Method for realizing quantitative transportation of material and special low pulsating rotary pump therefor

A rotor pump and material technology, used in rotary piston pumps, liquid fuel engines, rotary piston/oscillating piston pump components, etc. Measure pulsation, ensure accuracy, and eliminate the effect of pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

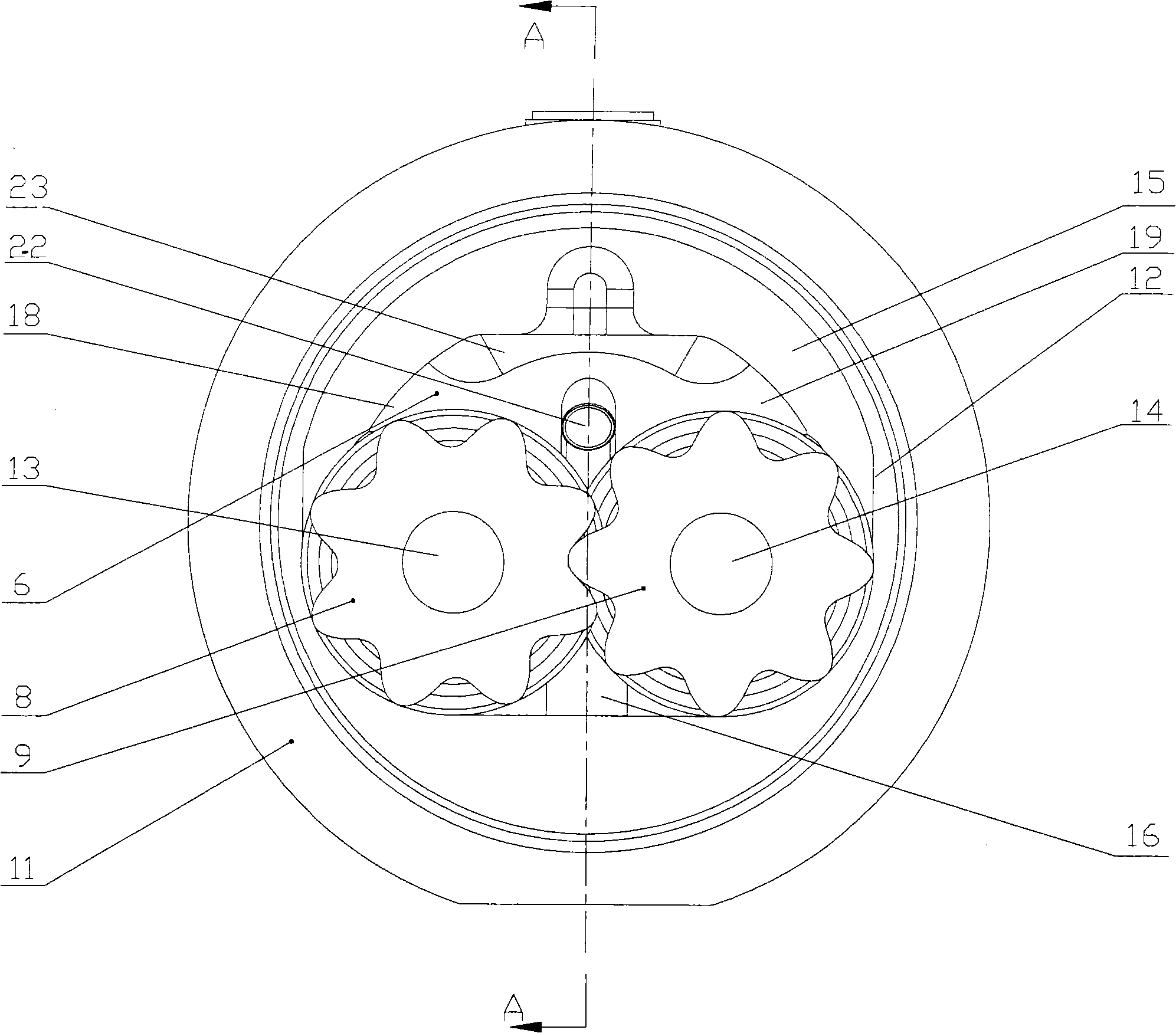

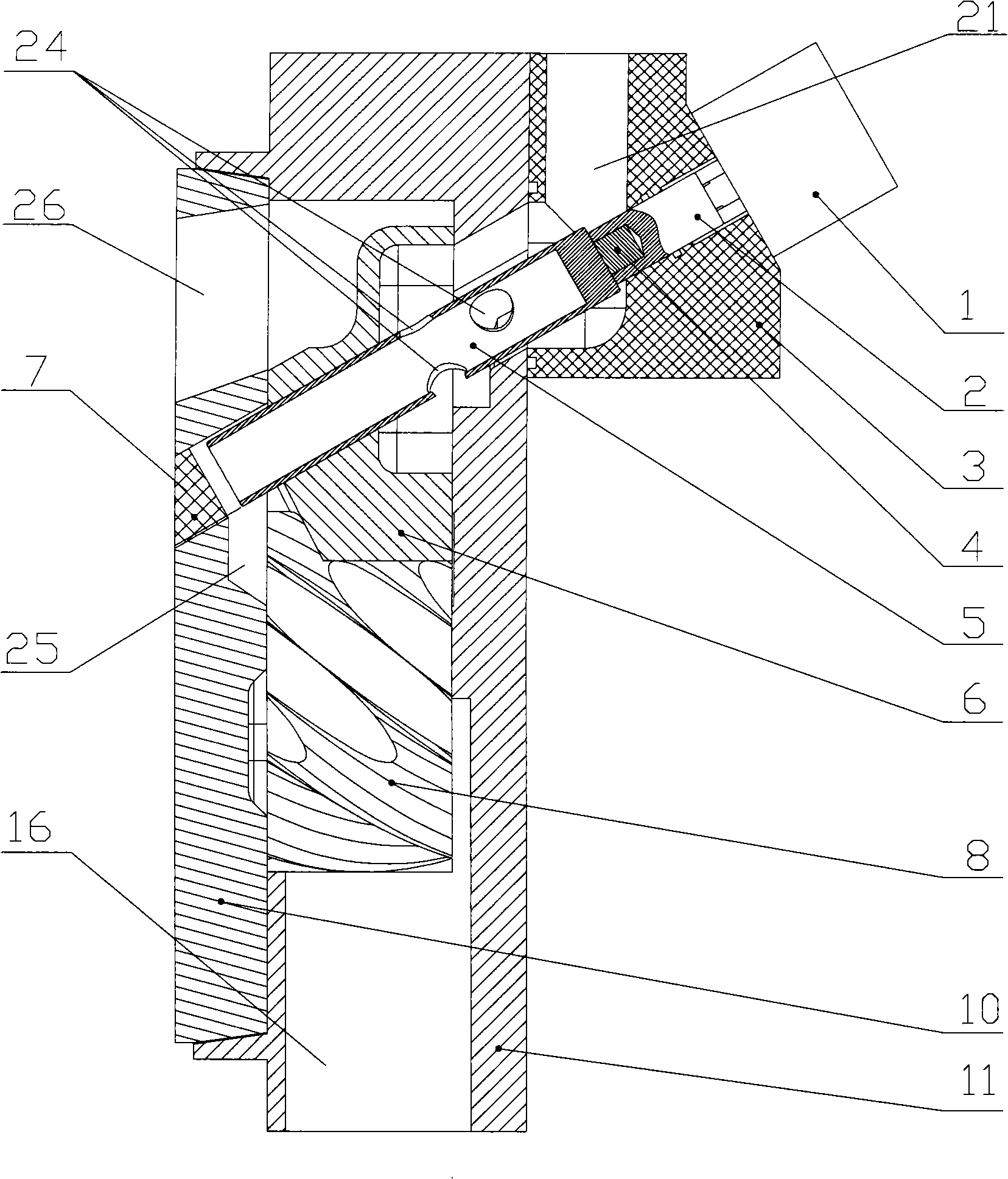

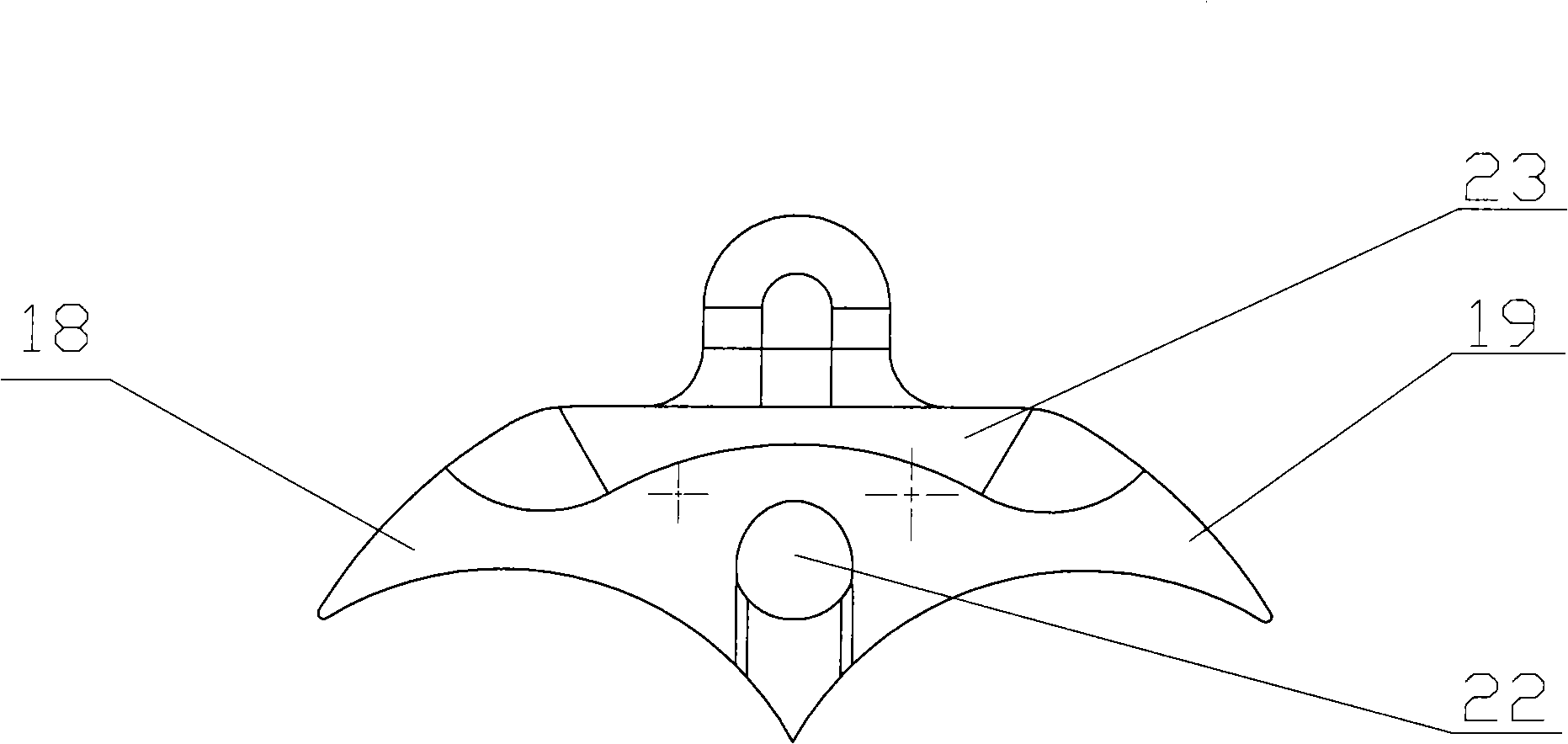

[0027] Depend on Figure 1-Figure 4 It can be seen that the low-pulsation rotor pump of the present invention includes a pump body 11 and a pump cover 10 pressed over the top of the pump body 11. The pump cover 10 is provided with a feed port 26 connected to the feeder. There is a pump chamber 12, the left rotor 8 and the right rotor 9 corresponding to and engaged with the left rotor 8 are respectively placed on the driving shaft 13 and the driven shaft 14 in the pump chamber 12, and the driving shaft 13 and the driven shaft 14 are in the opposite direction Rotate, so as to drive the left rotor 8 to engage with the right rotor 9 and rotate in reverse. In the pump chamber 12 above the joint of the two rotors, there is a loading area 15 opposite to the feed port 26. Below the joint, there is an outlet. The feed port 16, in this embodiment, each of the rotors 8 and 9 has eight teeth, each tooth is arc-shaped, and each rotor is twisted from its upper end surface to its lower end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com