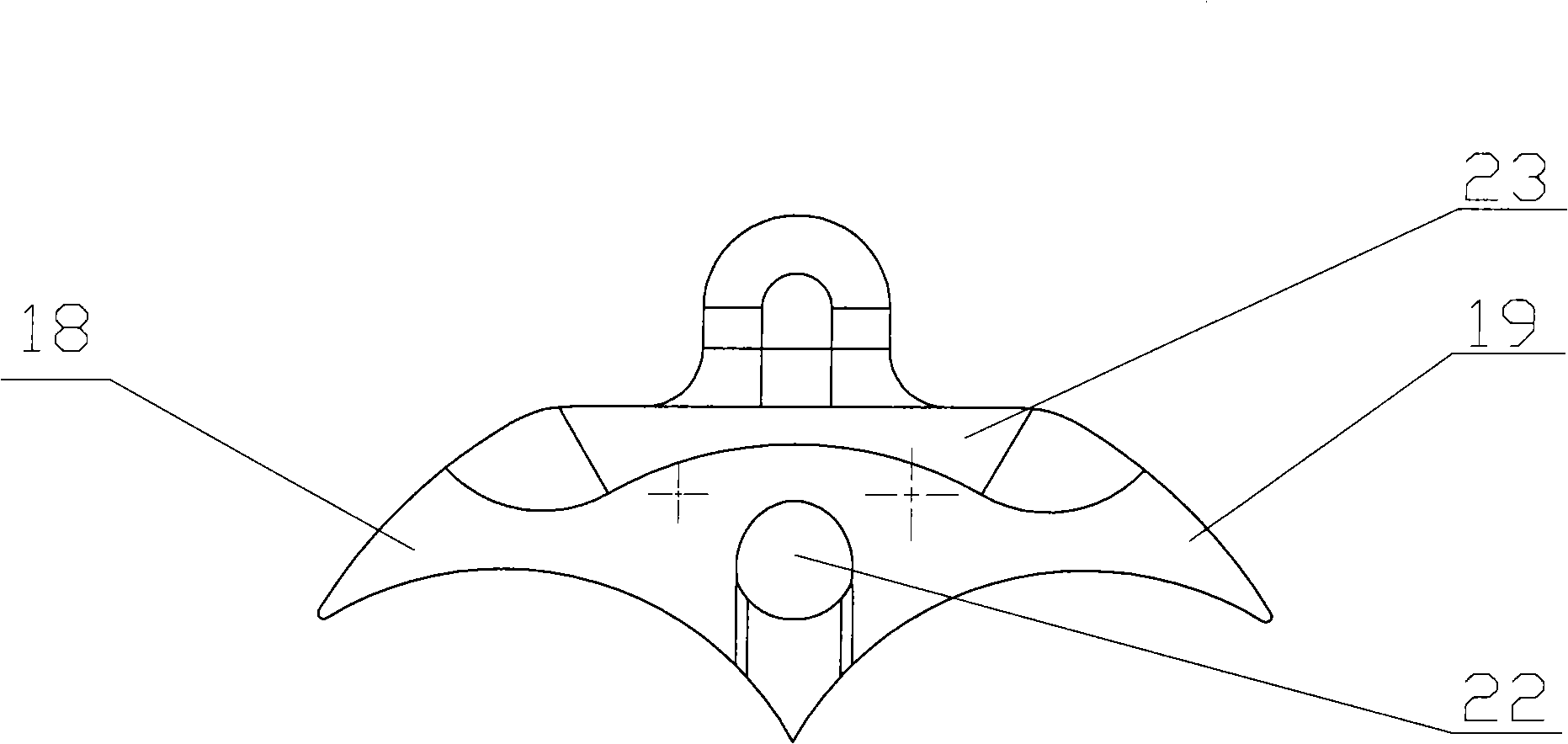

Method for realizing quantitative transportation of material and special low pulsating rotary pump therefor

ActiveCN101279646AGuaranteed accuracySmooth dischargeRotary piston pumpsRotary piston liquid enginesMotor driveRotary pump

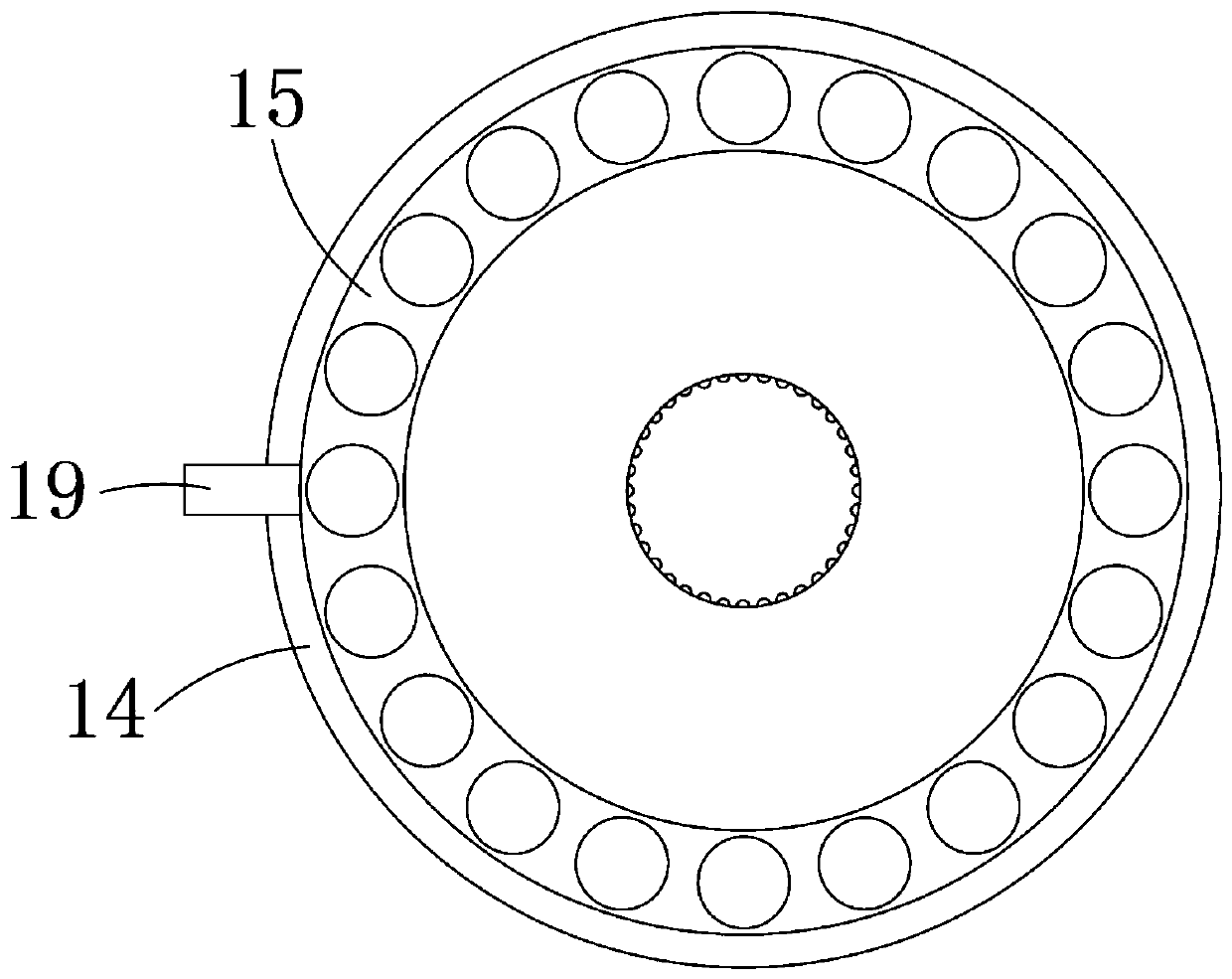

The invention relates to a method for realizing fixed-amount conveying of material and a special low-impulse rotor pump. The method is that: material is continuously supplied to a material carrying section (15) through a material inlet (26); then a servo motor drives a left rotor (8) and a right motor (9) to rotate; the material enters the material carrying section between two adjacent gears of the rotors (8, 9); the rotors (8) and (9) are meshed with each other in a rotating way, the material is pushed to a material outlet (16) to be discharged. The special low-impulse rotor pump comprises a pump body (11) and a pump cover (10) pressed above the pump body (11); the rotors (8) and (9) are corresponding to each other; gears on the surface is spiral rotor pair . By adopting the technical proposal, the rotor pump can effectively reduce discharge impulse with low cost and simple structure.

Owner:HEBEI XIAOJIN MACHINERY MFG

Electroplating device

The invention relates to the field of electroplating devices, and particularly discloses an electroplating device. The electroplating device comprises an electrolytic tank, a lifting structure, a discharging structure, a receiving structure, a shaking structure and a collecting structure. The lifting structure is arranged outside the electrolytic tank, so that suspended to-be-electroplated parts can be automatically put into the electrolytic tank for electrolysis, the parts can be automatically pulled out of the electrolytic tank after electroplating of the parts is completed, manual operation is not needed, the feeding and discharging efficiency can be improved, and skin injuries caused by contact with an electrolyte can be avoided; in the process that the parts are pulled out of the electrolytic tank through the lifting structure, the discharging structure can be synchronously driven to work, rapid discharging can be achieved through automatic discharging work of the discharging structure, the discharging efficiency can be improved, and skin injuries caused by mistaken contact with the electrolyte due to manual discharging can be avoided; and the lifting structure can synchronously drive the receiving structure to work in the vertical lifting process of the parts.

