A kind of graphene heat pipe and preparation method thereof

An ene heat pipe and graphene technology, applied in the field of heat pipes, can solve the problems of reduced effective condensation area, deterioration of heat transfer performance, complex preparation process, etc., and achieve the effects of reducing energy consumption, prolonging life, and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

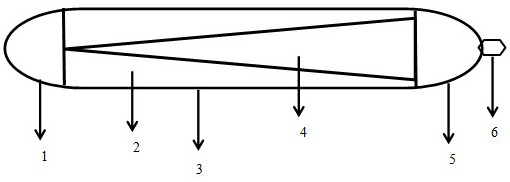

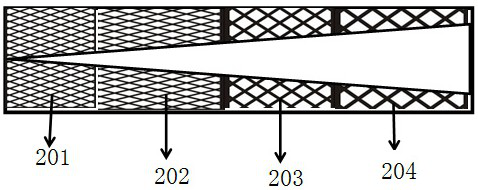

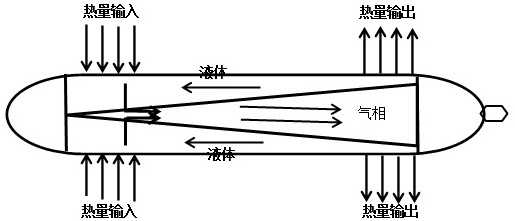

[0025] refer to figure 1 , the graphene heat pipe of the present invention includes an evaporation end cover 1 and a heat dissipation end cover 5, a tube shell 3 is arranged in the middle of the evaporation end cover 1 and a heat dissipation end cover 5, and a liquid-absorbing core 2 is arranged inside the tube shell 3 And the hollow part 4, the liquid-absorbing core 2 is composed of gradient one 201, gradient two 202, gradient three 203 and gradient four 204, the hollow part 4 is in the shape of a triangular cone, and its radius is smaller than the pipe diameter of the shell 3.

[0026] In this embodiment, the liquid-absorbing core 2 attached to the tube shell 3 is provided with variable apertures, and its specific distribution method is that the apertures increase sequentially from the evaporation end to the heat dissipation end; the four gradients are respectively: the number of apertures in gradient one 201 is 200 -300, the porosity change is 0.75-0.89, the number of pores...

Embodiment 2

[0035] refer to figure 1 , the graphene heat pipe of the present invention includes an evaporation end cover 1 and a heat dissipation end cover 5, a tube shell 3 is arranged in the middle of the evaporation end cover 1 and a heat dissipation end cover 5, and a liquid-absorbing core 2 is arranged inside the tube shell 3 And the hollow part 4, the liquid-absorbing core 2 is composed of gradient one 201, gradient two 202, gradient three 203 and gradient four 204, the hollow part 4 is in the shape of a triangular cone, and its radius is smaller than the pipe diameter of the shell 3.

[0036] In this embodiment, the liquid-absorbing core 2 attached to the tube shell 3 is provided with variable apertures, and its specific distribution method is that the apertures increase sequentially from the evaporation end to the heat dissipation end; the four gradients are respectively: gradient one 201 hole number 210 -300, the porosity change is 0.78-0.9; the number of pores in gradient two 20...

Embodiment 3

[0044] refer to figure 1 , the graphene heat pipe of the present invention includes an evaporation end cover 1 and a heat dissipation end cover 5, a tube shell 3 is arranged in the middle of the evaporation end cover 1 and a heat dissipation end cover 5, and a liquid-absorbing core 2 is arranged inside the tube shell 3 And the hollow part 4, the liquid-absorbing core 2 is composed of gradient one 201, gradient two 202, gradient three 203 and gradient four 204, the hollow part 4 is in the shape of a triangular cone, and its radius is smaller than the pipe diameter of the shell 3.

[0045] In this embodiment, the liquid-absorbing core 2 attached to the tube shell 3 is provided with variable apertures, and its specific distribution method is that the apertures increase sequentially from the evaporation end to the heat dissipation end; the four gradients are respectively: gradient one 201 hole number 210 -300, the porosity change is 0.75-0.9; the number of pores in gradient two 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com