Spring type key

A snap-press type, button technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of difficult button thickness reduction, high part mold cost, and complex part structure, etc., to achieve accurate and in place pressing, low cost, and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The elastic push button of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

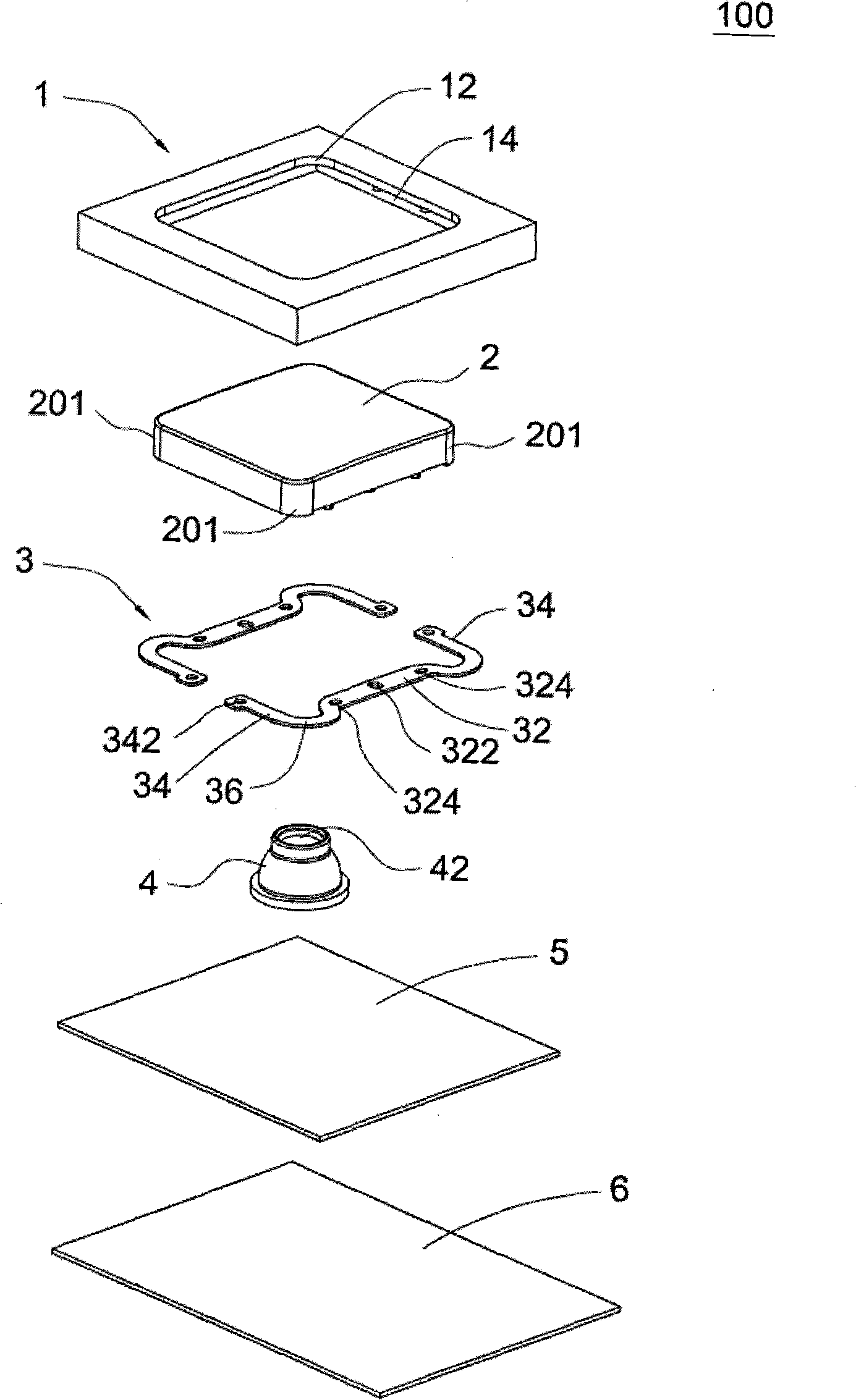

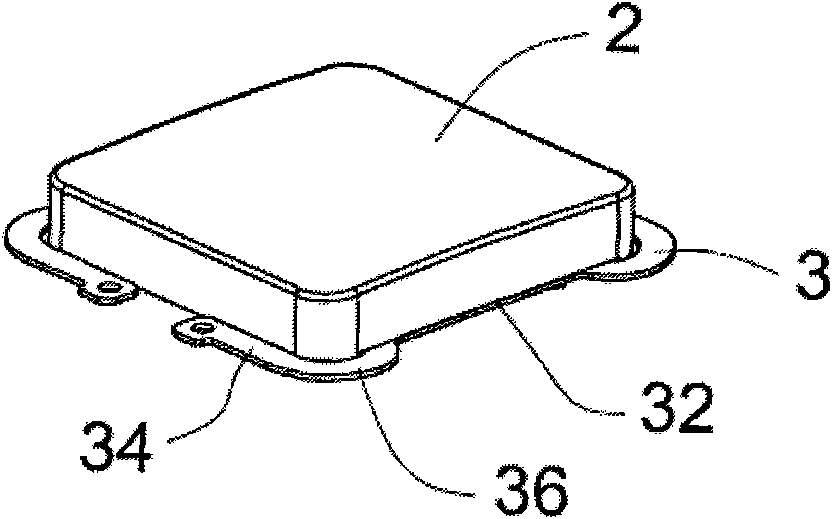

[0024] The snap button of the present invention can be used in computer keyboards, especially notebook computer keyboards, but is not limited to the above applications. Please refer to figure 2 as shown, figure 2 It is a