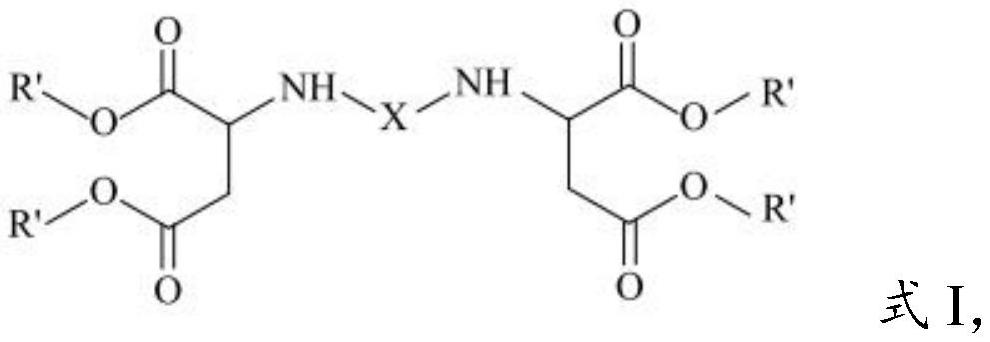

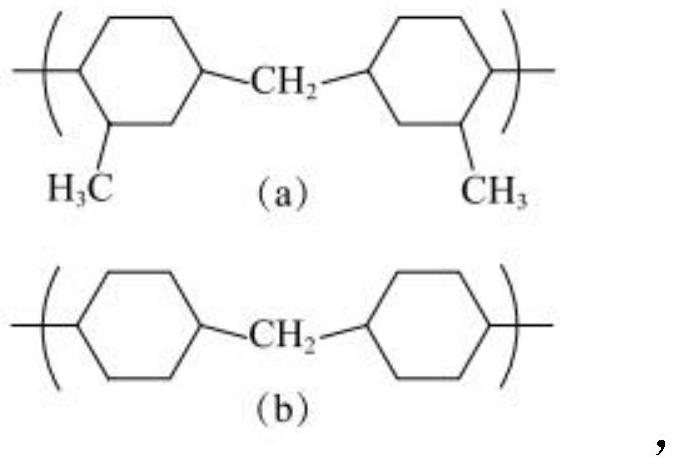

Low-viscosity solvent-free polyurea coating as well as preparation method and application thereof

A solvent-free, low-viscosity technology, applied in anti-corrosion coatings, coatings, etc., can solve the problem of high VOC emissions, achieve the effects of reducing construction time, improving appearance decoration, and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of the low-viscosity solvent-free polyurea coating described in the above technical scheme, comprising the following steps:

[0068] Mix polyaspartic acid ester resin, silane resin, pigments and fillers and additives to obtain component A;

[0069] Provide polyisocyanate curing agent to obtain B component.

[0070] The invention mixes polyaspartic acid ester resin, silane resin, pigments and fillers and additives to obtain component A.

[0071] In the present invention, it is preferred to add silane resin, composite anti-rust pigment, pigments and fillers and additives to the polyaspartic acid ester resin under stirring, then grind to a fineness of less than 30 μm, and the temperature reaches 45-65° C. to obtain the A components.

[0072] In the present invention, the viscosity of the component A is preferably 100-120KU.

[0073] The invention provides a polyisocyanate curing agent to obtain the B component.

...

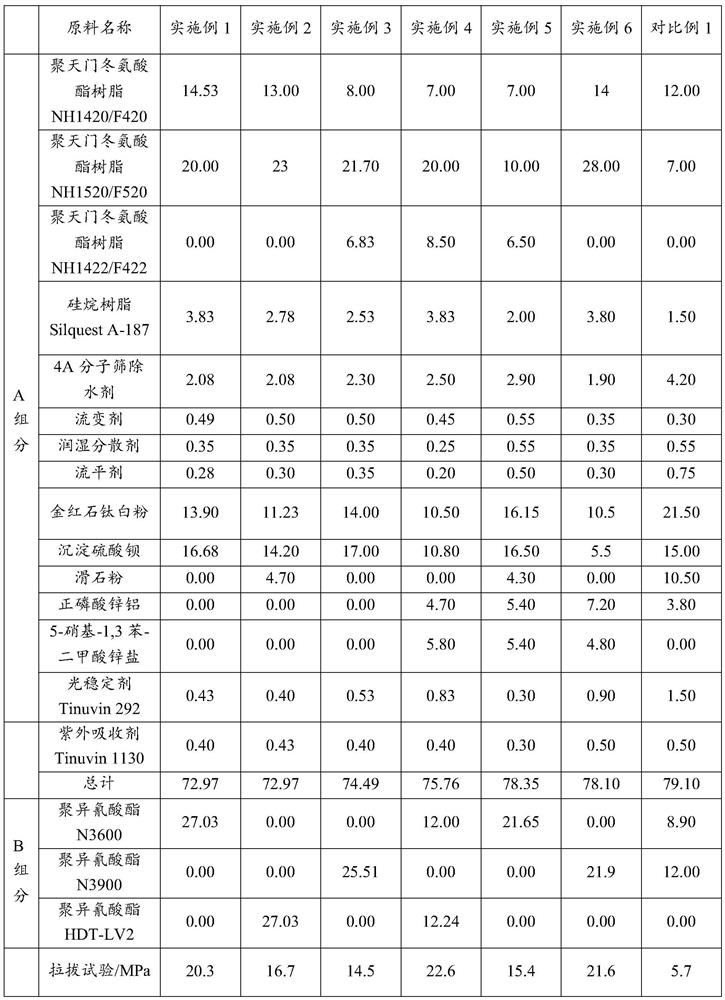

Embodiment 1~6

[0085] The low-viscosity solvent-free polyurea coating in embodiment 1~6 among the present invention realizes by following production process:

[0086] Component A: Add polyaspartic acid ester resin, add silane resin, molecular sieve water remover, rheology agent, wetting and dispersing agent, leveling agent, composite antirust pigment and pigment filler during stirring; grind to a fineness of less than 30 μm , the temperature reached 65°C, and kept for 20 minutes; added light stabilizer, UV absorber, and mixed evenly.

[0087] B component: polyisocyanate.

[0088] Before use, mix component A and component B according to the weight ratio shown in Table 1 to prepare the low-viscosity solvent-free polyurea coating of the present invention.

[0089] The compositions, physical parameters and film properties of the low-viscosity solvent-free polyurea coatings provided in Examples 1-6 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com