Microbial fermentation fertilizer production system

A microbial fermentation and production system technology, applied in the field of fertilizer production line, can solve the problems that materials are easy to adhere to the inner wall of the hopper, cannot guarantee the normal loading and unloading of materials, and reduce the utilization rate of Z-shaped elevator, so as to improve the efficiency of biochemical reactions , improve utilization and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

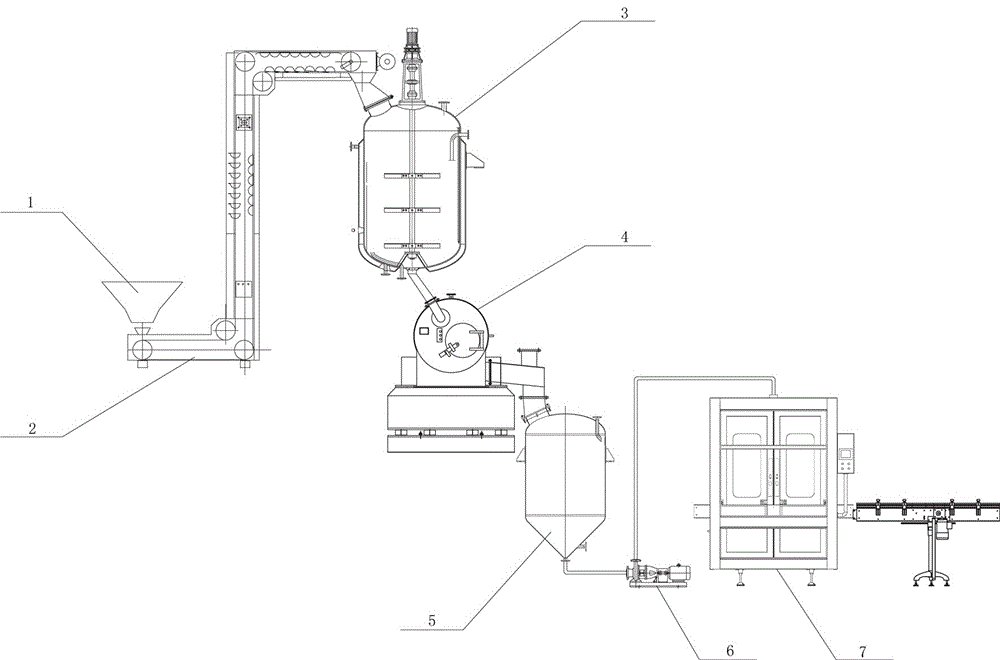

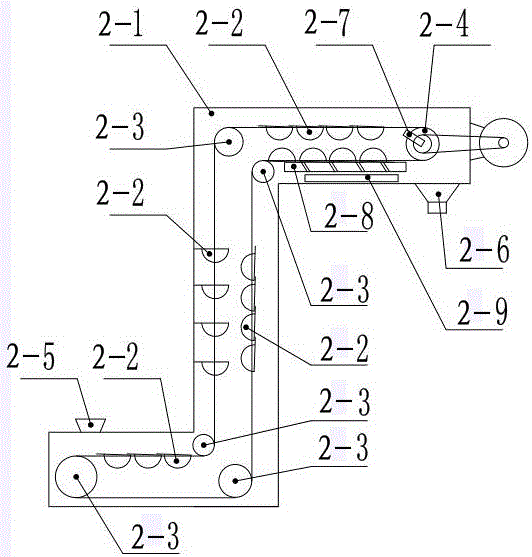

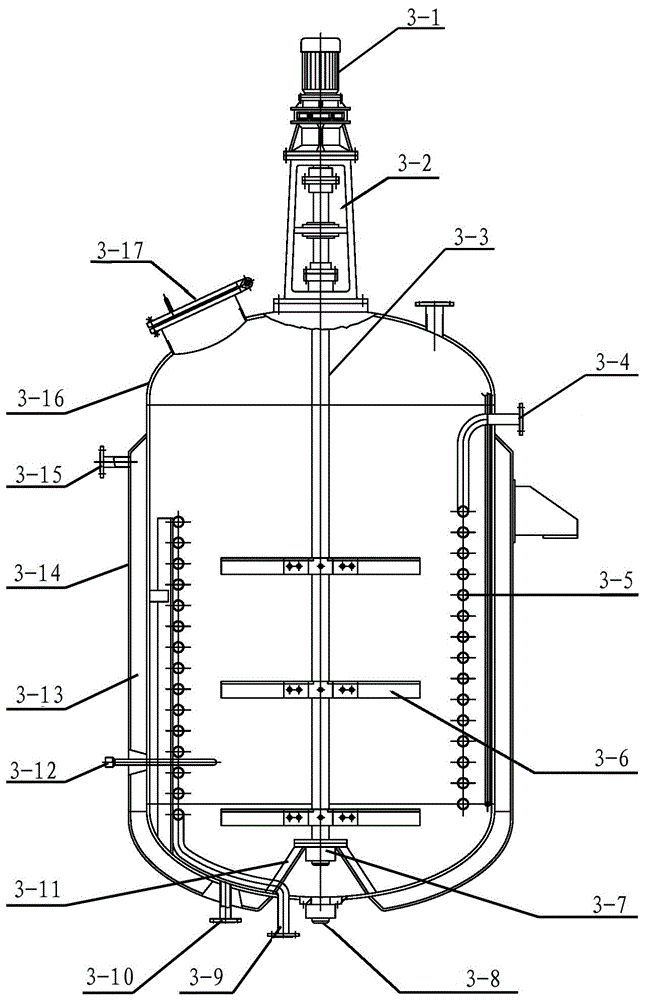

[0015] Such as figure 1 , figure 2 and image 3 , the embodiment of the present invention comprises the mixing material feeding hopper 1 that is arranged according to material operation sequence, Z shape hoist 2, fermentation tank 3, centrifuge 4, finished product tank 5, centrifugal feeding pump 6 and filling machine 7, mixing material The discharge port of the hopper 1 is located directly above the feed port 2-5 of the Z-shaped elevator 2, and the discharge port 2-6 of the Z-shaped elevator 2 is connected with the feed port 3-17 of the fermenter 3, and the fermentation The discharge electromagnetic valve 3-8 of the tank 3 is connected to the feed end of the centrifuge 4 through a pipeline, and the centrifuge 4 has a liquid phase discharge end and a solid phase discharge end, wherein the liquid phase discharge end is connected to the finished product tank 5 The feed end of the finished product tank 5 is connected to the filling machine 7 through the centrifugal feed pump 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com