Full-contact flexible lightweight rubber floating disc and its application

A full-contact, flexible technology, applied in packaging, large containers, transportation and packaging, etc., can solve problems such as poor sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

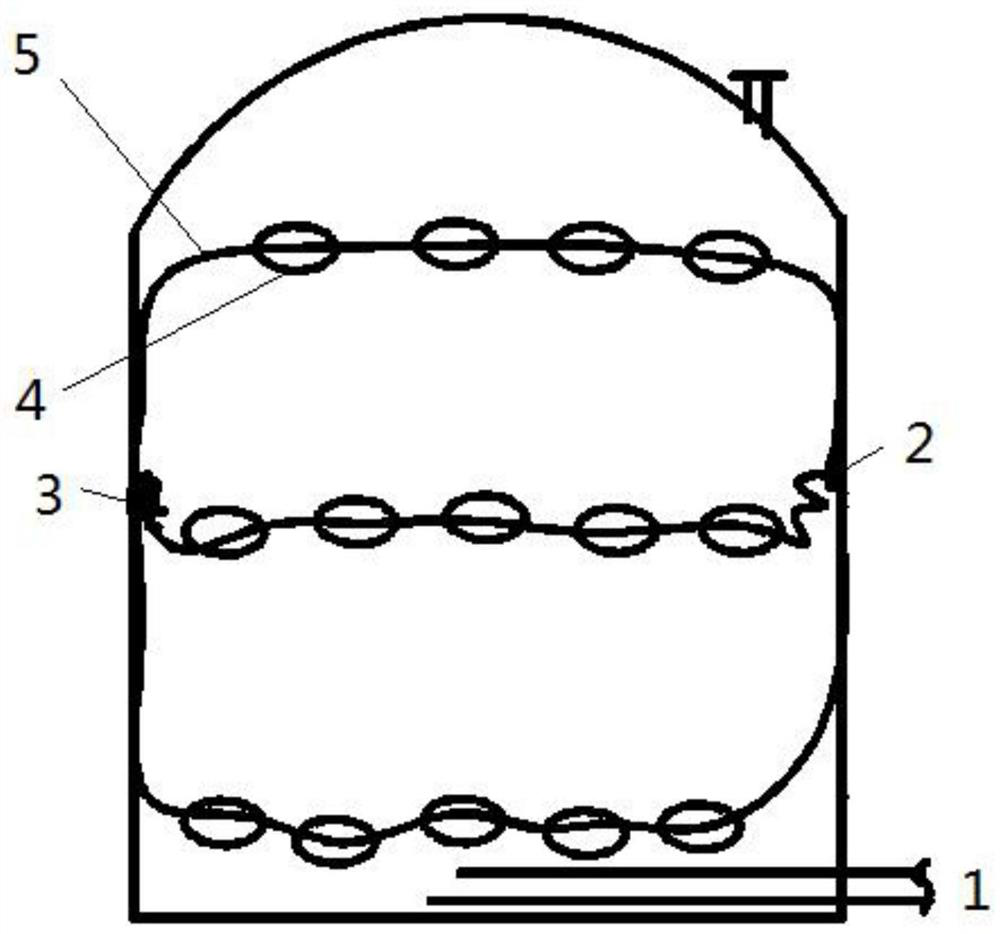

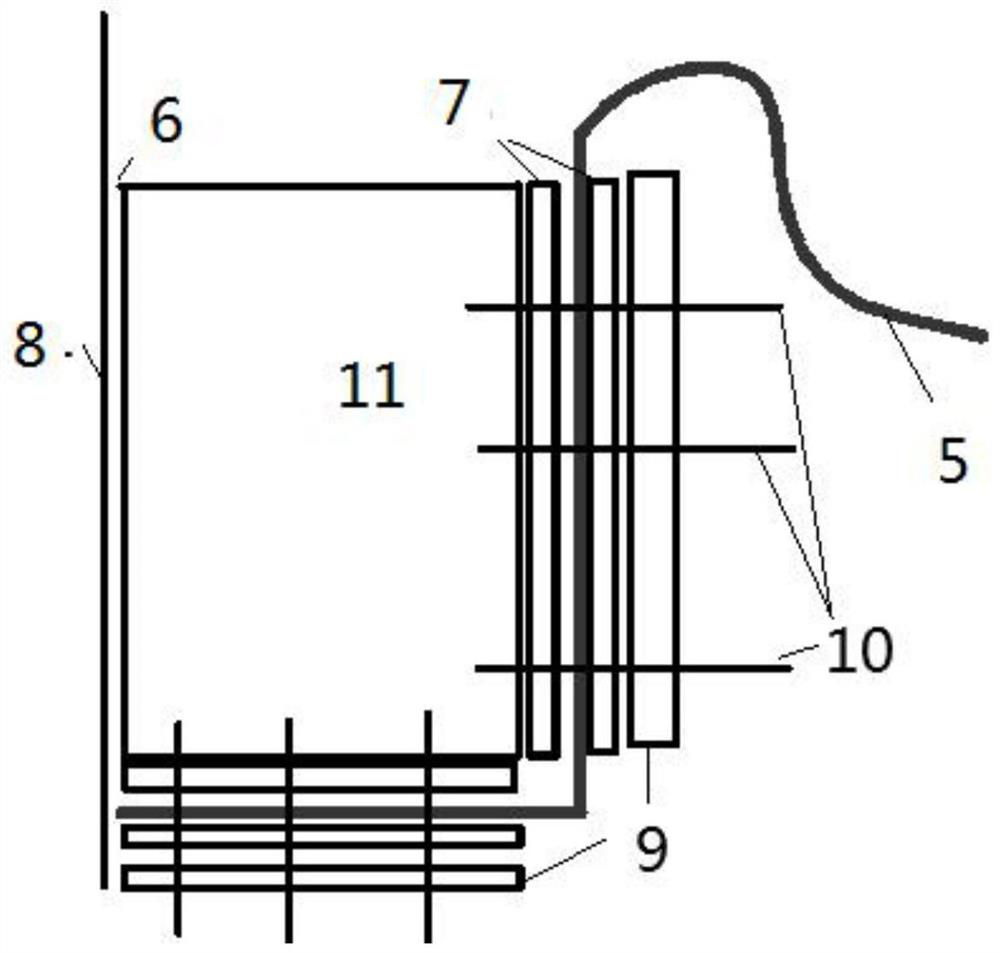

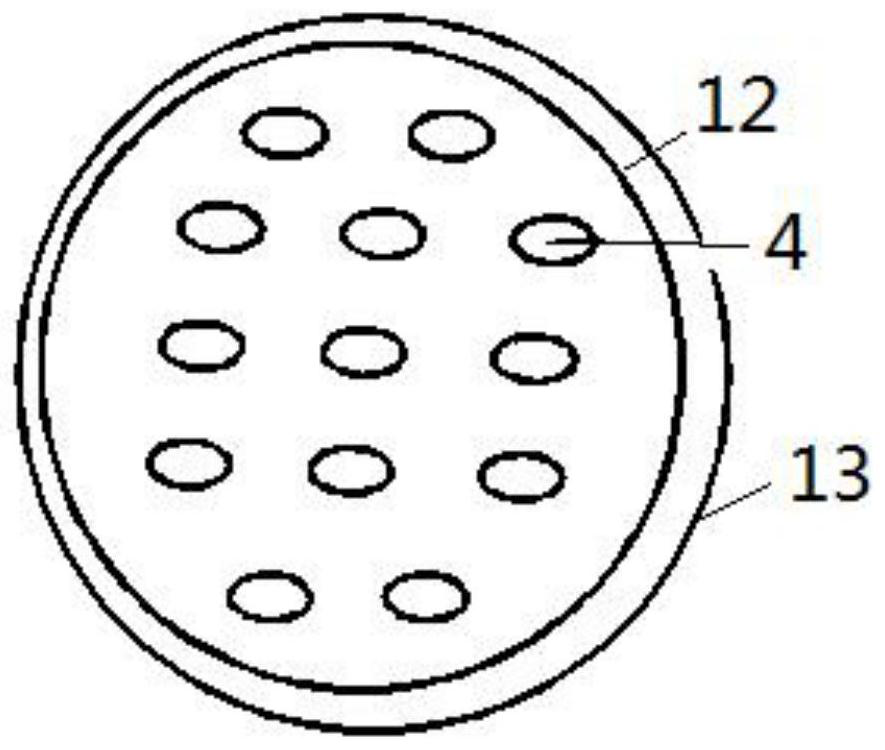

[0024] A full-contact flexible lightweight rubber floating disc, such as Figure 1-Figure 3 As shown, it includes a top rubber membrane, an inflatable capsule, a side rubber membrane, and a fixing device. The edge of the floating plate is fixed on the inner side of the storage tank wall through the side rubber membrane. Located under the top rubber membrane and connected to the top rubber membrane to form the full-contact flexible lightweight rubber floating plate, the diameter of the upper surface of the floating plate is larger than the diameter of the lower surface, and the diameter of the upper surface of the floating plate is smaller than the diameter of the storage tank. The total area of the inflatable capsule is 80% of the total area of the top rubber membrane. The rubber membrane is composed of multiple rubber membranes spliced together, and the seams must be sealed and meet the strength requirements. The inflatable capsules are strip-shaped and evenly arranged...

Embodiment 2

[0027] A full-contact flexible lightweight rubber floating disc, such as Figure 1-Figure 3 As shown, it includes a top rubber membrane, an inflatable capsule, a side rubber membrane, and a fixing device. The edge of the floating plate is fixed on the inner side of the storage tank wall through the side rubber