three-dimensional exploded schematic diagram of the first preferred embodiment of the snap button according to the present invention. In this preferred embodiment, the snap button 100 includes a key frame 1, a keycap 2, two elastic arms 3, an elastic body 4, and a conductive film 5 And bottom plate 6.

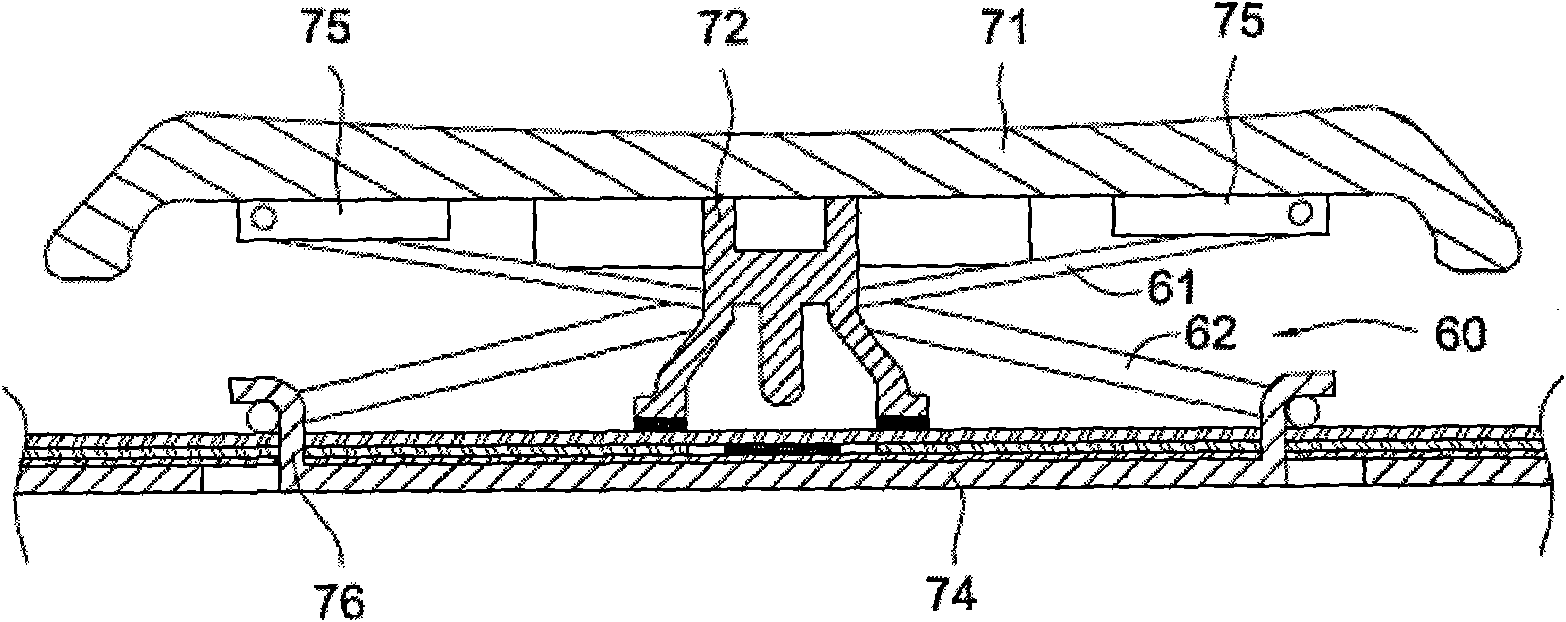

[0025] Please combine figure 2 and Figure 6 as shown, Figure 6 It is a schematic diagram of the local structure of the snap button 100 when it is not pressed. The key frame 1 is a square frame structure with a certain thickness, and its center has a square hole 12 through the upper and lower surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com