Owner:吴正鑫

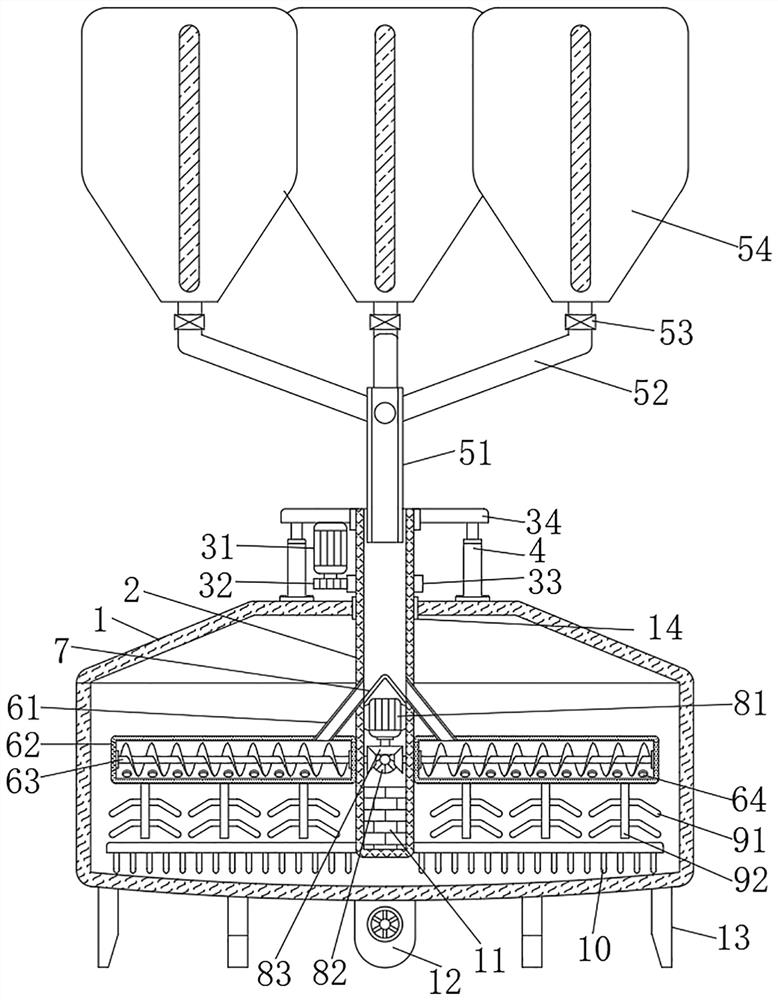

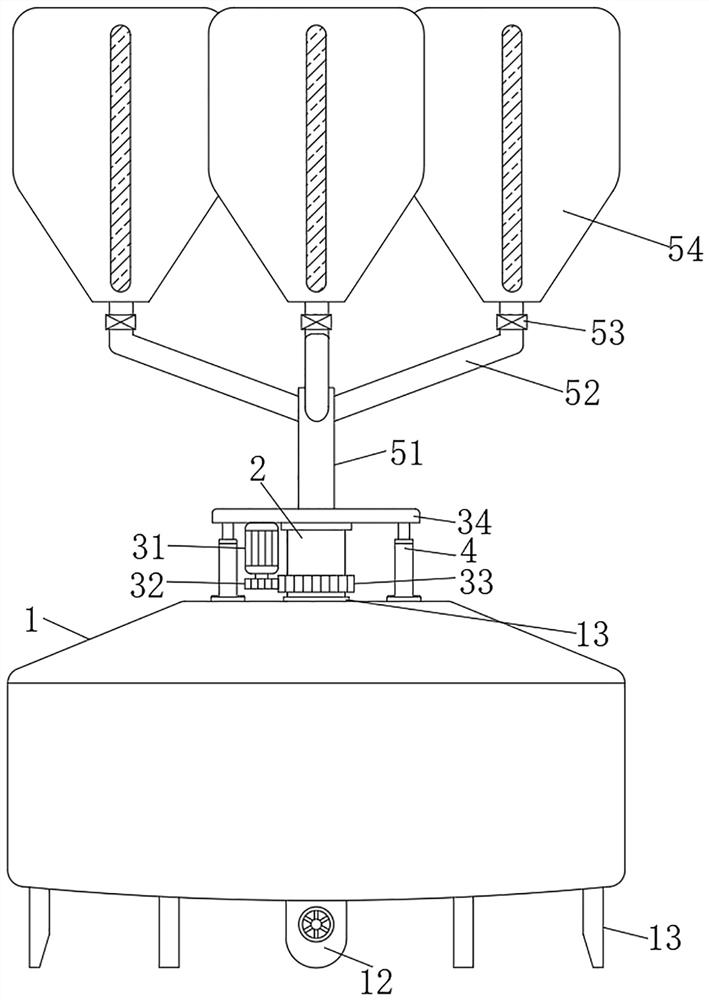

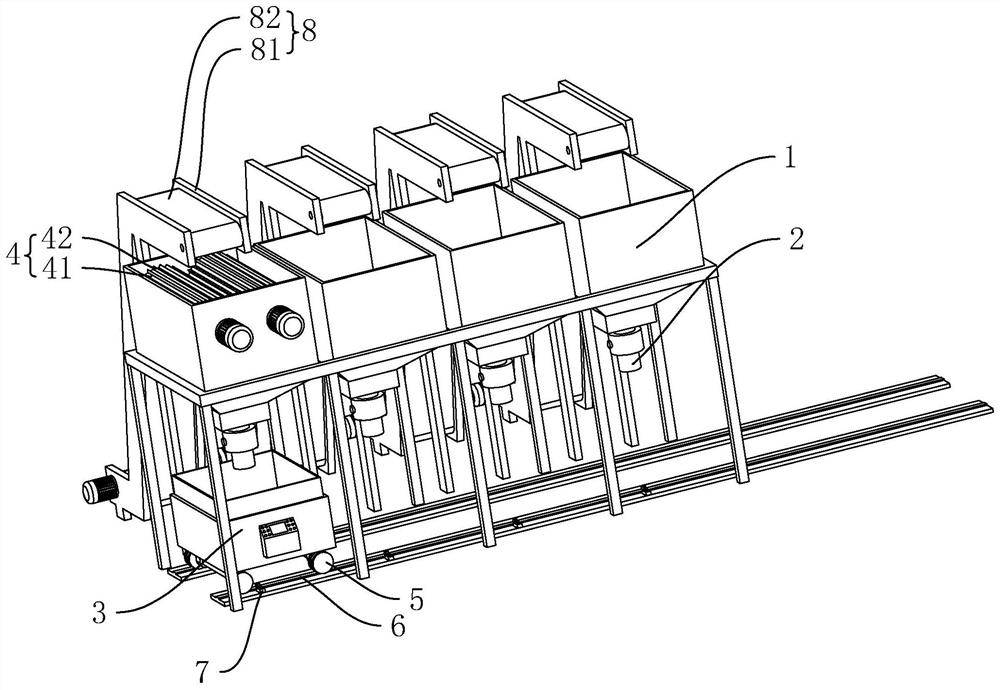

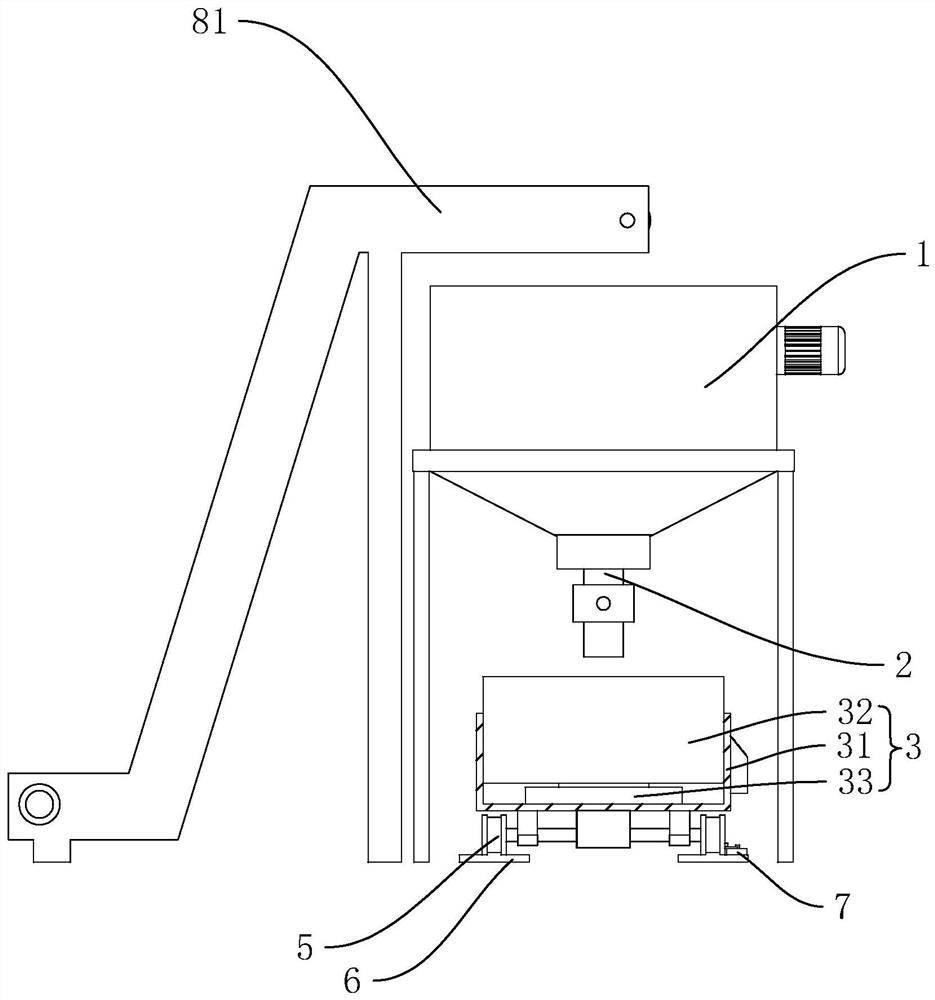

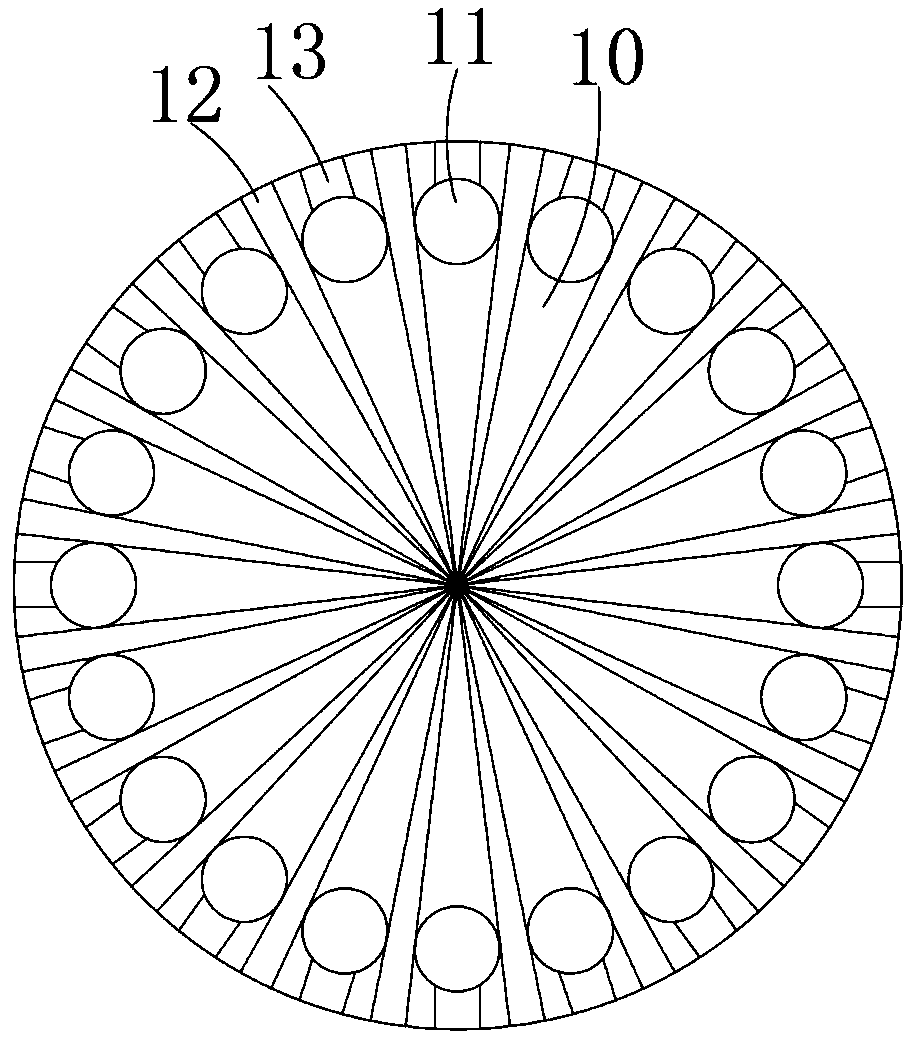

Layered feeding and mixing device for feed production

PendingCN114713125AWell mixedSpread evenlyBatteries circuit arrangementsFeeding-stuffGear wheelElectric machinery

The invention discloses a layered feeding and mixing device for feed production, and relates to the field of feed production.The layered feeding and mixing device comprises a mixing box, a discharging pipe and a discharging pipe arranged on the lower portion of the mixing box and further comprises a layered feeding mechanism and a lifting driving mechanism. Then through cooperation of a driving motor, a first bevel gear and a second bevel gear, a spiral conveying wheel conveys raw materials in feeding barrels from inside to outside, in the conveying process, feed falls into a mixing box through feeding holes, meanwhile, a stirring motor rotates, and through cooperation of a driving gear and a driven gear, a hollow shaft and the multiple feeding barrels rotate at the same time; the raw materials are uniformly spread in the mixing box in the rotating process of the feeding cylinder, the raw materials are poured into the mixing box one by one through the discharging pipe, so that the raw materials are spread layer by layer and are uniformly spread, accumulation of the raw materials is avoided, the raw materials are conveniently mixed, the mixing efficiency of the raw materials is improved, and meanwhile, the mixing effect of the raw materials is ensured.

