Wear-resistant polyformaldehyde composite material and preparation method thereof

A composite material, polyoxymethylene technology, applied in the field of wear-resistant polyoxymethylene composite materials and its preparation, can solve the problems of poor thermal stability and low wear resistance, achieve good thermal stability, improve wear resistance, and improve dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

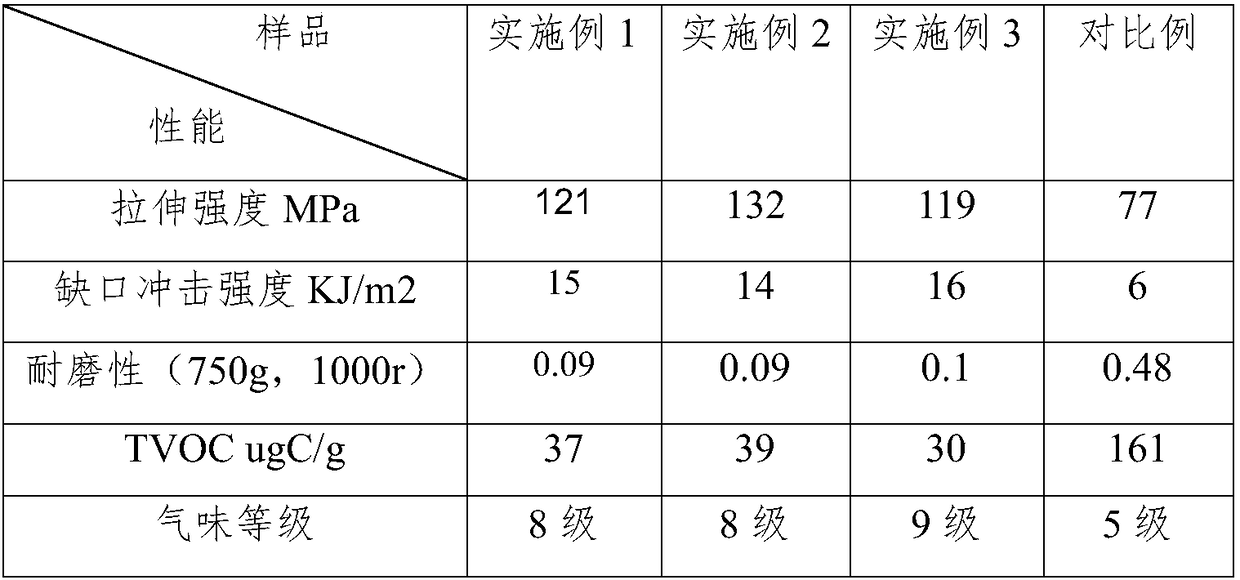

Examples

preparation example Construction

[0024] Preparation of modified glass fiber: After washing and drying the glass fiber, immerse it in the polytetrafluoroethylene / polyvinylidene fluoride dispersion, then take it out and dry it, bake and sinter at 280°C to obtain the modified glass fiber; polytetrafluoroethylene Ethylene / polyvinylidene fluoride dispersion is a colloidal solution formed by suspending polytetrafluoroethylene / polyvinylidene fluoride (mass ratio 1:1) resin with an average particle size of 0.2-0.3 μm in liquid water, and the viscosity of the colloidal solution is 0.03 Pa·s, the concentration is 50wt%, and the pH value is 10.

[0025] Preparation of odor adsorption masterbatch: 100 parts of polyoxymethylene, 10 parts of hydrophobic diatomite, 10 parts of hydrophobic activated carbon, 10 parts of needle-shaped zeolite molecular sieve, 10 parts of zinc ricinoleate, 5 parts of nano-silica, stearic acid Add 1 part of calcium, 5 parts of melamine, and 0.5 part of benzofuranone free radical scavenger into a...

Embodiment 1

[0030] The wear-resistant polyoxymethylene composite material in this example is made of the following raw materials in parts by weight: 70 parts of polyoxymethylene, 3 parts of odor absorption masterbatch, 0.5 parts of molybdenum disulfide, 25 parts of modified glass fiber, 1 part of silicone powder, 0.5 parts Part of antioxidant 1098, 0.5 part of antioxidant 168;

[0031] The preparation method of the wear-resistant polyoxymethylene composite material of this embodiment comprises the following steps:

[0032] S1. Clean and dry the glass fiber and then immerse it in the polytetrafluoroethylene / polyvinylidene fluoride dispersion, take it out and dry it, bake and sinter at 270°C to obtain the modified glass fiber;

[0033] S2. Weigh each raw material in parts by weight, pour polyoxymethylene, odor absorption masterbatch, molybdenum disulfide, silicone powder, antioxidant 1098, and antioxidant 168 into the mixer, stir evenly and place in twin-screw extrusion In the extruder, th...

Embodiment 2

[0036] The wear-resistant polyoxymethylene composite material in this embodiment is made of the following raw materials in parts by weight: 54 parts of polyoxymethylene, 1 part of odor absorption masterbatch, 0.2 part of molybdenum disulfide, 45 parts of modified glass fiber, 0.2 part of silicone powder, 0.1 Part of antioxidant 1098, 0.1 part of antioxidant 168;

[0037] The preparation method of the wear-resistant polyoxymethylene composite material of this embodiment comprises the following steps:

[0038] S1. Wash and dry the glass fiber and then immerse it in the polytetrafluoroethylene / polyvinylidene fluoride dispersion, take it out and dry it, bake and sinter at 290°C to prepare the modified glass fiber;

[0039] S2. Weigh each raw material in parts by weight, pour polyoxymethylene, odor absorption masterbatch, molybdenum disulfide, silicone powder, antioxidant 1098, and antioxidant 168 into the mixer, stir evenly and place in twin-screw extrusion In the extruder, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com