Gathering hopper of stirring station

The technology of mixing station and hopper is applied in the field of hopper of mixing station, which can solve the problems of easy wear and tear of the discharge port of the hopper, increase the workload of the staff, and affect the normal unloading of the hopper, so as to improve the discharge speed and shorten the time. The effect of working cycle and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

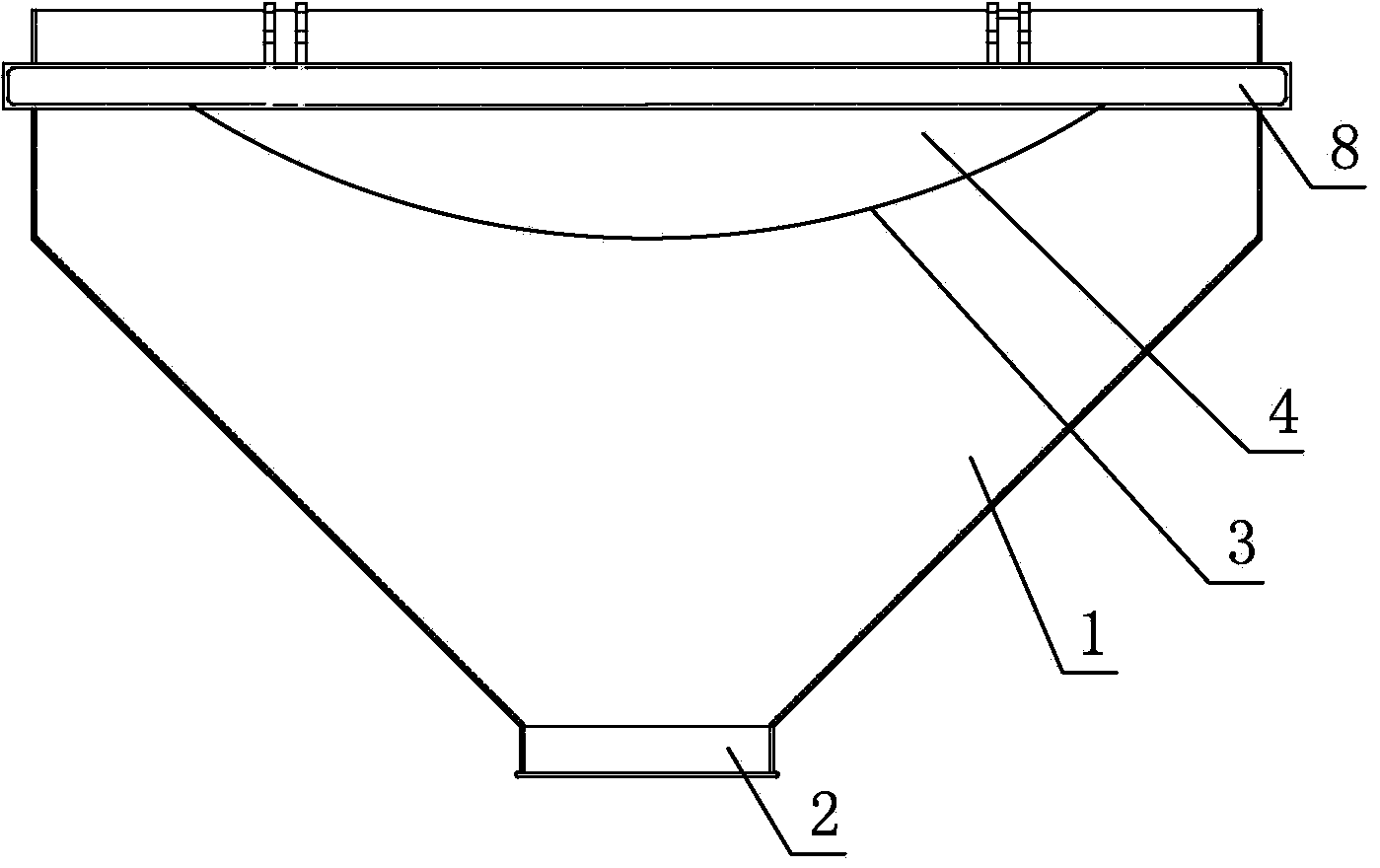

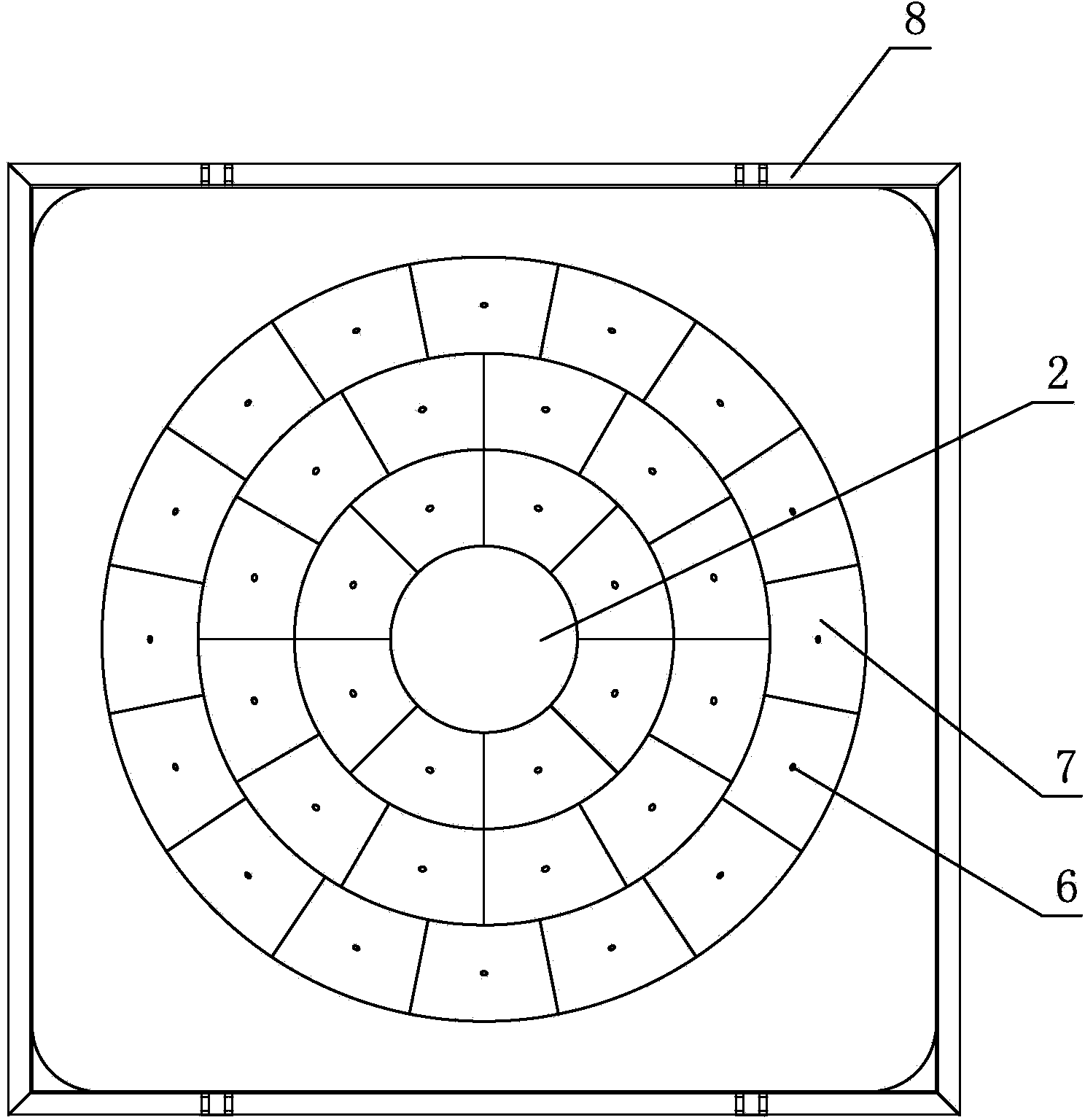

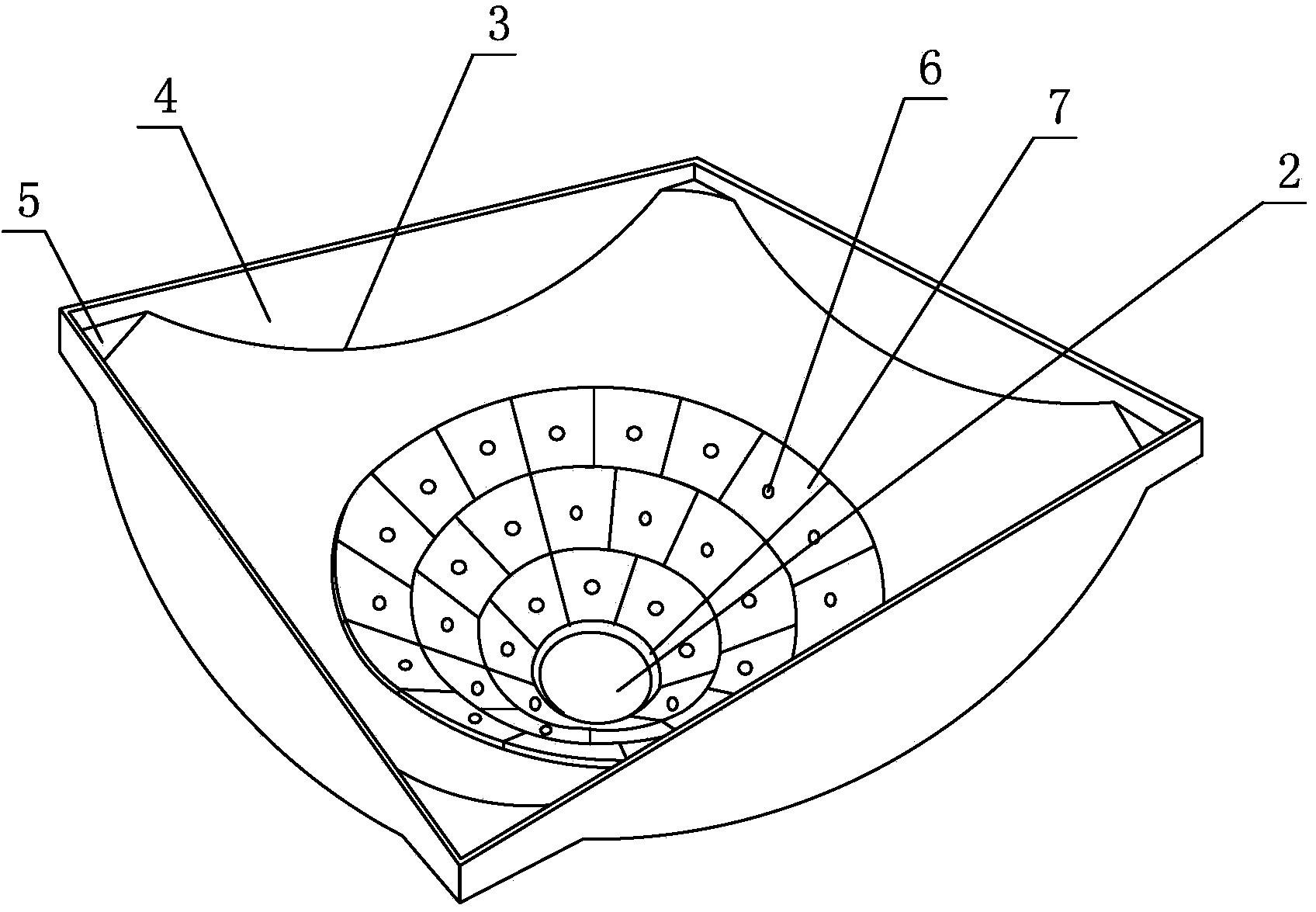

[0015] like Figure 1-3 As shown, a mixing hopper of a mixing station includes a conical material barrel 1, a feeding port 2 is provided at the bottom of the conical material barrel 1, and four uniform sizes are evenly arranged on the top of the conical material barrel 1 along the circumference. The arc-shaped notch 3 of each arc-shaped notch 3 is provided with a vertically arranged baffle plate 4 respectively, and the ends of adjacent two baffle plates 4 are welded vertically, and the four baffle plates 4 surround and stir The square feeding port matched with the square mounting port on the platform of the station, the top of the conical barrel 1 between two adjacent arc-shaped notches 3 and the two-phase welded stopper set at the two arc-shaped notches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com