Owner:河南海大九州生物科技有限公司

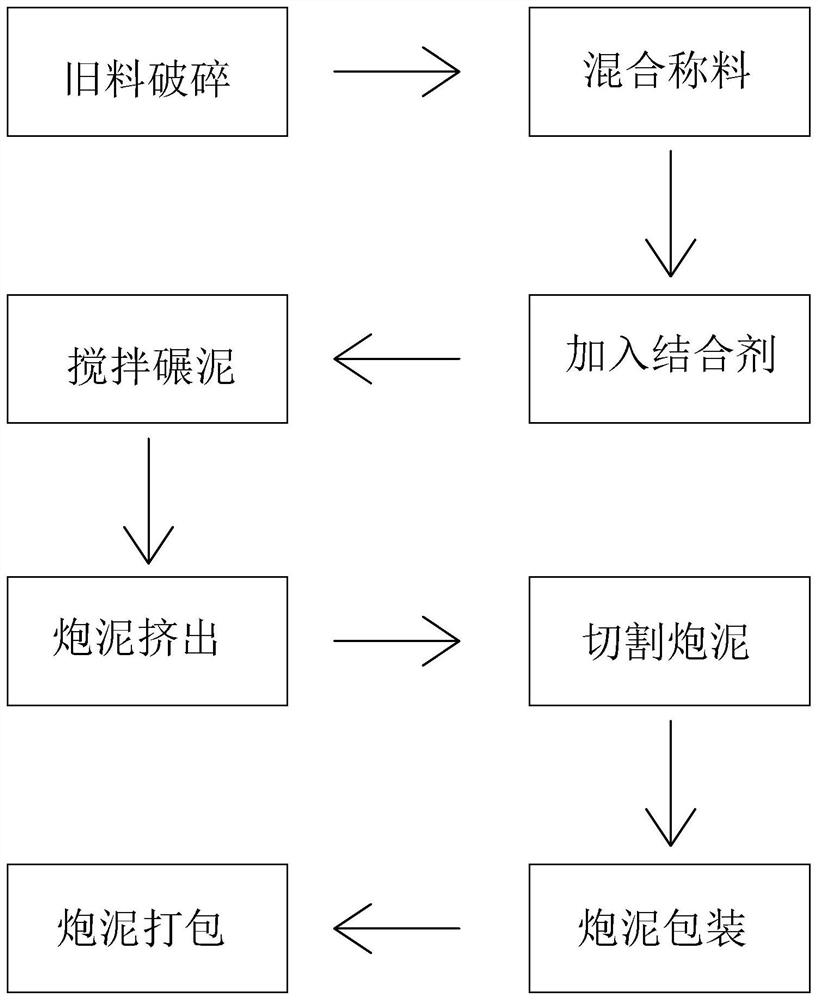

New and old mixed stemming manufacturing process and equipment applied to process

InactiveCN112519168ASave resourcesQuality improvementGrain treatmentsShaping pressProcess engineeringMixed materials

The invention relates to a new and old mixed stemming manufacturing process. The process comprises the following steps of 1, crushing old materials, namely crushing dried stemming until the stemming is crushed into powder; 2, performing mixing and weighing, namely weighing and proportioning the crushed stemming and stemming raw materials in proportion and performing mixing; 3, adding a binding agent, and adding the binding agent while stirring the mixed material; 4, stirring and grinding the stemming, namely grinding and stirring the stemming by adopting an edge runner mill; 5, extruding the stemming, namely putting the stemming obtained after grinding and stirring into a stemming extruder to be extruded; 6, cutting the stemming, namely cutting the the stemming obtained after extrusion; 7,packaging the stemming, namely packaging the cut stemming; and 8, bailing the stemming, namely bailing the packaged stemming. The process has the advantages that the dried stemming is crushed and mixed with new materials for new stemming manufacturing, the dried stemming can be reused, and resources are saved.

