Throwing and refloating device

A fishing device and main body technology, which is applied in the field of fishing devices, can solve problems such as the deflection of the main body of the connecting head fishing device, and achieve the effect of reducing the pulling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

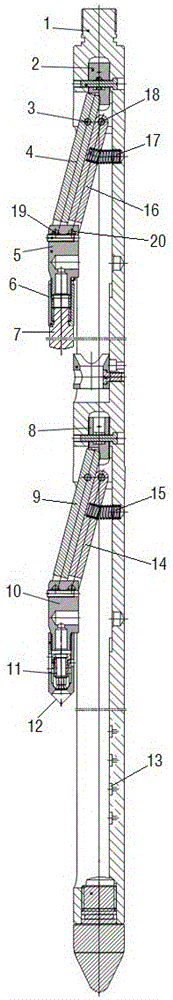

[0017] An example of a dropper is figure 1 As shown, it includes a thrower main body 1 extending in the up and down direction. The thrower main body 1 is respectively provided with a delivery claw mechanism and a salvage claw mechanism along the upper and lower sides, wherein the delivery claw mechanism includes a delivery outer claw 4 and a delivery inner claw mechanism. The claw 16, the upper end of the delivery outer claw 4 and the delivery inner claw 16 are respectively hinged with the fish thrower main body 1, and the hinge shafts are respectively hinge axis one 3 and hinge axis two 18, and the delivery outer claw 4 and the delivery inner claw 16 The lower end of the lower end is respectively hinged with the delivery joint 5, and the hinge axes are respectively hinge axis three 19 and hinge axis four 20, and hinge axis one 3, hinge axis two 18, hinge axis three 19 and hinge axis four 20 are respectively in four parallelograms. On the apex, the connecting line of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com