Rotary cindervalve

An ash discharge valve and valve body technology, which is applied in the field of rotary valves, can solve the problem of uneven discharge of the rotary ash discharge valve, and achieve the effect of ensuring the blanking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

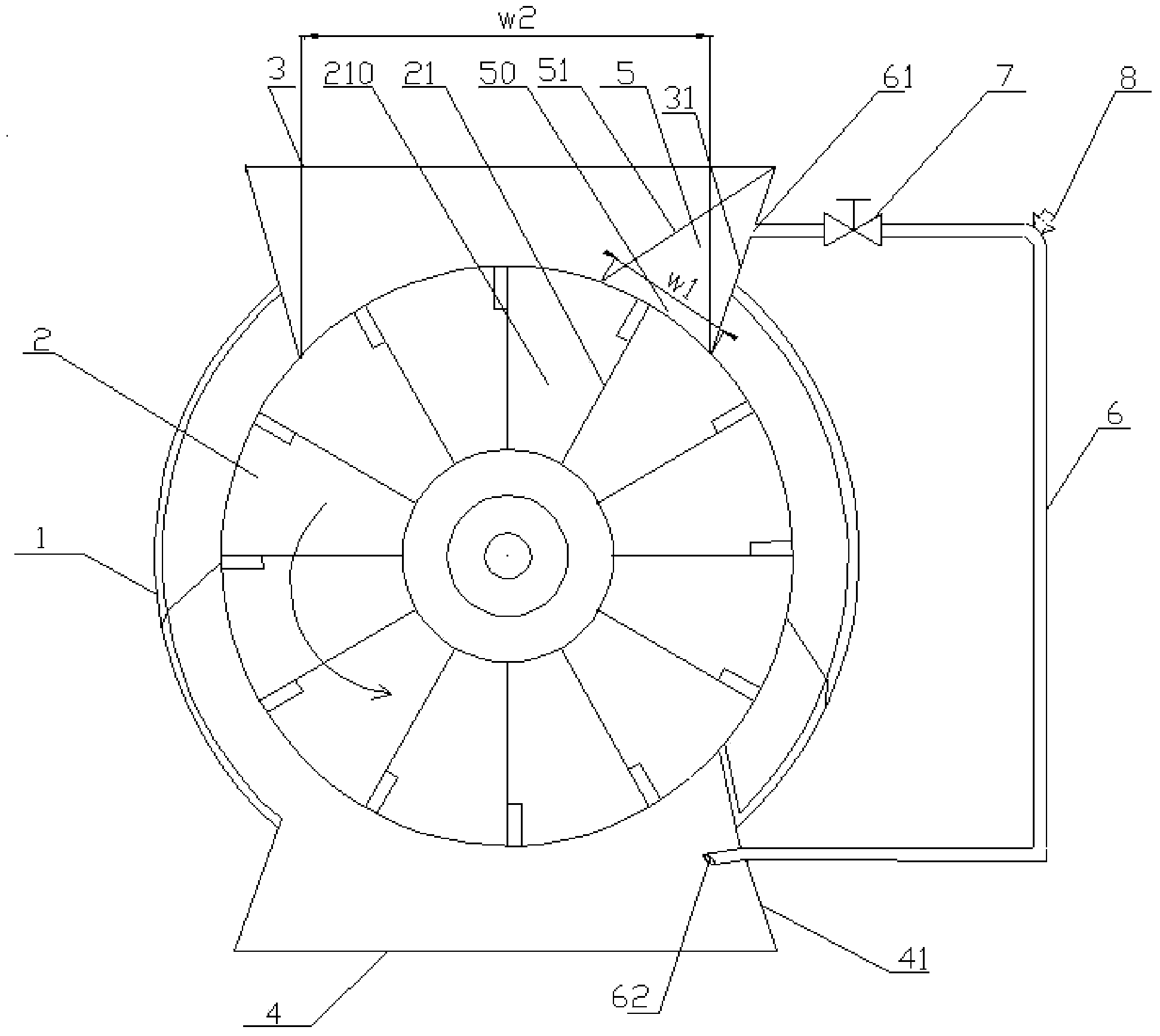

[0019] figure 1 Schematically shows the structure of a preferred embodiment of the present invention, as shown, this preferred embodiment includes a valve seat 1, a valve body 2, a material inlet 3, a material outlet 4, a gas collection chamber 5, and a guide channel 6 Wait.

[0020] Specifically, the valve body 2 is located inside the valve seat 1, and a plurality of baffles 21 are distributed along its circumferential direction on the valve body 2, and the space between adjacent baffles 21 is formed to accommodate powdery materials, such as The grid groove 210 for the dedusted ash formed in the coking process of the coking plant. The material inlet 3 is located on the upper part of the valve seat 1, and it is used to make the powdery material fall into the grid groove 210 of the valve body 2. For example, the material inlet 3 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com