SCS (steel concrete steel) bridge deck with internal vertical J-shaped connecting structures

A technology of steel plate concrete and connecting structure, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of limiting the structure and size of the lower supporting pier body, the development and application of concrete bridge decks, and the tendency of cracks in concrete bridge decks, etc. Achieve the effect of low input construction cost, good connection effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

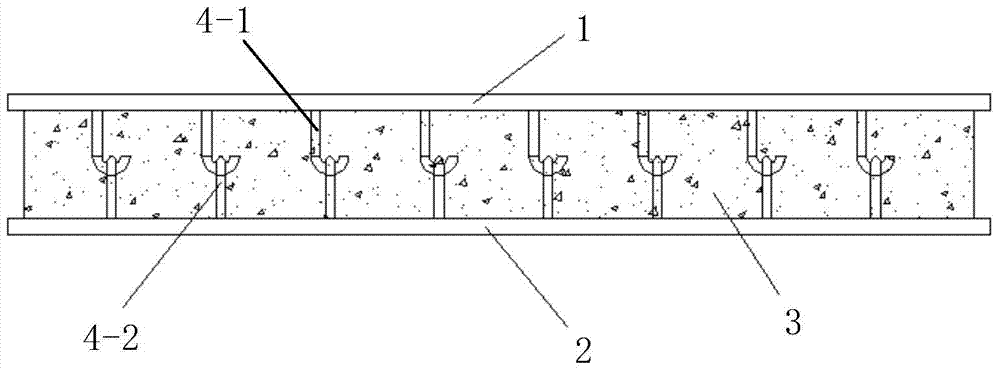

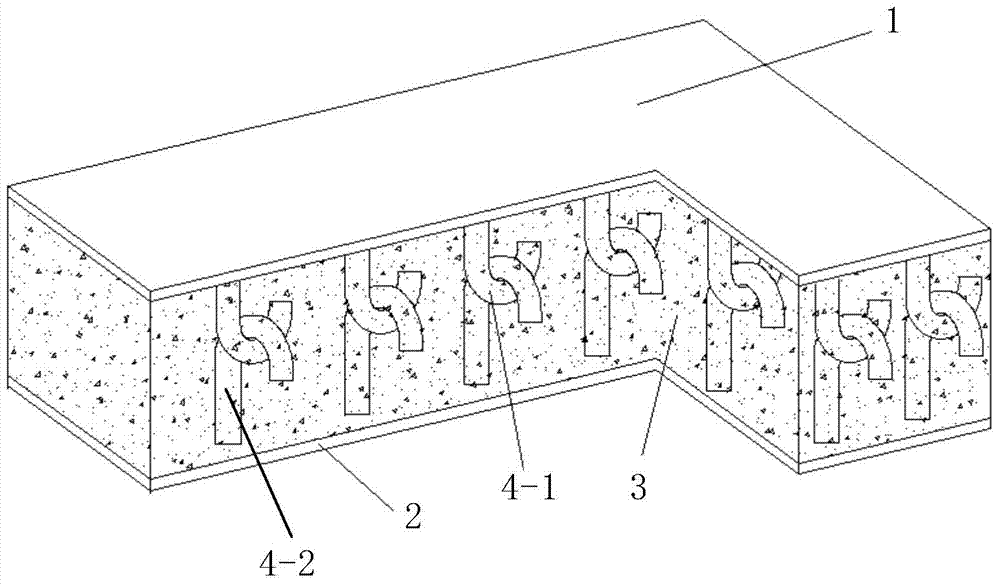

[0034] Such as figure 1 , figure 2 As shown, the present invention includes a bridge deck bottom plate 2, a bridge deck top plate 1 arranged directly above the bridge deck bottom plate 2 and arranged in parallel with the bridge deck bottom plate 2, and N columns are arranged on the bridge deck top plate from left to right along the transverse bridge direction 1 and the vertical J-shaped connection structure between the bridge deck bottom plate 2 and the inter-slab concrete structure 3 formed by pouring concrete between the bridge deck top plate 1 and the bridge deck bottom plate 2, the bridge deck top plate 1 and the bridge deck Base plate 2 is a horizontal steel plate. The vertical J-shaped connection structures in the N columns are all poured in the inter-slab concrete structure 3, and the bridge deck top plate 1 and the bridge deck bottom plate 2 are fastened to the vertical J-shaped connection structures in the N columns through the inter-slab concrete structure 3 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com