Owner:山东恒信力众新型材料有限公司

Cylindrical husk steaming machine

PendingCN106336984AIncrease productivityGuaranteed blankingAlcoholic beverage preparationThermal insulationGate valve

The invention relates to a cylindrical husk steaming machine which comprises an exhaust fan, an upper cover and a cylinder body, wherein the cylinder body comprises a cylinder body upper part and a cylinder body lower part, the cylinder body upper part is cylindrical, the cylinder body lower part takes the shape of an inverted circular truncated cone, the cylinder body upper part and the cylinder body lower part are connected to form the cylinder body, cylinder walls of the cylinder body upper part and the cylinder body lower part are filled with a thermal insulation material, a discharge port is arranged at the lower end of the lower part of the cylinder body, a discharge pneumatic gate valve is arranged in the discharge port, a cleaning hole is formed in the side surface of the lower end of the cylinder body lower part, a side wall of the cylinder body lower part is connected with a cooling fan, an inner screen is arranged on an inner wall of the cylinder body lower part, a crushing bridging device is arranged in the cylinder body and corresponds to the center of the discharge port, an inlet hole is formed in the side surface of the cylinder body upper part, a steam pipe is arranged in the cylinder body upper part and is connected with the steaming machine, the upper end of the cylinder body upper part is connected with the upper cover, a feed port is formed in the upper end of the upper cover, the exhaust fan is arranged on the side of the feed port, and an upper cover screen is arranged in the feed port. The cylindrical husk steaming machine rapidly cools after completing steaming, and the interior of the cylinder body is rapidly cleaned.

Owner:南通裕盛智能装备有限公司

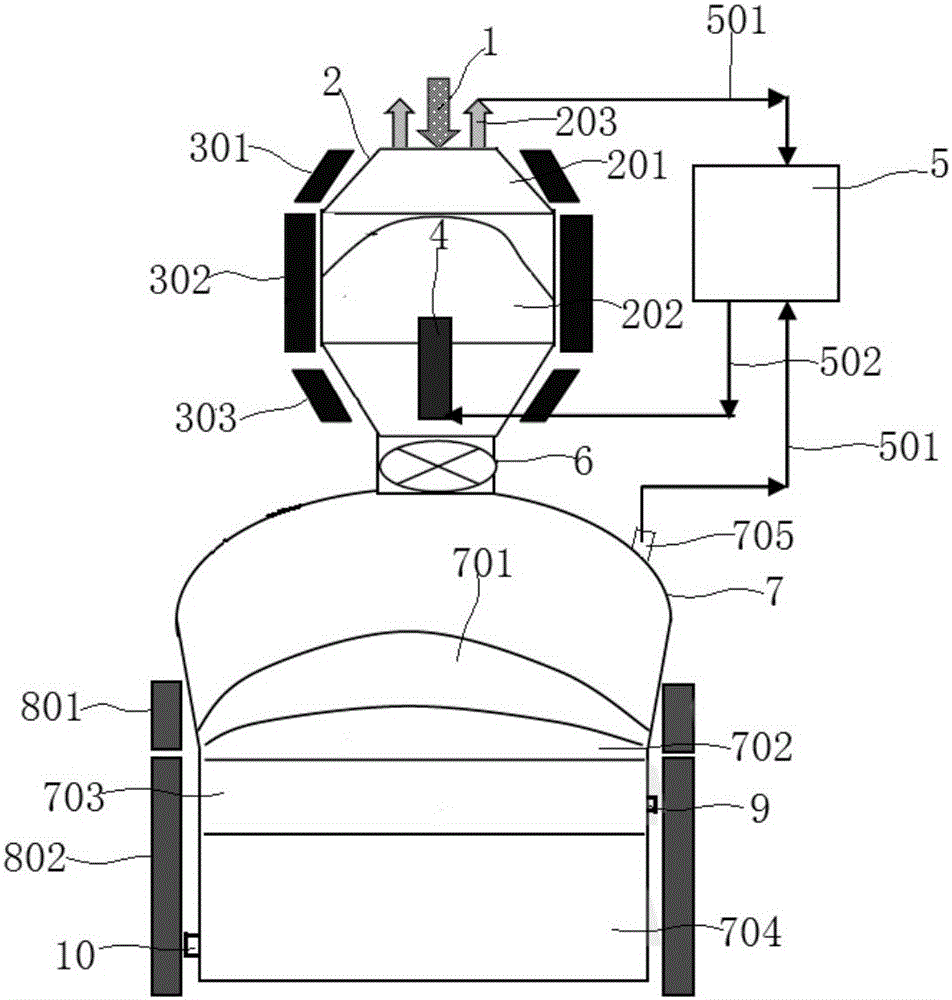

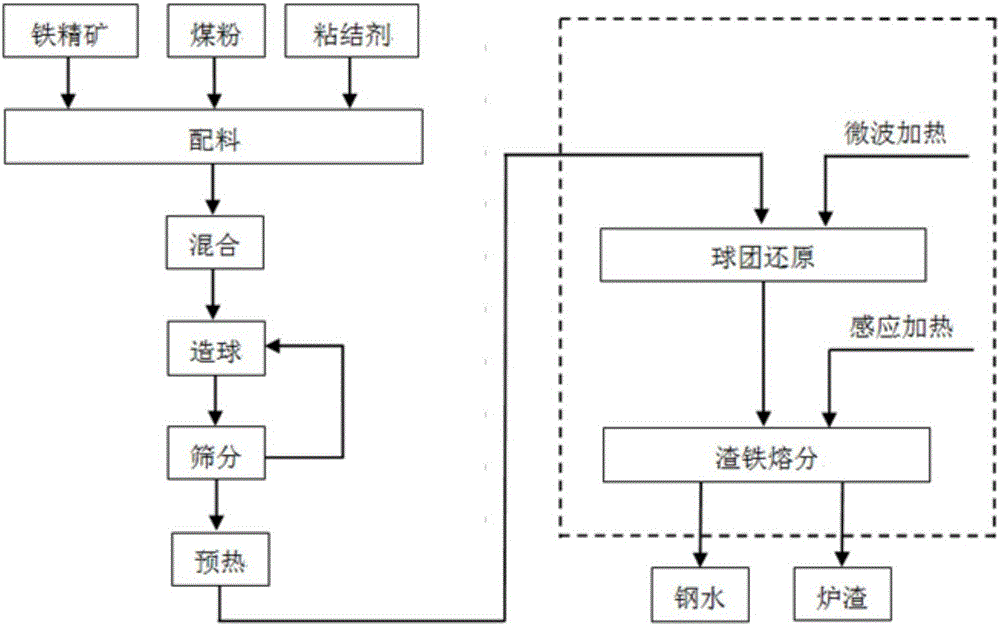

Device for continuously producing molten steel by performing microwave and induction heating on carbon-containing pellets

ActiveCN105755197AIncrease metallization rateImprove breathabilitySmelting processContinuous production

The invention discloses a device for continuously producing molten steel by performing microwave and induction heating on carbon-containing pellets, and belongs to the technical field of iron and steel metallurgy. The device for continuously producing the molten steel by performing microwave and induction heating on the carbon-containing pellets disclosed by the invention comprises a steel refining furnace body; the steel refining furnace body comprises an upper microwave reducing furnace and a lower induction smelting separating furnace; the microwave reducing furnace is used for heating and reducing the carbon-containing pellets; the induction smelting separating furnace is used for performing an iron slag smelting separating reaction; the microwave reducing furnace is communicated with the induction smelting separating furnace through a material discharging valve. By adoption of the technical scheme of the invention, the problems of furnace slag foaming, insufficient reduction of the carbon-containing pellets, and low metallization ratio in the existing steel smelting process can be effectively solved, and the quality of the finally obtained molten steel is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

