Intelligentized rotary table metal casting sprue separating integrated machine and method thereof

A metal casting and nozzle separation technology, which is applied in the field of intelligent turntable metal casting nozzle separation integrated machine, can solve the problems of unclean frame removal, inability to separate cleanly, low efficiency, etc., and achieves compact structure, simple structure and simple operation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

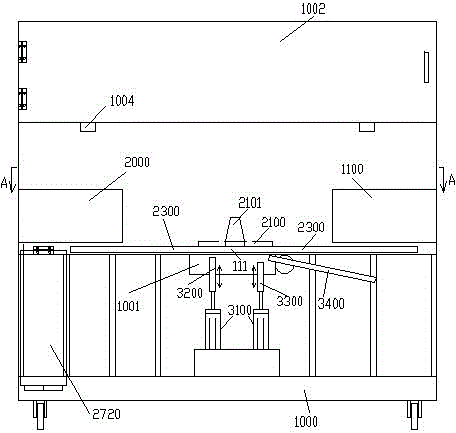

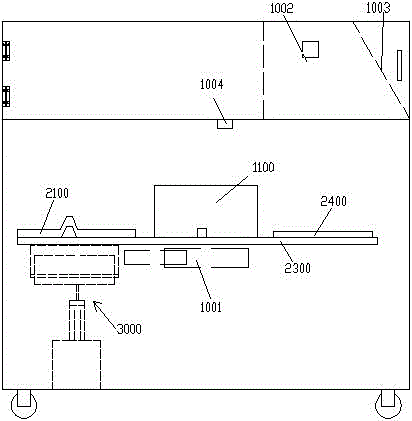

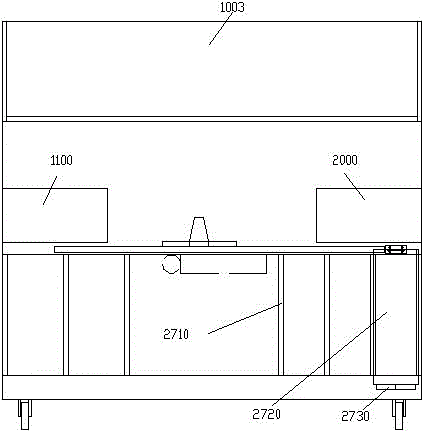

[0057] refer to Figure 1 to Figure 23

[0058] An intelligent turntable metal casting nozzle separation integrated machine, including a cabinet 1000, the lower side of the cabinet is provided with casters, and the middle part of the cabinet is provided with an annular turntable 2300 driven by an electric indexing plate 1001, and the upper side of the annular turntable is arranged at intervals There is a positioning rod 2400 for placing metal castings 2100. One side of the ring turntable is provided with a metal casting nozzle separation device 1100 for separating the nozzle waste 2103 after the metal castings rotate to this position. The other side of the ring turntable is provided with metal castings Metal ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com