1800MPa-grade hot forming steel as well as hot stamping forming method and application thereof

A technology of hot stamping and hot forming steel, applied in the directions of transportation and packaging, superstructure sub-assembly, bumper, etc., can solve the problem of high weldability and production cost, difficulty in promotion, strength and elongation to be improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The raw material is smelted and forged in a vacuum induction furnace to obtain a slab with a thickness of 30 mm and a chemical composition shown in Table 1;

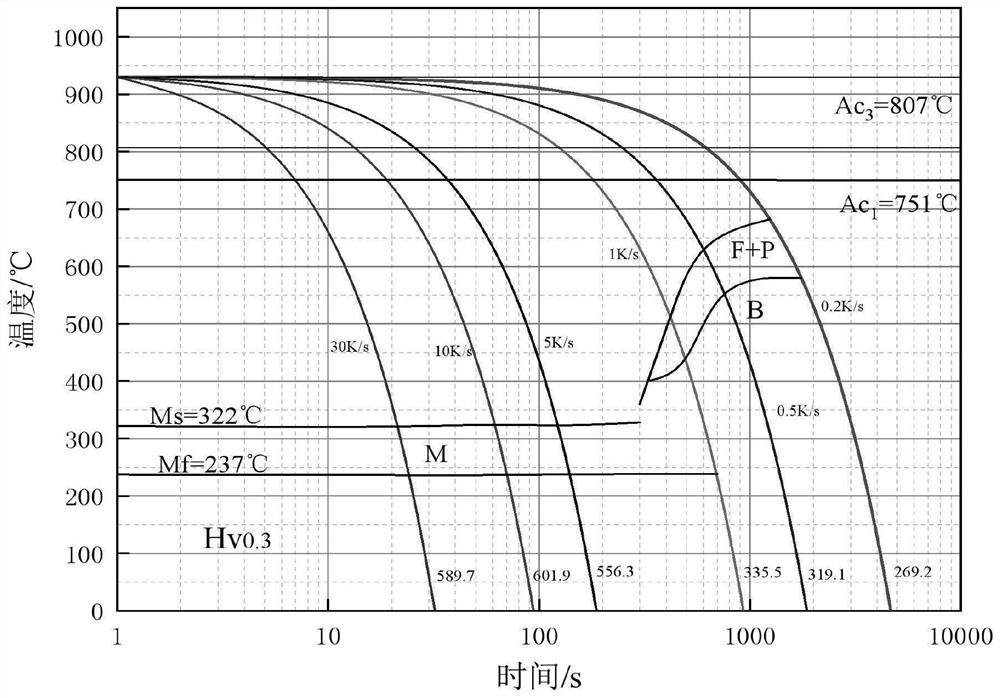

[0057] The CCT map of the slab is as follows figure 1 As shown, among them, Ac 3 is the end temperature of transformation into austenite when heated; Ac 1 is the temperature at which pearlite transforms to austenite when heated; Ms is the temperature at which martensite begins to transform, and M f is the completion temperature of martensitic transformation, F is ferrite, P is pearlite, and B is bainite. Depend on figure 1 The critical cooling rate and austenitization temperature of 1800MPa grade hot forming steel can be obtained, which provides the basis for the hot stamping process parameters of 1800MPa grade hot forming steel.

[0058] The slab is subjected to hot rolling and pickling to obtain a hot-rolled plate with a thickness of 3.0±0.3mm; wherein, the heating temperature of the slab for hot rolling is ...

Embodiment 2~4

[0066] According to the method of Example 1, 1800MPa hot-formed steel was prepared. The preparation conditions of Examples 2-3 are shown in Table 2, and the other preparation conditions are the same as those of Example 1.

Embodiment 2

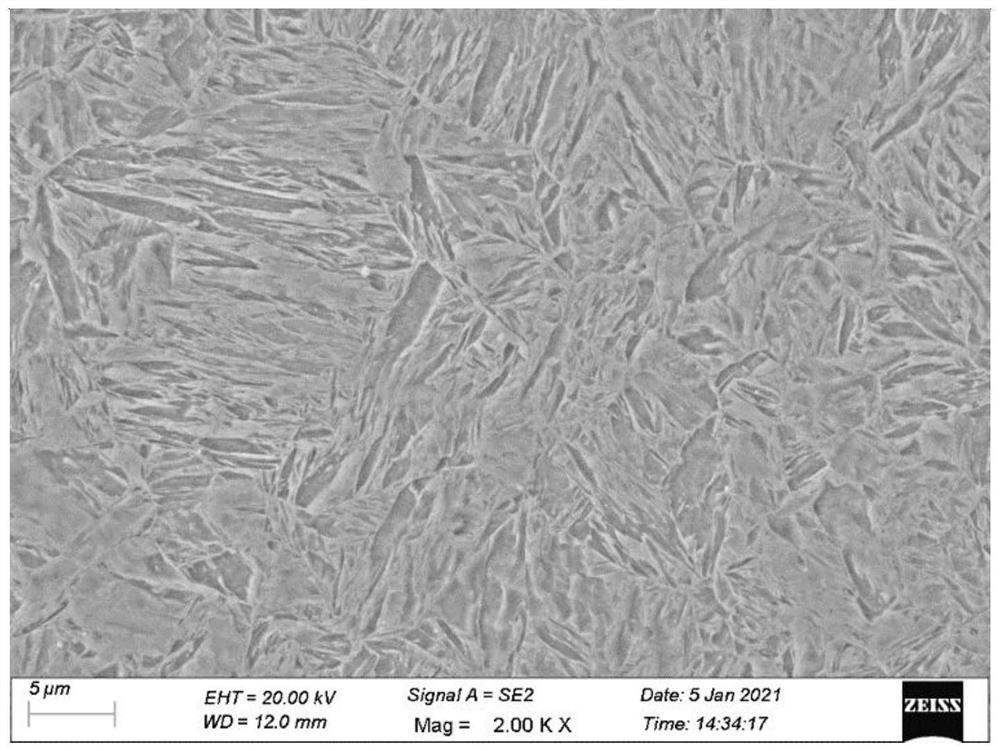

[0074] The microstructure of the 1800MPa grade hot-formed steel prepared by embodiment 2 is as follows: image 3 shown by image 3 It can be seen that the structure tempered at 200°C for 10 minutes is tempered martensite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com