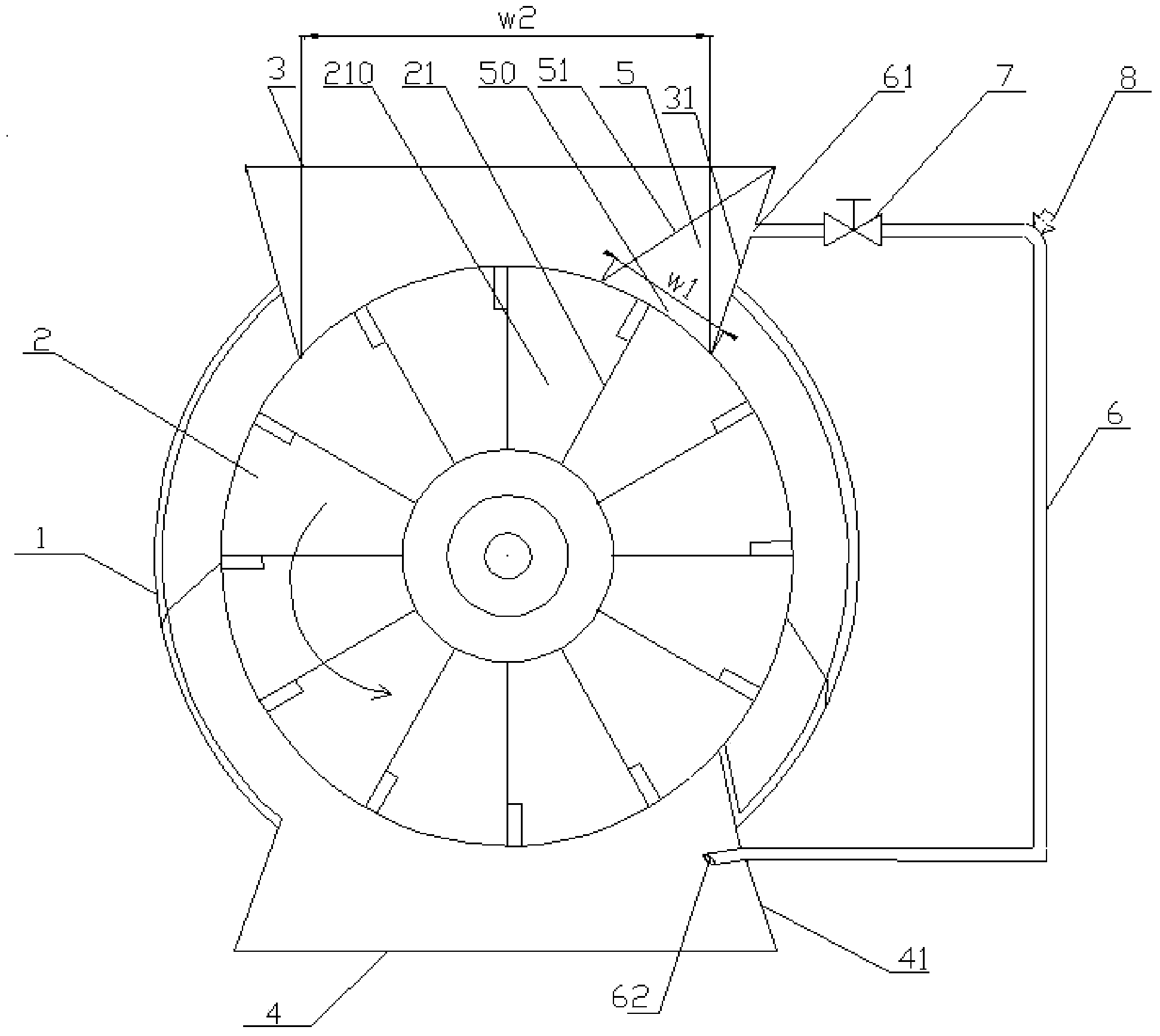

Rotary cindervalve

The invention provides a rotary cindervalve, which comprises a valve seat, a valve seat, a receiving port and a discharging port, wherein the valve body is arranged inside the valve seat; a plurality of lattice grooves used for containing powdery materials are distributed in the valve body along the peripheral direction; the receiving port is located in the upper part of the valve seat and is used for enabling the powdery materials to fall into the lattice grooves of the valve body; the discharging port is located in the lower part pf the valve seat and is used for discharging the powdery materials which are contained in the lattice grooves of the valve body. In addition, the rotary cindervalve also comprises a gas collection chamber and a flow guide channel, wherein the gas collection chamber is located at one side, where the valve body is upwards rotated, of the receiving port, and is of a cavity structure with an opening in the lower part, and the opening faces and is close to the lattice grooves of the valve body; one end of the flow guide channel is communicated with the gas collection chamber; the other end of the flow guide channel is used for discharging gas in the gas collection chamber. According to the rotary cindervalve, the flow direction of the gas in the valve can be changed, air bubbles are prevented from forming in a dedusting bin, and the blanking is enabled to be uniform.