membrane. Located under the top rubber membrane and connected to the top rubber membrane to form the full-contact flexible lightweight rubber floating plate, the diameter of the upper surface of the floating plate is larger than the diameter of the lower surface, and the diameter of the upper surface of the floating plate is smaller than the diameter of the storage tank. The total area of the inflatable capsules is 20% of the total area of the top rubber membrane. The rubber membrane is composed of multiple rubber membranes spliced together, and the seams must be sealed and meet the strength requirements. The inflatable capsules are strip-shaped and evenly arrange...

Embodiment 3

[0030] A full-contact flexible lightweight rubber floating disc, such as Figure 1-Figure 3As shown, it includes a top rubber membrane, an inflatable capsule, a side rubber membrane, and a fixing device. The edge of the floating plate is fixed on the inner side of the storage tank wall through the side rubber membrane. Located under the top rubber membrane and connected to the top rubber membrane to form the full-contact flexible lightweight rubber floating plate, the diameter of the upper surface of the floating plate is larger than the diameter of the lower surface, and the diameter of the upper surface of the floating plate is smaller than the diameter of the storage tank. The total area of the inflatable capsules is 50% of the total area of the top rubber membrane. The rubber membrane is composed of multiple rubber membranes spliced together, and the seams must be sealed and meet the strength requirements. The inflatable capsules are strip-shaped and evenly arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com