Heat pipe and heat-radiating device using same

A heat pipe and pipe body technology, applied in the field of heat pipes and heat dissipation devices using the heat pipe, can solve the problems of affecting the heat conduction performance of the heat pipe, breaking the capillary structure of the heat pipe, and insufficient strength of the heat pipe, so as to improve the heat conduction performance, increase the strength, and enhance the return flow speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The heat pipe of the present invention and the heat dissipation device using the heat pipe will be further described below with reference to the accompanying drawings.

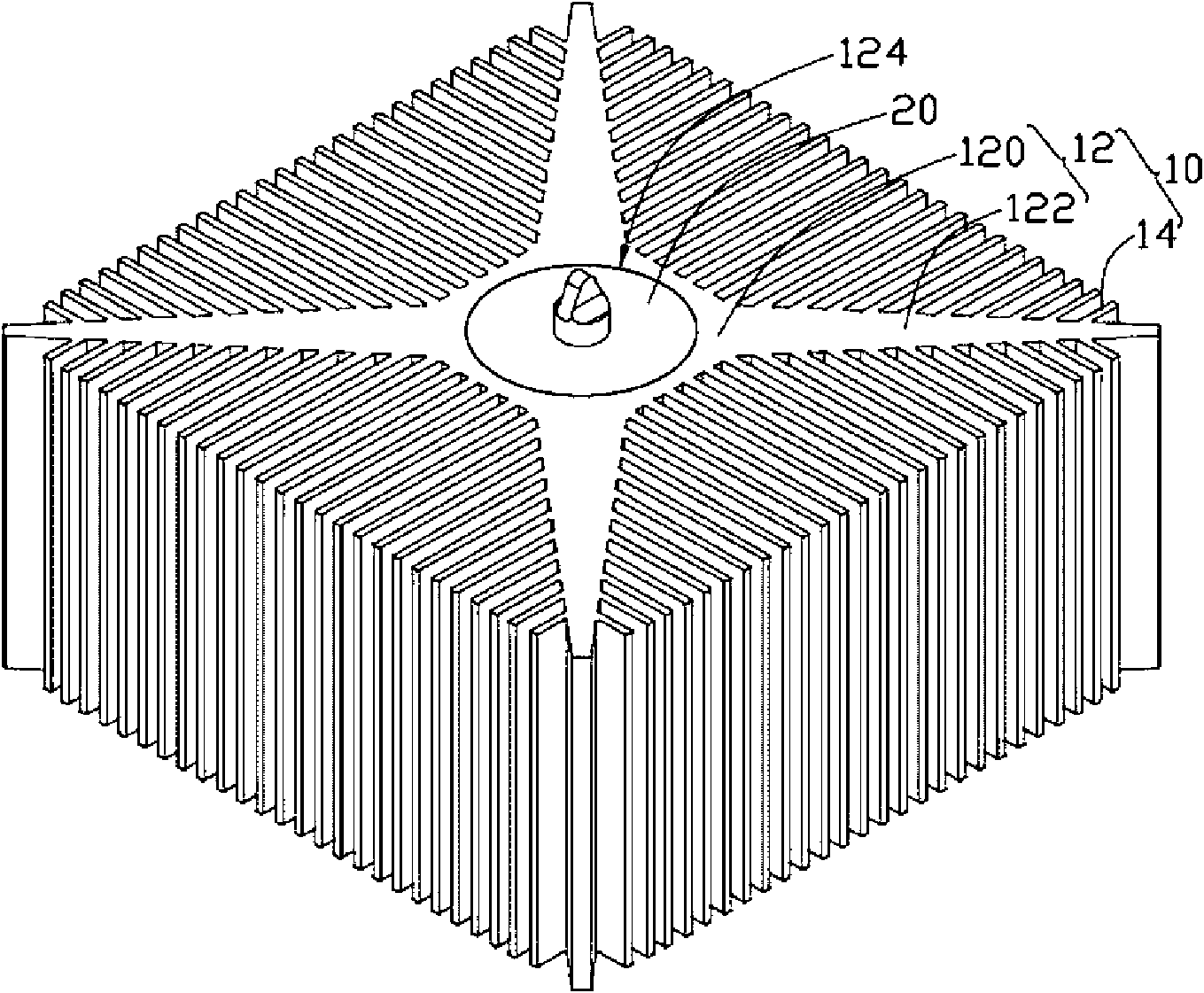

[0016] like figure 1 As shown, the heat dissipation device includes a heat sink 10 and a heat pipe 20 passing through the heat sink 10 .

[0017] The overall shape of the heat sink 10 is generally rectangular, and includes a central portion 12 and a plurality of cooling fins 14 radially extending from the periphery of the central portion 12 . The central portion 12 includes a cylinder 120 and four heat-conducting branch portions 122 extending from the periphery of the cylinder 120 . The cylinder 120 is a quadrangular prism, and a circular perforation 124 is formed at the center of the cylinder 120 through which the heat supply pipe 20 penetrates. The perforation 124 penetrates from the top surface of the cylinder 120 to the bottom surface thereof. The heat-conducting branch portions 122 radiate outwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com