Owner:LAIWU IRON & STEEL GRP

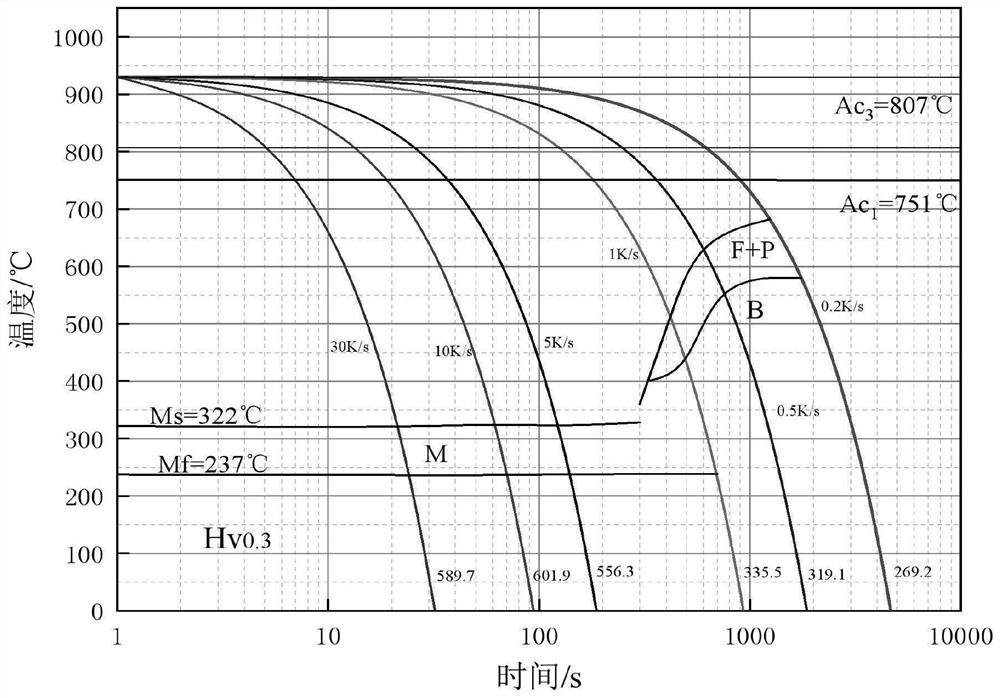

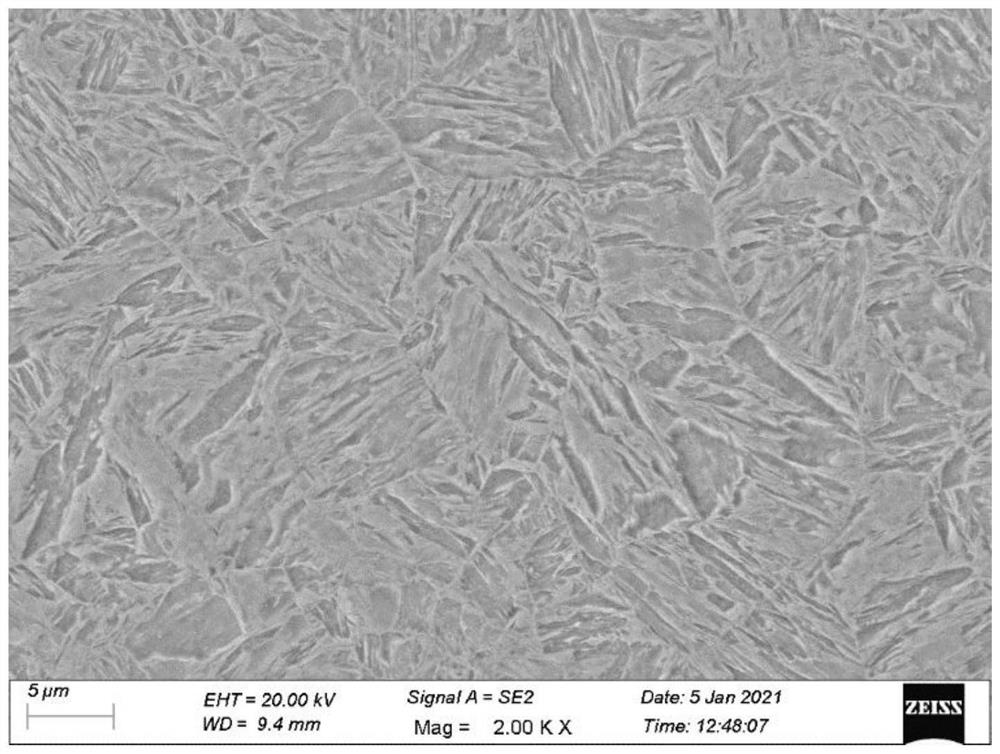

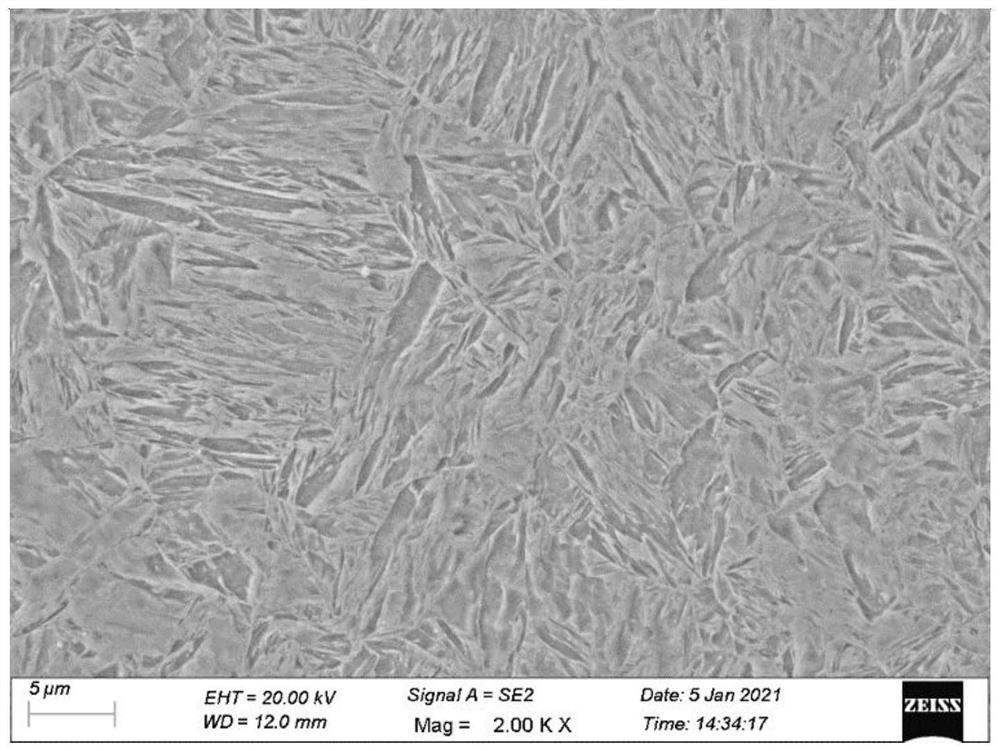

1800MPa-grade hot forming steel as well as hot stamping forming method and application thereof

InactiveCN113337785AReduce intensityGood formabilitySuperstructure subunitsBumpersHot stampingChemical composition

The invention provides 1800MPa-grade hot forming steel as well as a hot stamping forming method and application thereof, and belongs to the technical field of hot forming steel. The 1800MPa-grade hot forming steel provided by the invention comprises the following chemical components: 0.28 to 0.32 percent of C, 0.2 to 0.3 percent of Si, 1.5 to 1.7 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.002 to 0.0035 percent of B, 0.15 to 0.25 percent of Cr, 0.02 to 0.05 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.005 percent of N, 0.04 to 0.055 percent of Nb, 0.15 to 0.25 percent of V and the balance of Fe and impurities. The tensile strength and the ductility of a 1800MPa-grade hot forming steel member are guaranteed through the combined action of C, Si, Mn, P, S, B, Cr, Al, Ti, N, Nb and V with specific contents and tempering through waste heat after quenching.

Owner:SHANGHAI UNIV

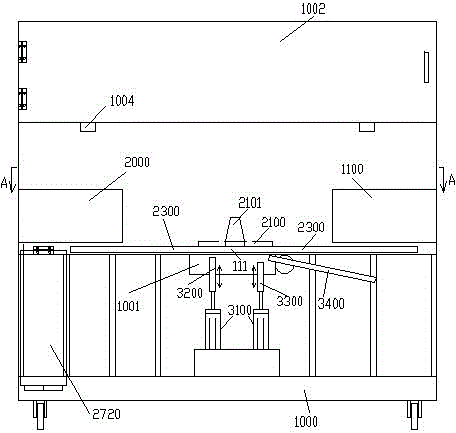

Intelligentized rotary table metal casting sprue separating integrated machine and method thereof

The invention relates to an intelligentized rotary table metal casting sprue separating integrated machine and a method thereof. The intelligentized rotary table metal casting sprue separating integrated machine comprises a machine cabinet. An annular rotary table driven by an electric index plate is arranged in the middle of the machine cabinet. Positioning poles used for placing metal castings are arranged on the annular rotary table at intervals. A metal casting sprue separating device used for achieving sprue waste separation after the metal castings are rotated to the position is arranged on one side of the annular rotary table. A metal casting separating device used for achieving metal casting product separation after the metal castings are rotated to the position is arranged on the other side of the annular rotary plate. An ejection mechanism used for ejecting metal casting wastes after the metal casting wastes are rotated to the position along with the annular rotary plate is further arranged on the lower side of the annular rotary table and on the front portion of the machine cabinet. The intelligentized rotary table metal casting sprue separating integrated machine is compact in structure; metal casting sprue separation and metal casting separation are convenient; the automation degree is high, and the operation method is simple and convenient.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

Automatic material dropping and ball inserting device for producing Christmas balls and working method thereof

PendingCN107235337AGuaranteed blankingSimple structureConveyorsReligious equipmentCircle of a sphereNozzle

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

Directional conveying switch valve

The invention discloses a directional conveying switch valve. The directional conveying switch valve is provided with a valve body, the valve body is provided with a material inlet, a first discharging port and a second discharging port, and the valve body is provided with a V-shaped valve plate; V-shaped plate grooves are formed in the two side walls of the valve body, the V-shaped valve plate penetrates through the V-shaped plate grooves and extends out of the V-shaped plate grooves, and the V-shaped valve plate can reciprocate along the V-shaped plate grooves, so that the first dischargingport is disconnected and the second discharging port is connected at the same time, or the first discharging port is connected and the second discharging port stops switch between the two work stations; and the valve body is fixedly connected with a support, a driving device is fixed to the support, and the V-shaped valve plate is connected to the driving device which drives the V-shaped valve plate to reciprocate. The directional conveying switch valve has the characteristics that the material flow direction is reliably switched, smooth opening and closing are achieved, flowing is not easilyblocked, and the closing effect is good. Normal discharging of an overall conveying system is guaranteed.

