Automatic material dropping and ball inserting device for producing Christmas balls and working method thereof

A technology of blanking device and Christmas ball, applied in the direction of floor fabric, application, household appliances, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of high efficiency, improved production efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

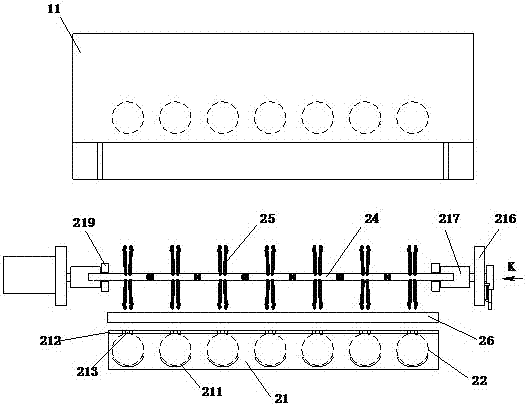

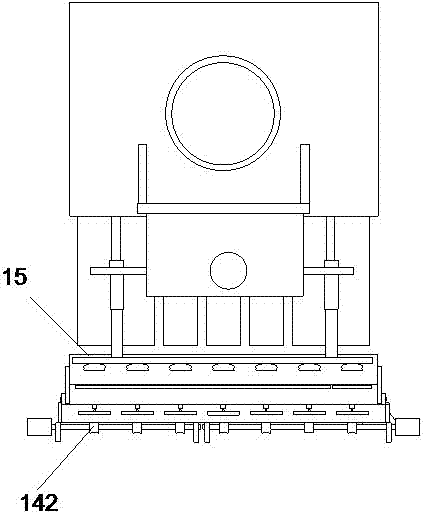

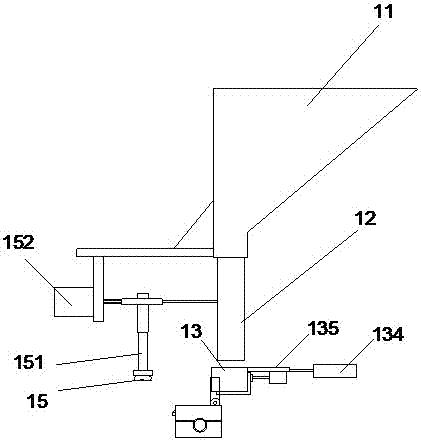

[0036] Such as Figure 1~13 As shown, an automatic blanking device for producing Christmas balls, including a frame and an automatic blanking device and a quick ball insertion device arranged on the frame.

[0037] The function of the automatic blanking device is to blank the Christmas balls and limit the direction of the Christmas ball insertion hole of the Christmas ball 25 to the bulge 215 on the inserter 25 to facilitate the insertion of the Christmas balls. The Christmas ball insertion hole is set There are pinch protrusions 101 .

[0038] The automatic blanking device includes a blanking hopper 11 for holding Christmas balls, a blanking pipe 12 arranged below the blanking hopper 11 and communicating with the inner cavity of the blanking hopper, and a material receiving device is arranged below the blanking pipe 12, and the connecting device The material receiving device includes a material receiving tray 13, which has a through hole 131 for carrying the drop tube to dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com