Owner:河南众森电力设备有限公司

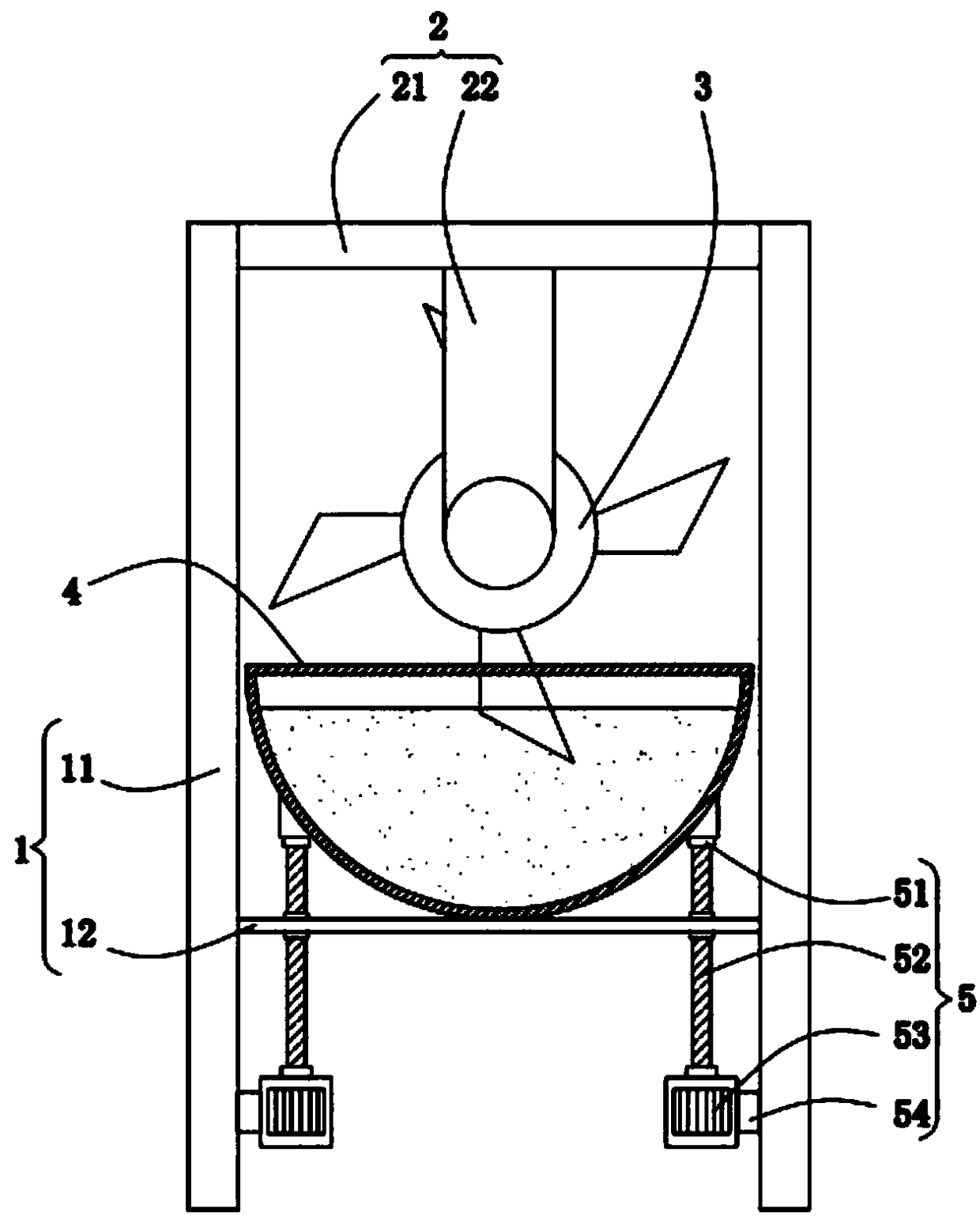

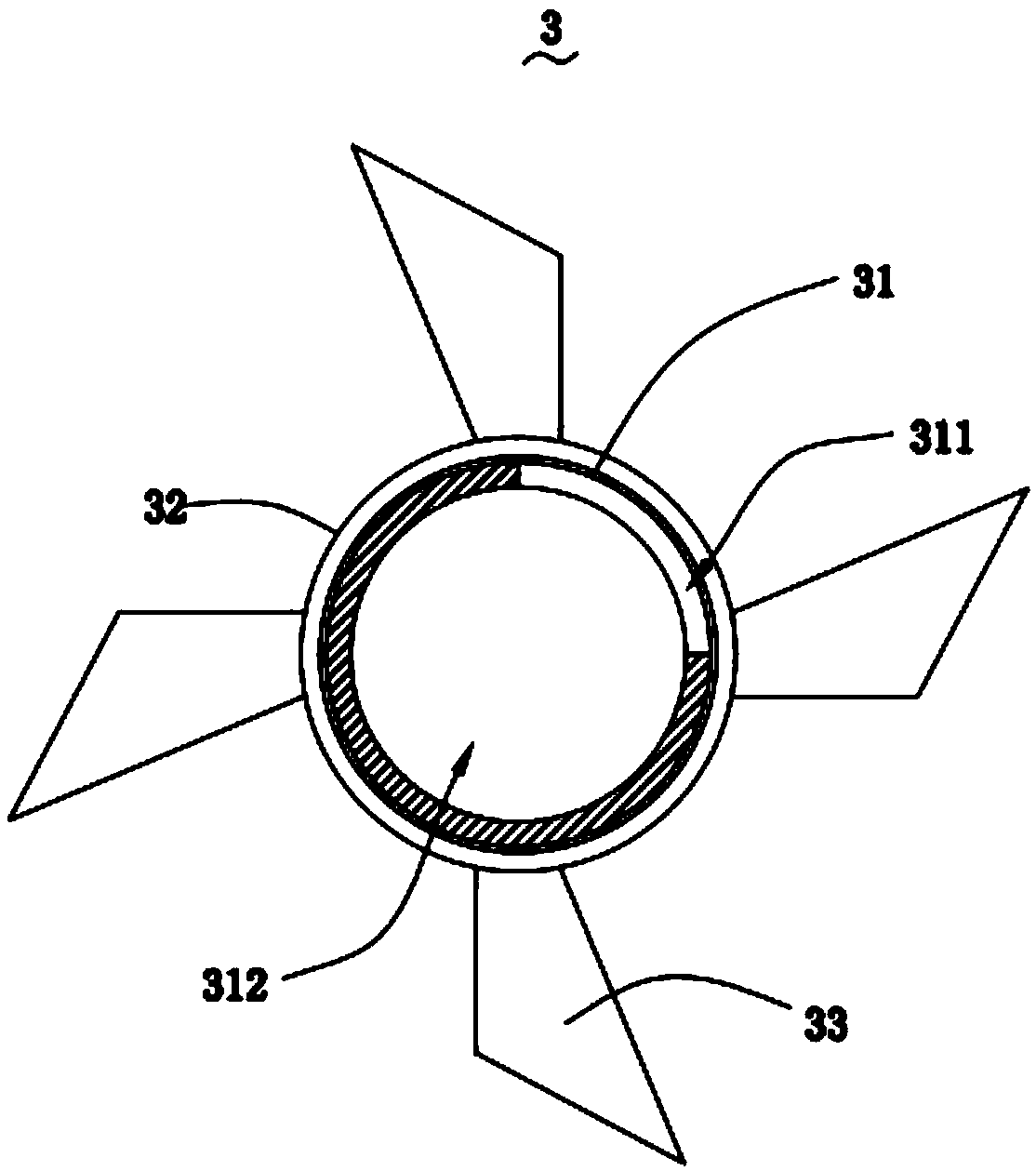

Efficient stirring device for steelmaking continuous casting tail end and using method of efficient stirring device

InactiveCN113059132AImprove labor enthusiasmGuaranteed stirringElectric machineryProcess engineering

The invention discloses an efficient stirring device for a steelmaking continuous casting tail end and a using method of the efficient stirring device, and relates to the technical field of steelmaking stirring equipment. The efficient stirring device comprises a stirring box and a control panel, wherein a stirring assembly is installed in the stirring box and comprises a rotating sleeve and a stirring bin, and the stirring bin is installed in the stirring box. The device has the beneficial effects that the rotating assembly, a third motor and a fourth motor are arranged, the labor enthusiasm of workers is improved, normal stirring operation is implemented through operation of the fourth motor, and it is guaranteed that stirring, controlled discharging and peculiar smell purification are conducted at the same time; quantitative control over discharging is implemented through a quantitative assembly, blockage happens less, and the overall service life is prolonged; as a conveying assembly is arranged, conveying treatment, it is convenient for conveying treatment to be carried out, the labor intensity of workers is reduced, and the overall stirring work efficiency is improved.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Garment production cloth transferring mechanism

ActiveCN109205204AImprove transfer efficiencyImprove automation performanceMechanical conveyorsTransfer mechanismAssembly line

The invention discloses a garment production cloth transferring mechanism. The cloth transferring efficiency can be greatly improved through the cloth transferring mechanism; in use, annular moving tracks of the garment production cloth transferring mechanism can be arranged on all garment production stations, so that technical cloth transferring is conducted on all the garment production stations, cloth transferring can be achieved according to the needs, the transferring efficiency is high, the automation performance of a garment production assembly line is greatly improved, and the garmentproduction efficiency is ensured; platform main frames of the cloth transferring mechanism move stably and reliably, various cloths can be placed on cloth transferring supporting tables so as to meetthe needs of all the stations, feeding, fixing and discharging of the cloths can be facilitated through cloth lifting assemblies, operation convenience is improved, and operation stability during cloth transferring can be ensured through cloth fixing assemblies; and the garment production cloth transferring mechanism adopts the annular moving tracks for guiding, moving driving assemblies can conduct free driving transformation, and circulating motion is facilitated.

Owner:LINGNAN NORMAL UNIV

Method for improving crop purity

ActiveCN108940857AImprove purityImprove dust removal efficiencyGas current separationEngineeringCrop

The invention relates to the technical field of crops, in particular to a method for improving the crop purity. A supporting mechanism, a hoisting mechanism, a material taking mechanism, a storage box, a lifting mechanism, a discharging mechanism, a dust removal mechanism and a stop mechanism are included. The cyclic rotation material taking mechanism is arranged on the top of the storage box, andwhen material taking hoppers enter the storage box, the crops in the storage box can be shoveled out and upwards rotated to the position of a feeding groove, the crops are poured into a circulation groove, then, the crops are discharged into the dust removal mechanism through the discharging mechanism, automatic feeding and dust removal are achieved, crop storage equipment and conveying and dustremoval equipment are integrated, and the dust removal efficiency is greatly improved. During dust removal, the lifting mechanism can slowly upwards lift the storage box, the material taking hoppers constantly make contact with the crops to the maximum degree, and feeding is more thorough; and the semicircular-design storage box is adopted, the storage shape can be similar to the motion track of the material taking hoppers, and the material taking hoppers can conveniently take materials.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Material guiding groove

InactiveCN109335596AShorten speedAvoid direct impactConveyorsLarge containersMechanical wearEngineering

The invention belongs to the field of material conveying equipment, and particularly relates to a material guiding groove. The material guiding groove comprises a material guiding groove body and brackets used for supporting the material guiding groove. The material guiding groove is characterized in that the material guiding groove body comprises lower side plates positioned at the two ends of abelt and upper side plates fixedly connected with the lower side plates, the inner sides of the lower side plates are all provided with horizontal material blocking plates in a horizontal direction, the horizontal material blocking plates are fixedly connected with the lower side plates through supporting plates arranged in an inclining direction, a blanking opening is formed between the horizontal material blocking plates, and the width of the blanking opening is smaller than the width between the two lower side plates. According to the material guiding groove, the horizontal material blocking plates are utilized to buffer materials, and concentrated stacking of the materials in the middle region of the belt is achieved, so that material overflow between a sealing plate and the belt and the mechanical wear can be effectively reduced. Due to the arrangement of the buffering material blocking plates, the speed at which the materials fall onto the belt can be reduced, and the direct impact of the materials on the belt is avoided.

Owner:SHAANXI LONGMEN IRON & STEEL

Drying and crushing integrated equipment for peach gum production with uniform drying function

ActiveCN110756271AQuick unloadingEven drying effectDrying gas arrangementsGrain treatmentsEngineeringMechanical engineering

The invention discloses drying and crushing integrated equipment for peach gum production with a uniform drying function. The drying and crushing integrated equipment comprises a crushing box, a crushing cavity is formed in the crushing box, a discharging hopper is arranged on the crushing box, a constant-speed discharging device is arranged in the discharging hopper, a first mounting block is arranged in the crushing cavity, and a plurality of drying cavities are formed in the first mounting block. According to the equipment, the speed of discharging the peach gum materials is controlled through utilizing a screw conveyer and a first motor, so that the drying effect of the peach gum material under the subsequent drying is prevented from being affected by too fast stacking of the peach gummaterials; due to the fact that the peach gum materials are tumbled before entering the drying cavities, the peach gum materials in the drying cavities also fall in a tumbling mode; and the drying effect is uniform and consistent due to the fact that each peach gum material falls onto a metal screen along the drying cavities, and crushing rollers are arranged in a radial incremental manner from top to bottom, so that the crushed peach gum crushed particles are uniform in size.

Owner:福州康来生物科技有限公司

Discharging door

PendingCN112809930AImprove coherenceGuaranteed blankingDischarging apparatusLarge containersEngineeringStructural engineering

The invention discloses a discharging door. The discharging door comprises a protective cover, a discharging opening is formed in the upper portion of the protective cover, a discharging opening is formed in the lower portion of the protective cover, a rotating shaft is arranged on the side wall of the protective cover, an arc-shaped door body is further arranged in the protective cover, the arc-shaped door body comprises two convex arc-shaped baffles arranged in parallel and an arc-shaped door plate arranged between the two convex arc-shaped baffles, the arc-shaped door plate is matched with the discharging opening on the lower portion of the discharging opening, and therefore when the discharging opening is closed, the arc-shaped door plate is in contact sealing with the discharging opening; and a driving assembly is further arranged on the side wall of the protective cover, one end of the rotating shaft is matched with the power output end of the driving assembly, and the other end of the rotating shaft is connected with the convex arc-shaped baffles, so that the convex arc-shaped baffles are driven to rotate to enable the arc-shaped door plate to open or close the discharging opening. Compared with a traditional discharging door of a double-door structure, the arc-shaped door plate of the discharging door can achieve contact sealing with the discharging opening through rotation, the rotating consistency of the arc-shaped door plate during sealing is good, the defects of material leakage, material scattering and the like between two door plates when a traditional door plate is closed are overcome, and normal discharging is guaranteed.

Owner:SHANTUI JANEOO MACHINERY

Slicing equipment for processing fruit with kernels and use method of slicing equipment

PendingCN114347117AStrong overall linkageSimple structureFruit stoningMetal working apparatusEngineeringAnnular array

The invention discloses slicing equipment for processing fruit with kernels and a using method of the slicing equipment, and belongs to the technical field of fruit processing.The slicing equipment comprises a rack, a disc is rotationally installed on the rack, three discharging mechanisms are arranged on the disc and distributed in an annular array mode, a kernel removing mounting frame is installed on the rack, and the kernel removing mounting frame is arranged on the rack; a pitting cutter cylinder is slidably mounted on the pitting mounting frame, and the three discharging mechanisms are a pitting station, a discharging station and a feeding station in sequence from the lower portion of the pitting mounting frame in the anticlockwise direction; the disc and the coring cutter cylinder are used in cooperation with the driving mechanism, the incomplete gear, the first cylindrical gear and the second cylindrical gear are used in cooperation, the coring cutter cylinder does not move when the disc rotates for feeding, the coring cutter cylinder moves when the disc does not move, fruit coring operation can be achieved, the fruit is sliced after coring is completed, and the fruit coring efficiency is improved. The slicing knife can be prevented from being damaged due to direct slicing without removing fruit kernels, the overall linkage performance is high, and the structure is simple.

Owner:洪乙辉

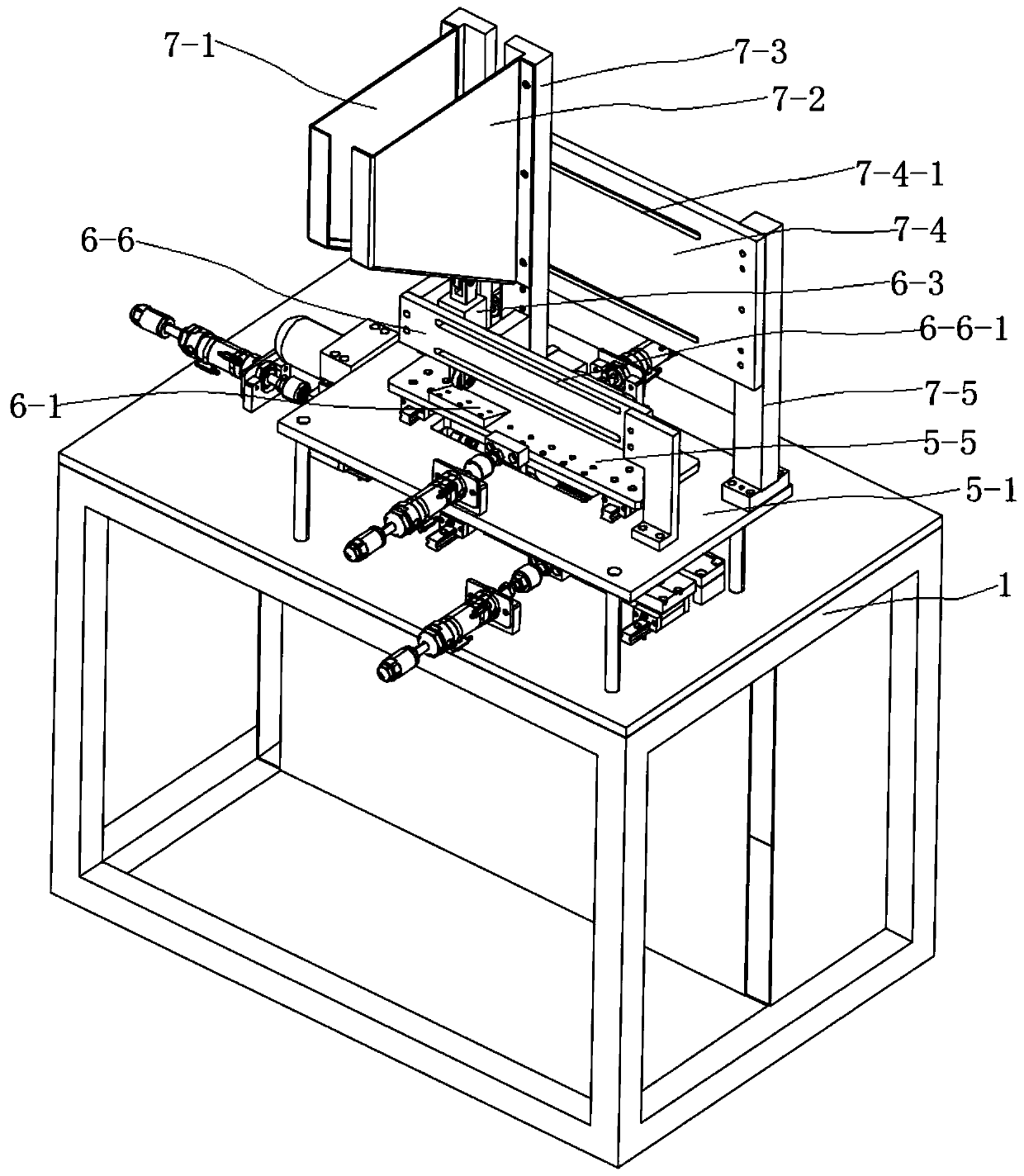

Automatic rod piece inner hole wall polishing machine

PendingCN111203796ASimple structureEasy to operateGrinding carriagesPolishing machinesPolishingWorkbench

The invention discloses an automatic rod piece inner hole wall polishing machine. A support is included. A workbench of the support is provided with a rod piece rotation supporting mechanism. The position, located on one side of a rod piece on the rod piece rotation supporting mechanism, of the workbench of the support is provided with a rod piece rotating driving mechanism for rod piece rotating.The part, located at the end portion of the rod piece on the rod piece rotation supporting mechanism, of the workbench of the support is provided with a polishing mechanism for polishing the inner hole wall of the rod piece which is arranged on the rod piece rotation supporting mechanism and driven by the rod piece rotating driving mechanism to rotate. The part, located on the upper side of the rod piece rotation supporting mechanism, of the workbench of the support is provided with an automatic rod piece feeding mechanism for feeding rod pieces in a material bin to the rod piece rotation supporting mechanism one by one. The automatic rod piece feeding mechanism communicates with a discharging port in the lower end of the material bin on the support workbench through a vertical channel, and a feeding port is formed in the upper end of the material bin. Work is automatic in the whole process, time and labor are saved, rod piece inner hole wall polishing is uniform, and the polishing quality is good.

Owner:常州赛凯电器设备有限公司

Bottom grinding machine for barrels for chemical engineering

InactiveCN112720127ARealize automatic grindingGuarantee positioning qualityEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a bottom grinding machine for barrels for chemical engineering, and belongs to the field of automatic welding line processing. The bottom grinding machine for the barrels for chemical engineering comprises a rotating disc support, a rotating disc capable of rotating is arranged on the rotating disc support, a rotatable clamping station is arranged on the rotating disc, the rotatable clamping station is away from the rotating center of the rotating disc by a certain distance, and a barrel to be ground is arranged on the rotatable clamping station; and a rotatable grinding wheel disc is arranged above the rotating disc, the center line of the grinding wheel disc is superposed to the center line of the rotating disc, and the grinding wheel disc can grind the barrel, rotating to a certain position, of the rotatable clamping station on the rotating disc. According to the bottom grinding machine for the barrels for chemical engineering, through the structure, automatic grinding of a welding line at the bottom of the barrel can be achieved, the production efficiency and quality are improved, and the labor force is reduced.

Owner:孙志兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com